Patents

Literature

75results about How to "Precise sliding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

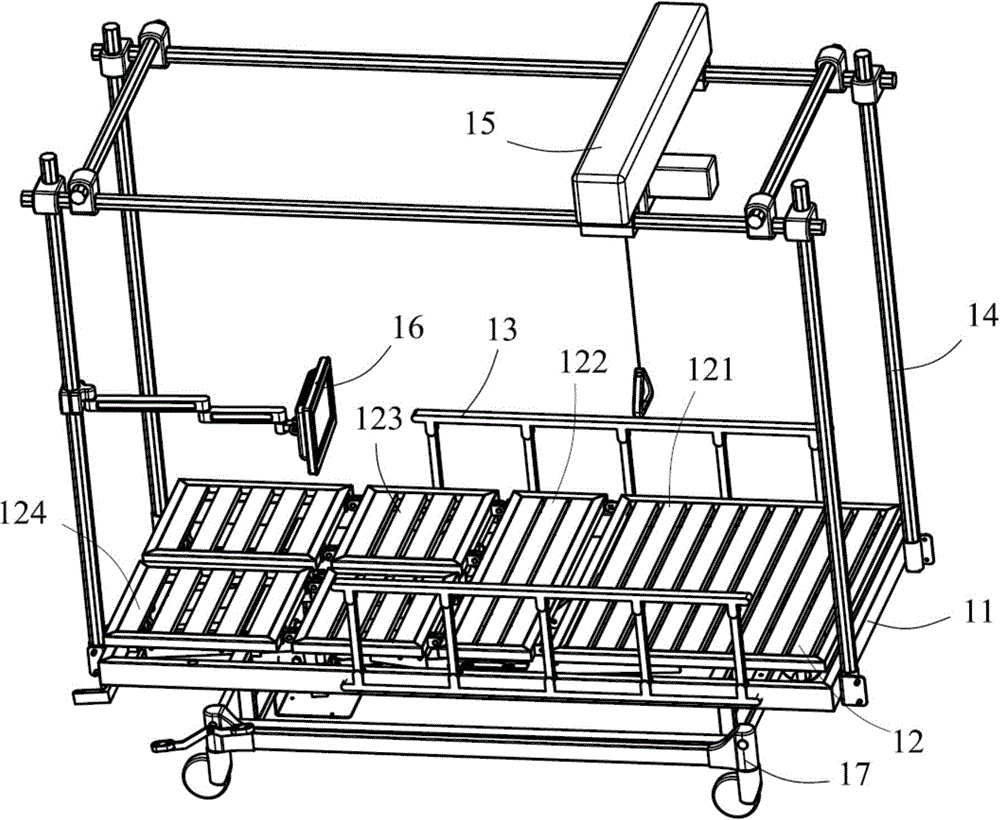

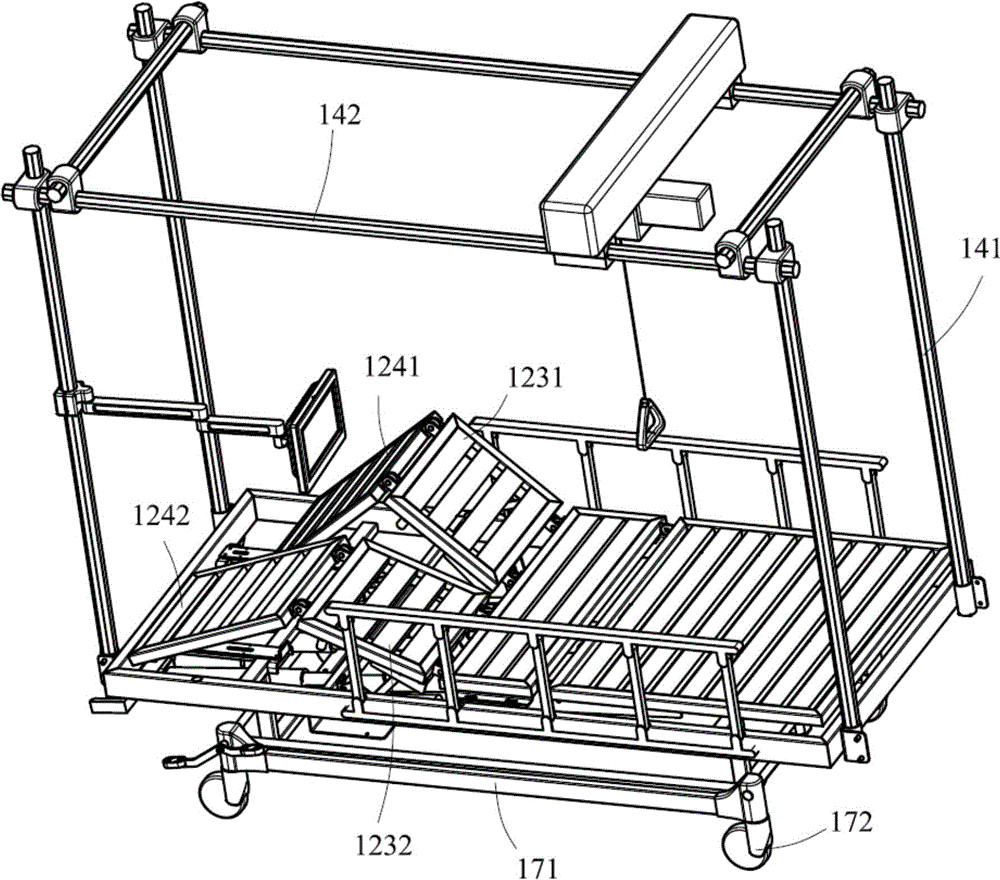

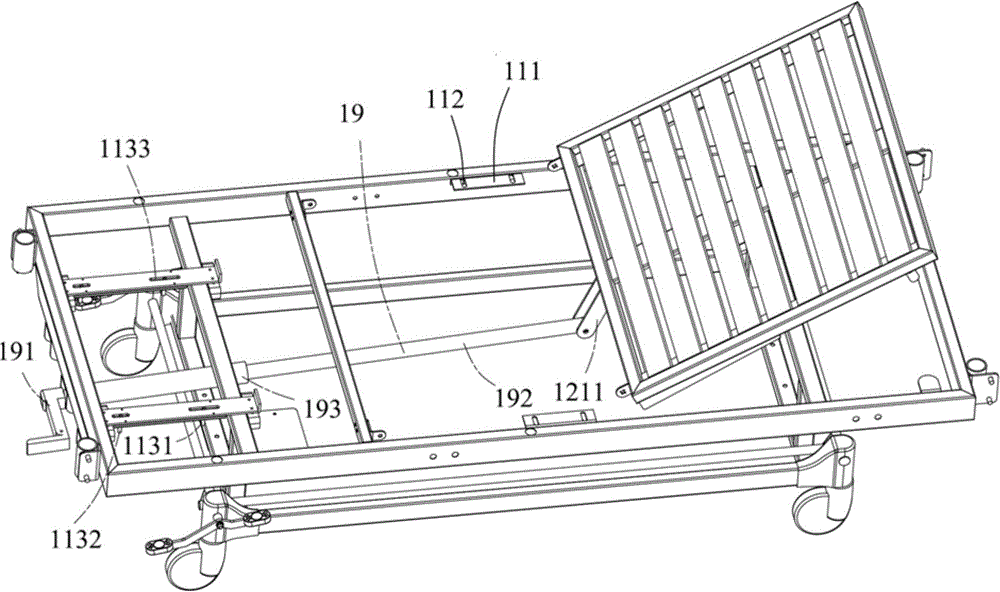

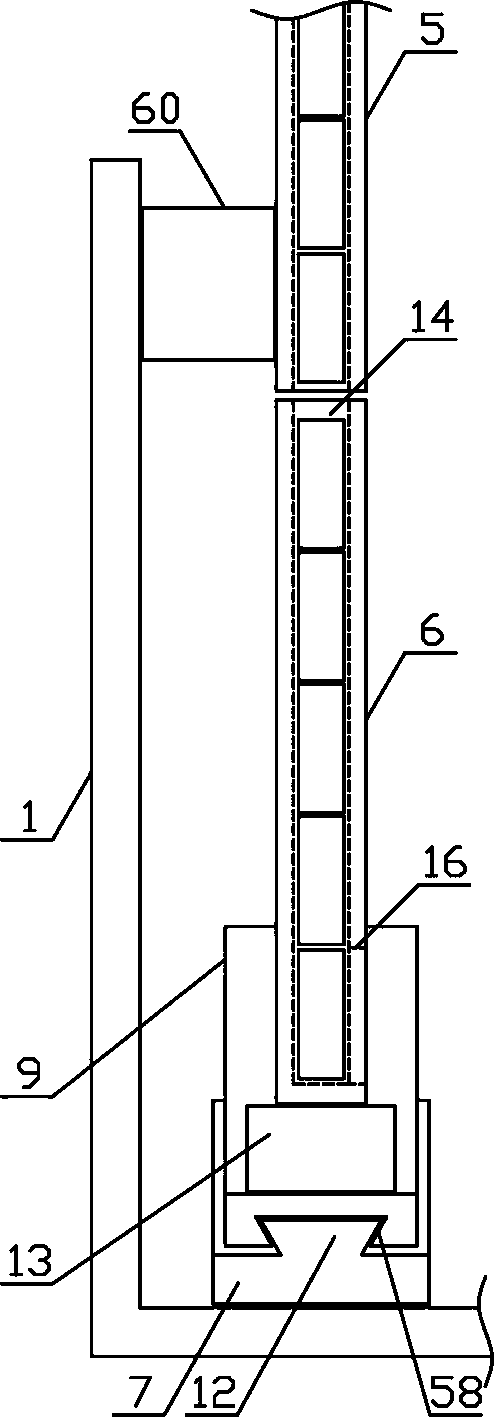

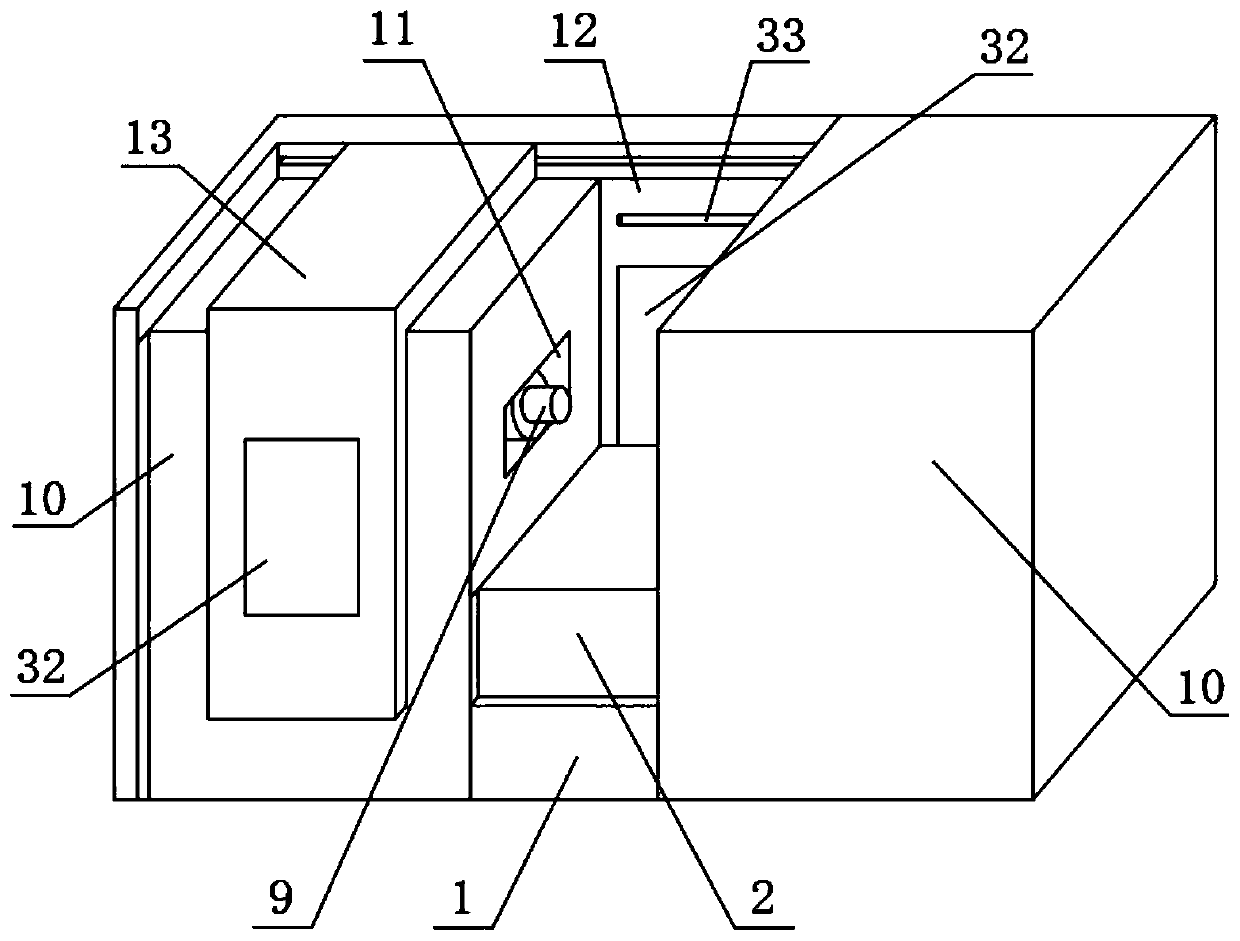

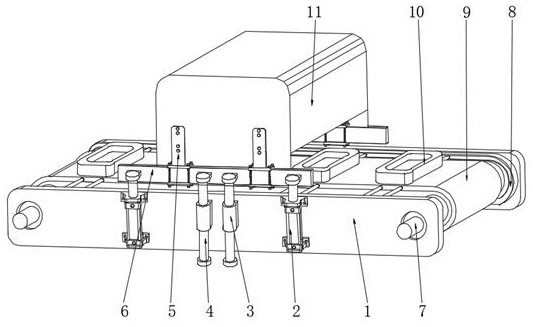

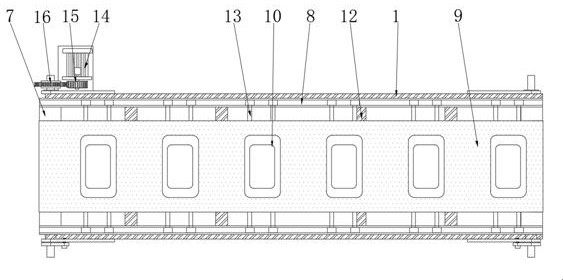

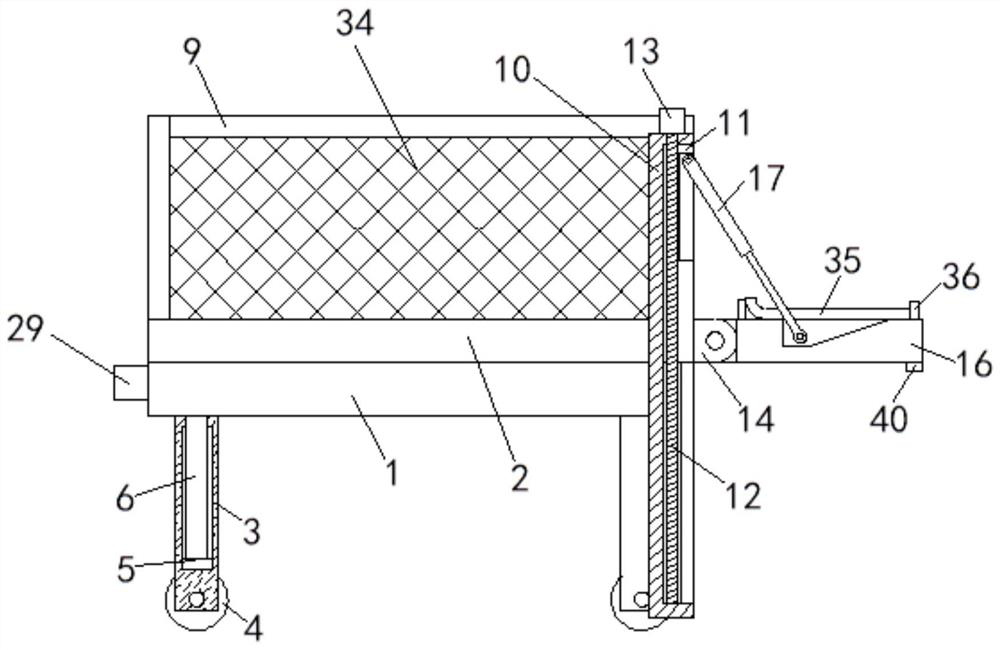

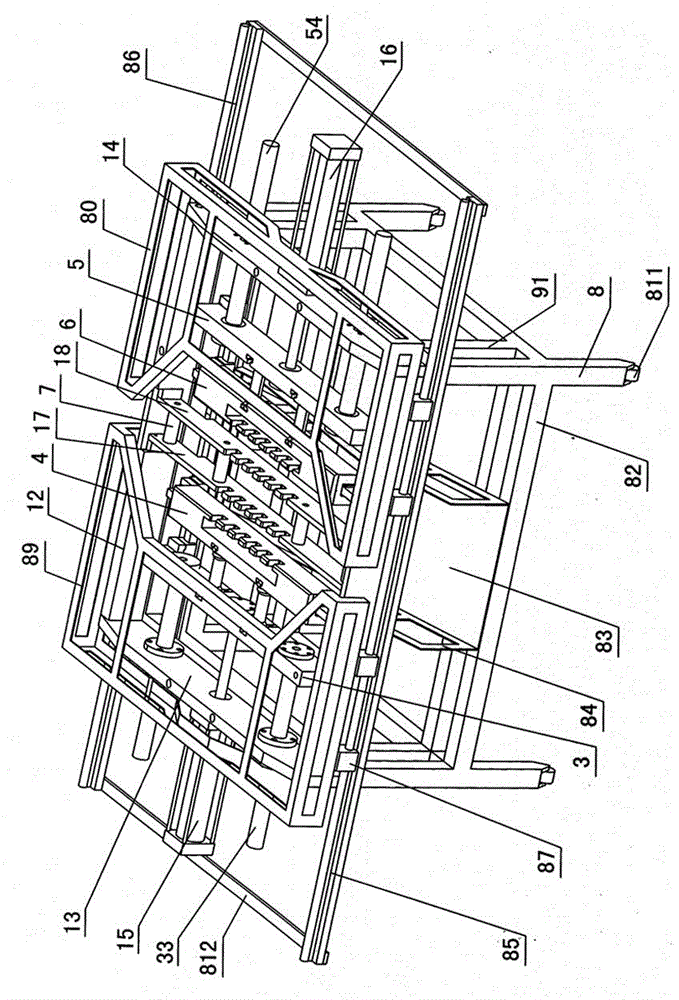

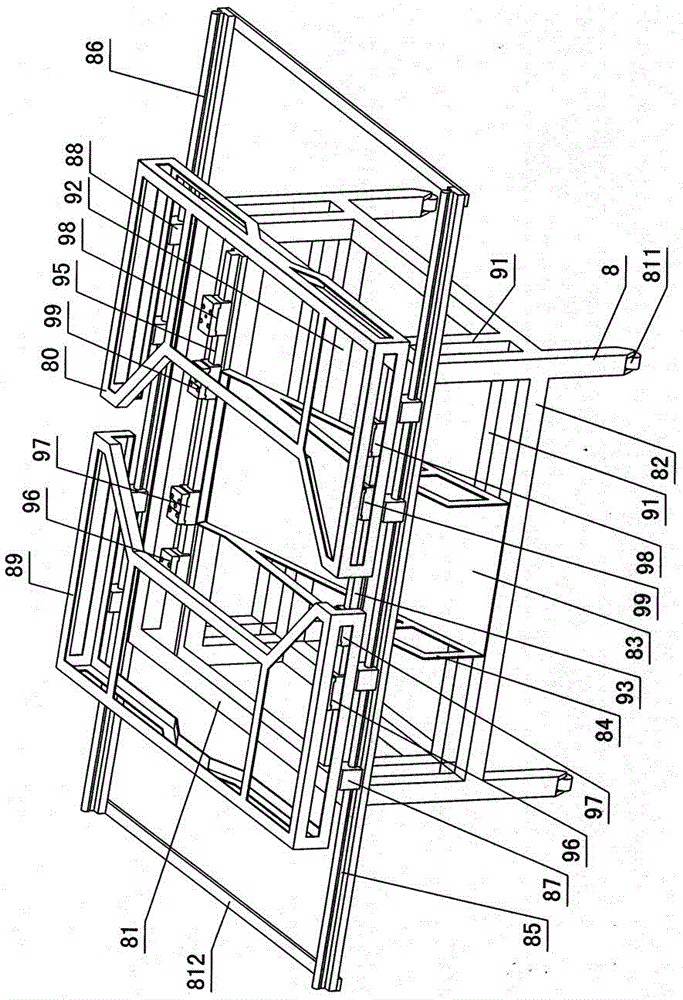

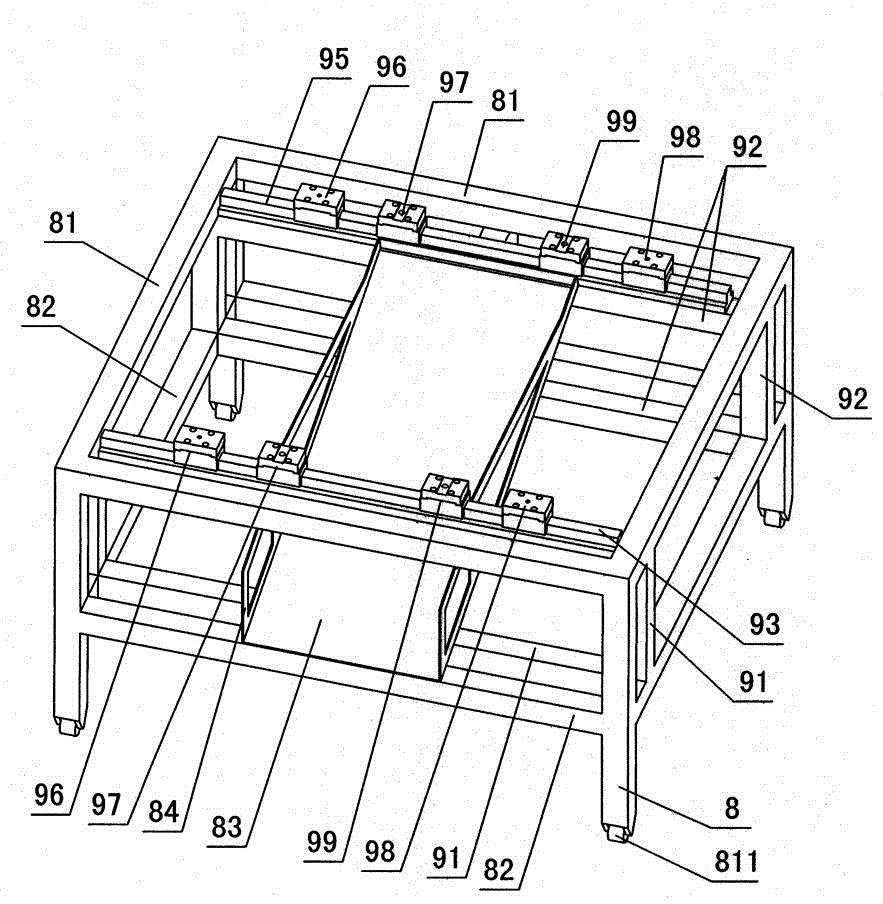

Bed for rehabilitation exercise of four limbs

ActiveCN103976847ARealize rehabilitation exerciseReduce frictionChiropractic devicesMuscle exercising devicesThighArm exercise

