A high-efficiency induction blowing device and a pulse bag filter for a dust collector

A technology of blowing device and dust collector, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of low dust removal efficiency, poor dust removal effect, and influence on dust removal efficiency of dust collectors, etc., and achieves improvement Dust removal efficiency, improvement of dust removal effect, and effect of ensuring dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

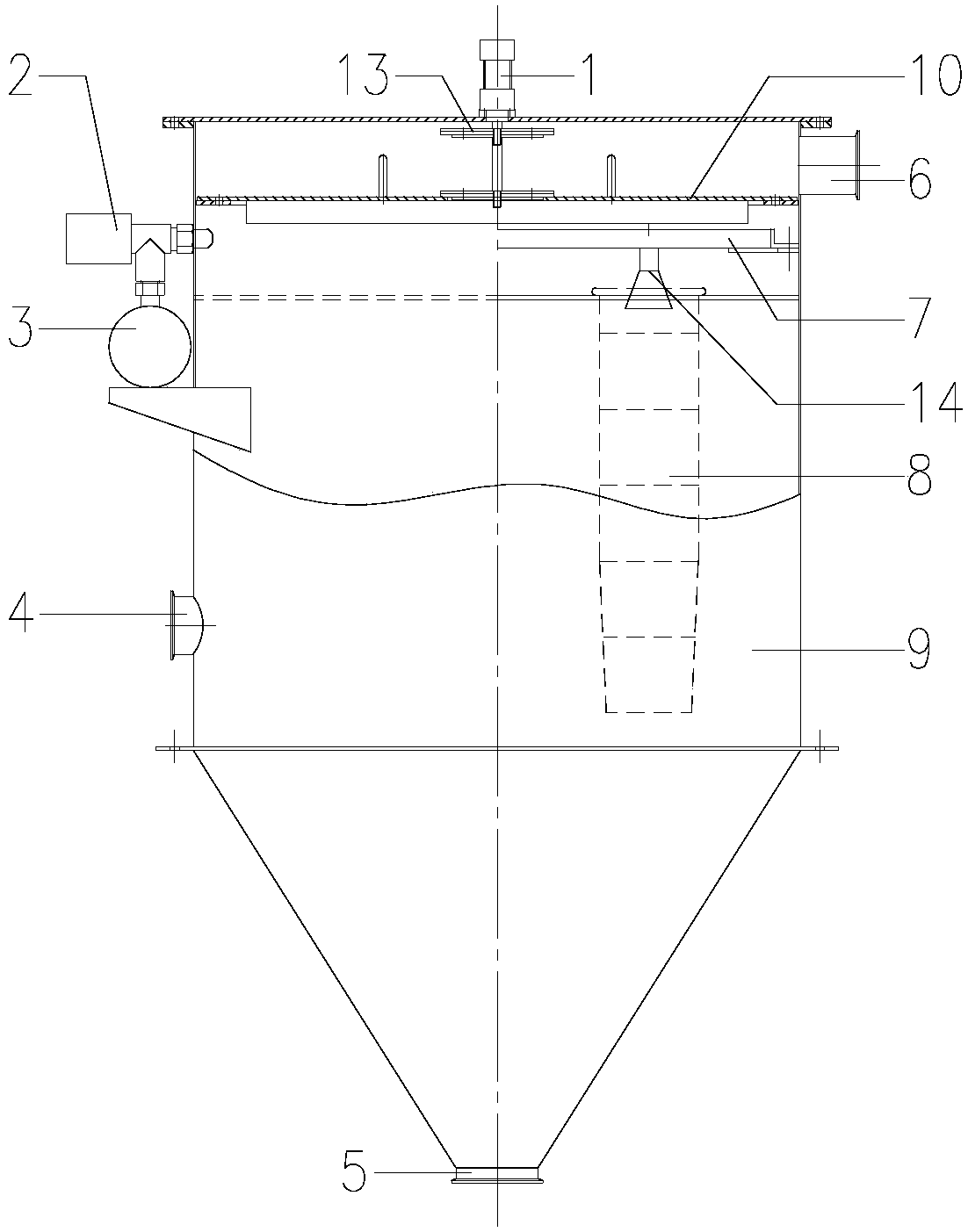

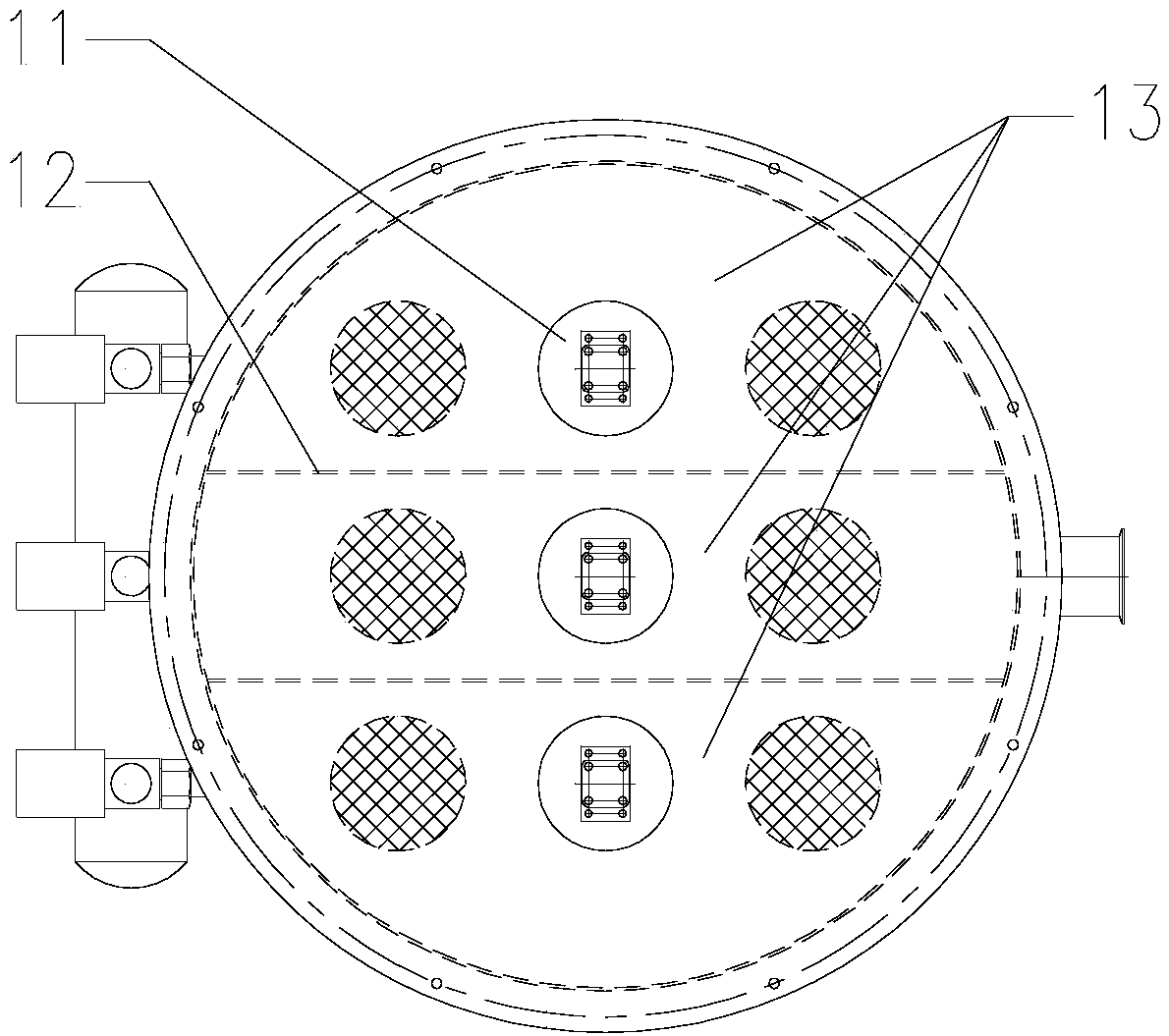

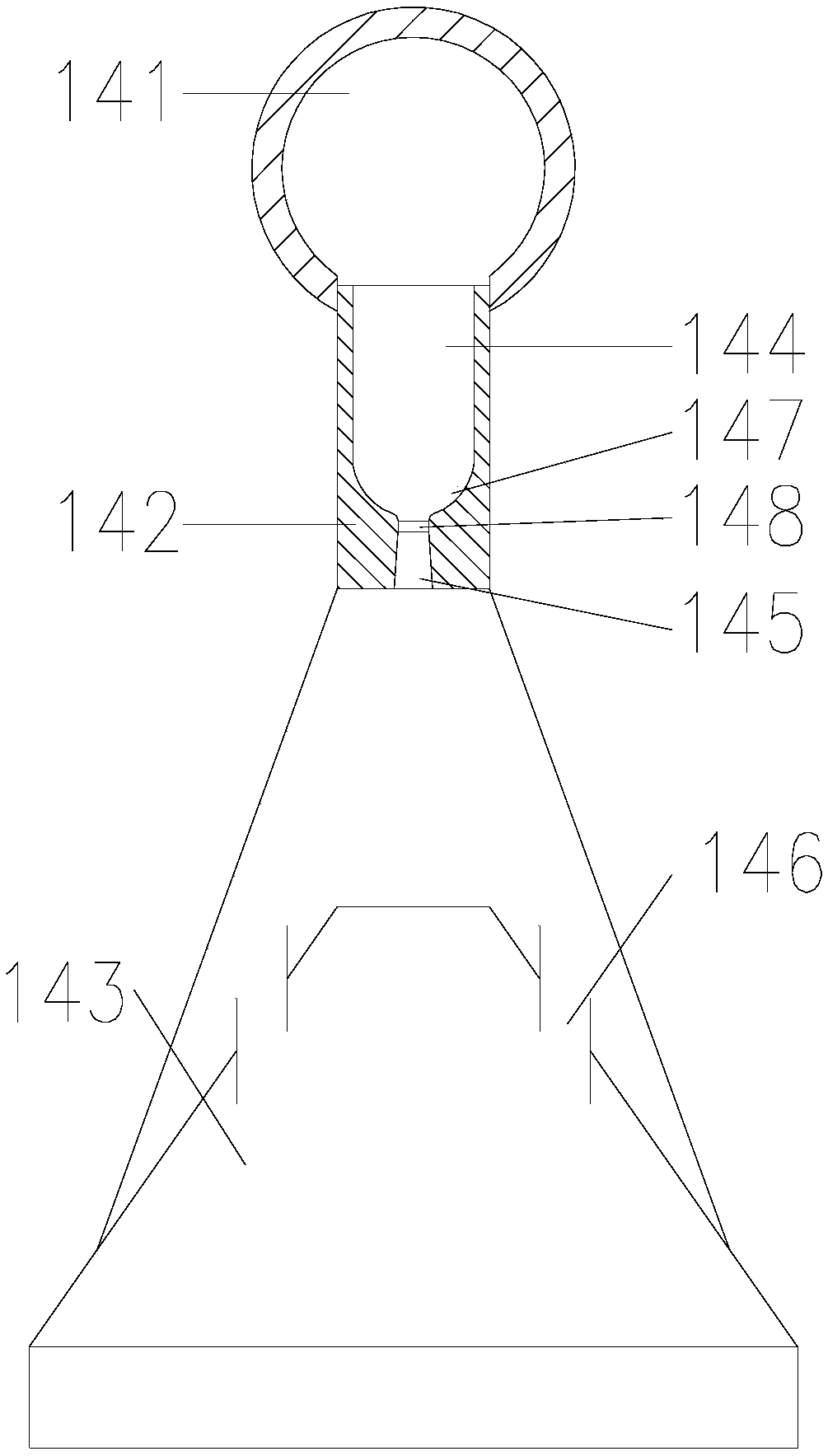

[0045] A high-efficiency induction blowing device for a dust collector, including a blowing branch pipe 141. One end of the blowing branch pipe 141 should communicate with the blowing pipe 7 in the corresponding clean air small chamber, and the other end of the blowing branch pipe 141 is connected with a supersonic The induction nozzle 142 , the other end of the supersonic induction nozzle 142 communicates with an airflow diffuser 143 , and the airflow diffuser 