Forming mold and forming method of fiber reinforced composite material grid rib

A composite material and fiber-reinforced technology, which is applied in the field of fiber-reinforced composite material grid rib forming molds and molding, can solve the problems of difficult product quality assurance, retention, and difficult impregnation of resin evenly, so as to achieve increased fiber content, less air bubbles, and avoid The effect of fiber shear breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiment: In order to have a clearer understanding of the process characteristics, purpose and effect of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings.

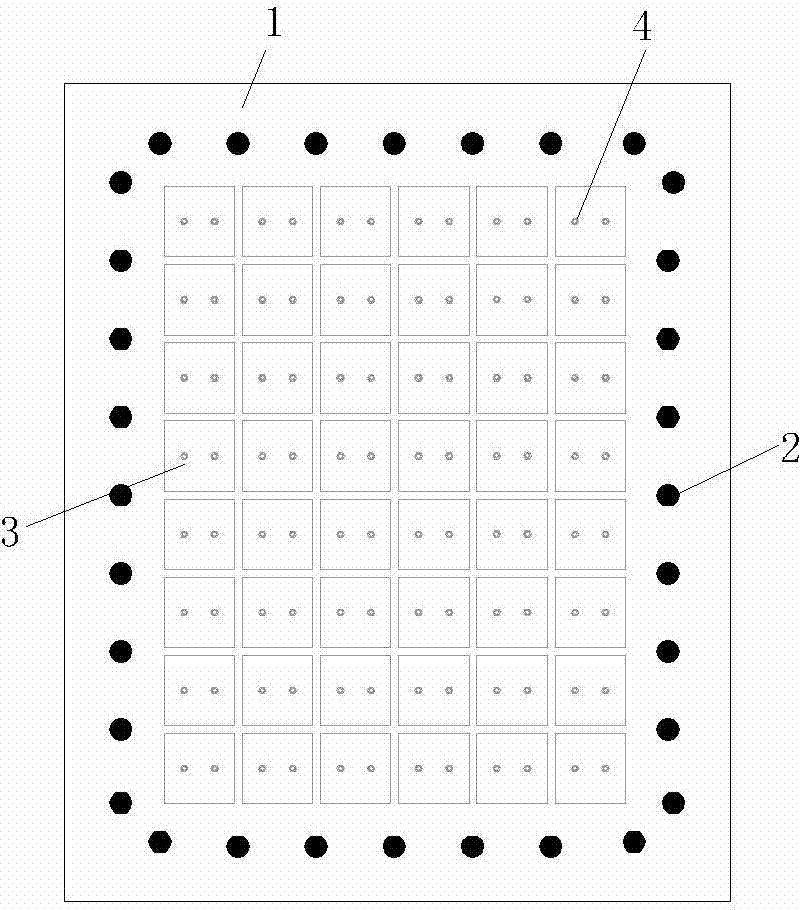

[0038] figure 1 It is a schematic diagram of the connection structure between the bottom mold 1 and the filling mold 3. The filling mold 3 is fixed on the bottom mold 1 by bolts 4 to form a grid channel for laying fiber tow. Positioning card 2 is arranged on the center line of the channel, and the diameter of positioning card 2 cannot be lower than 0.5cm, and the purpose is to protect the tight fiber from being easily broken when cornering.