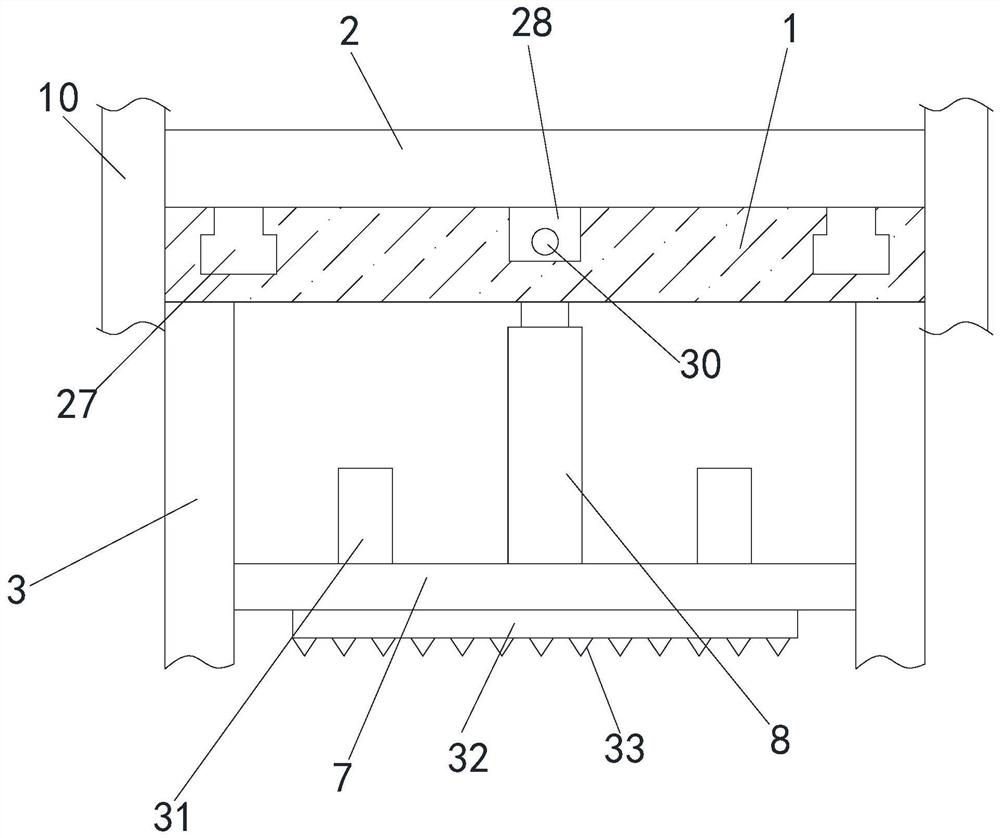

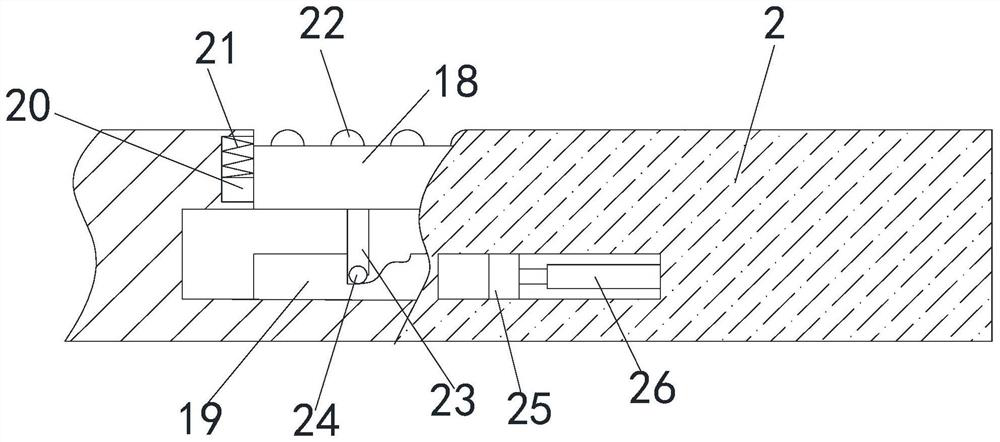

The invention discloses a bed for the rehabilitation exercise of the four limbs. The bed comprises a bed body, a bed board, first driving devices, brackets, an arm exercise assemblies and a control device, wherein the bed board is supported on the bed body and comprises a first bed plate, thigh bed plates and shank bed plates, which are sequentially arranged on the bed body, one end of each thigh bed plate is rotatably connected to the corresponding shank bed plate, and the other end of each thigh bed plate is rotatably connected to the bed body or the first bed plate; the first driving devices are mounted between the thigh bed plates and the bed body, so as to drive the thigh bed plates to rotate; the brackets are mounted on the bed body; the arm exercise assemblies are mounted on the brackets and are located above the bed board; the control device is connected to the first driving devices and the arm exercise assemblies and can control the first driving devices to drive the thigh bed plates to reciprocate in a certain angle range. The leg bed plates are of split arrangement, and the bed plates of left and right legs are driven to move alternately by motors, so that leg rehabilitation exercise can be realized; meanwhile, through the arm exercise assemblies mounted on the brackets, arm rehabilitation exercise can also be realized.

Owner:江苏永发医用设备科技股份有限公司

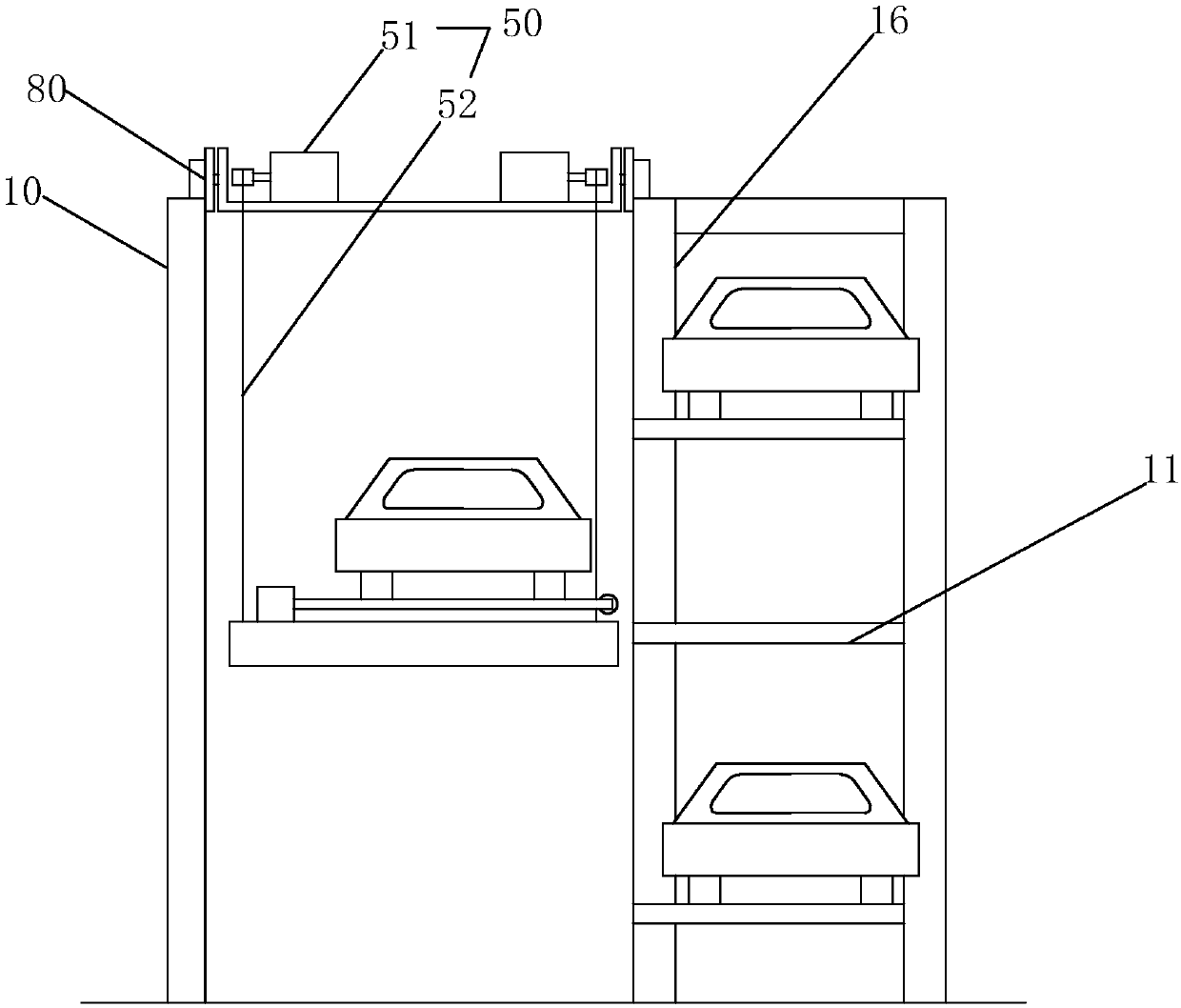

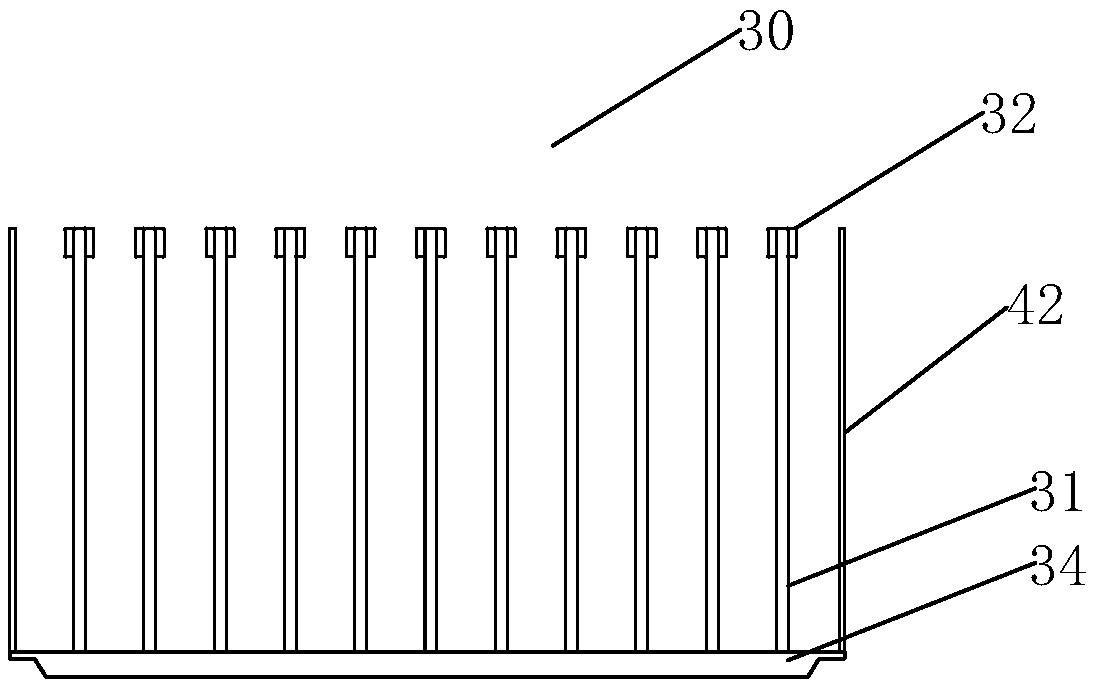

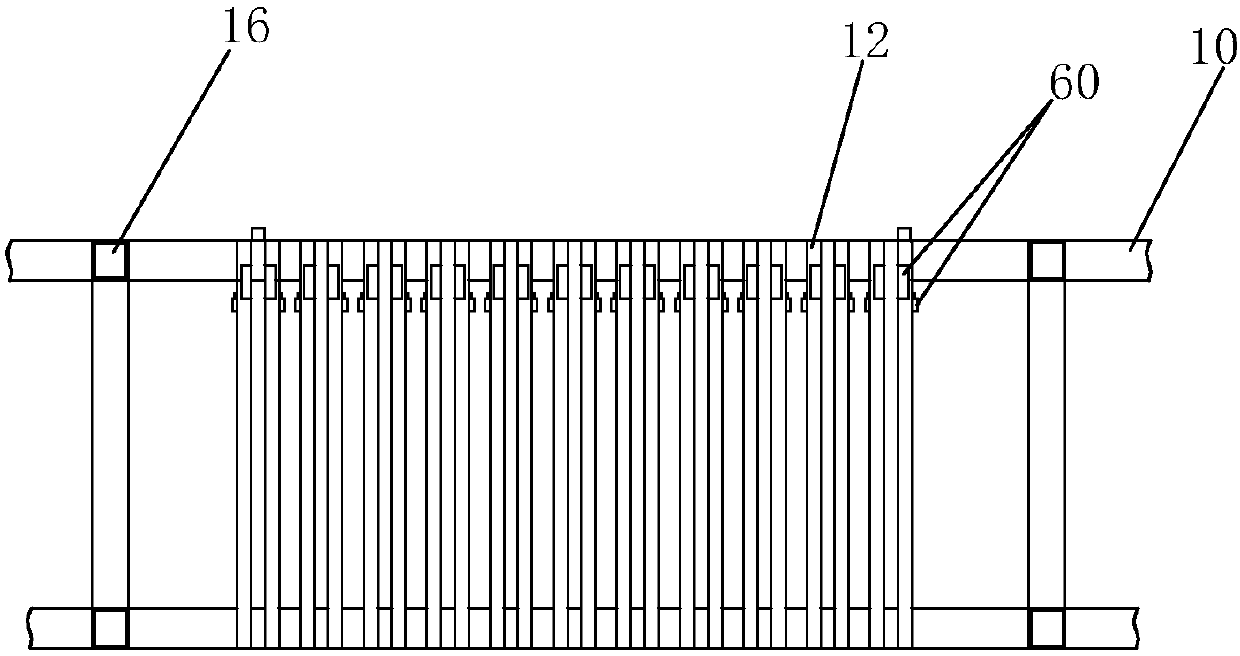

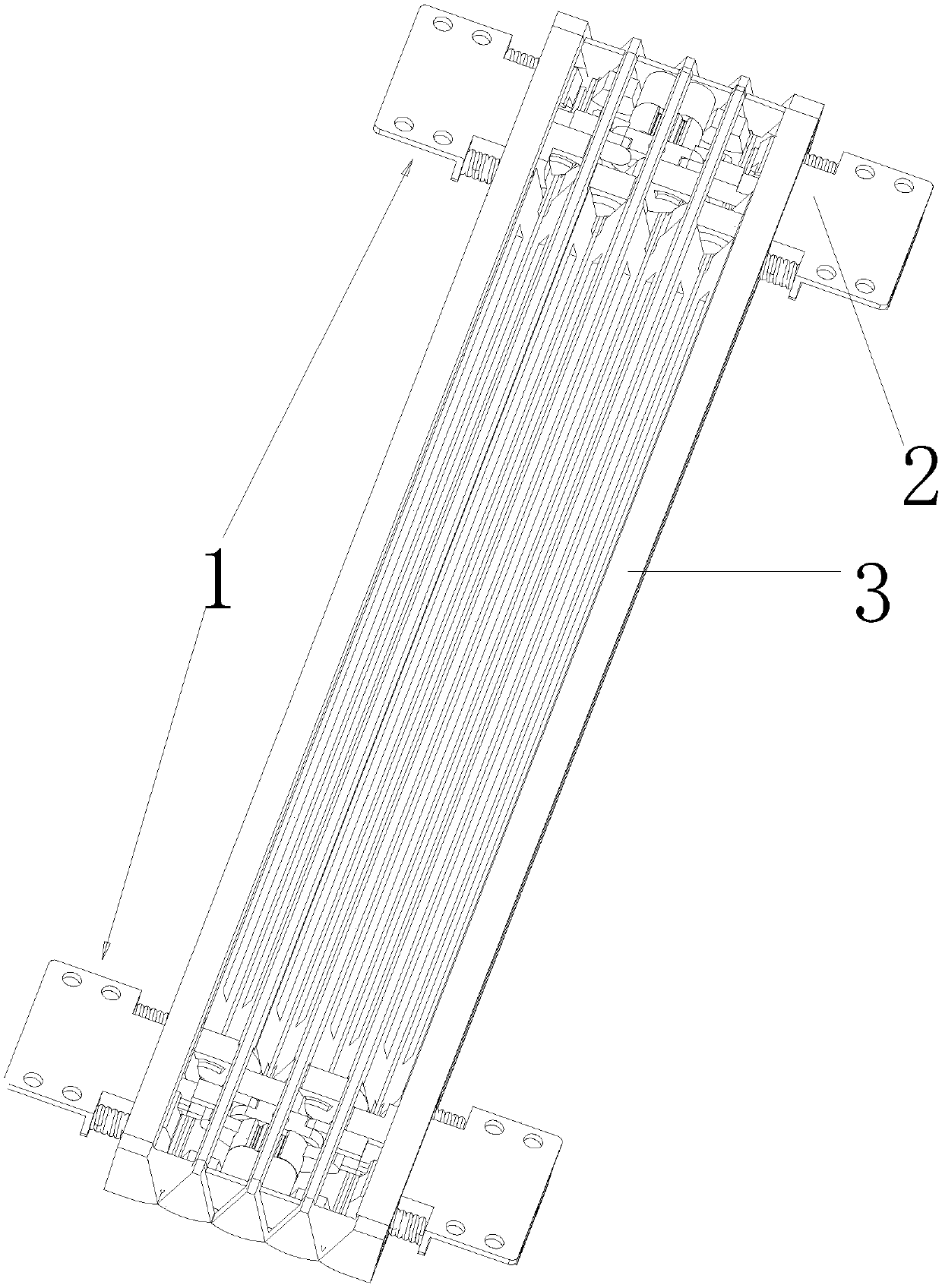

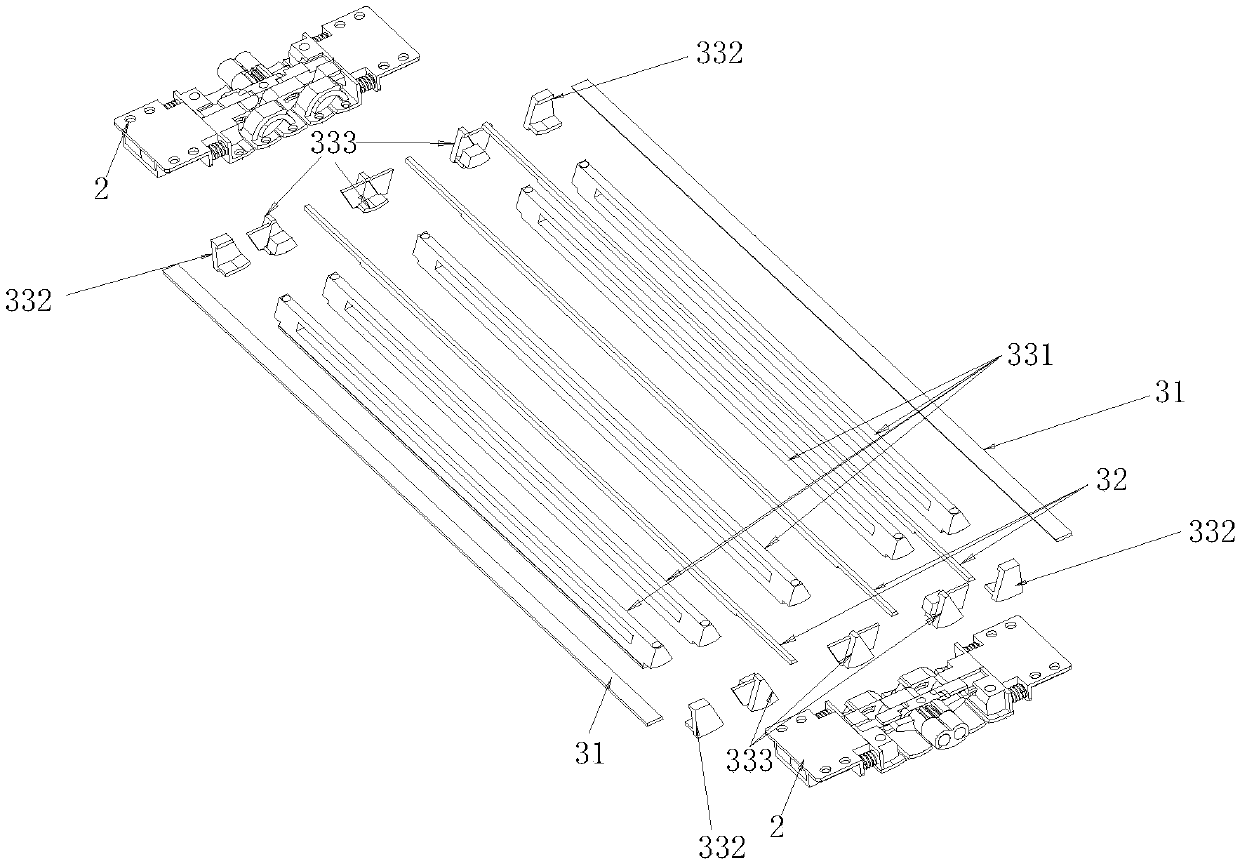

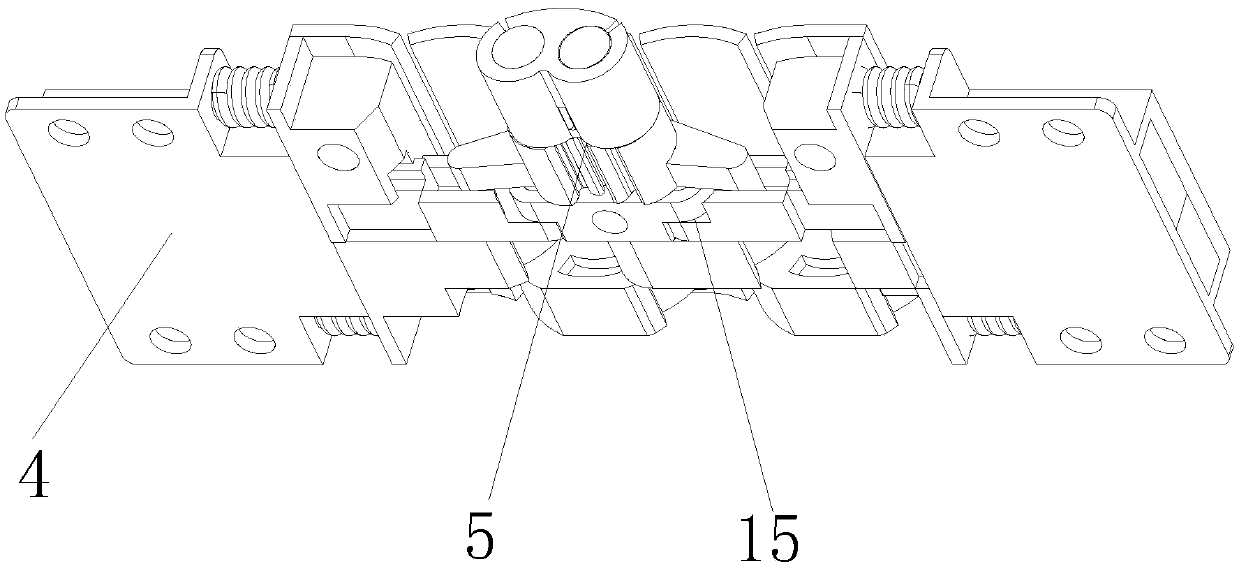

Three-dimensional parking garage

A three-dimensional parking garage comprises a parking frame, a car loading plate, a comb plate, a side-moving driving mechanism and a lifting driving mechanism. A plurality of parking plates are arranged on the parking frame; the comb plate is located on the car loading plate; the lifting driving mechanism is connected with the car loading plate and drives the car loading plate to go up and down;the three-dimensional parking garage further comprises switching mechanisms; the parking plates comprise a plurality of guide rails which are arranged in parallel at intervals, and each guide rail isprovided with an upper guide rail surface and a lower guide rail surface; the side-moving driving mechanism is connected with the comb plate and drives the comb plate to slide along the upper guide rail surfaces or the lower guide rail surfaces; the switching mechanisms are installed at the positions close to the tail ends of the guide rails so as to lead the comb plate to slide to the lower guide rail surface from the corresponding upper guide rail surface for parking or lead the comb plate to slide to the upper guide rail surface from the corresponding lower guide rail surface for picking up a car. The three-dimensional parking garage is simple and ingenious in structure, small in occupied space, low in cost and easy to implement.