143 is provided with a diffuser air hole 146 . The high-speed and high-pressure airflow in the blowing pipe 7 can be sprayed out from the scattering air hole 146 of the airflow scattering device 143 after passing through the spraying branch pipe 141, the supersonic induction nozzle 142, and the airflow diffuser 143 successively, and is sprayed by the scattering airhole 146 of the airflow diffuser 143. The high-speed and high-pressure gas will directly act on the filter bag 8 to clean up the dust on the filter bag 8, so a...

Embodiment 2

[0047] On the basis of embodiment one, the ratio of the outer diameter of the supersonic induction nozzle 142 to the outer diameter of the injection branch pipe 141 is 1:2, and the ratio of the length of the supersonic induction nozzle 142 to the outer diameter of the injection branch pipe 141 The ratio of the length of the airflow diffuser 143 to the length of the supersonic induction nozzle 142 is 1.5:1, and the ratio of the opening diameter of the airflow diffuser 143 to the diameter of the supersonic induction nozzle 142 is 4:1.

Embodiment 3

[0049] On the basis of Embodiment 1 or Embodiment 2, the airflow channel of the supersonic induction nozzle 142 is the first steady-flow air hole 144 and the pressurized air hole 145. The booster air hole 145 is located on the air outlet side of the supersonic induction nozzle 142, the first steady-flow air hole 144 communicates with the booster air hole 145, and the inner diameter of the booster air hole 145 gradually increases along the airflow direction. In addition, a spherical transitional air hole 147 and a second steady-flow air hole 148 can also be arranged sequentially between the first steady-flow air hole 144 and the pressurized air hole 145, and the airflow in the supersonic induction nozzle 142 passes through the first steady-flow air hole 144, spherical After the transition air hole 147, the second steady flow air hole 148, and the pressurized air hole 145, enter the airflow diffuser 143; A smooth transition is achieved between the air holes 145 , which reduces t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com