Cold roll forming equipment of single board

A technology of cold forming and single-piece board, which is applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems that it is difficult to obtain products with accurate dimensions and single-piece boards are easy to deviate, and achieve a compact body, The effect of low scrap rate and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

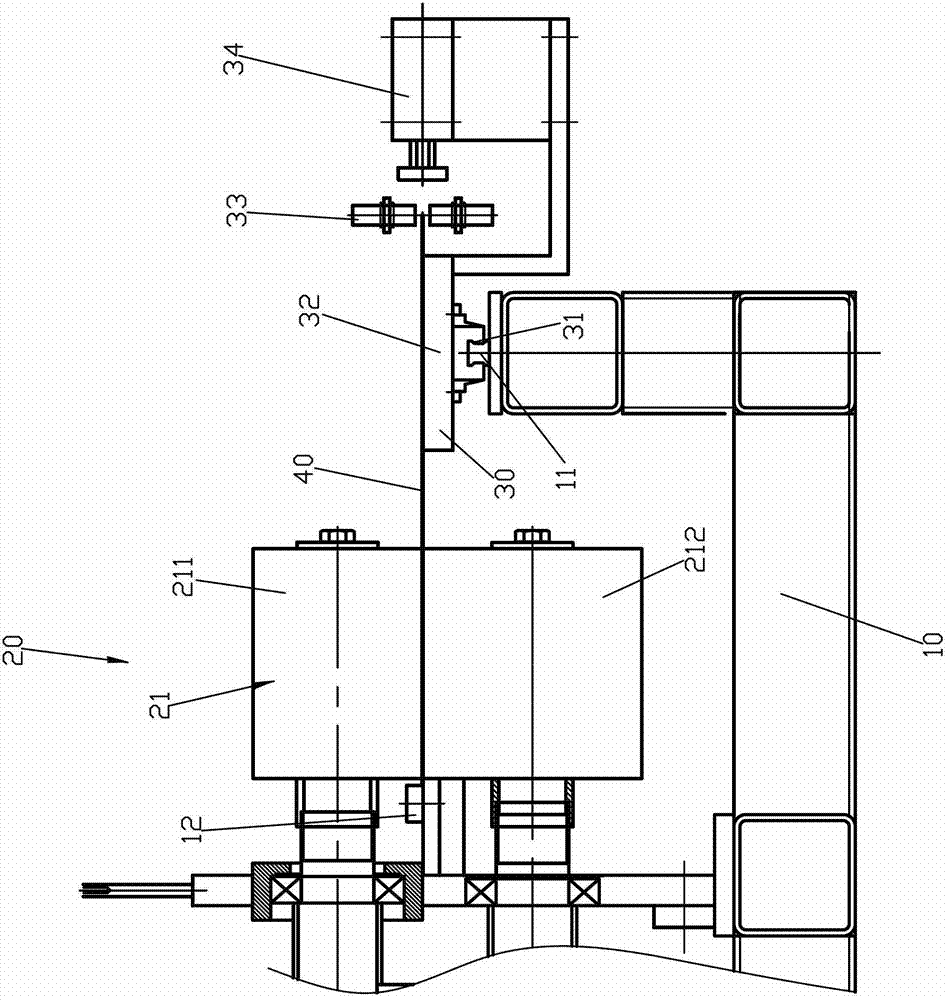

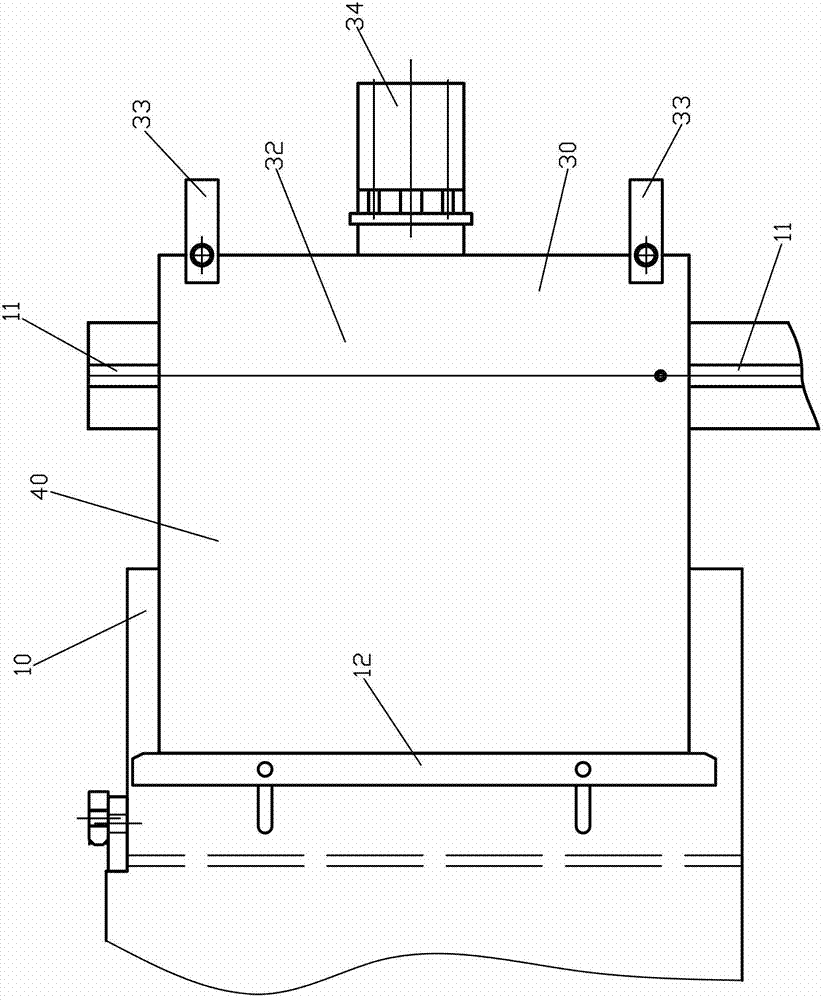

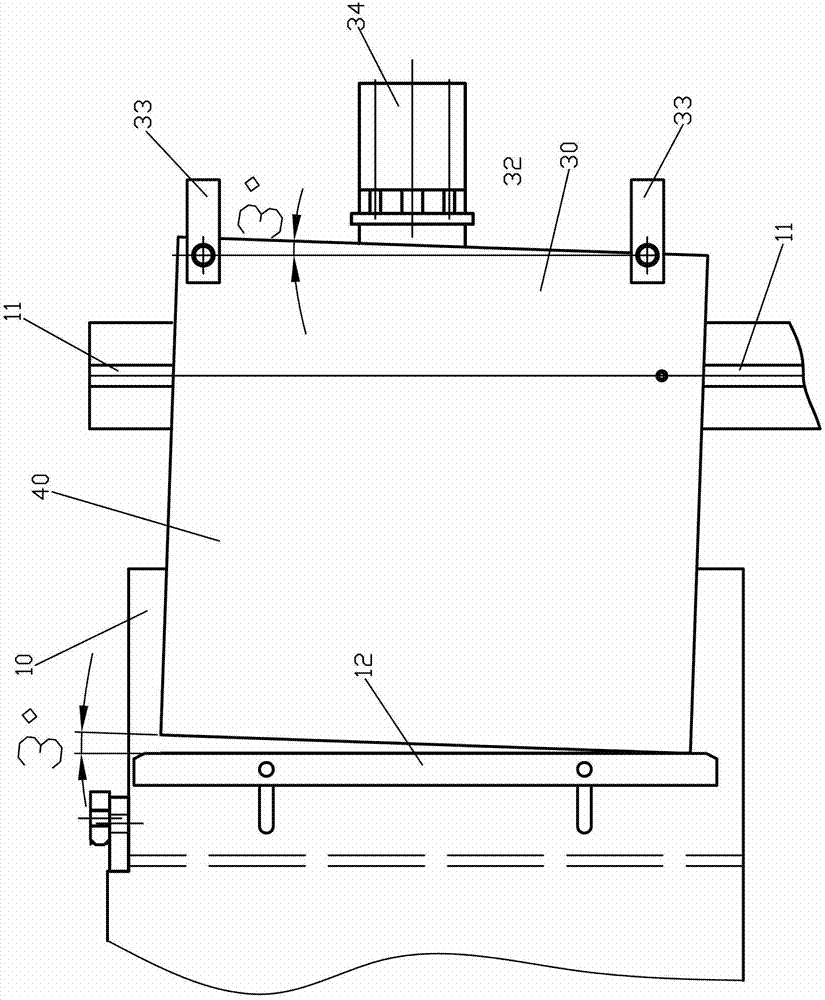

[0027] Please check Figure 1 to Figure 4 , single sheet cold bending forming equipment, including a machine platform 10, a cold bending forming device 20 located on the machine platform 10 and a signal connection control device of the cold forming device 20 and a guide platform 30, the control device is located at On the machine platform 10, the control device is such as a PLC controller.

[0028] The machine platform 10 is provided with at least one guide rail 11 and a fixed baffle plate 12 . The cold bending forming device 20 includes at least one cold bending forming roll mechanism 21. In this embodiment, the number of the cold bending forming roll mechanism 21 is multiple, and the multiple cold forming roll mechanism 21 runs along the guide rail 11. The direction is arranged front and back, and the single-piece plate 40 is sequentially processed by the multi-channel cold-bending forming roller mechanism 21 to make it bend and form, such as Figure 5 , which is a structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com