Owner:李文岚

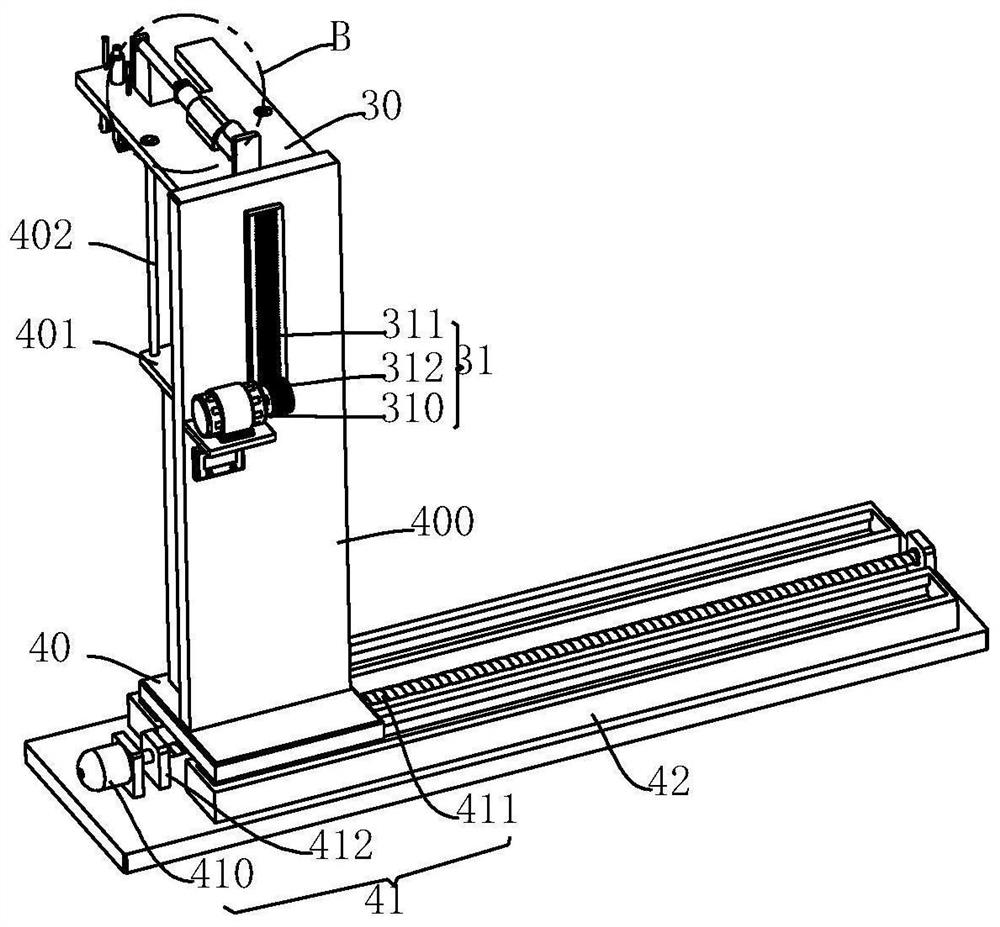

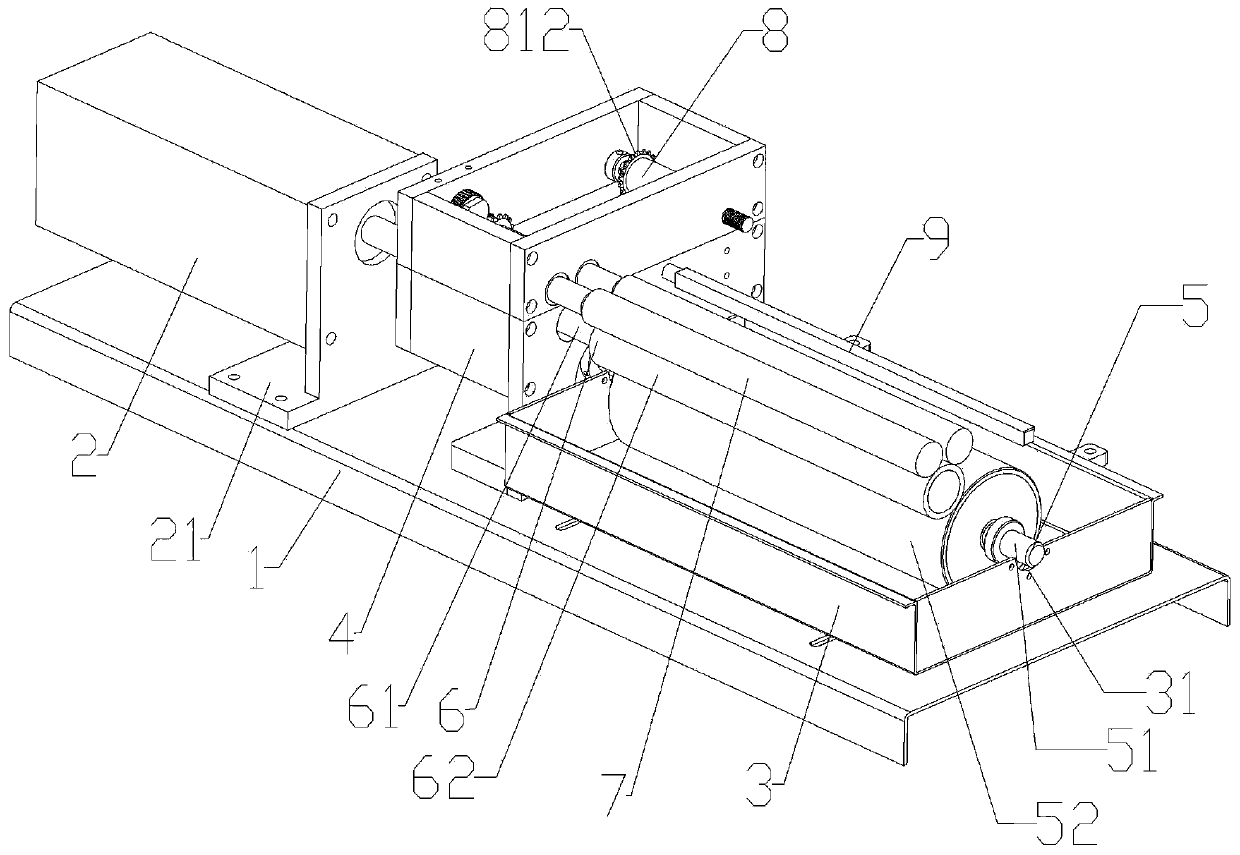

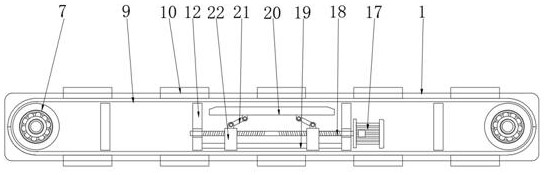

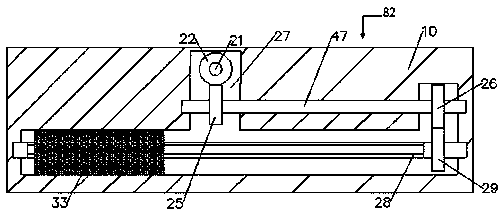

Sheet workpiece continuous feeding mechanism

InactiveCN109648378AReasonable structural designRealize continuous feedingMetal working apparatusEngineeringMechanical equipment

The invention discloses a sheet workpiece continuous feeding mechanism and belongs to the field of workpiece machining and conveying mechanical equipment. A feeding mechanism body and a material conveying mechanism of the feeding mechanism are sequentially arranged on the part, on one side of a material guiding mechanism, of a fixing bracket in the horizontal direction; a translation bracket is horizontally arranged on the part, on the lower side of a storage hopper, of the fixing bracket; a translation connecting plate is slidably arranged on a translation guide bar in the horizontal direction; the middle of the lower side of a rotating disc is fixedly connected with the upper end of a feeding rotating shaft; a material suction guiding plate is vertically arranged on one side of a material suction bracket; the output end of a material suction air cylinder is fixedly connected with the middle of one side of the material suction guiding plate; a plurality of material suction mechanismsare sequentially and uniformly arranged on the material suction guiding plate in the horizontal direction; and a material conveying belt is arranged on the upper side of a material conveying bracket.The feeding mechanism is reasonable in structure design, a plurality of sheet workpieces can be sequentially sucked and fixed, and the multiple sucked and fixed sheet workpieces can be synchronously transferred and conveyed, so that the sheet workpiece feeding automation degree is increased, and the machining demands are met.

