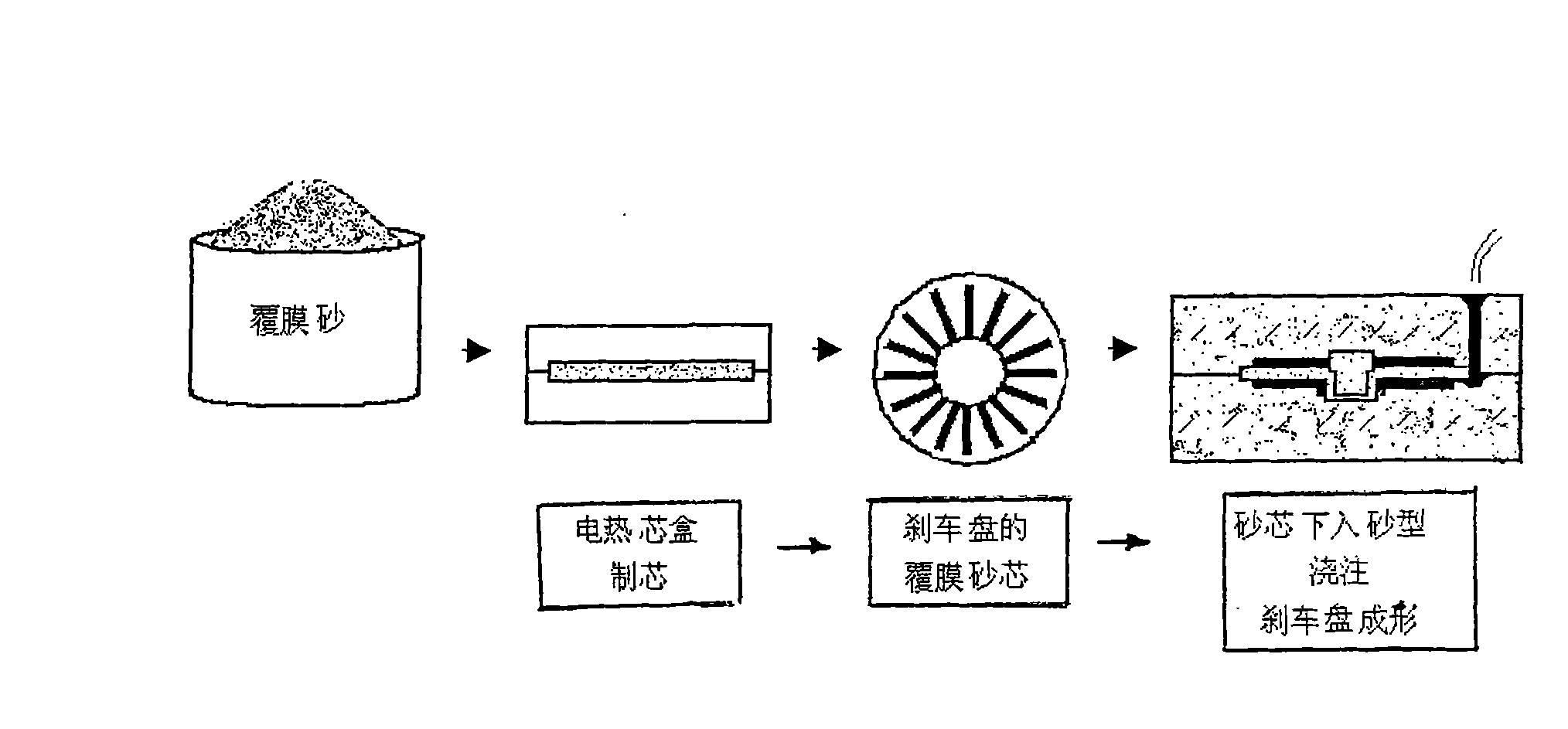

Production technology for casting brake disk air channel with pre-coated sand core method

A production process and technology of coated sand, which is used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problem of the shape, size, and quality of the brake disc air duct, which is difficult to guarantee, pollutes the atmosphere and the environment, and has low strength of greased sand. problem, to achieve the effect of good binder effect, environmental protection and high refractoriness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

