Air hole structure on relay shell

A relay and ventilation hole technology, which is applied in the directions of relay ventilation/cooling/heating, relay base/shell/cover, etc., can solve the problems of easy blockage of the outer end of the ventilation hole, difficult molding technology, and technical difficulty, etc. Reduce the difficulty of manufacturing molding technology, reliable molding, and good economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

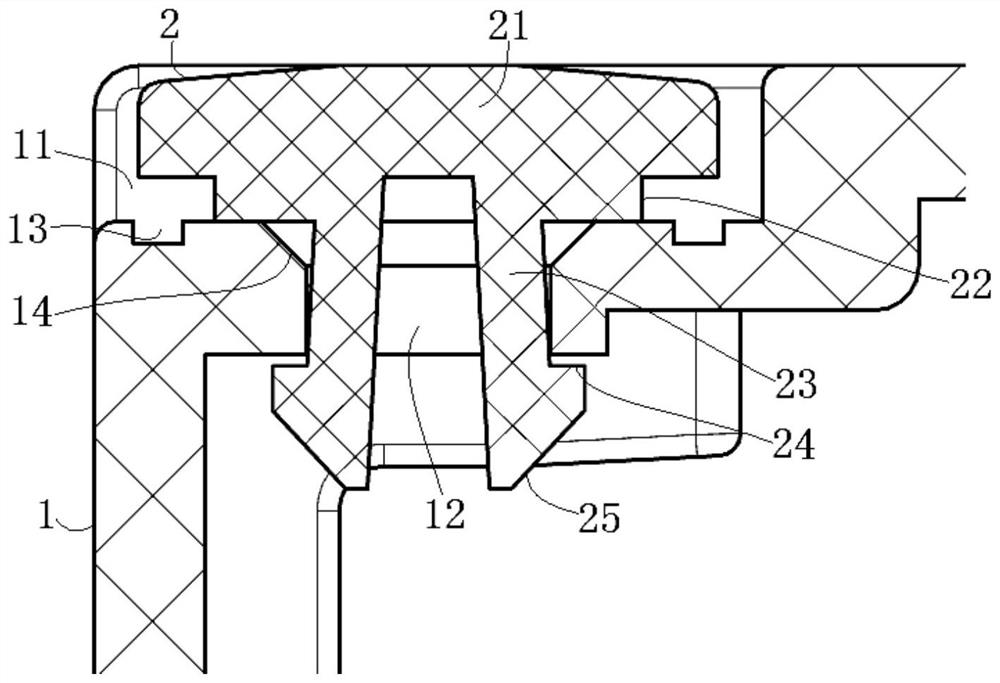

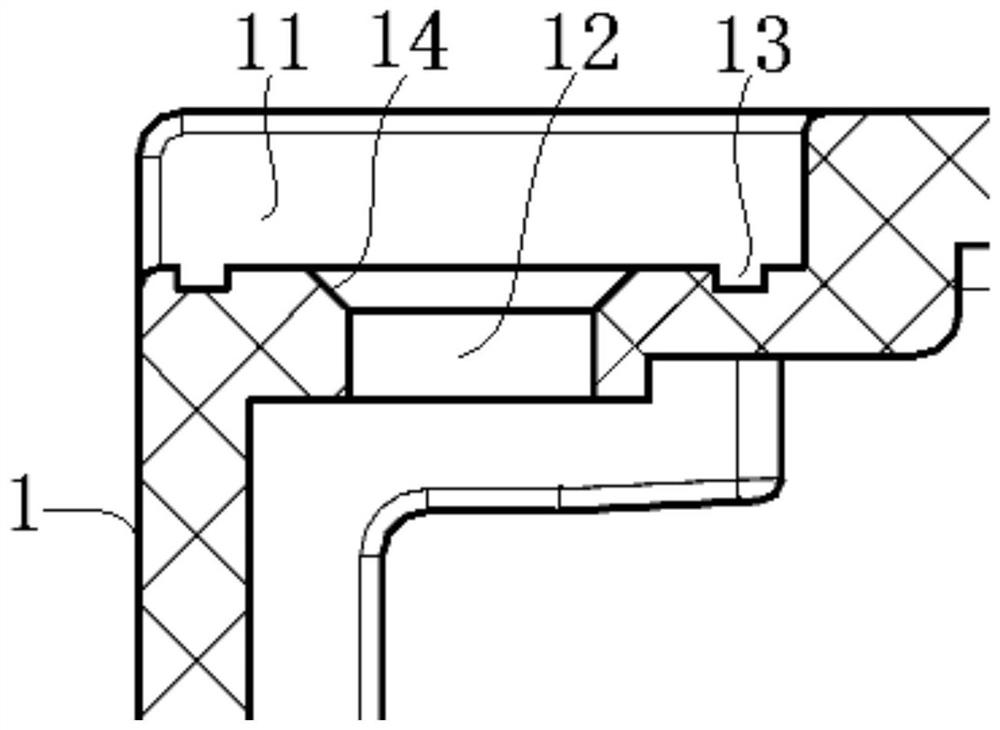

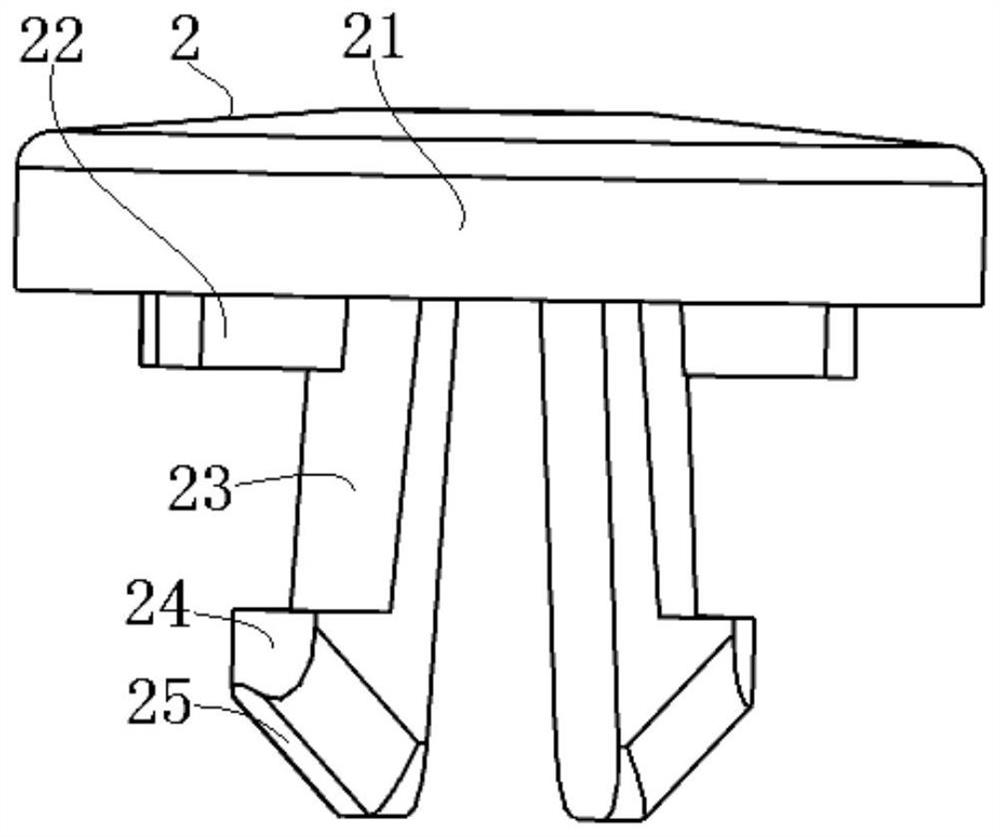

[0030] see figure 1 , figure 2 and image 3 As shown, the present invention is a vent structure on the relay housing, which includes a base hole 12 formed on the relay housing 1 that can communicate with the inside and outside of the housing, and an expansion card that can be assembled in the base hole 12 Plug 2.

[0031]Specifically, one corner of the relay housing 1 is used as the forming area of the base hole 12, and the outer surface of this area has a concave cavity 11 for forming the base hole 12. The depth of the cavity 11 should correspond to the The top of the expansion plug 2 is substantially flush with or slightly lower than the outer surface of the current board of the relay housing 1, and the area of the cavity 11 should be larger than the area of the plug cap 21 of the expansion plug 2. Since the concave cavity 11 is formed at a corner of the relay housing 1, the outer peripheral walls on both sides of the concave cavity 11 are open structures, that is,...

Embodiment 2

[0045] The invention relates to a vent hole structure on a relay housing, which includes a base hole formed on the relay housing that can communicate with the inside and outside of the housing, and an expansion plug that can be assembled in the base hole.

[0046] Specifically, one corner of the relay housing is used as the forming area of the base hole, and the outer surface of this area has a concave cavity for forming the base hole. The depth of the cavity should correspond to the top of the assembled expansion plug It is basically flush with or slightly lower than the outer surface of the current board of the relay housing, and the area of the concave cavity should be larger than the area of the plug cap of the expansion plug. Since the concave cavity is formed at one corner of the relay casing, the outer peripheral walls at the two sides of the concave cavity are open structures, that is, the corner of the current plate of the relay casing is a stepped surface struct...

Embodiment 3

[0060] The other contents of this embodiment are the same as those of Embodiment 1 or Embodiment 2, except that there is no dirt collection tank structure on the relay housing.

[0061] Under this technical measure, in order to effectively prevent the intrusion of pollutants, it is best to design the plug cap of the expansion plug large enough, so that the air passage at the outer end of the base hole (that is, the bottom surface of the plug cap and the relay) The air passage formed between the shell surfaces) is long enough to counteract the kinetic force of the pollutant intrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com