Owner:嘉兴汉羿文化传播有限公司

Cam follower roller device

Owner:AB SKF

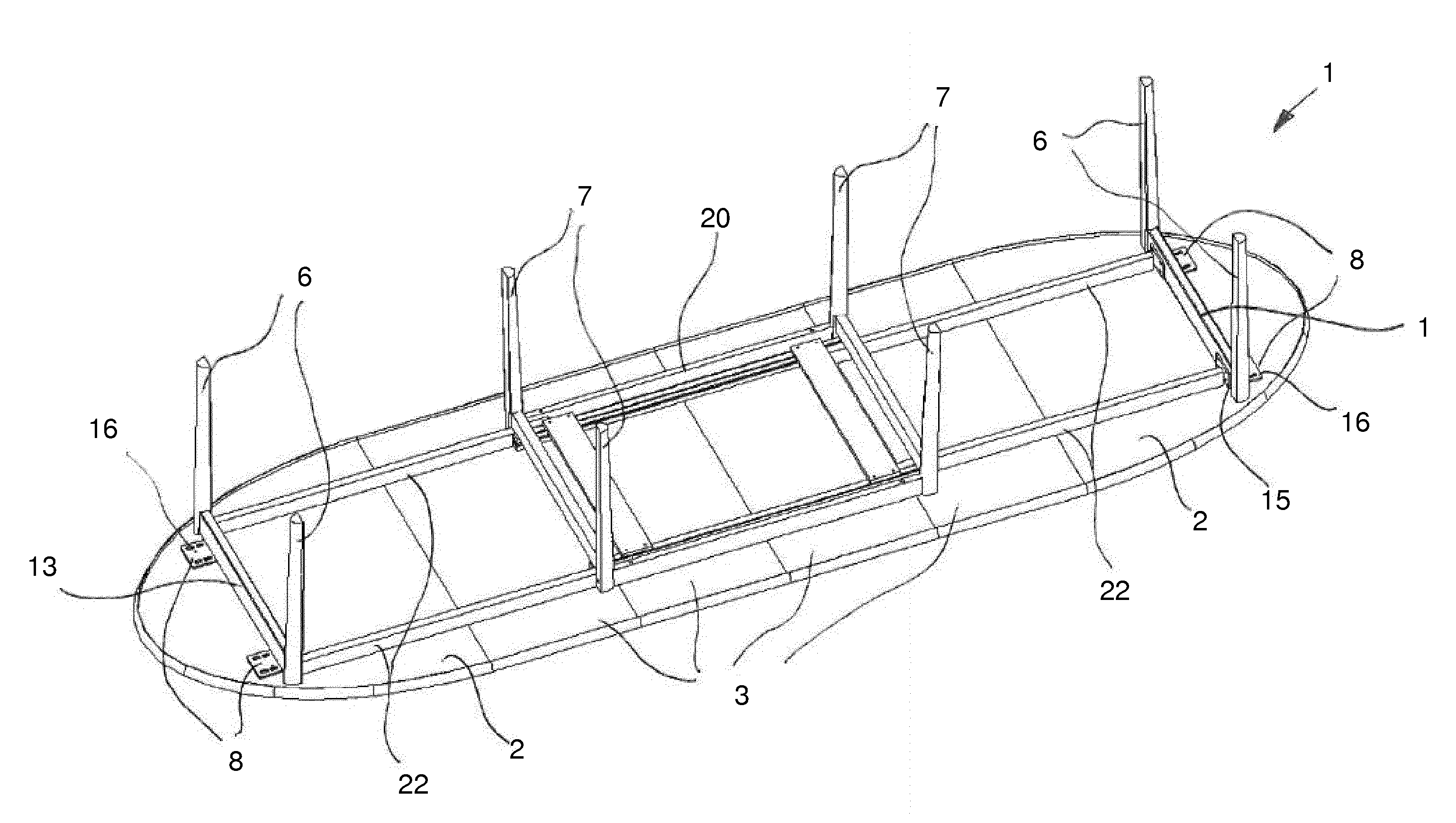

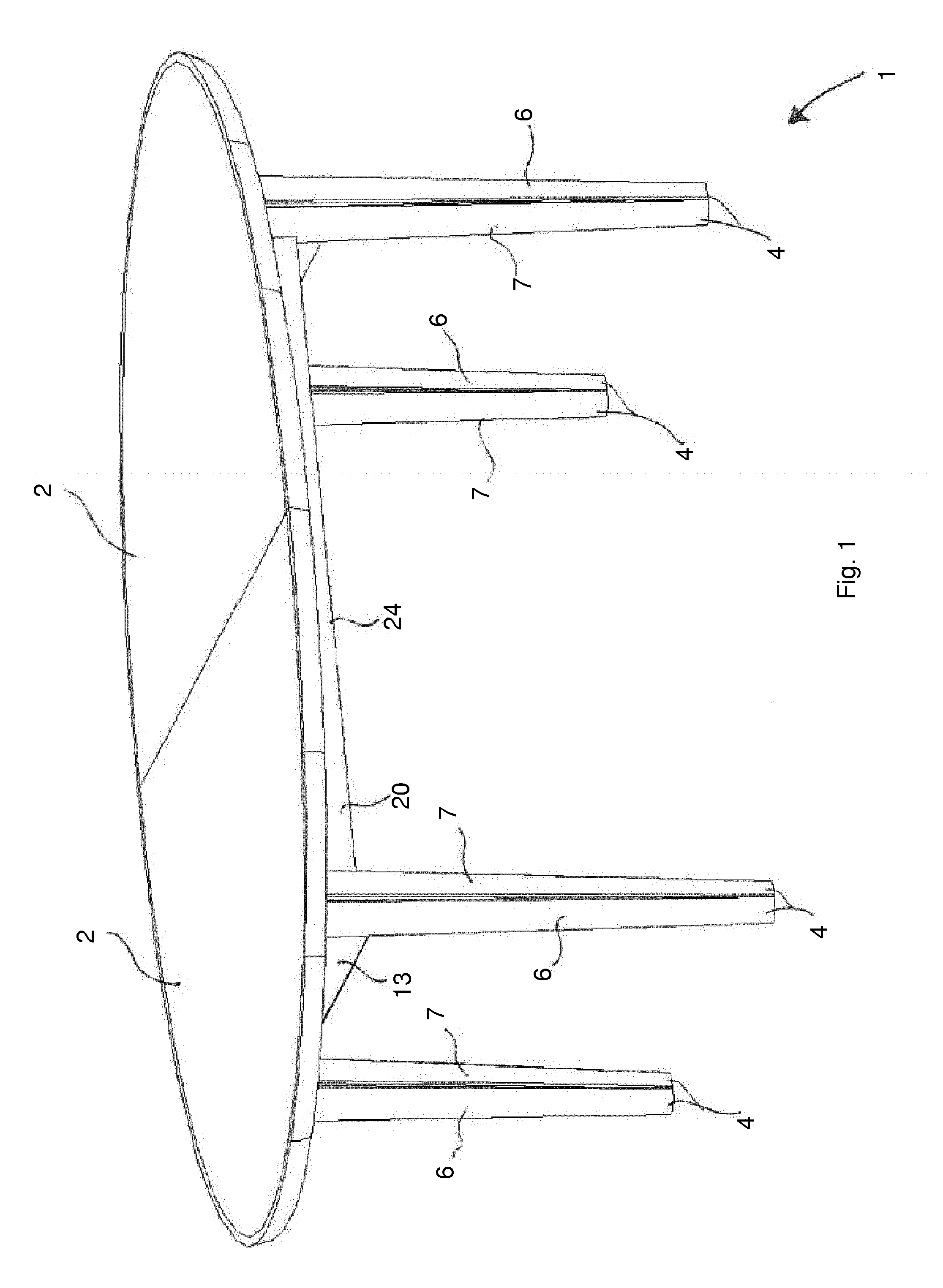

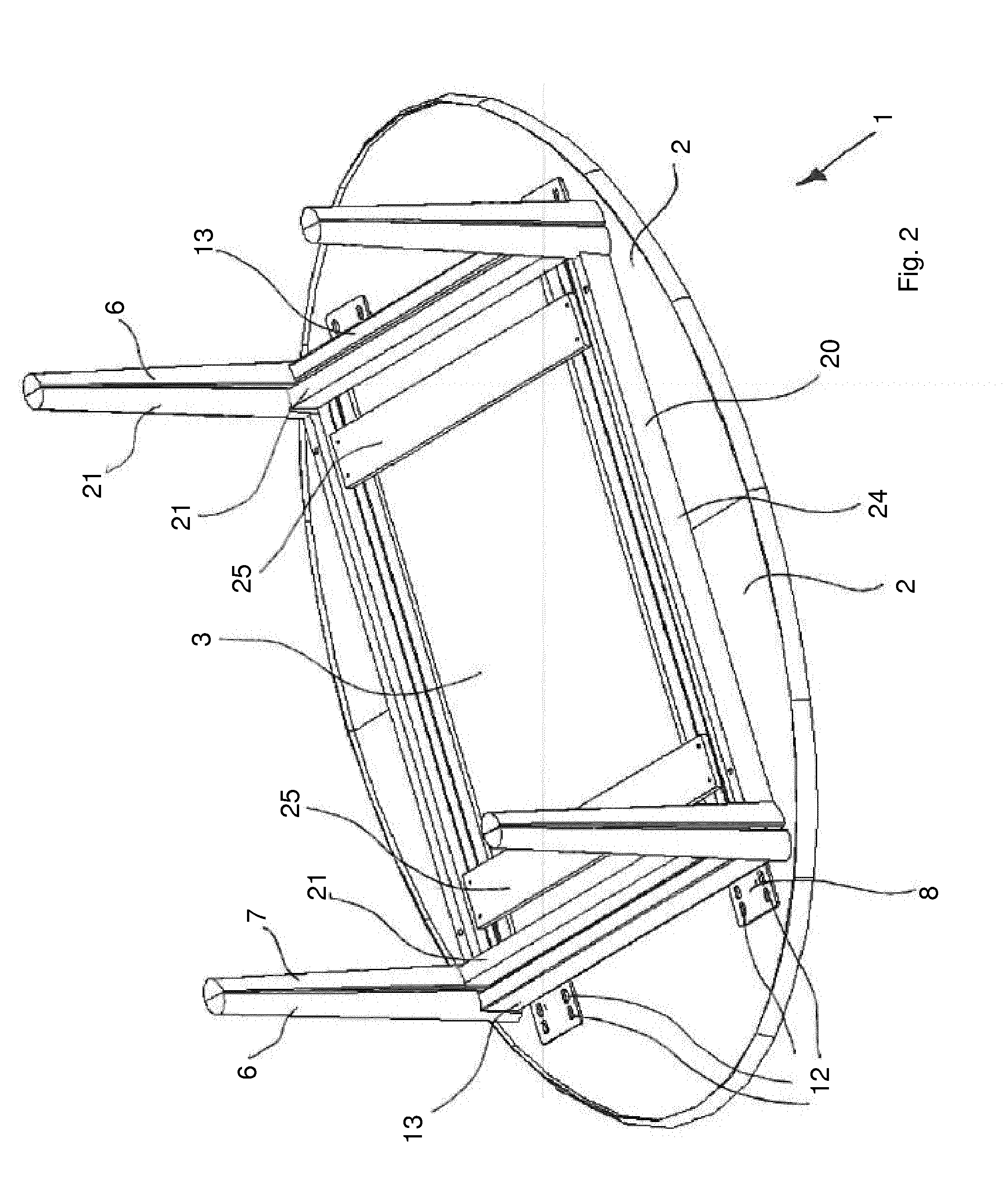

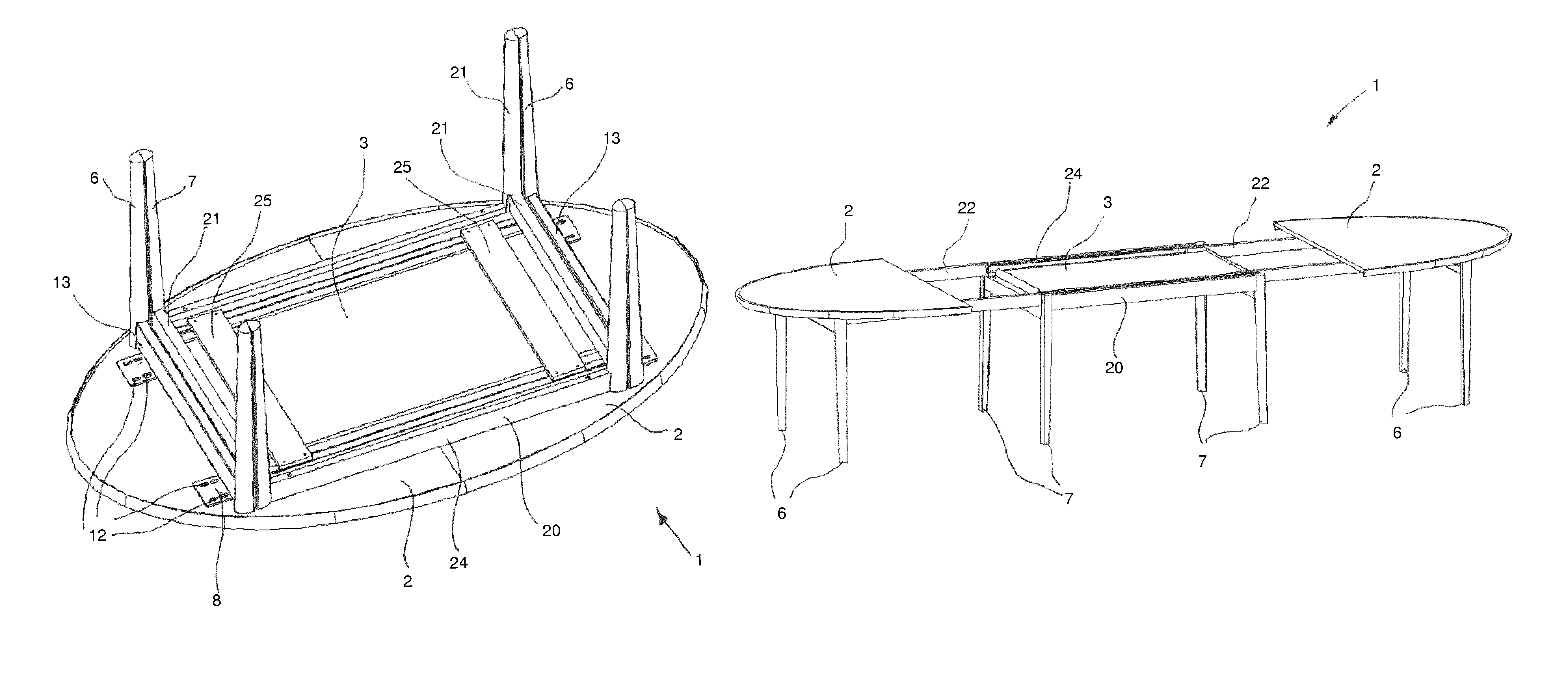

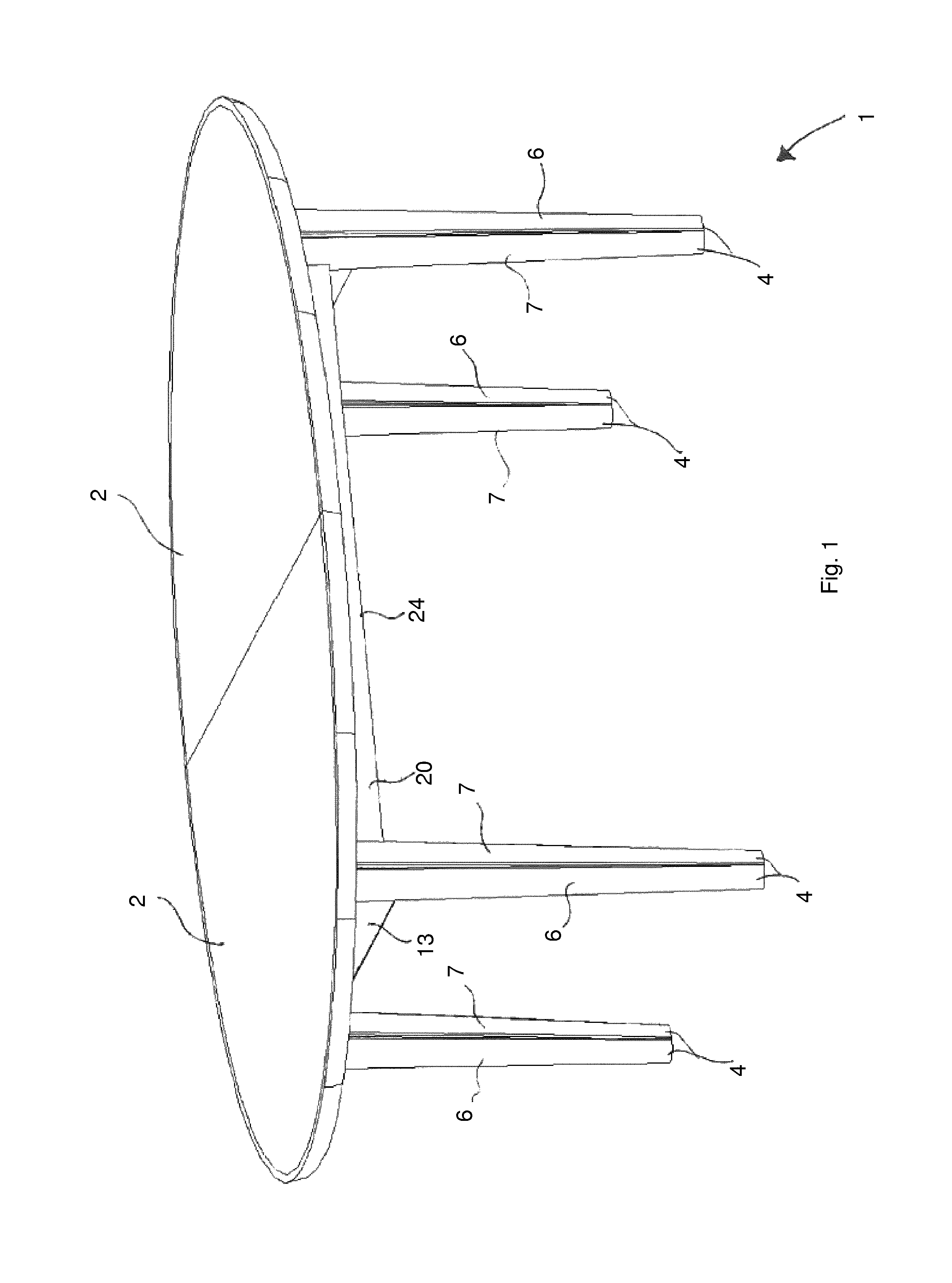

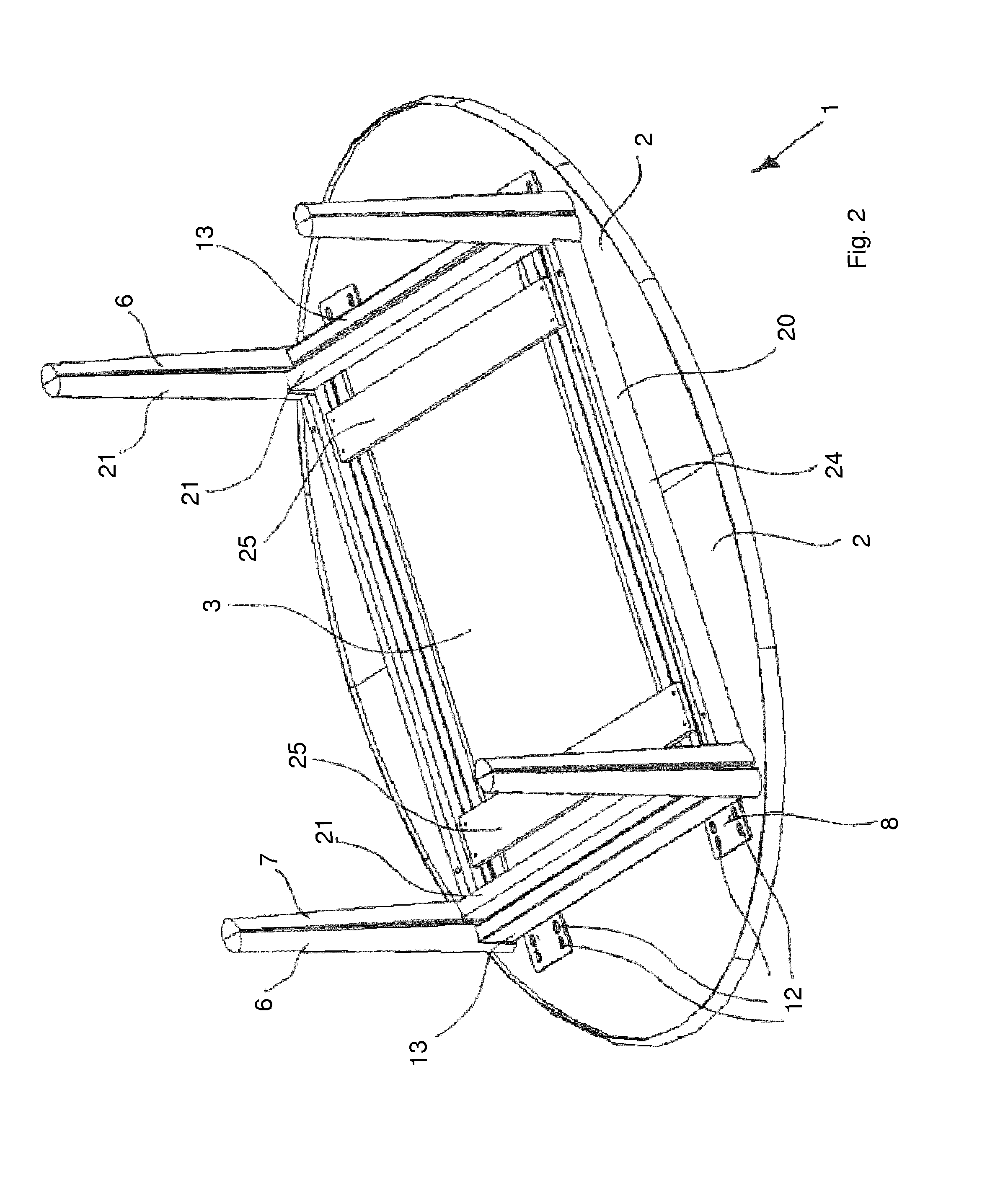

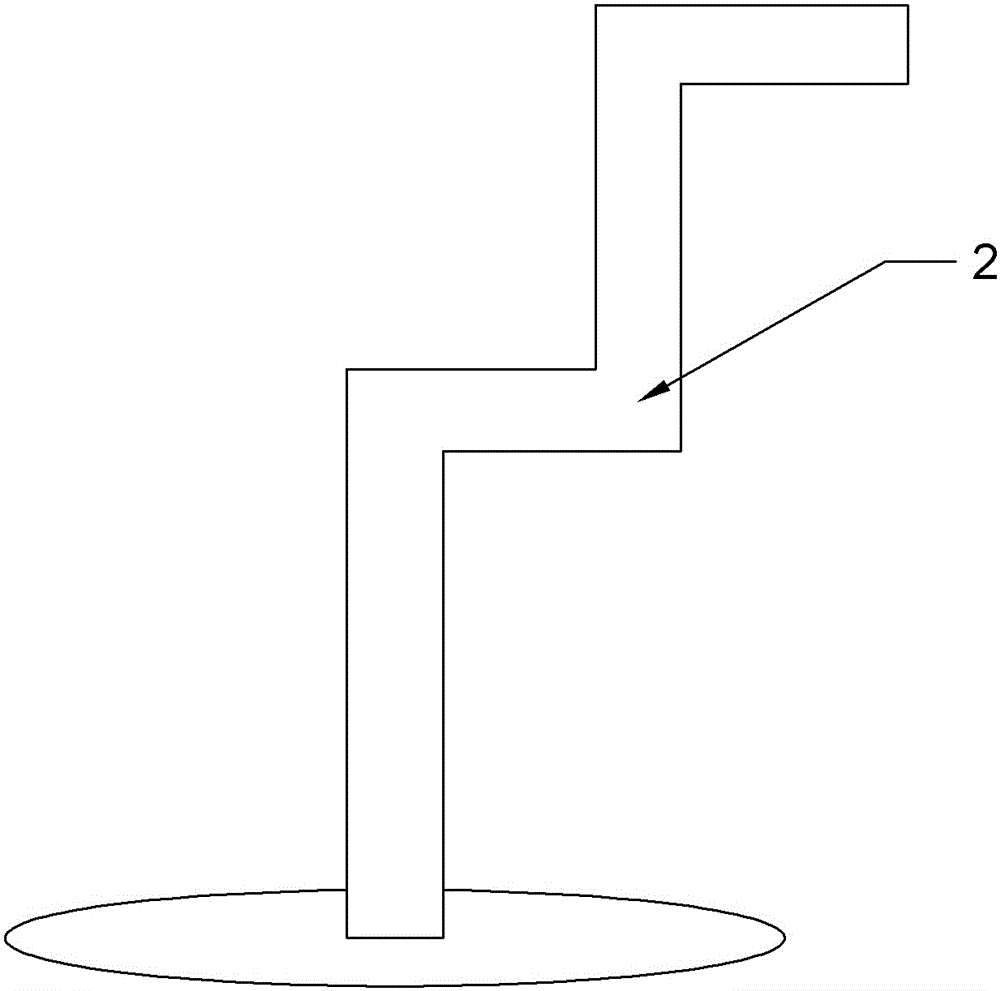

Extension table with multiple legs

ActiveUS20140352579A1Improve stabilityRelieve stressExtensible tablesFurniture partsProgramming languageFastener

An extension table with multiple legs with two table tops sliding back and forth in relation to each other and a number of leaves and at least four supporting members each comprising at least two table legs—a first table leg and a second table leg—said supporting members supporting the extension table with multiple legs when the sliding table tops are joined in a first position and supporting the extension table when the sliding table tops are pulled apart in a second position. The first table legs in each supporting member are directly or indirectly connected to the sliding table tops by means of fasteners comprising sliding means, and by said fastener, the first table leg and the corresponding sliding table top are arranged to slide relative to each other from a position A to a second position B differing from position A and in the extension direction of the table as well as with fastening means co-operating with the sliding means of the fastener in order to secure the first table leg in the chosen position.