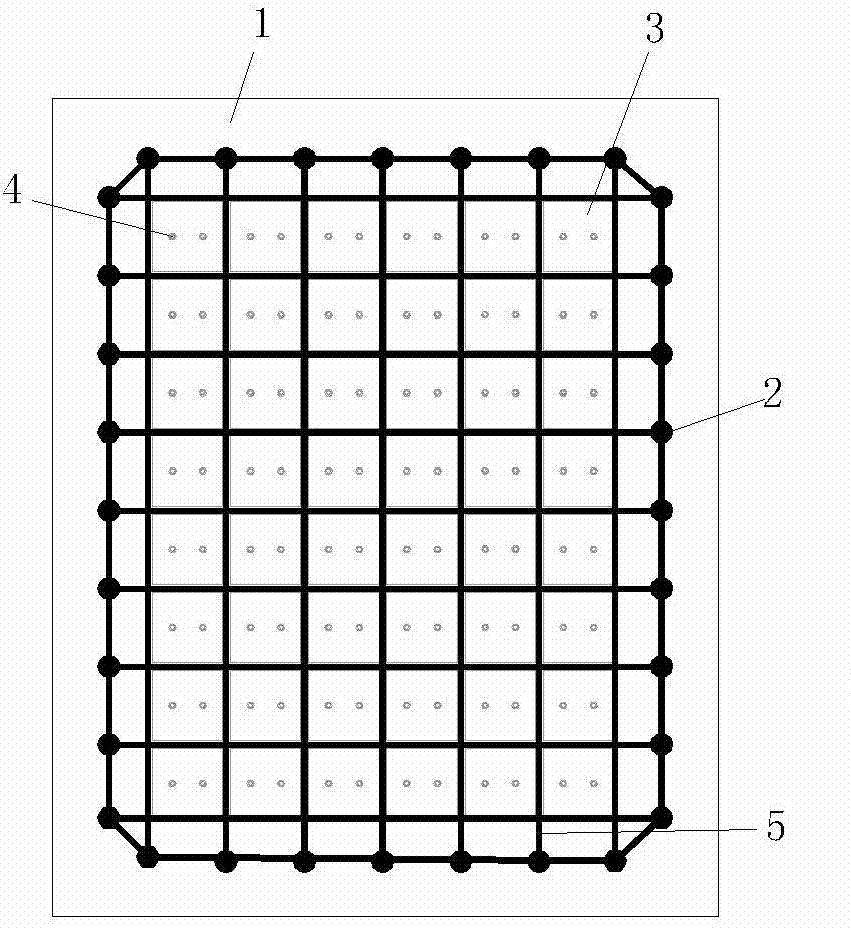

[0039] figure 2 It is a laying diagram of the fiber tow 5 in the channel. The fiber tows 5 are laid at intervals in the warp and weft directions in the grooves formed by the array arrangement of the filling molds 3 , and are kept continuously and tautly laid all the time.

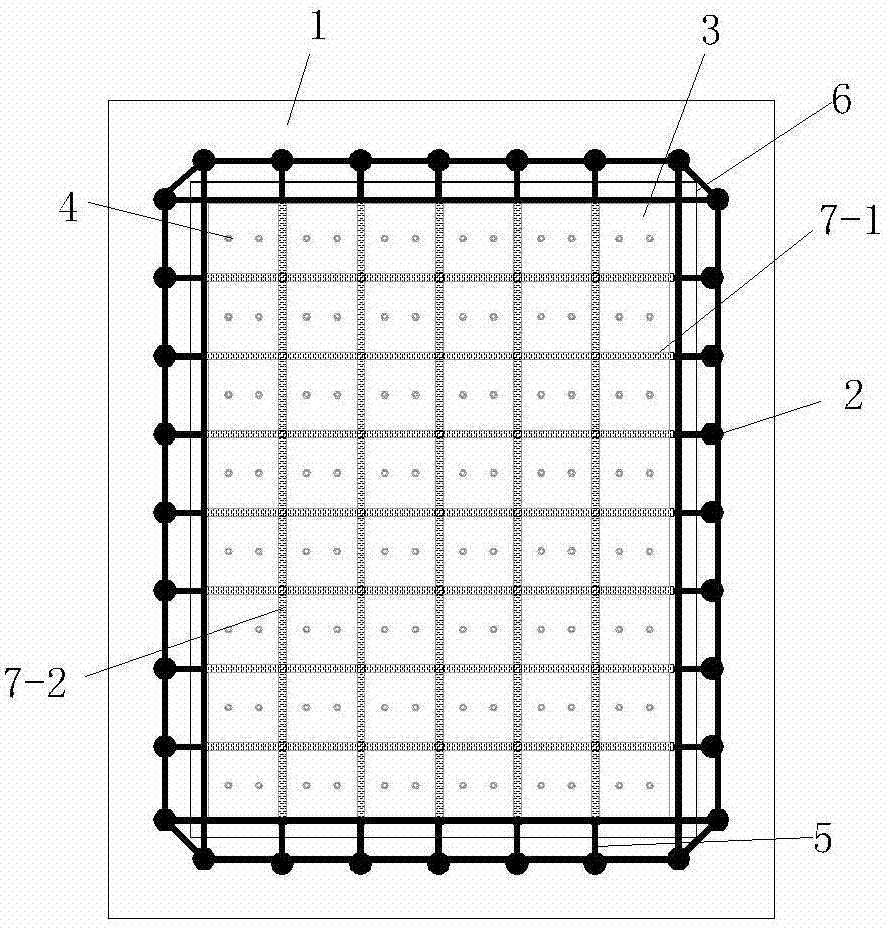

[0040]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com