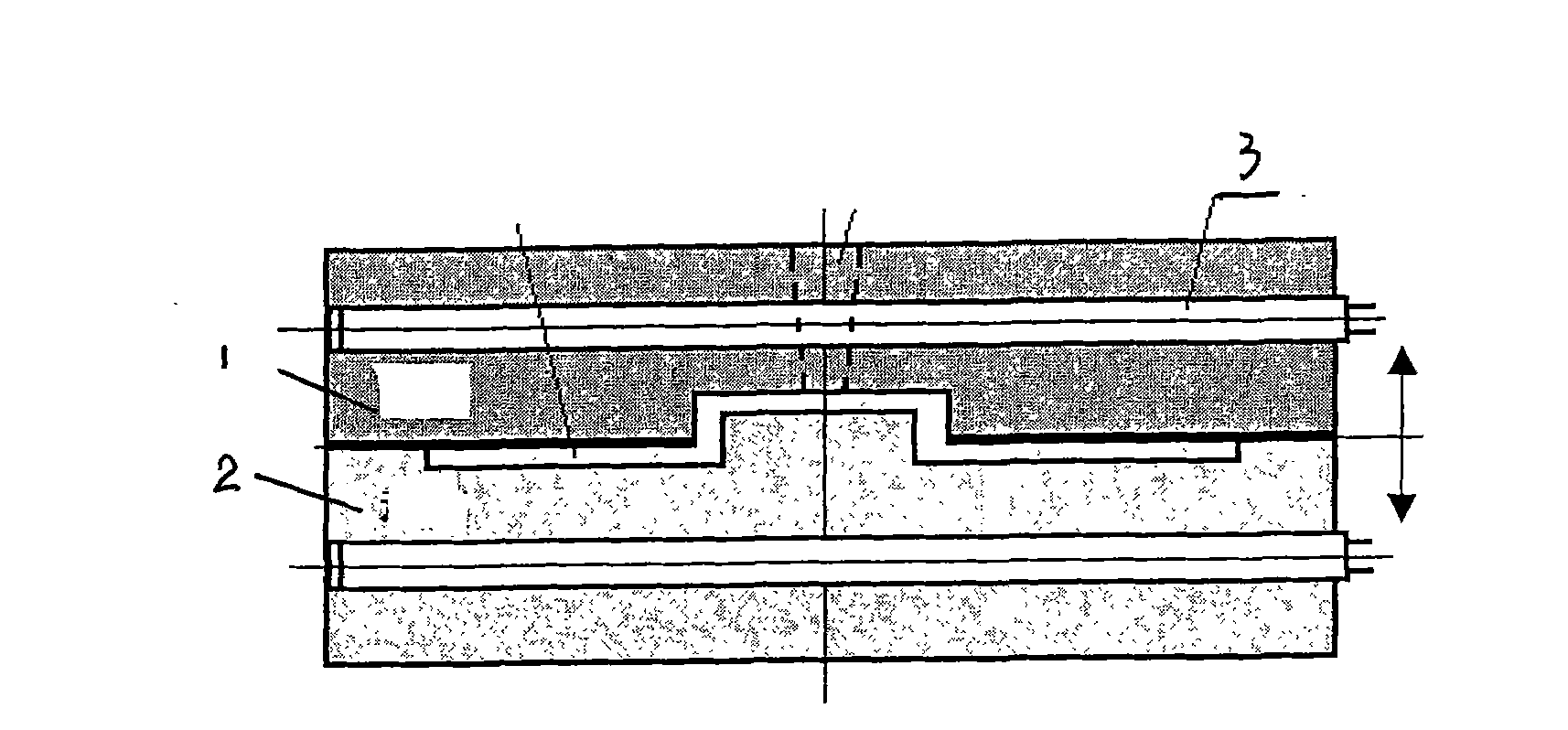

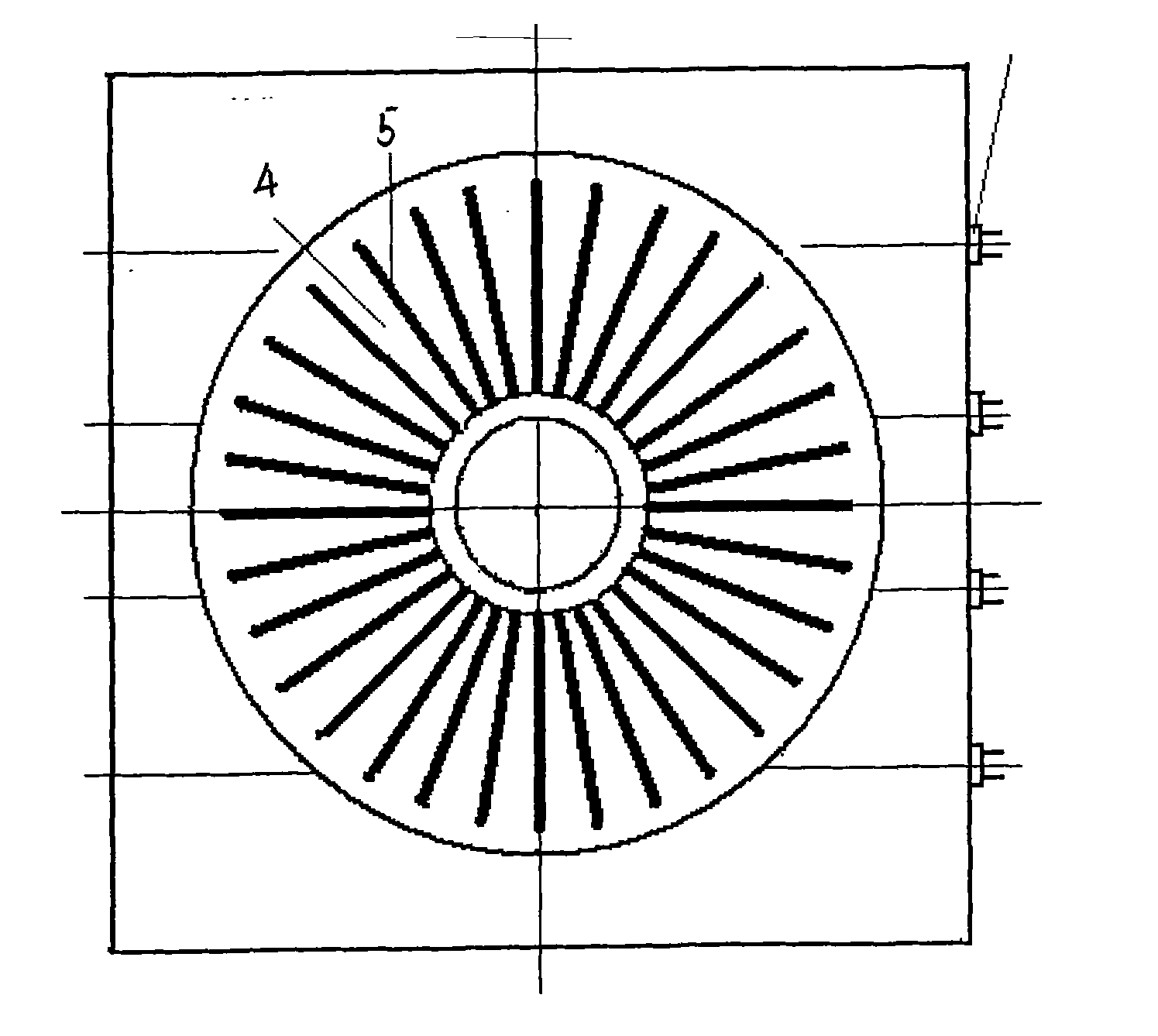

[0016] Embodiment 1: A production process for casting brake disc air ducts by using the film-coated sand core method, which is carried out according to the following steps: (1) Outsourcing the film. The original sand particle size of the coated sand is between 50-100 mesh, the hot bending strength is 2.5MPa, the gas generation is 14ml / g, the melting point is 103°C, and the collapsibility is good. (2) Install the electric heating core box on the core shooting machine, close the mold and take the coated sand into the electric heating core box quantitatively. The sand shooting time of the core shooting machine is 5 seconds, the electric heating and curing temperature is 250 ° C, and the heating and curing time is 50 Seconds, the coated sand is solidified in the electric heating core box to form a coated sand core, and the sand core is yellowish brown. (3) Take out the coated sand core from the electric heating core box, trim and inspect it before use; (4) Put the coated sand core...

Embodiment 2

[0018] Embodiment 2: A production process for casting brake disc air ducts by using the film-coated sand core method, which is carried out according to the following steps: (1) Outsourcing the film. The original sand particle size of the coated sand is between 50-100 mesh, the hot bending strength is 2.5MPa, the gas generation is 14ml / g, the melting point is 103°C, and the collapsibility is good. (2) Install the electric heating core box on the core shooter, close the mold and take the coated sand into the electric heating core box quantitatively. The sand shooting time of the core shooting machine is 8 seconds, the electric heating curing temperature is 280°C, and the heating curing time is 90 Seconds, the coated sand is solidified in the electric heating core box to form a coated sand core, and the sand core is yellowish brown. (3) Take out the coated sand core from the electric heating core box, trim and inspect it before use; (4) Put the coated sand core into the sand mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Gas output | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com