Owner:SKOVBY MOEBELFAB

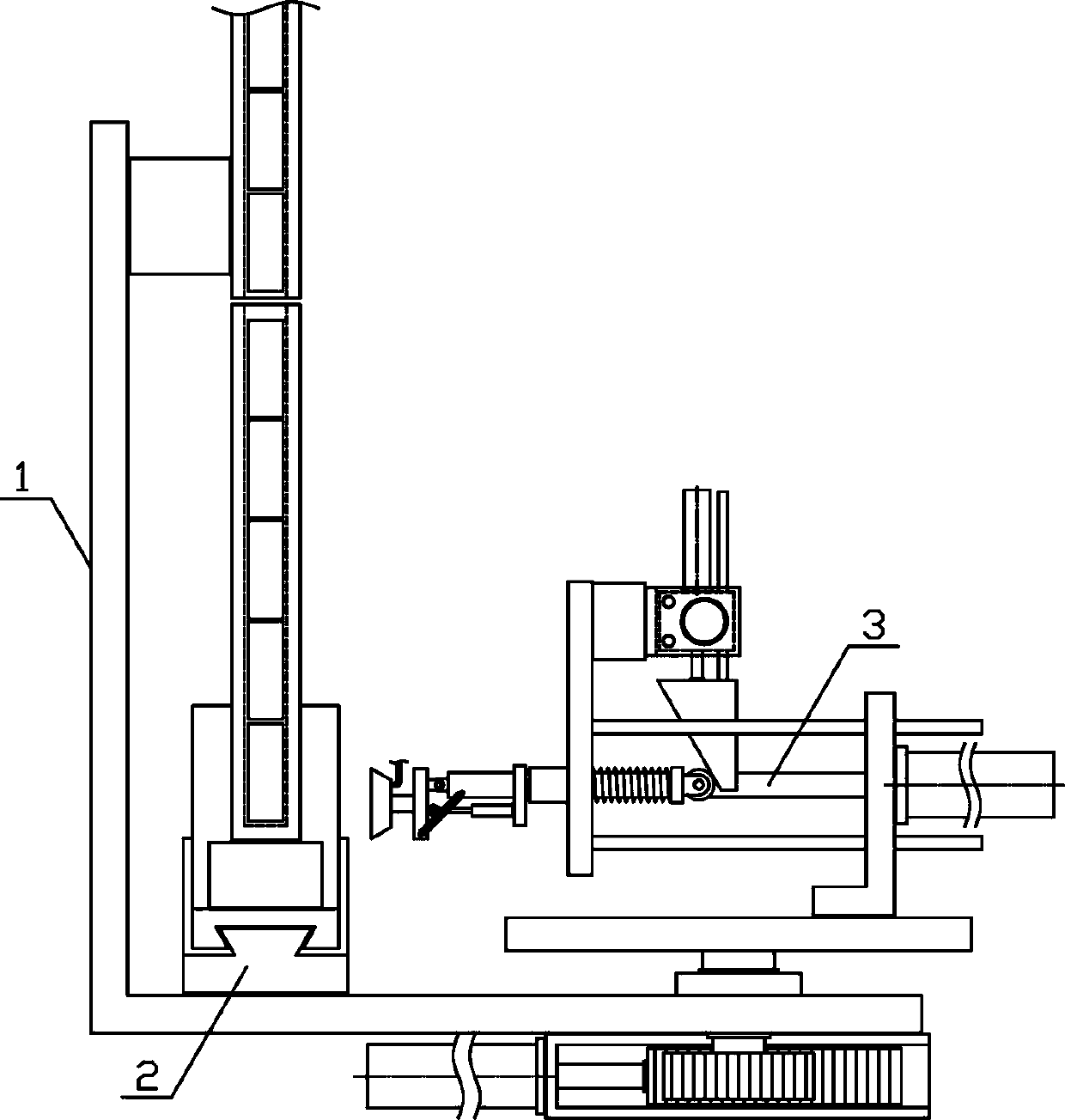

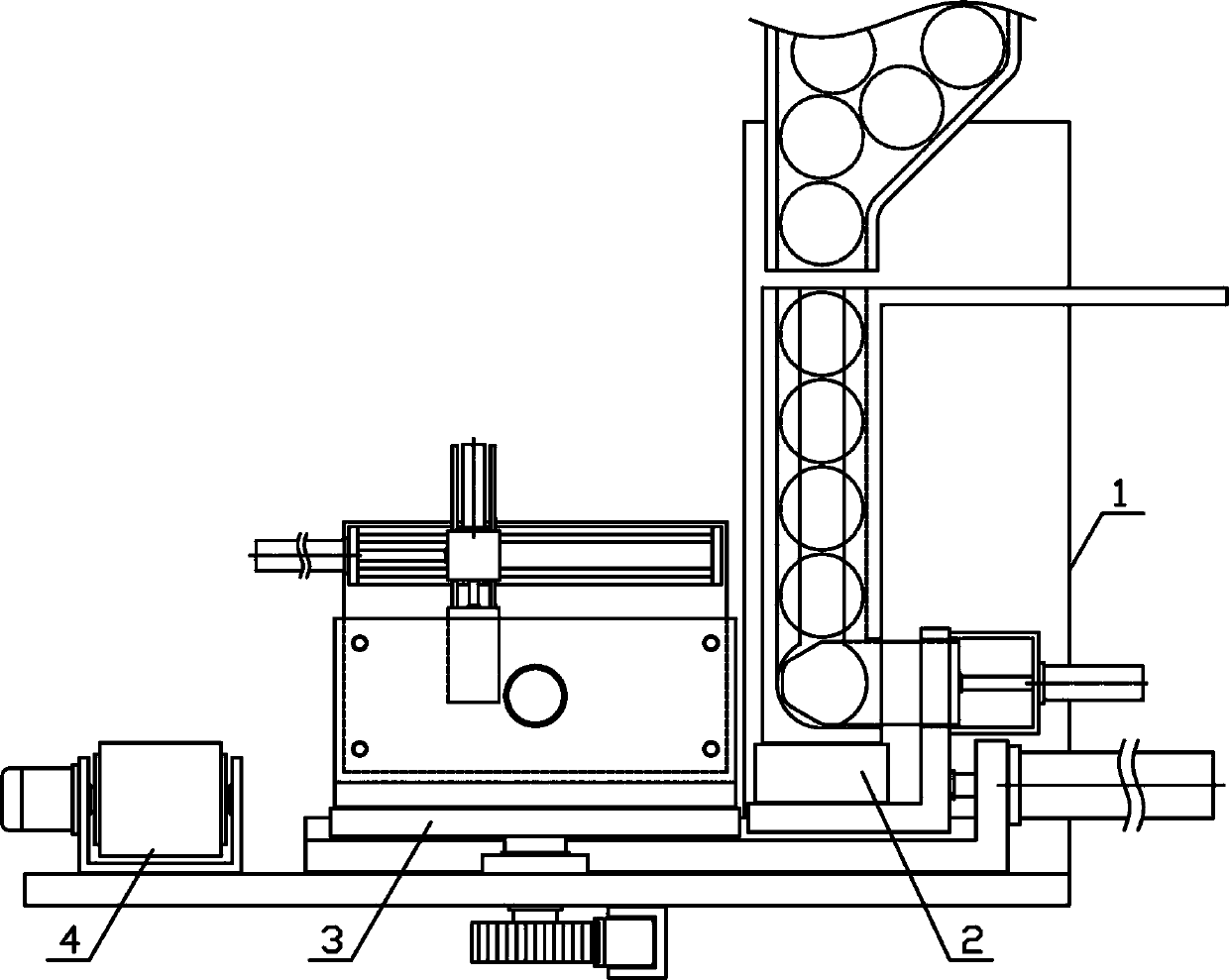

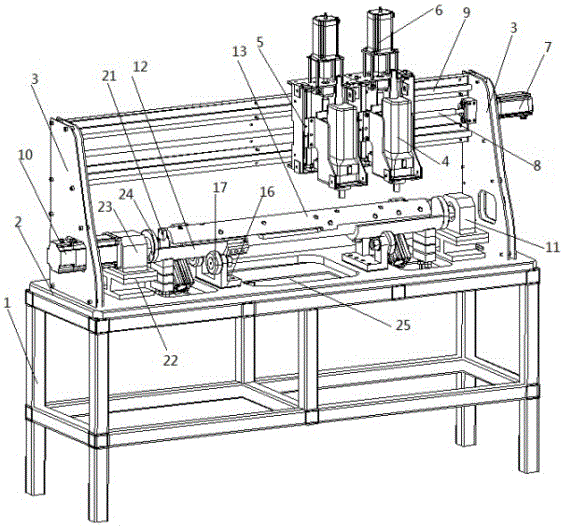

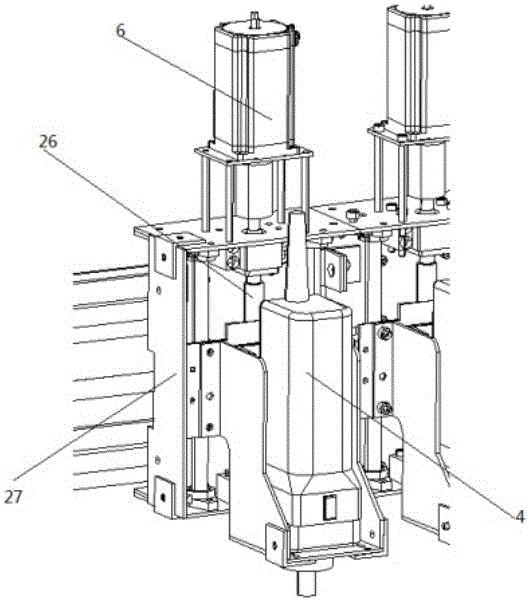

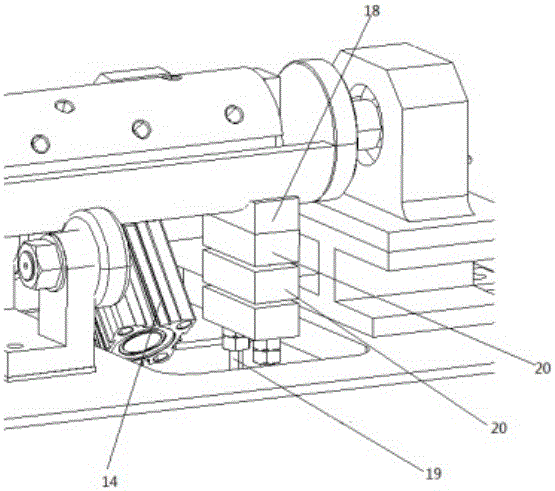

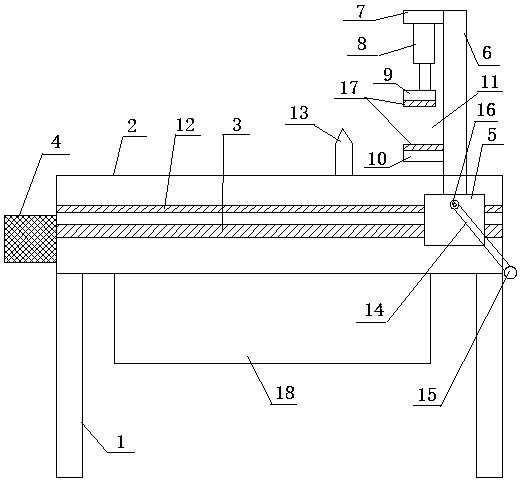

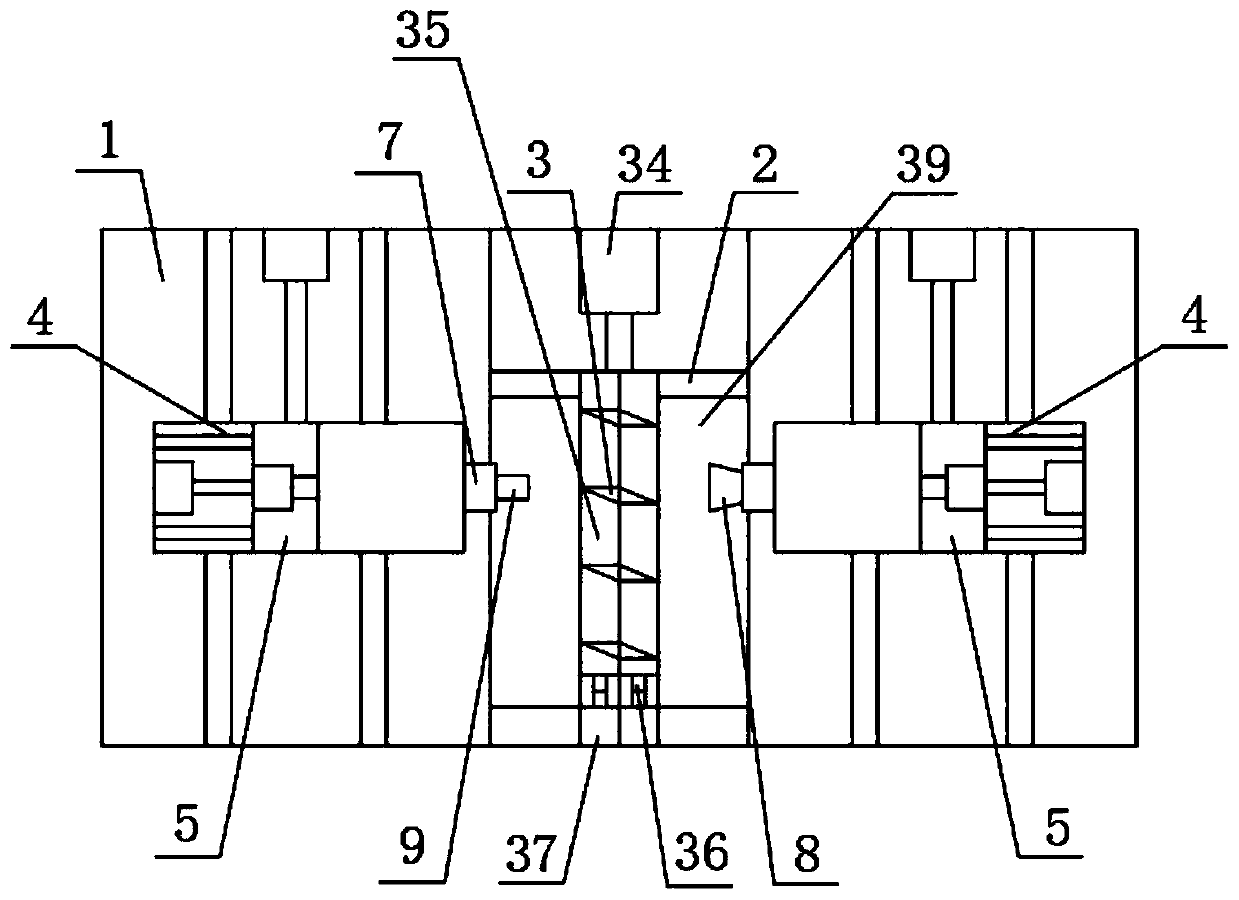

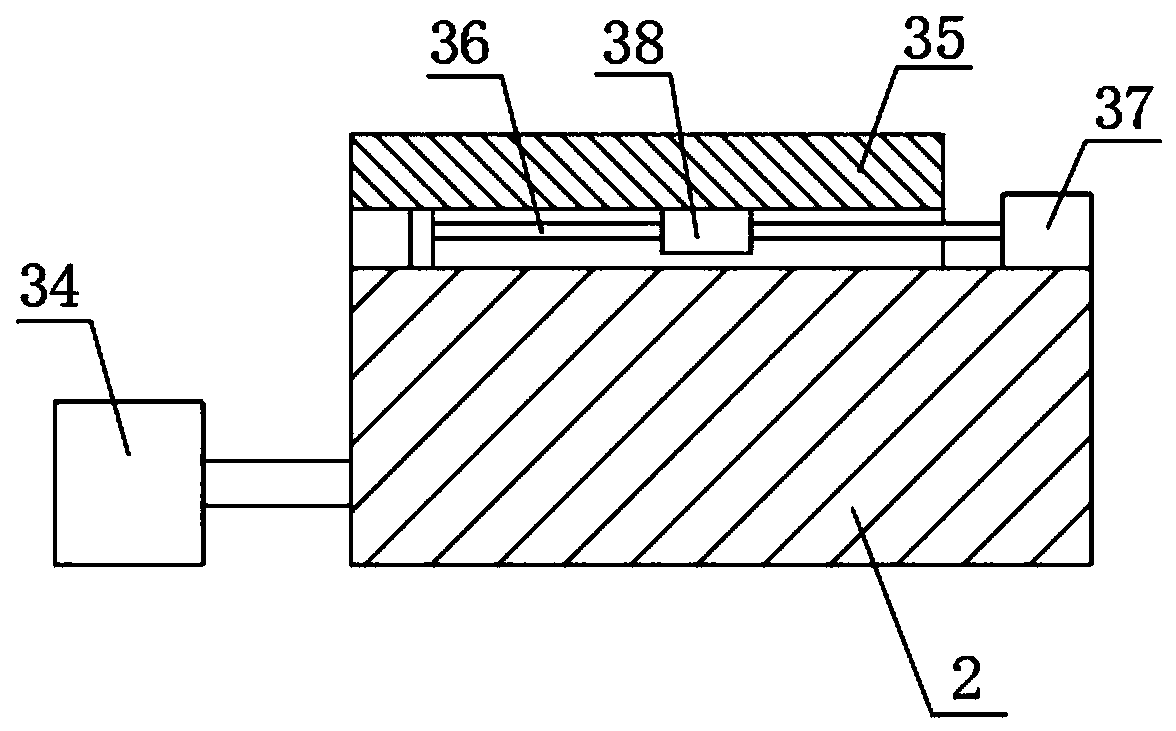

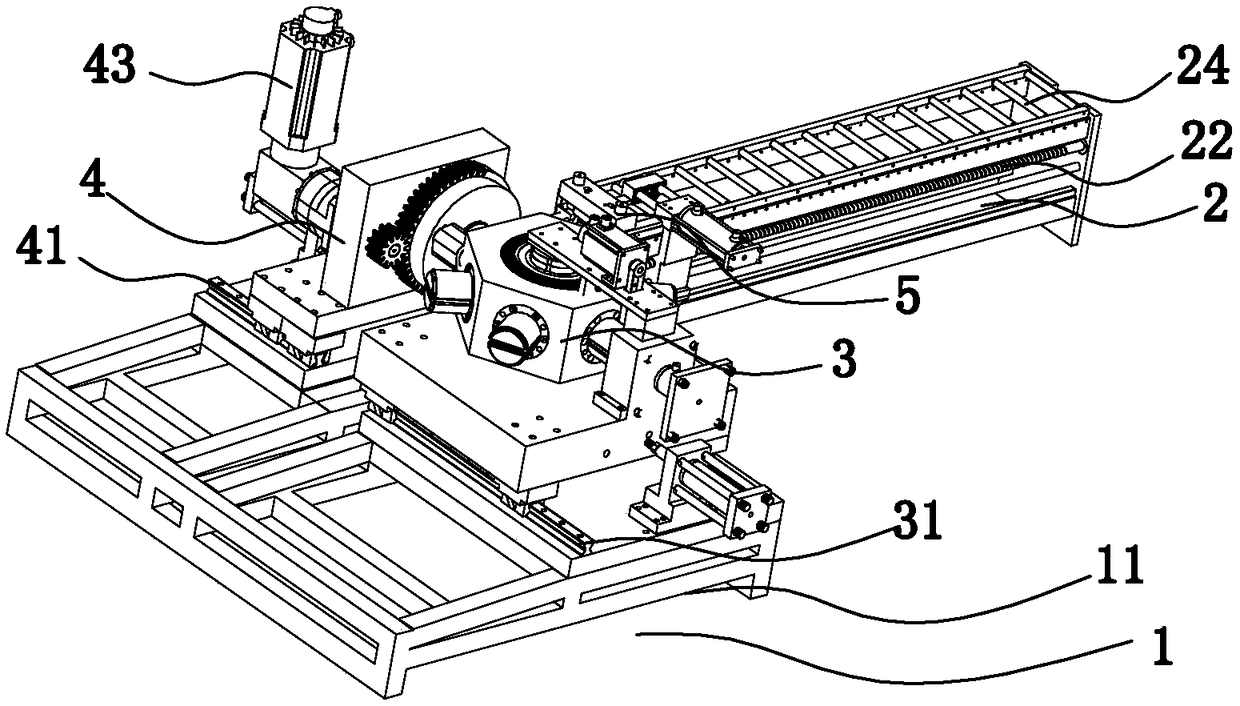

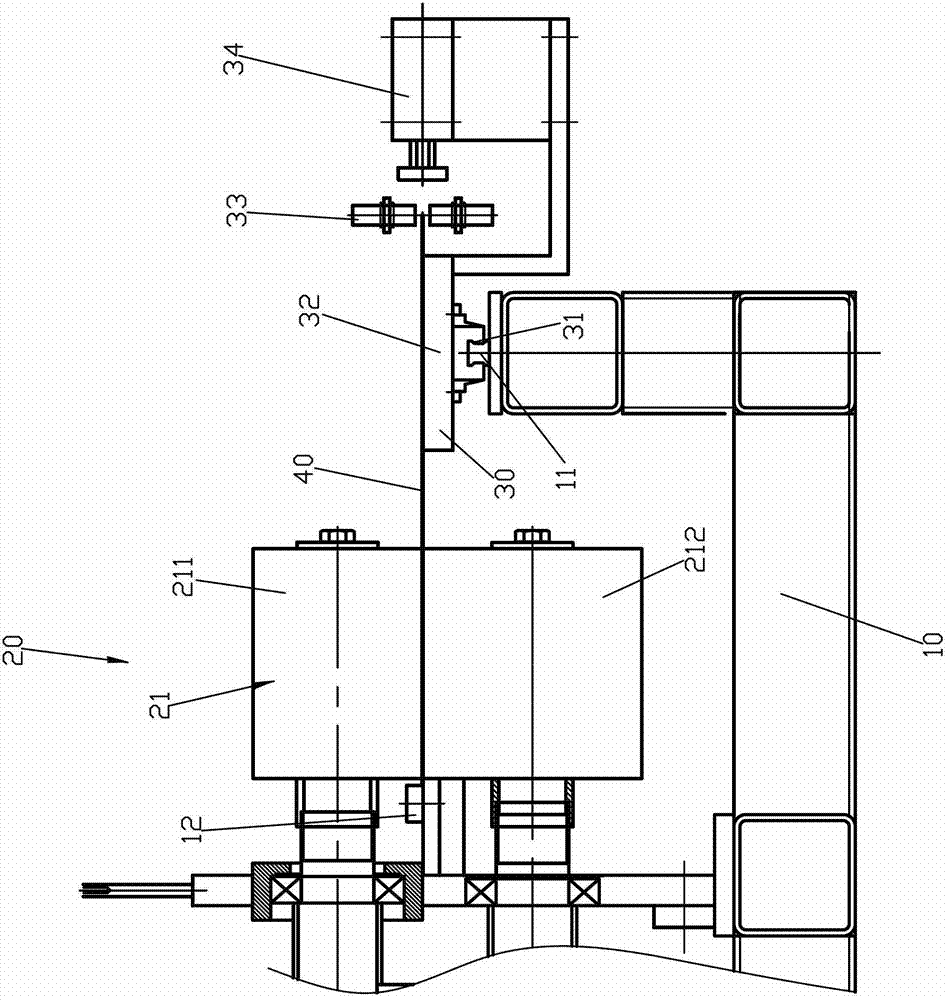

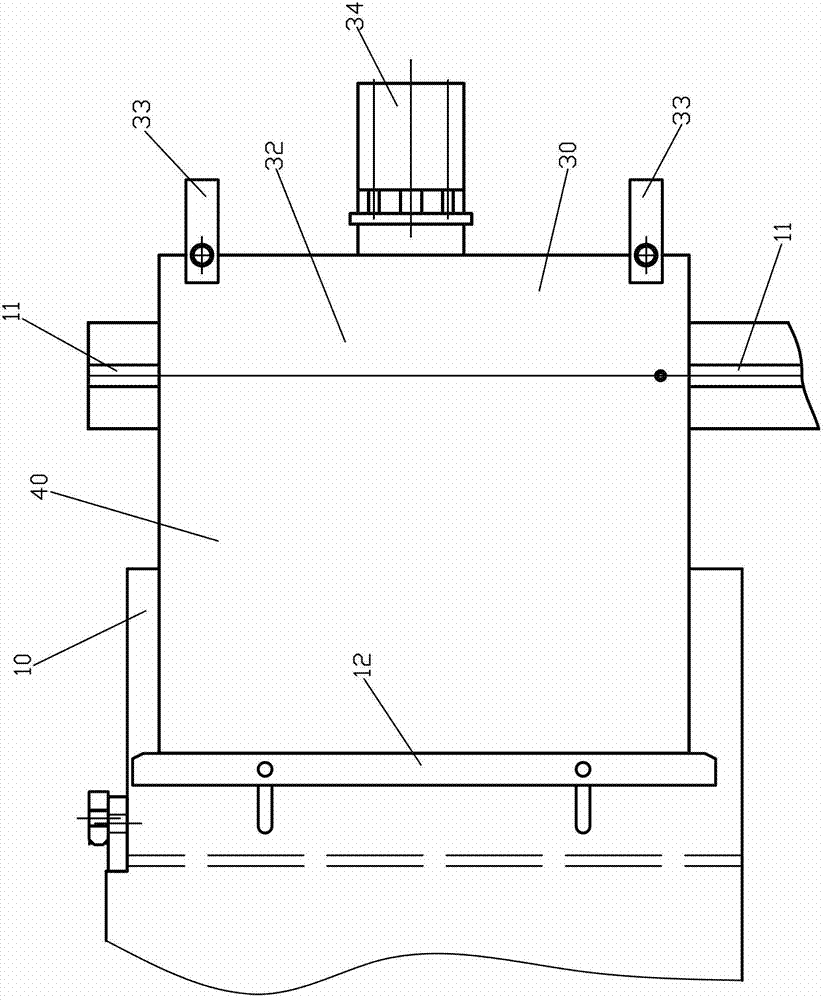

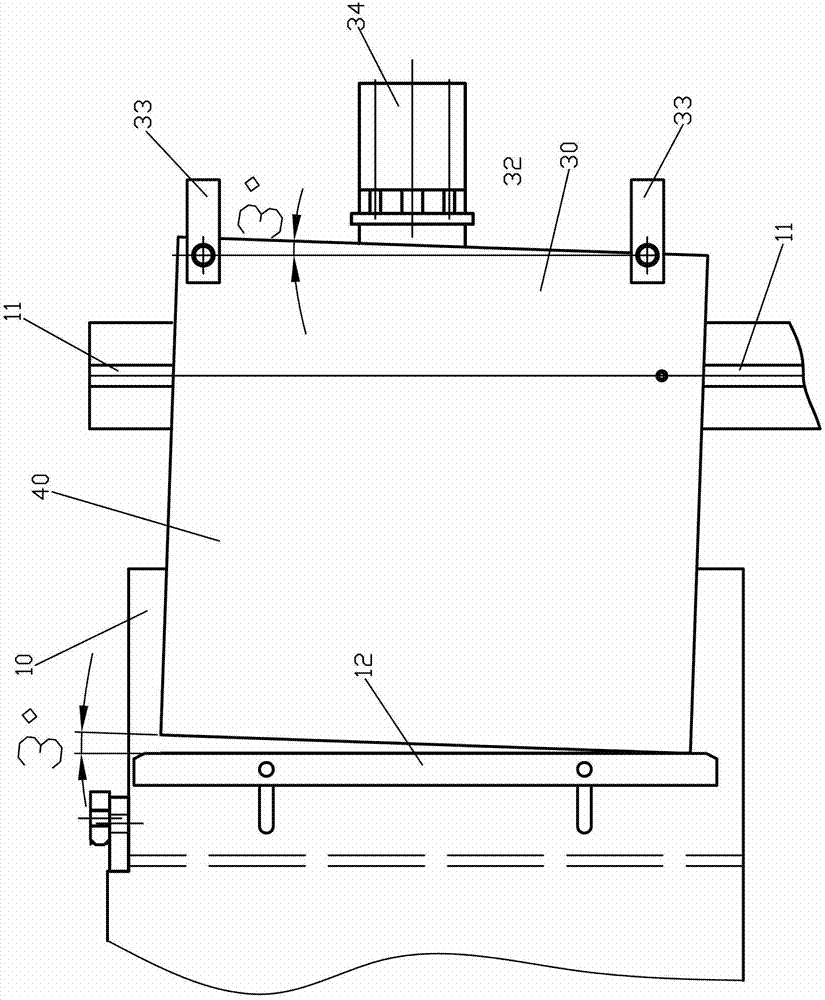

Cross beam pipe punching equipment in automobile fitting

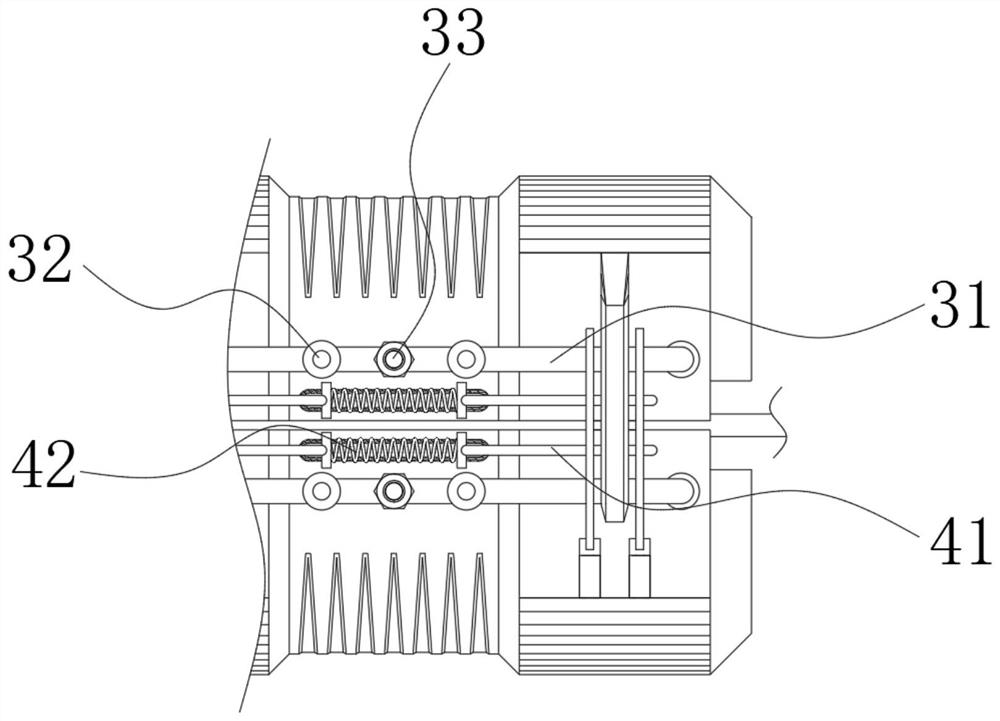

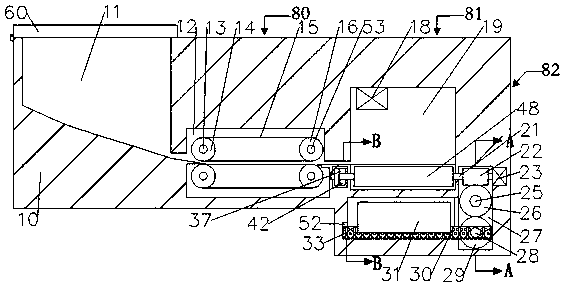

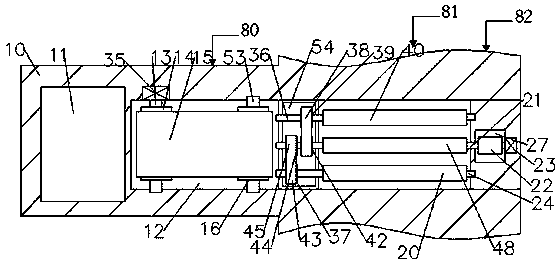

PendingCN106736766APrecise slidingRotation doesn't happenWork clamping meansPositioning apparatusElectric machineryDrilling machines

The invention provides cross beam pipe punching equipment in an automobile fitting. The cross beam pipe punching equipment comprises a rack, wherein the rack is provided with a worktable; the worktable is provided with two supporting plates; the two supporting plates are arranged on two sides of the worktable respectively; a punching mechanism and a positioning mechanism are arranged between the two supporting plates; the punching mechanism comprises a drilling device and a sliding device; the drilling device is movably connected with the sliding device; the drilling device comprises a drilling machine, a connecting device and a servo motor A; the drilling machine is connected with the servo motor A through the connecting device; the sliding device comprises a servo motor B, a sliding rod and a sliding rail; and the servo motor B is connected with the sliding rod and is used for driving the sliding rod.

