Die mechanism of vibration molder with slide block on middle part and operation method thereof

A vibration molding machine and sliding block technology are applied in the field of refractory material molding to achieve the effects of high molding efficiency, avoiding laminar crack defects and reliable molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

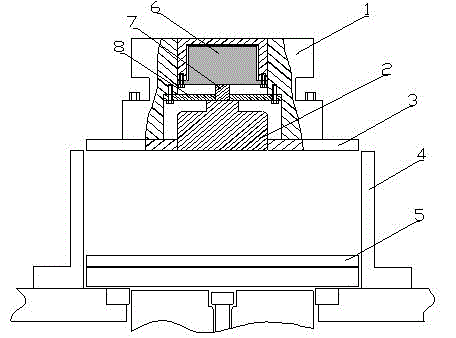

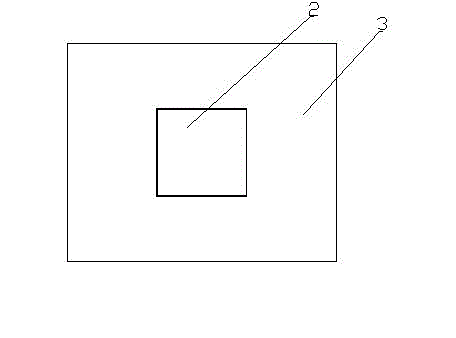

[0056] Embodiment 2: In this embodiment, the material of the molded green body is self-bonding silicon carbide, the size of the molded green body is 700×500×300 mm, and the size of the pressing surface of the pre-pressing slider is 320×200 mm.

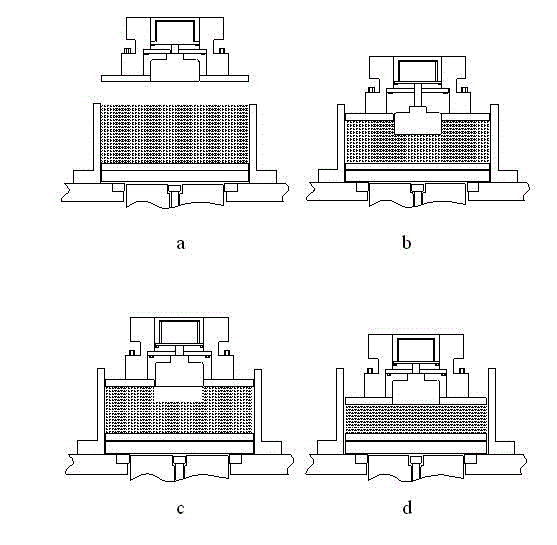

[0057] A method for operating the die head mechanism of a vibration forming machine with a slider in the middle, the specific steps are as follows:

[0058] a. Feeding: Add 288kg of self-bonded silicon carbide mud into the mold frame 4 and pave it flat;

[0059] b. Preloading: Under the action of cylinder 6, the preloading slider 2 protrudes downwards from the upper template, and the distance from the preloading slider to the upper template is 120mm. After preloading, the lower end surface of the preloading slider reaches the lower template The vertical height of the upper end surface is 335mm; after the pressure test, the vibration time of the preload is determined to be 28 seconds;

[0060] c. Retraction of the preloading slider: A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com