Production process method for stamping molds for back boards of liquid crystal displays of curved-surface televisions

A liquid crystal display and production method technology, applied in the field of stamping die production, can solve problems such as size deviation, increased assembly difficulty, unstable product quality, etc., and achieve the effect of stable and reliable molding and accurate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the mode of the present invention is further elaborated:

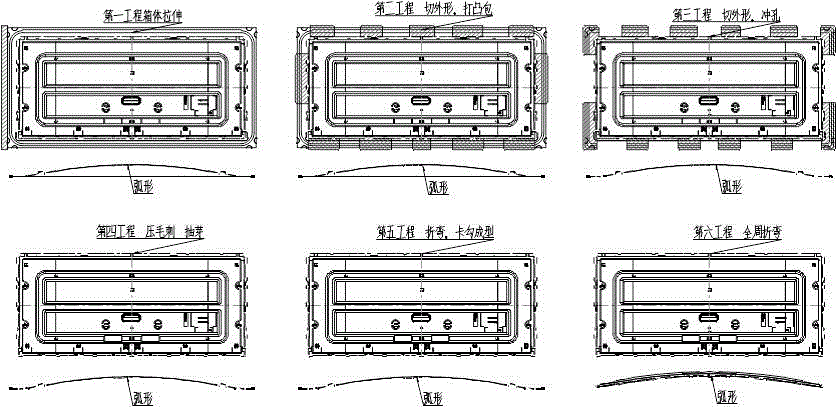

[0014] image 3 As shown, according to the inventive scheme, 6 sets of molds made according to the new scheme are respectively installed on 6 stamping machines for installation and debugging in place.

[0015] The general division of labor is as follows:

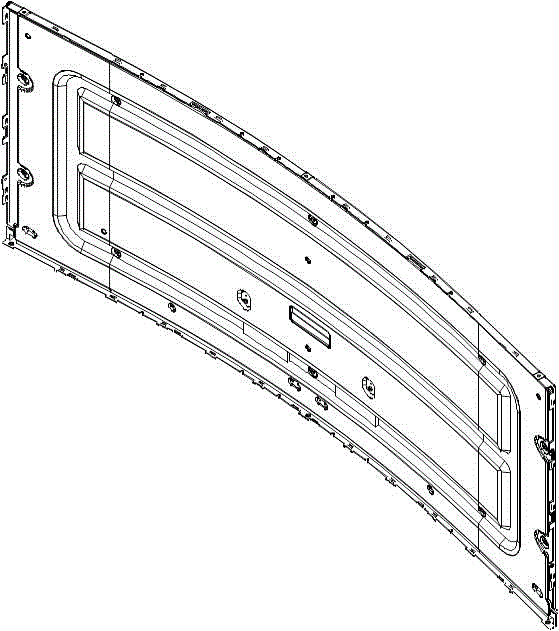

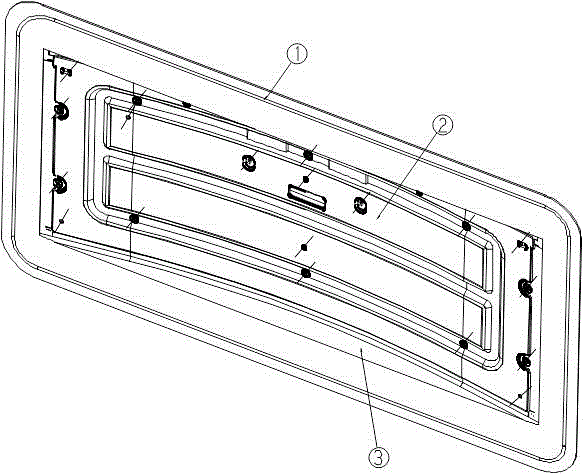

[0016] The coil material is fed into the No. 1 punching machine by the feeder, and beading is provided on the whole circumference ( figure 2 ) 1, press the blank, stretch out the box with the bottom of the arc surface 2, and at the same time, the convex hull on the arc surface is also stretched together.

[0017] The semi-finished product in the No. 1 punching machine is taken out by the mechanical arm and transferred to the No. 2 punching machine. The shape of the product is cut, the convex hull is shaped on the arc surface, and the hook is formed.

[0018] The semi-finished product in the No. 2 punching mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com