Method for casting steel anode template through composite sand mould

A technology of sand casting and anode plate, which is applied in the direction of casting molding equipment, molds, cores, etc., to achieve the effects of compact structure, reduced manufacturing cost, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0015] Choose a steel anode plate mold made of ZG20MnMo, weighing 2.4 tons, 1435mm long, 1360mm wide, and 280mm thick. The specific casting process is as follows:

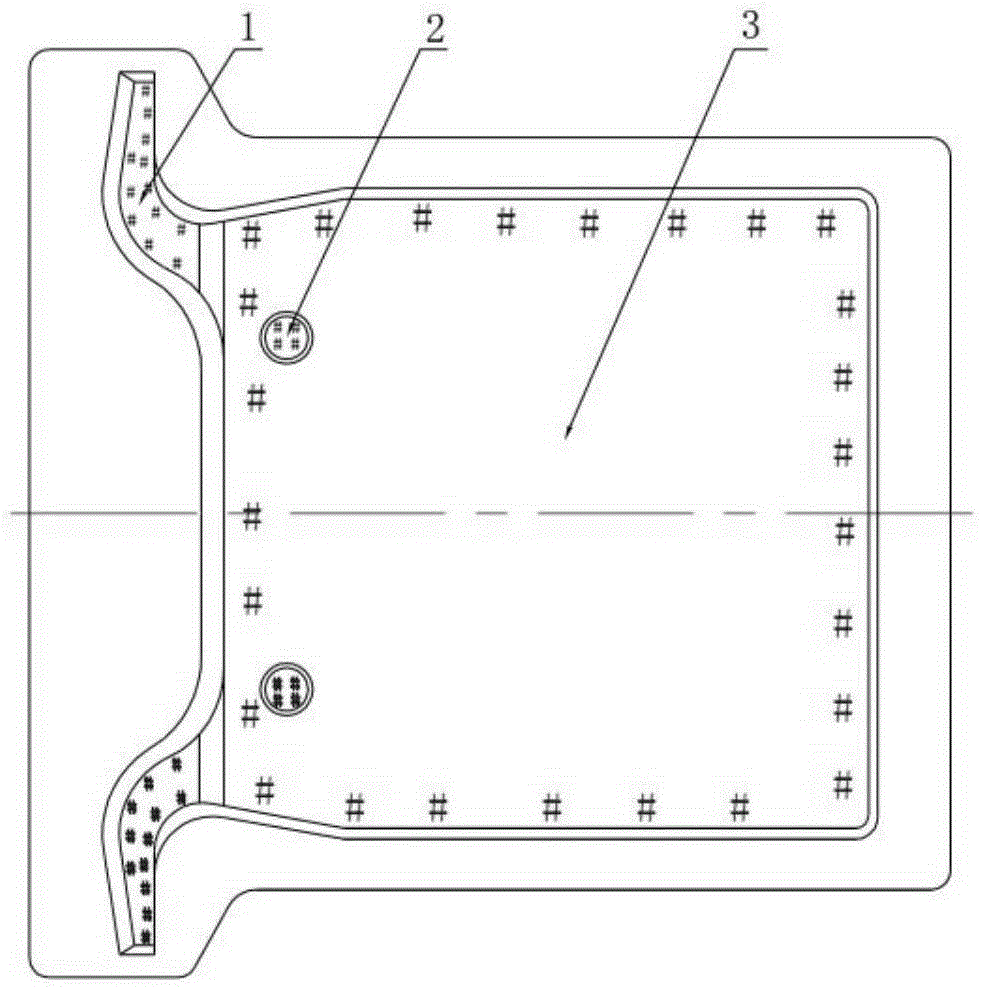

[0016] (1) Sand blending and molding: according to 100 parts by weight of chromite sand, 2.8 to 3.2 parts by weight of modified water glass, and the ratio of organic ester to 14% to 16% of the weight of water glass, prepare chromium with a small sand mixer For iron ore molding sand, lay 10-15mm thick chromite molding sand on the large plane 3 of the anode formwork model, lay chromite molding sand on all the lifting lug 1, and use ferrochrome for the sand core at the thimble hole 2 Mineral sand. According to 100 parts by weight of quartz sand, 2.8 to 3.2 parts by weight of modified water glass (produced by Yixing Hexing Chemical Co., Ltd., Jiangsu Province), and organic ester (produced by H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com