Owner:河北科斯特自动化科技有限公司

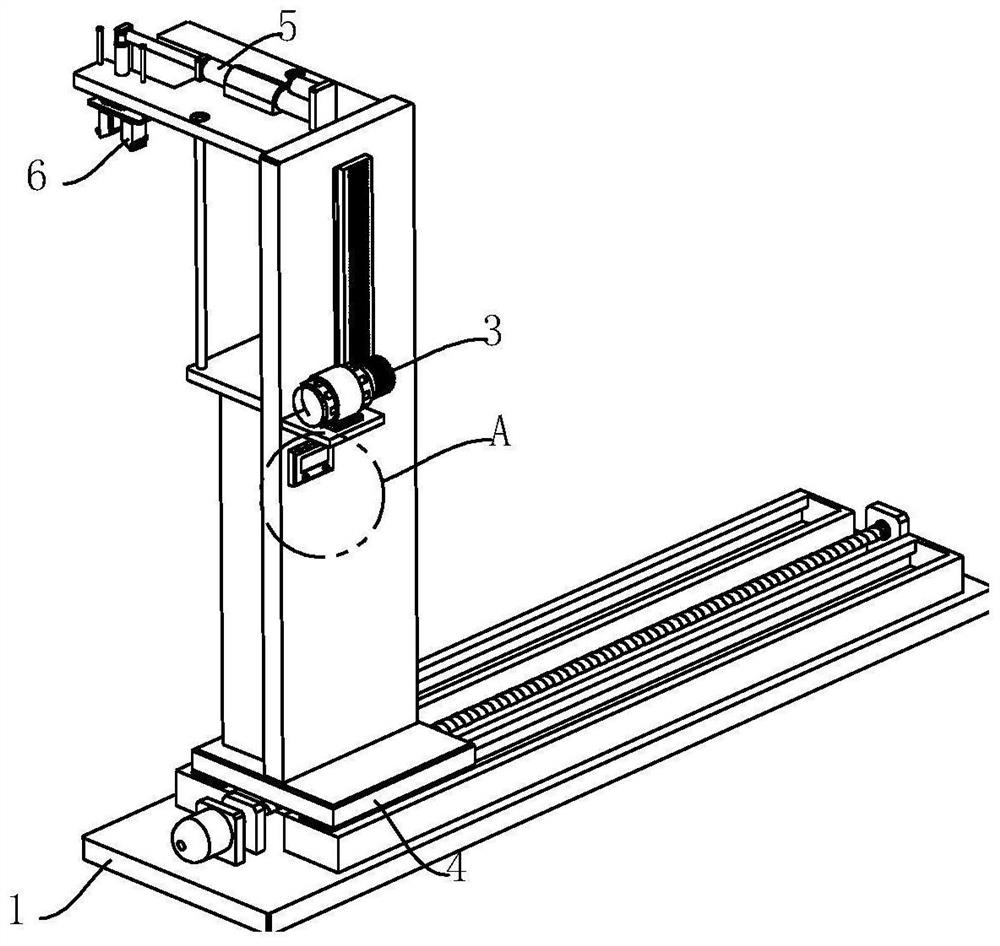

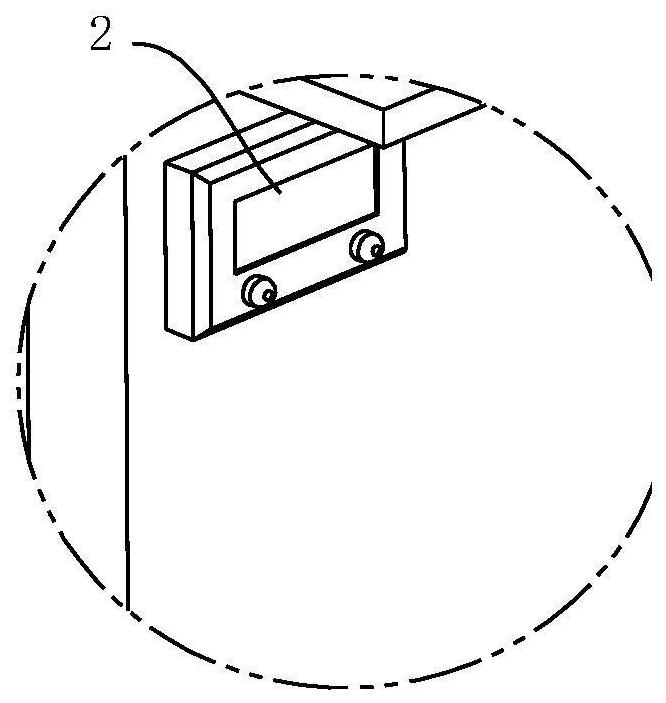

Mixed type traditional Chinese medicine automatic precision grabbing device

ActiveCN112645040AImprove crawling efficiencyThe grabbing process is simple and fastConveyorsConveyor partsEngineeringMechanical engineering

The invention relates to the technical field of traditional Chinese medicine grabbing, in particular to a mixed type traditional Chinese medicine automatic precision grabbing device. The mixed type traditional Chinese medicine automatic precision grabbing device comprises a base and further comprises a controller, a lifting mechanism, a sliding mechanism, a hooking mechanism and a grabbing mechanism. The sliding mechanism comprises a sliding plate, a driving assembly and two guide rails. The lifting mechanism is arranged at the top of the sliding plate and used for supporting the grabbing mechanism to ascend and descend, the lifting mechanism comprises a lifting plate and a transmission assembly, the hooking mechanism is arranged at the top of the lifting plate and used for opening and closing cabinets, the hooking mechanism comprises a hook plate and a telescopic assembly, and the grabbing mechanism comprises a pushing assembly, a clamping assembly and two grabbing shovels. The driving assembly, the transmission assembly, the telescopic assembly, the pushing assembly and the clamping assembly are all electrically connected with the controller. According to the mixed type traditional Chinese medicine automatic precision grabbing device and a using method, the grabbing process is simple and rapid, the number of steps is small, the grabbing efficiency can be improved, meanwhile, the medicine grabbing amount of the controller can be precisely controlled, and errors are prevented.

Owner:青岛格恩制药有限公司

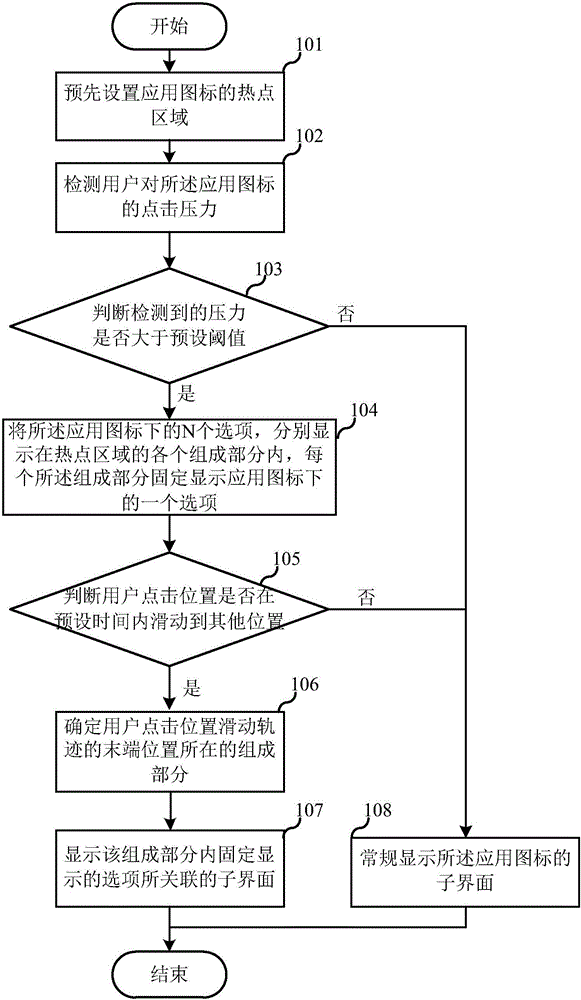

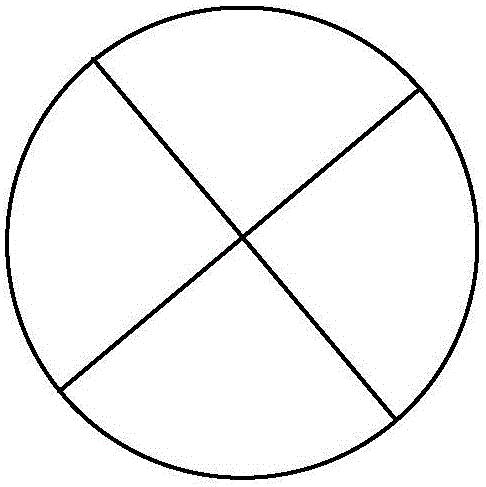

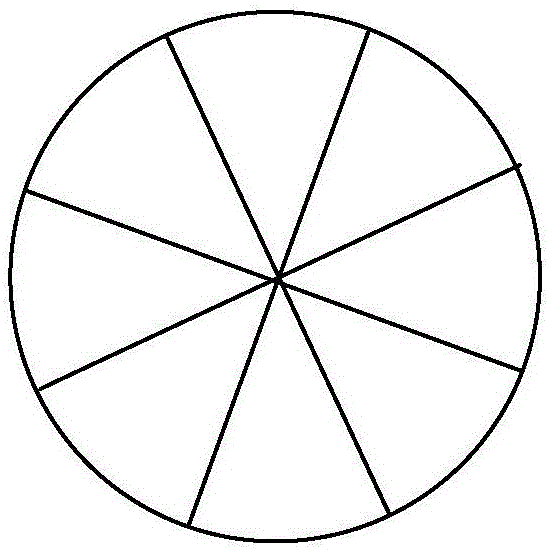

Method for displaying icon options and terminal equipment

InactiveCN106055224AImprove operational efficiencyPrecise slidingInput/output processes for data processingTerminal equipmentComputer terminal

The invention relates to the field of electronic equipment and discloses a method for displaying icon options and terminal equipment. The method comprises the steps that a hot spot area of an application icon is preset, wherein the hot spot area is centered on the application icon, the hot spot area is divided into N constituent parts, and each constituent part is located in different directions of the center of the hot spot area; clicking pressure on the application icon is detected; and if the detected pressure exceeds a preset threshold, N options under the application icon can be displayed in each constituent part of the hot sport area respectively, wherein one option under the application icon is displayed fixedly by each constituent part. According to the embodiment of the invention, when a user checks each functional option each time, the user does not need to search the location of the functional option in a list deliberately and can enter an interested field according to a memory habit of sliding directions at ordinary times, so that operation efficiency is increased.

Owner:LETV HLDG BEIJING CO LTD +1

Extension table with multiple legs

Owner:SKOVBY MOEBELFAB

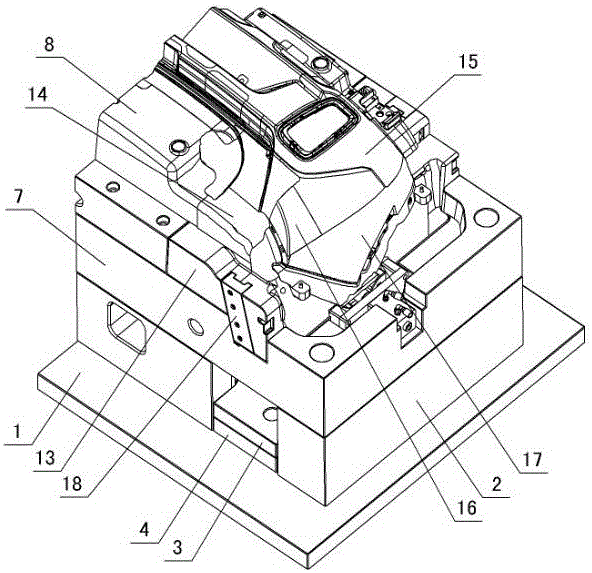

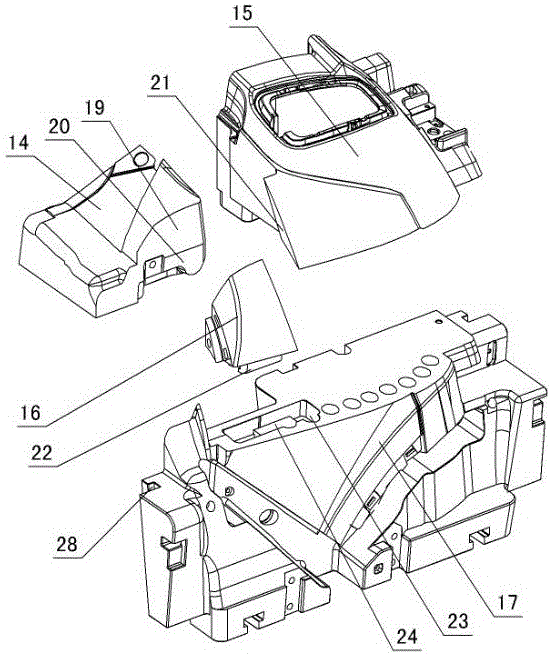

Bumper injection mold deformation space avoiding mechanism

Owner:TAIZHOU HUANGYAN KUNTAI MOLD CO LTD

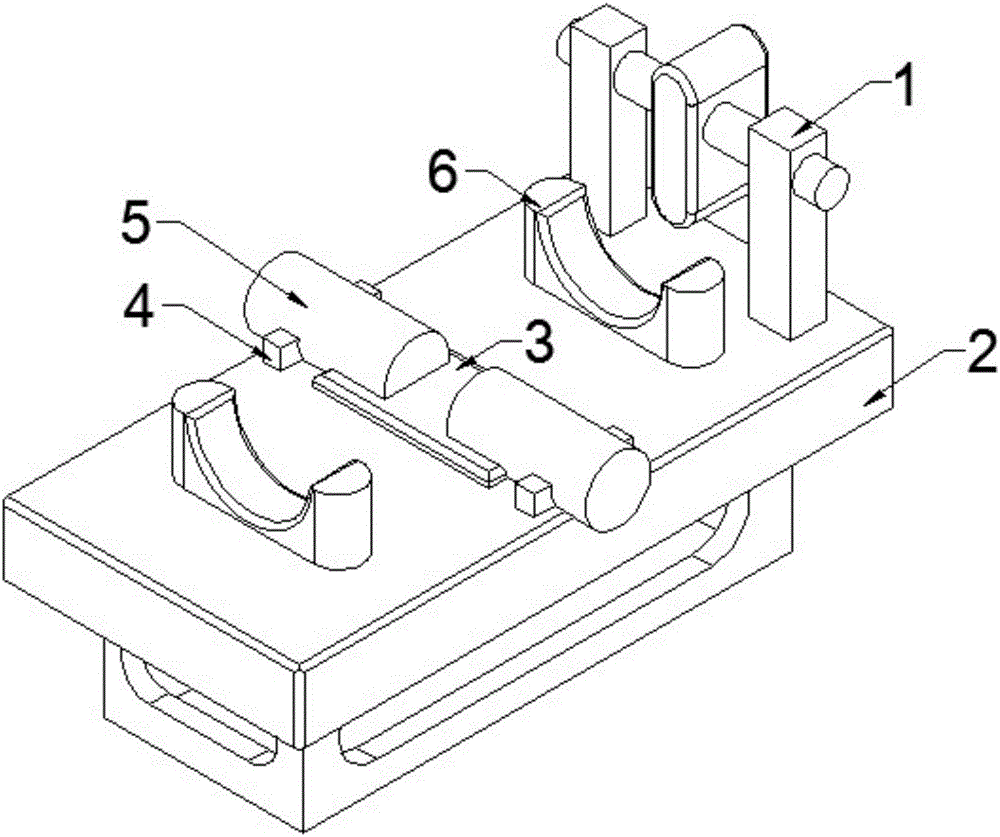

Fixing platform for bicycles

InactiveCN106425262AImprove welding qualityEasy flat welding operationWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention provides a fixing platform for bicycles. The fixing platform comprises an operation platform, wherein a bracket is fixedly arranged in the position, close to the edge part, of the upper end face of the operation platform; a mounting shaft is arranged on the bracket; a top plate is arranged on the mounting shaft in a sleeving manner; the top plate performs rotation motion, with the mounting shaft adopted as the center line; guide blocks are symmetrically arranged in the positions, on one side of the top plate, in the operation platform, with the geometric center line of the operation platform adopted as the symmetry axis; a base plate is arranged between the symmetrically distributed guide blocks; limiting rods are further arranged on the base plate parallel to the guide blocks; the limiting rods and the operation platform are connected in a sliding manner; and the limiting rods comprise locating blocks used for limiting positions of the limiting rods. The fixing platform has the beneficial effects that two to-be-welded bicycle steel pipes are successfully subjected to butt joint through the arranged guide blocks, the two to-be-welded bicycle steel pipes are reinforced through the arranged limiting rods, and the problem that a weld joint is increased due to shaking during the welding process is avoided; and in the design, through well limiting the steel pipes, the flat welding quality is greatly improved.

Owner:天津瑞阳运动器材有限公司

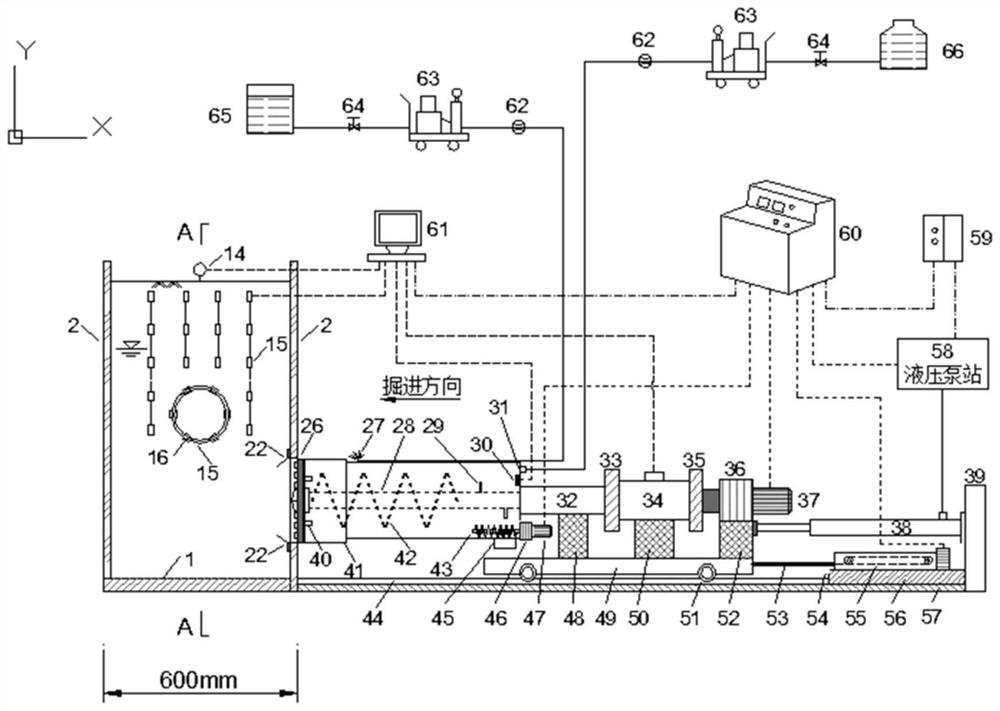

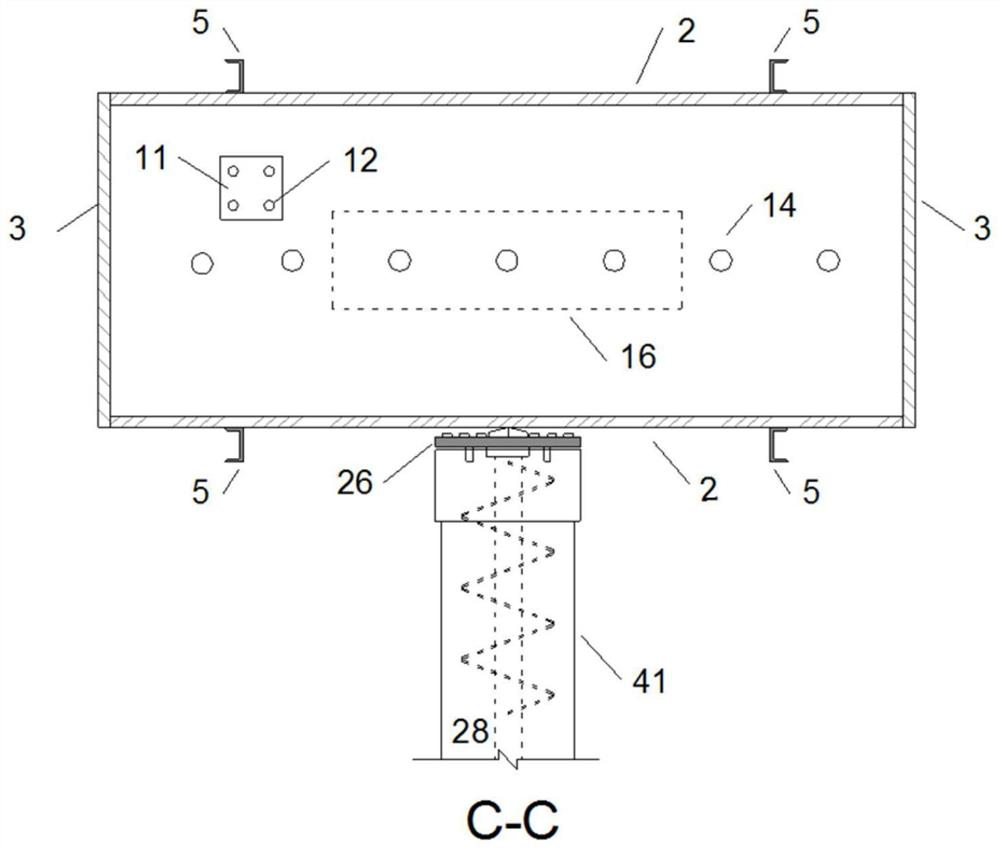

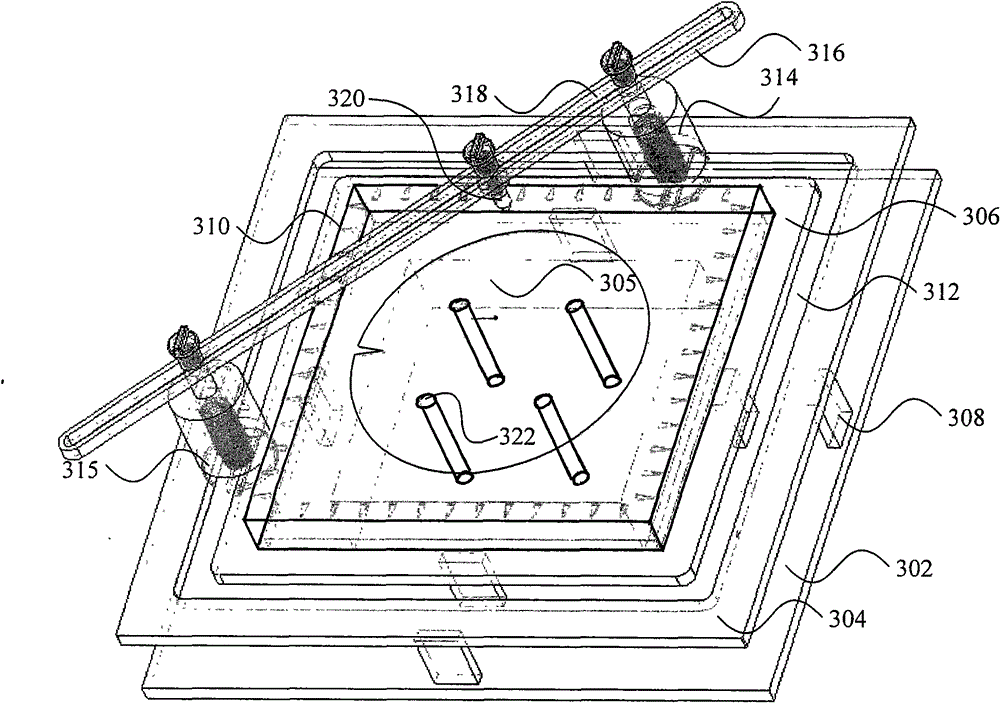

Model test device for simulating micro-disturbance construction of shield near-grounding structure

