Coal-fired sleeve shaft kiln injection plugging removal system

A sleeve and shaft kiln technology, applied in cleaning methods and appliances, cleaning methods using gas flow, chemical instruments and methods, etc., can solve problems such as blocking the smooth passage of airflow, materials cannot fall smoothly, unfavorable technical indicators, etc., to achieve High blockage removal efficiency, reduced number of kiln shutdowns for maintenance, and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

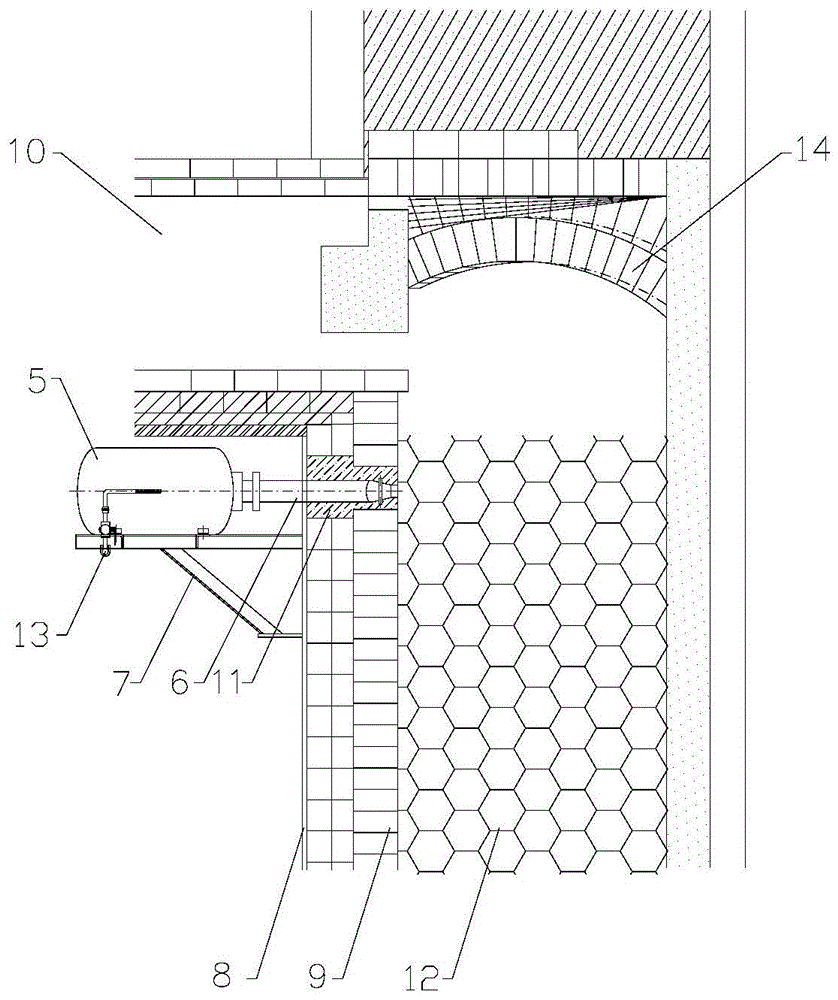

[0018] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

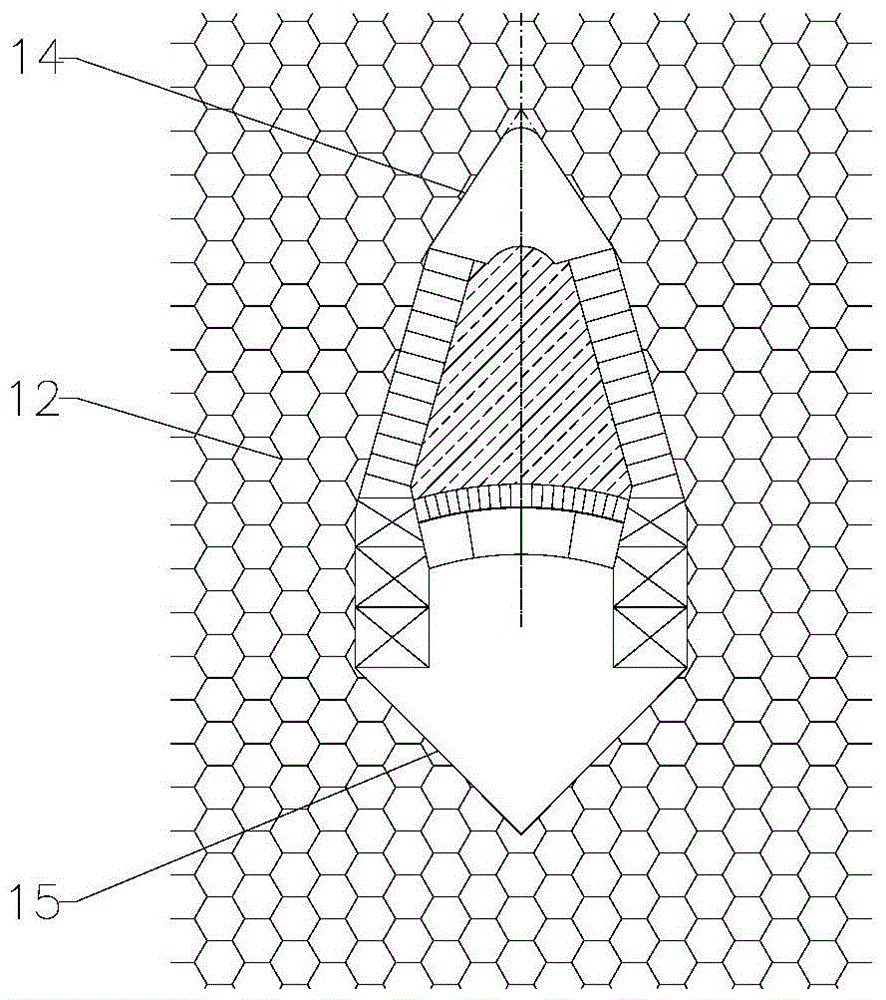

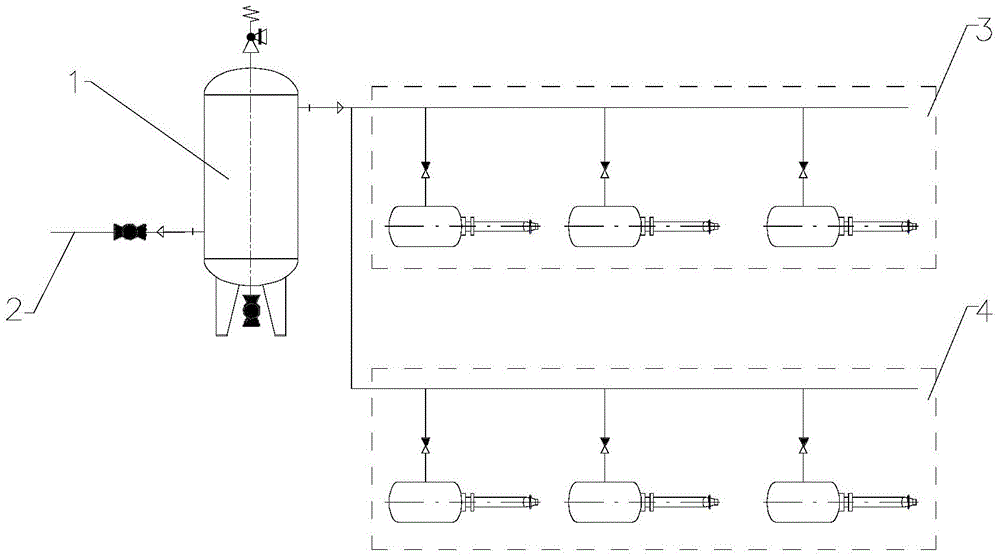

[0019] Such as figure 2 , image 3 As shown, the coal-fired sleeve shaft kiln blowing and plugging removal system includes a compressed air storage tank 1, and the compressed air storage tank 1 is connected to the gas source through an external gas source pipeline. The compressed air storage tank 1 is connected to each blowing and cleaning unit through the air source interface 13; the blowing and cleaning unit is arranged at the lower part of each burner combustion chamber 10 of the sleeve shaft kiln, and the blowing and cleaning unit corresponding to the upper combustion chamber It is the blowing and unclogging device 3 for the upper combustion chamber, and the corresponding blowing and unclogging unit for the lower combustion chamber is the blowing and unclogging device 4 for the lower combustion chamber.

[0020] The blowing and cleaning unit inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com