Air-compression disc-type anti-lock brake

An anti-lock and brake technology, applied in hydraulic brakes, brake actuators, gear shifting mechanisms, etc., can solve the problems of brake pads stuck and returned to failure, motor burnout, etc., and achieves a wide range of air pressure adjustment, Cost saving and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

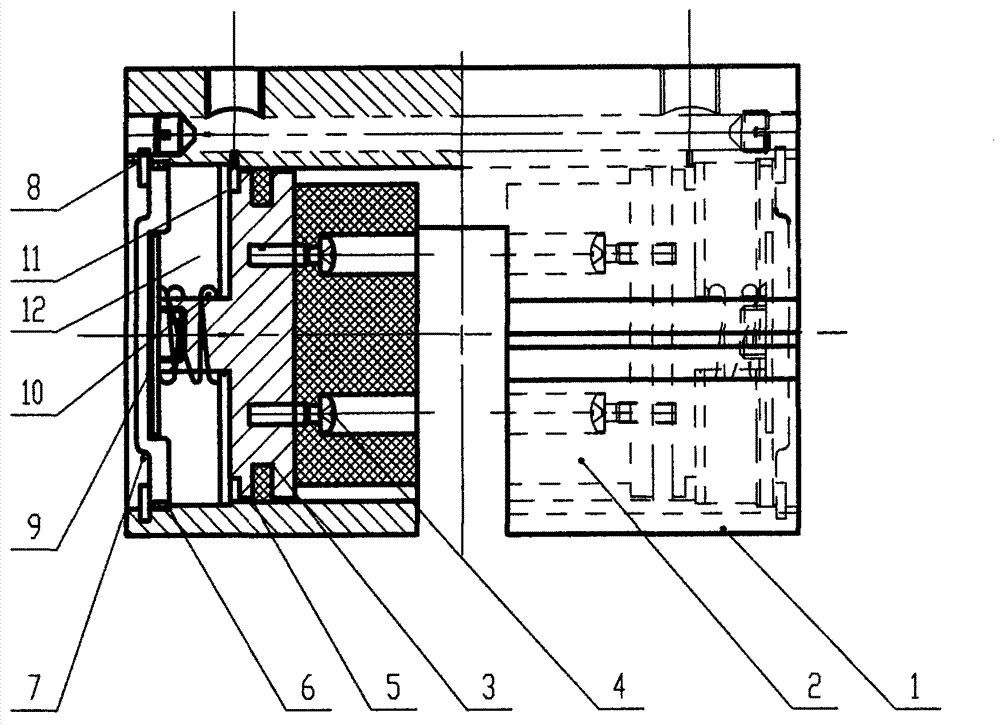

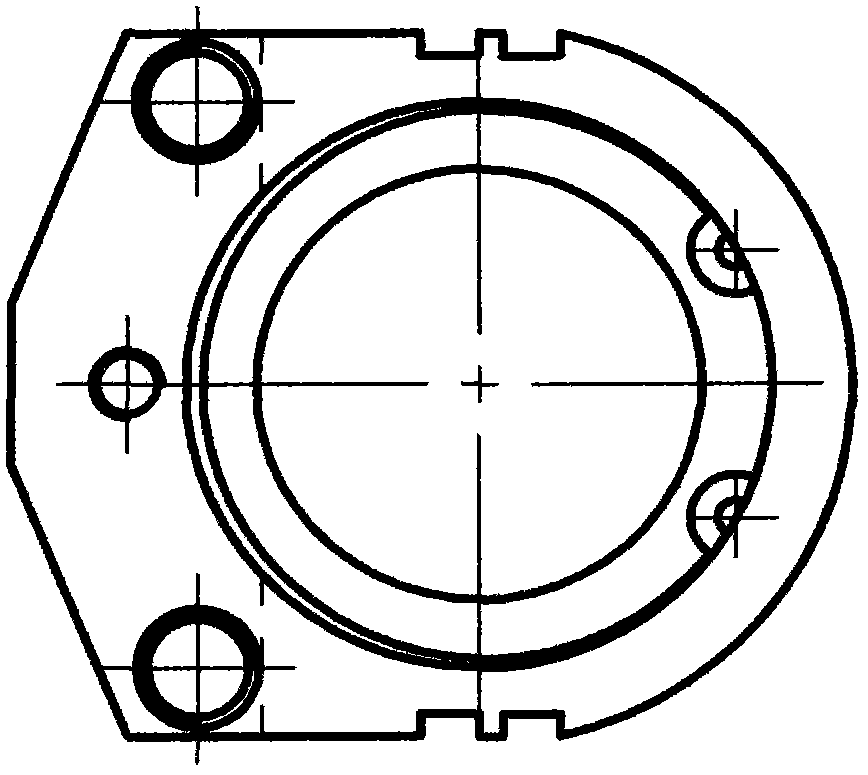

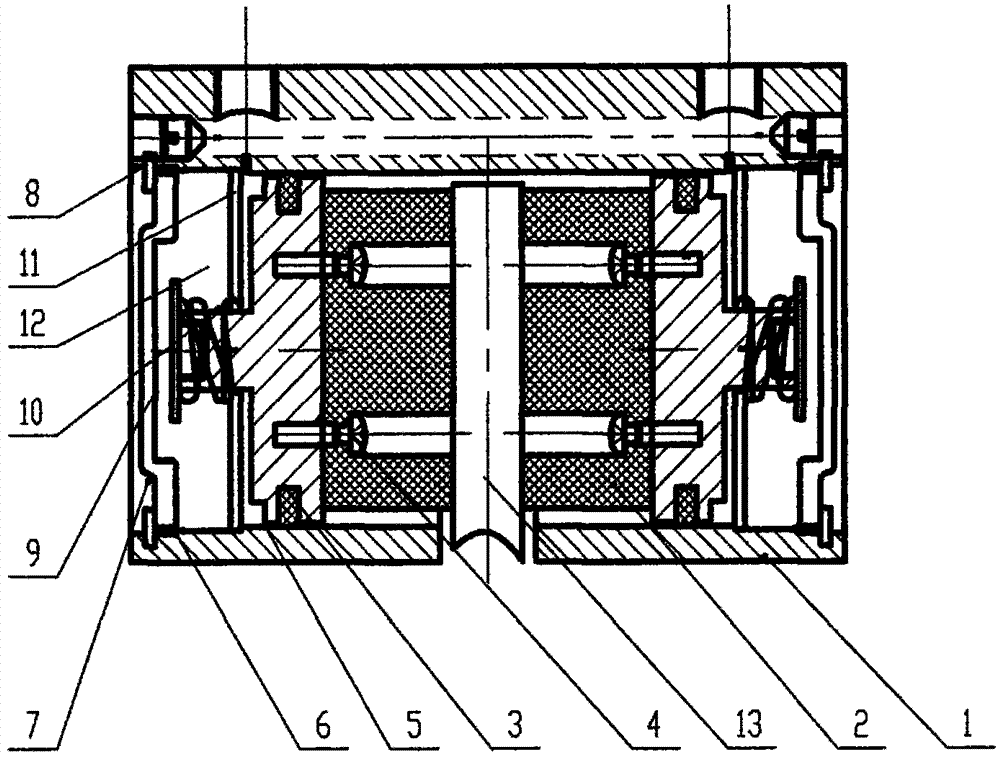

[0024] Attached below figure 1 , 2 The air pressure disc type anti-lock brake of the present invention will be described in detail below.

[0025] as attached figure 1 , 2 As shown, the structure of the pneumatic disc anti-lock brake of the present invention includes two groups of brake assemblies symmetrically arranged on both sides of the brake disc 13, and each group of brake assemblies includes a cylinder body 1, a brake pad 2, a piston 3. End cover 7, disc bolt 9, spring 10 and flat pad 11. In order to improve product grade and reduce product cost, the cylinder block 1 is made of SDA cylinder block molding material, and the inner cavity of the cylinder block 1 An end cover 7, a piston 3 and a brake pad 2 are arranged sequentially from the outside to the inside, the end cover 7 is sealed and positioned by a retaining ring 8, a first sealing ring 5 is arranged between the piston 3 and the cylinder body 1, the end cover 7 and the A second sealing ring 6 is arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com