PendingCN113266376AImprove accuracyImprove realismMining devicesUnderground chambersMuckData acquisition

The invention relates to a model test device for simulating micro-disturbance construction of a shield near-grounding structure. A soil box module comprises a soil box body, a soil body is arranged in the soil box body, a pile foundation module and a tunnel module are buried in the soil body, a shield tunneling module cuts the soil body, and a propulsion control module is used for propelling the shield tunneling module; a grouting control module and a muck improvement module are used for injecting grouts and a muck improver, an underground water level control module is used for adjusting height of the underground water level in the soil box body, and a ground pressure loading module is used for adjusting pressure of the soil body; a data acquisition module comprises a data acquisition terminal and a sensor unit. Compared with the prior art, multiple modules are arranged, complex and diversified stratum conditions can be simulated, the construction disturbance influence of different shield parameters, propulsion parameters, grouting parameters and muck parameters on an underground structure can be considered, obtained data are closer to real construction data, and the accuracy is higher.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD +2

Convenient puller

Owner:JINJIANG HENGDA ZIPPER MFG

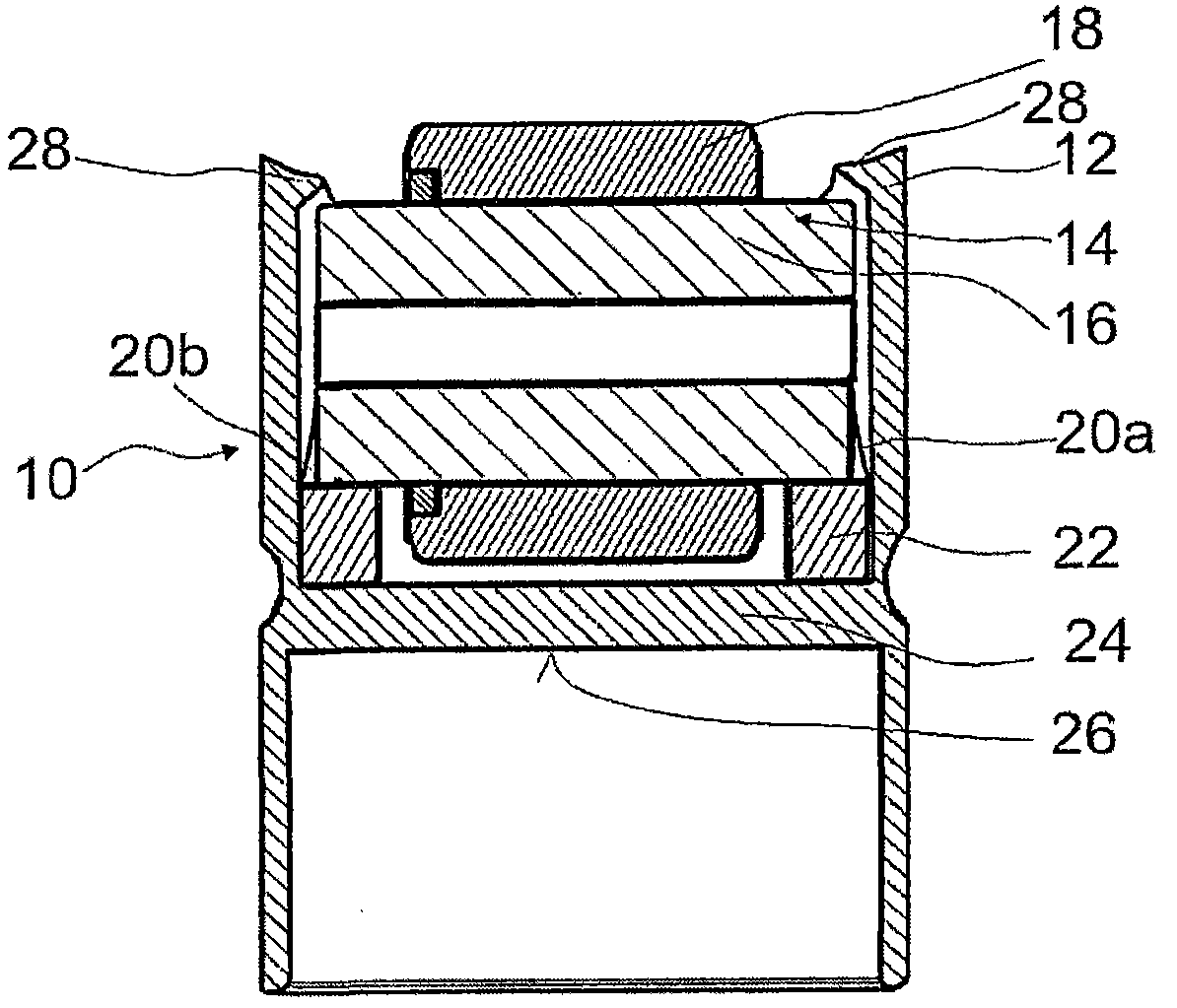

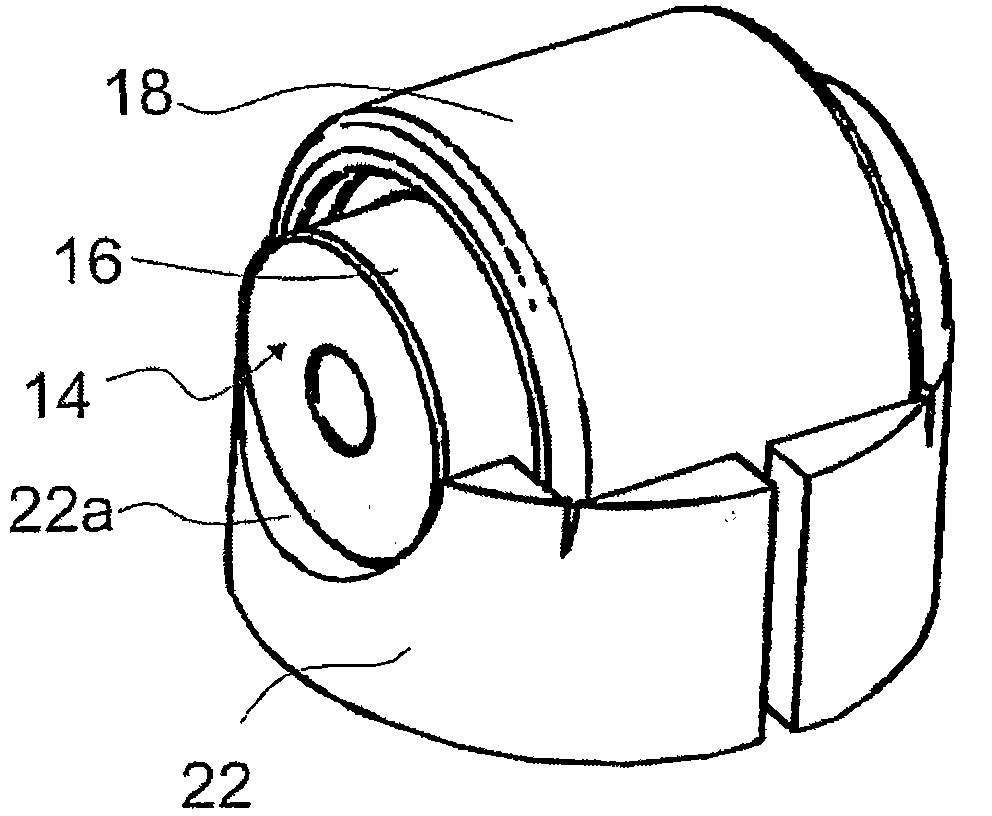

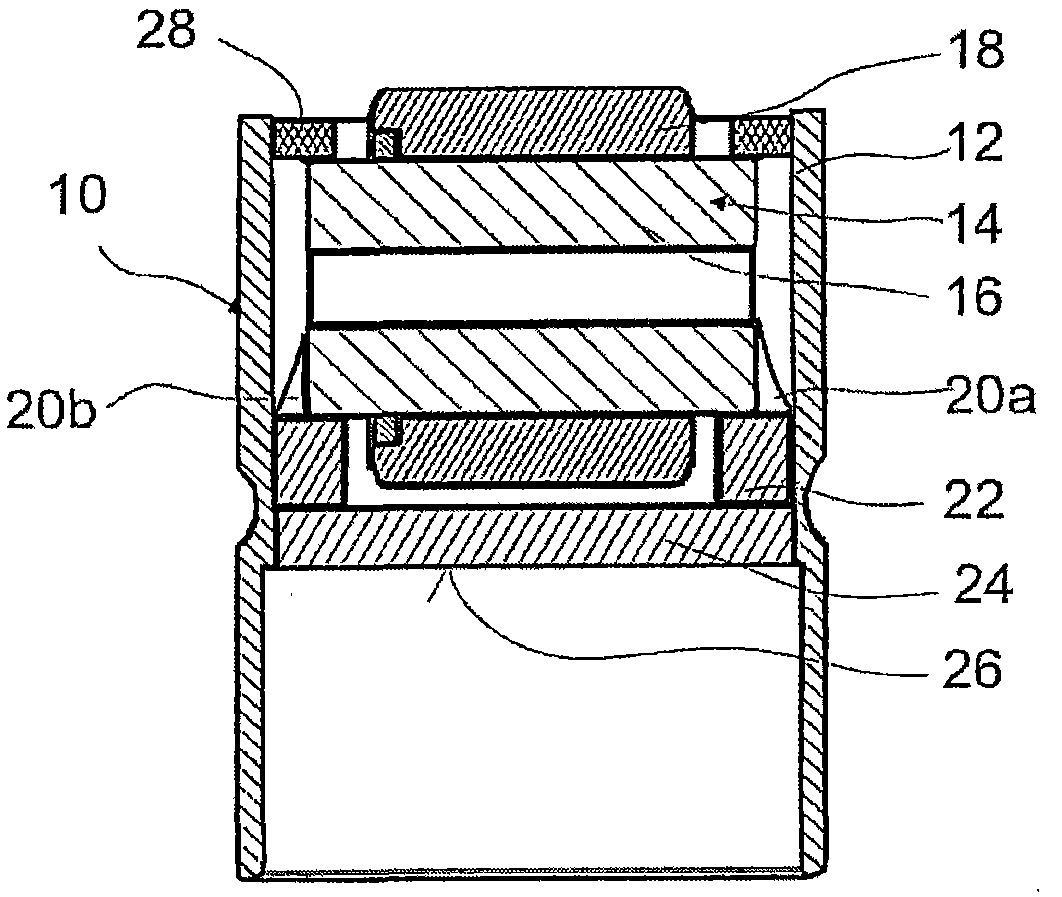

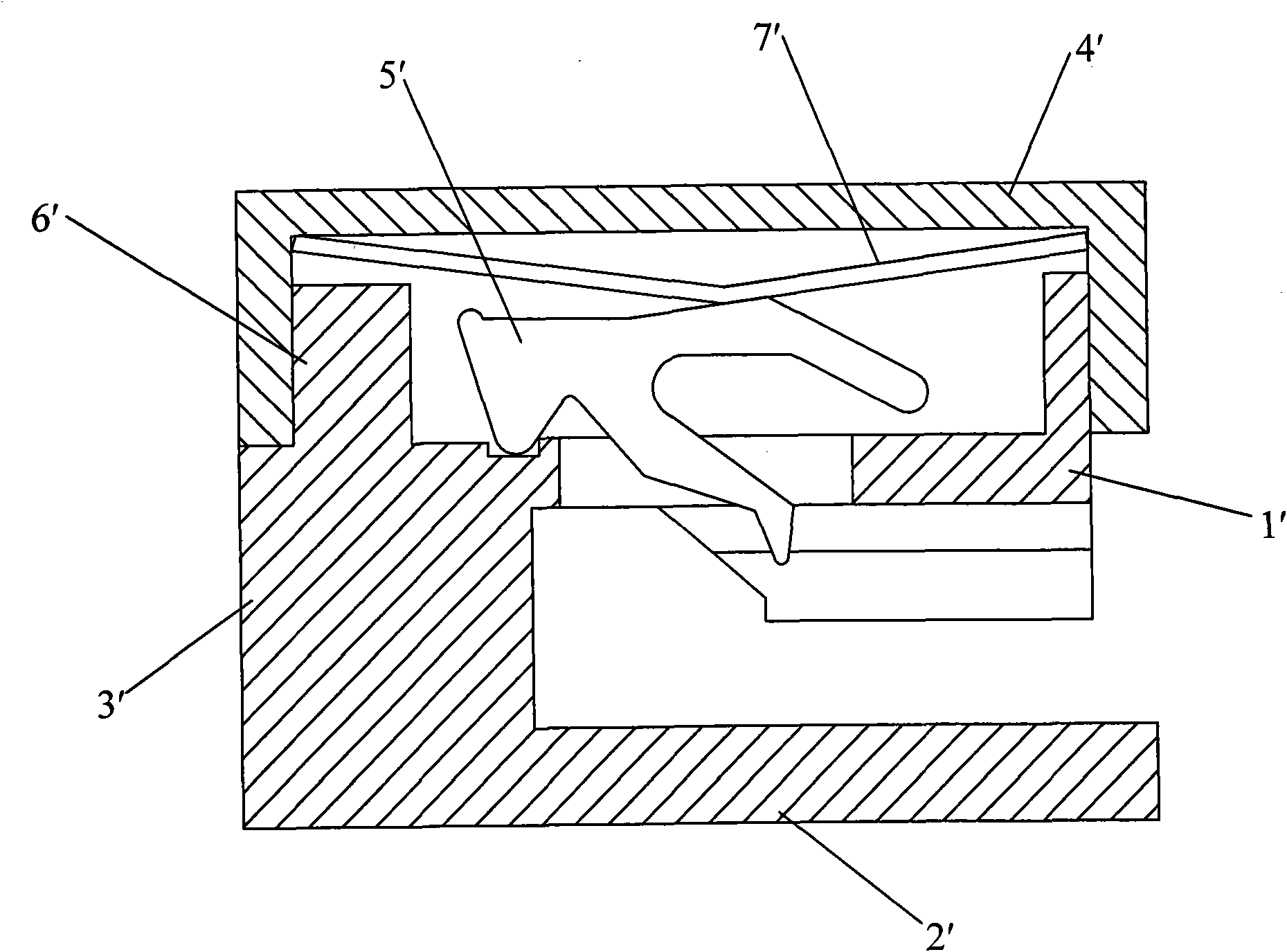

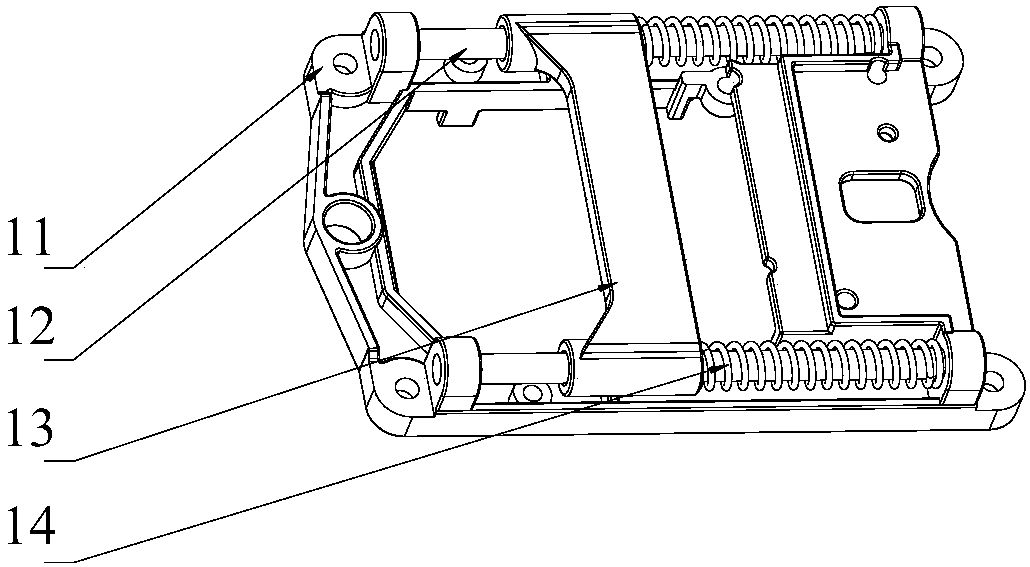

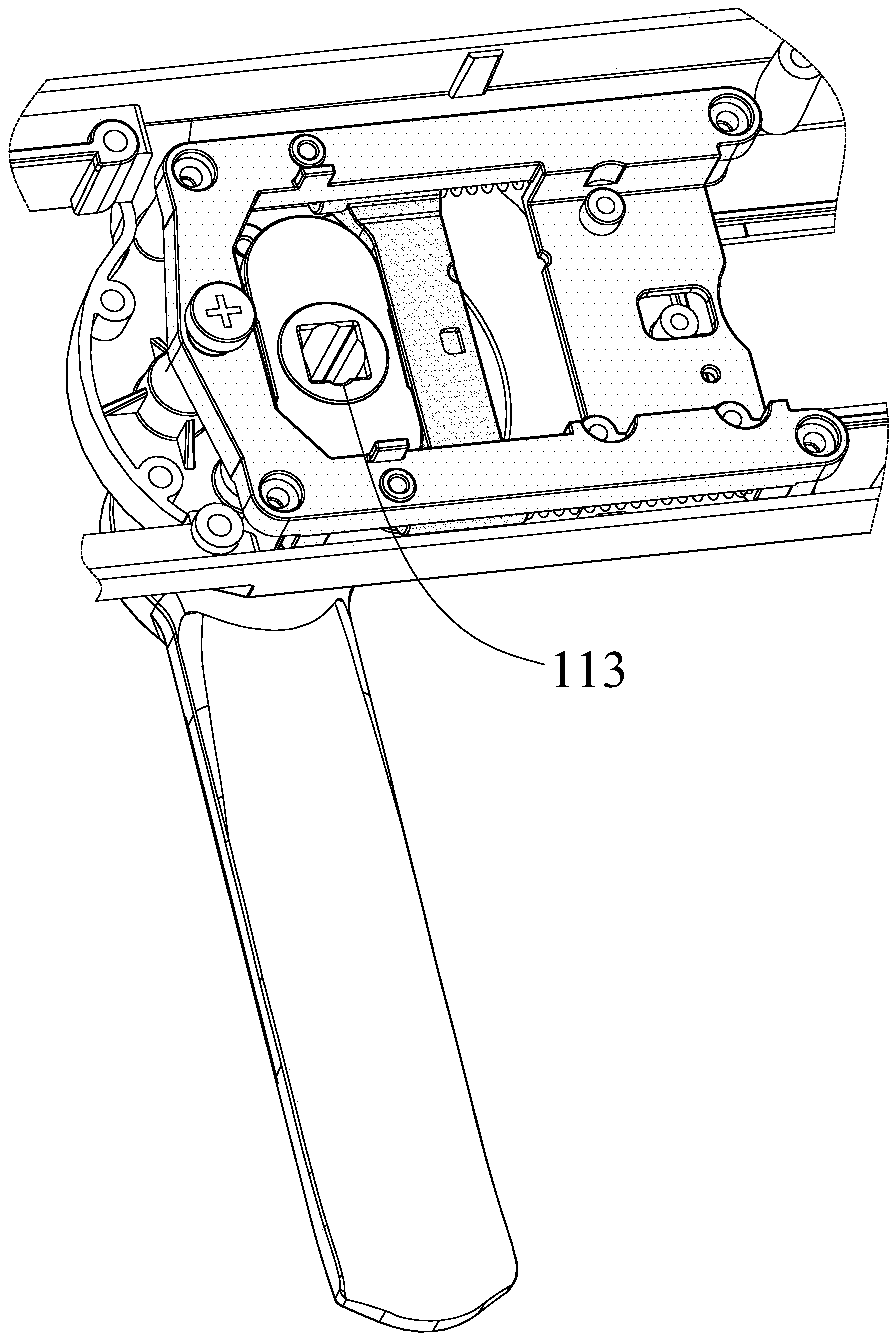

Simple two-shaft rotating mechanism with double teeth folded outwards

PendingCN109555779ASimple structural designPrecise slidingPivotal connectionsDouble teethEngineering

The invention discloses a simple two-shaft rotating mechanism with double teeth folded outwards. The mechanism comprises a structure main body; the structure main body consists of two sets of outward-folded rotating shafts and packing bodies; the outward-folded rotating shafts consist of spring bases with two symmetric edges, and connected double-tooth circling mechanisms; the double-tooth circling mechanisms comprise damping circles, and combined and connected connecting blocks; first gear shafts and second gear shafts for realizing synchronous rotation are arranged between the connecting blocks and the damping circles; the double-tooth circling mechanisms are rotationally connected with multiple sets of slide blocks; the slide blocks are provided with guide arcs and arc chutes; the guidearcs are slidingly connected with the arc chutes, and are matched with the circle centers for rotation to realize 180-degree sliding and limiting to meet R5 bending standards; the double-edge rotating shafts are combined with the packing bodies to realize rotation; the outward-folded rotating shafts achieve damping and torsion effects during realizing synchronous rotation through the double-toothcircling mechanisms; and the multiple sets of guide arcs are matched with the circle centers for rotation to realize 180-degree rotation and limited sliding.

Owner:DONGGUAN JINFENG ELECTRONICS

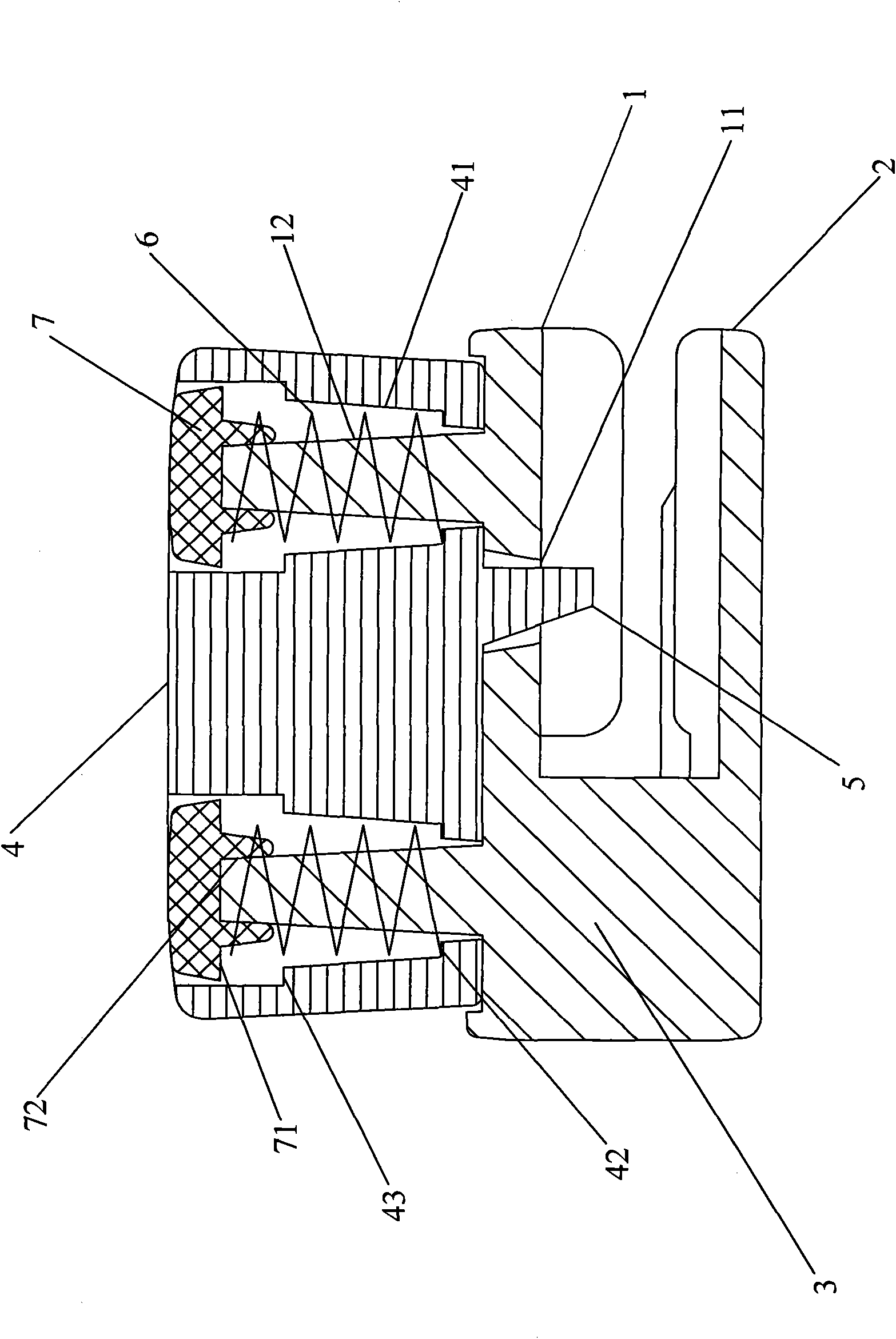

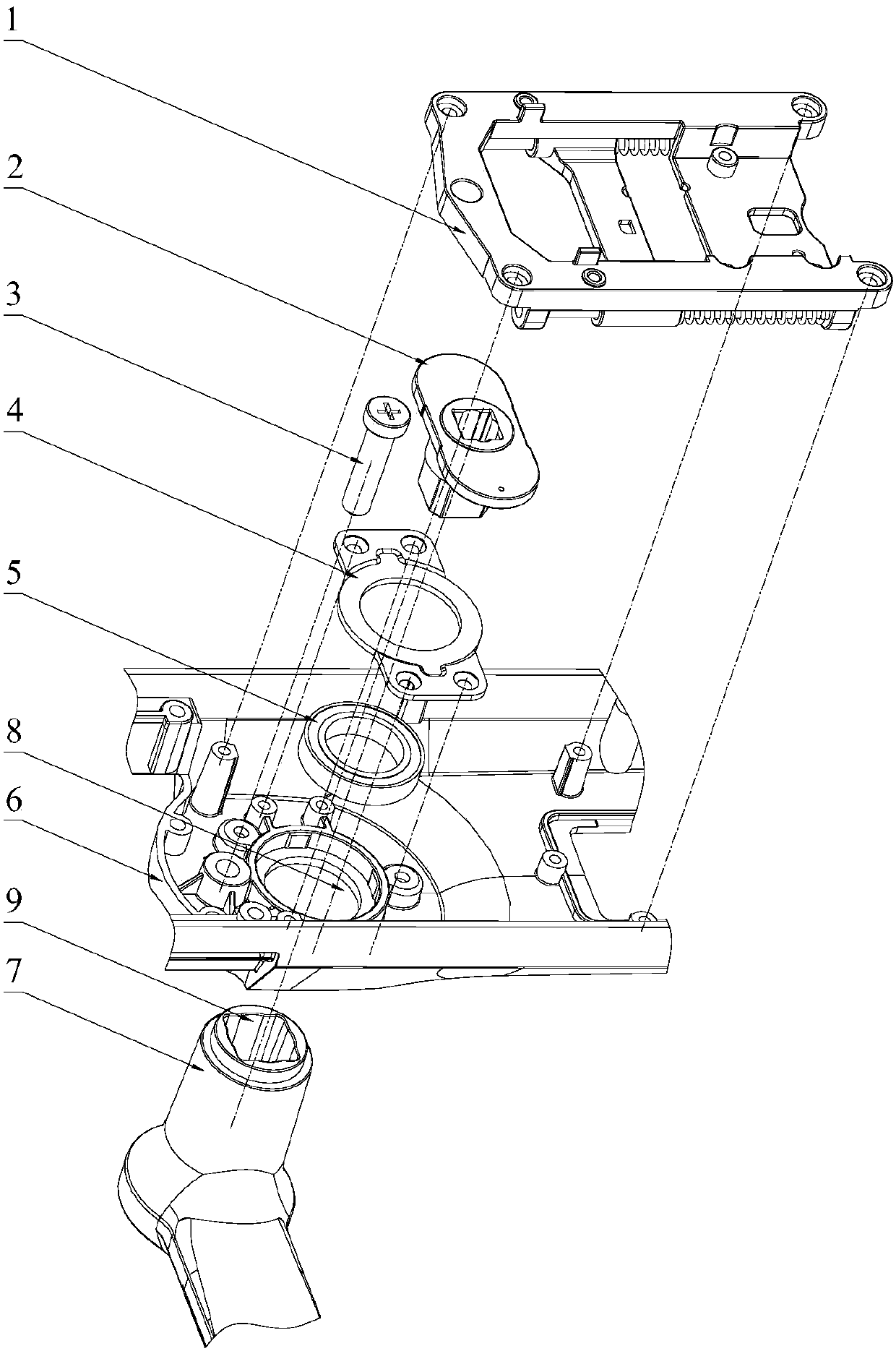

Doorknob structure

The invention discloses a doorknob structure which comprises a face plate, a handle, a handle spring base, a slide block and an external clutch assembly. A handle turning block is arranged on the side, penetrating through the face plate, of the handle, a guiding column is arranged on the spring base of the handle and is sleeved with an elastic part, the handle turning block rotates to drive the slide block to move along the guiding column back and forth, the external clutch assembly comprises an outer rotating block provided with a bolt hole, a cover plate, a first rotating piece, a second rotating piece and a bolt, and a clutching rotation block is arranged between the rotating block and the cover plate and is provided with a groove for accommodating a first rotating piece and a second rotating piece. When the clutching rotation block rotates clockwise, the first rotating piece leaves the groove of the clutching rotation block, and when the clutching rotation block rotates to 180 degrees, the second rotating piece enters the groove of the clutching rotation block rotates. When the clutching rotation block rotates back anticlockwise, the first rotating piece enters the groove of the clutching rotation block, and when the clutching rotation block rotates beyond 180 degrees, the outer rotating block can be driven to rotate. When the structure works, the bolt is pushed towards thebolt hole by a motor driving assembly or leaves the bolt hole under the effect of a bolt spring.

Owner:胡昌阵

Locating device for wood processing

PendingCN108544573AReduce the chance of getting hurtTo meet the needs of different pressing positionsGuide fencesCircular sawsEngineeringPiston

The invention discloses a locating device for wood processing. The locating device comprises a base and a working table. The working table is arranged on the base. A screw rod is arranged on the sidewall of the working table. The two ends of the screw rod are connected to the side walls of the working table, and one of the two ends is connected with an output shaft of a motor. The motor is fixedly connected to the side wall of the working table. The screw rod is provided with a sliding seat. The sliding seat is provided with a fixing rod. The fixing rod is provided with a transverse rod whichextends to the table. An inverted air cylinder is arranged on the transverse rod. The piston end of the air cylinder is connected with a tightly-pressing block. The fixing rod is provided with a corresponding pressure bearing block. A gap formed between the pressure bearing block and the tightly-pressing block serves as a storage groove for storing wood. The side wall of the working table is provided with guide rails used for guiding the sliding seat. The sliding seat is provided with sliding grooves matched with the guide rails. A cutting electric saw is arranged at one side of the working table. By means of the locating device, accidental injuries caused by manual operation can be effectively reduced, and in addition, locating is conducted precisely.

Owner:湖州南浔三宝木业有限公司

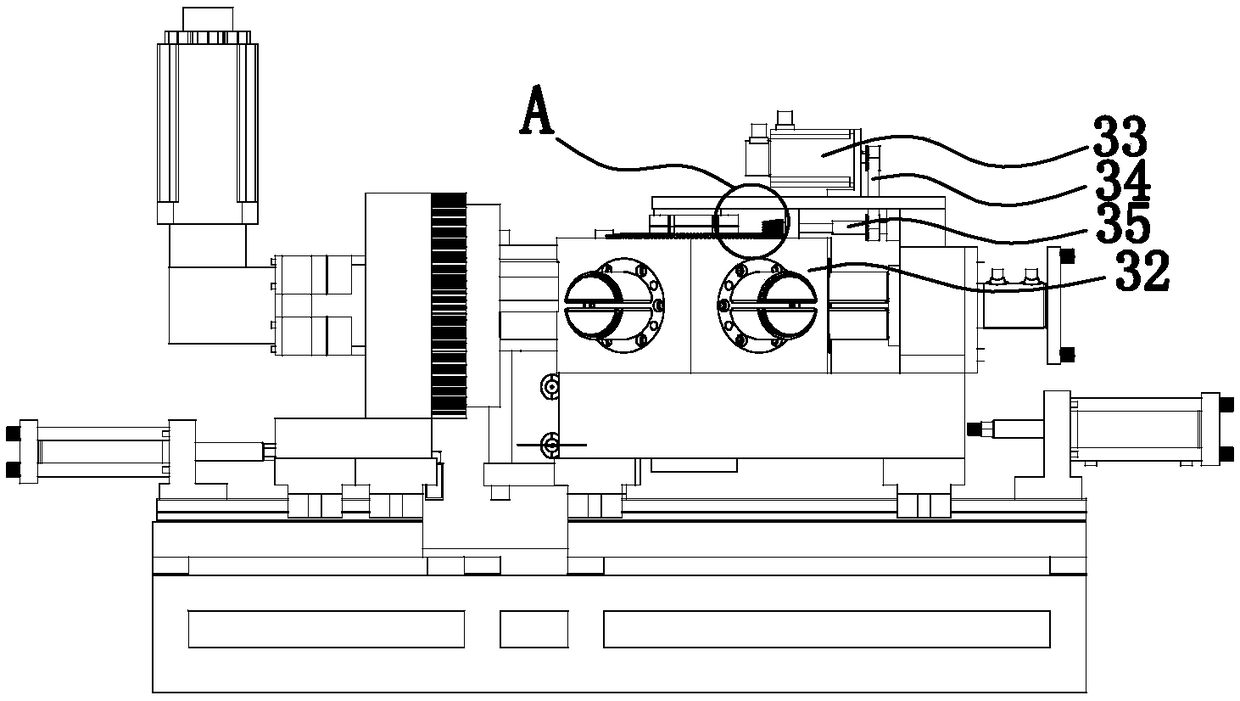

Butt joint type automatic double-spindle numerical control machine tool for polygon turning

ActiveCN110280787AReduce workloadPrevent splashAutomatic/semiautomatic turning machinesMaintainance and safety accessoriesTool holderEngineering

The invention discloses a butt joint type automatic double-spindle numerical control machine tool for polygon turning. The machine tool comprises a base, wherein a gang tool holder is arranged in the middle of the base, transverse sliding bases are arranged on the positions, corresponding to the two sides of the gang tool holder, of the base, each transverse sliding seat is provided with a vertical sliding seat, each vertical sliding seat is provided with a spindle, the two spindles are fixedly provided with an outer clamp cylinder clamp and an inner support clamp head, outer covers are arranged at the positions, corresponding to the two sides of the gang tool holder, of the base, horizontal open grooves are formed in the positions, corresponding to the outer clamp cylinder clamp and the inner support clamp head, of the two outer covers, a vertical baffle is fixed at the sides, corresponding to the open grooves, between the two outer covers, and an inverted L-shaped door cover which is horizontally and slidably arranged on the outer covers is arranged on one side of the baffle. The machine tool not only can reduce environmental pollution, but also has the advantages of being small in labor intensity, convenient in part clamping, high in working efficiency, strong in part clamping stability and long in service life.

Owner:兰溪瑞鼎机床股份有限公司

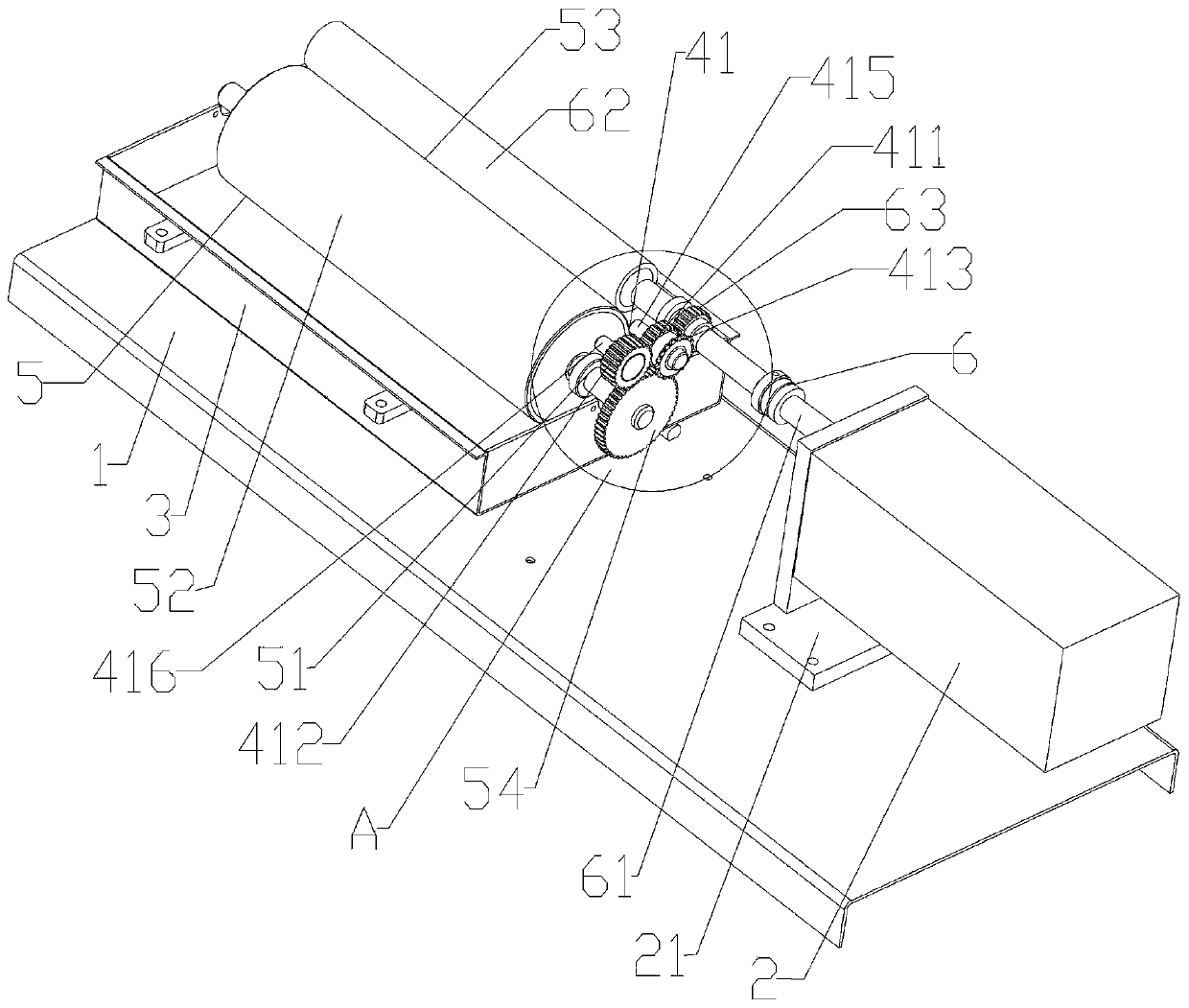

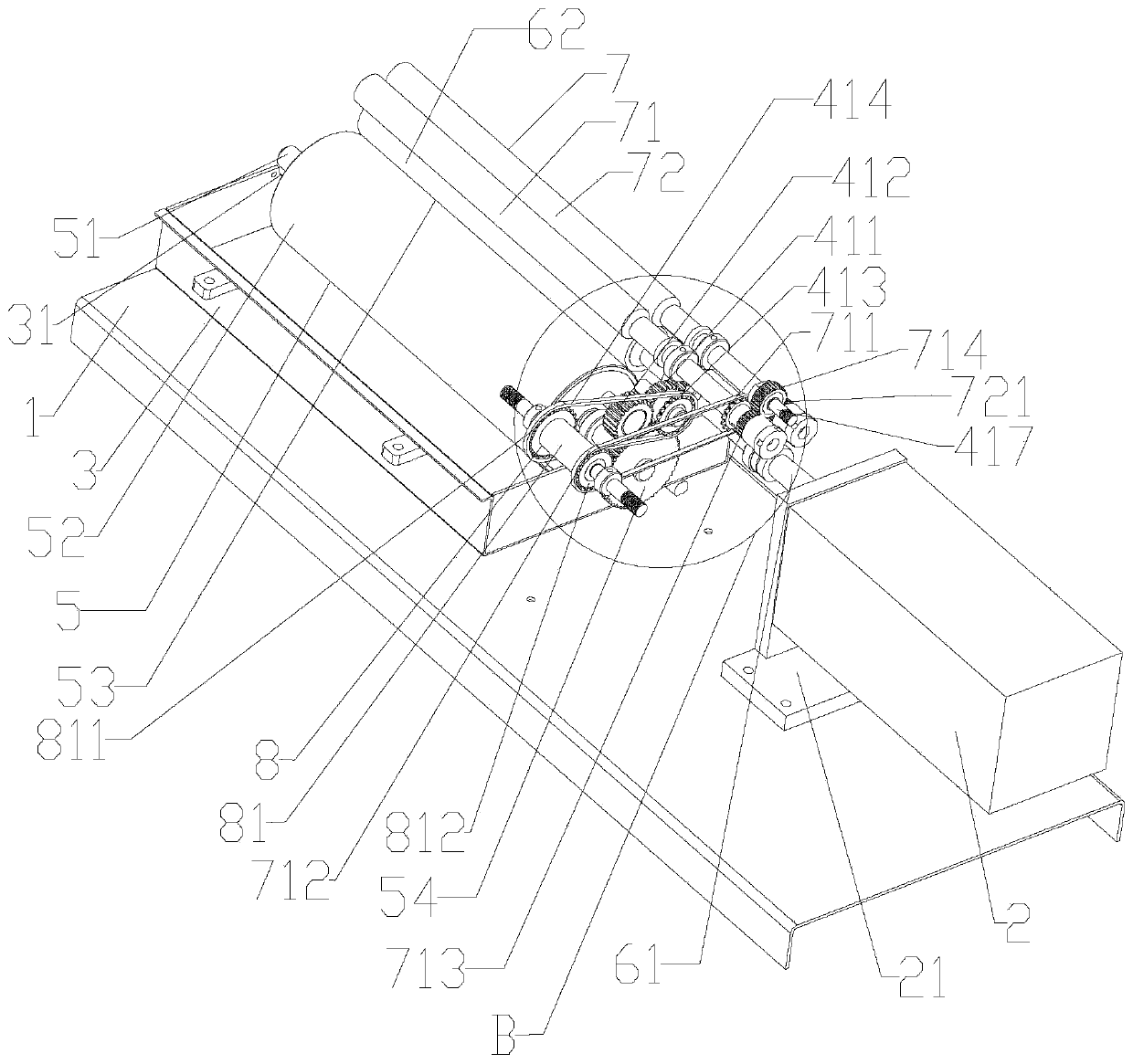

Lamination machine

PendingCN110538759ASimple structureEasy maintenanceLiquid surface applicatorsCoatingsGear wheelEngineering

The invention discloses a lamination machine which comprises a base of the lamination machine, wherein a speed reduction motor and a storage groove used for storage of glue are disposed on the base; agearbox used for storing a gear set is also disposed on the base; a first rolling mechanism is in rotatable connection to the upper end face of the storage groove; a second rolling mechanism which islocated above the first rolling mechanism is in rotatable connection to the outer side wall of the gearbox; the first rolling mechanism is in transmission connection to the second rolling mechanism by the gear set; a fixation mechanism which can adhere a to-be-laminated product with the outer side wall of the second rolling mechanism is disposed above the second rolling mechanism; and the end, remote from the first rolling mechanism, of the second rolling mechanism passes through the gearbox and is then fixedly connected to a power output end of the speed reduction motor.

Owner:GUANGBO GRP

Electric power safety internet-of-things insulation shielding cover

ActiveCN112820498AImprove fixation efficiencyImprove fixation stabilityTransformers/inductances casingsTransformers/inductances coils/windings/connectionsStructural engineeringMechanical engineering

The invention discloses an electric power safety internet-of-things insulation shielding cover which comprises a shielding shell, an anti-skid device, a tightening device and a fixing assembly. The anti-skid device is arranged in the center of the shielding shell, the shielding shell is of two sets of symmetrical semicircular shell structures, and the tightening device is transversely arranged along the splicing edge of the semicircular shells. An arc-shaped plate is fixed on the semicircular shell above the left side and the right side of the anti-skid device, an arc-shaped clamping plate is fixed on the semicircular shell below the left side and the right side of the anti-skid device, so that the arc-shaped plate is vertically embedded into the arc-shaped clamping plate; a fixing assembly is further arranged close to the inner side of the tightening device, therefore, the arc-shaped plate and the arc-shaped clamping plate which are of a sandwich structure are fixed.

Owner:ELECTRICAL SERVICE & ELECTRIFICATION ENG

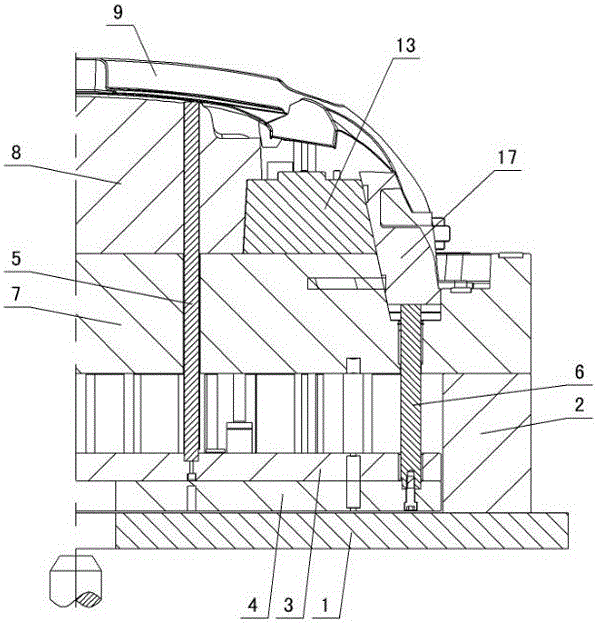

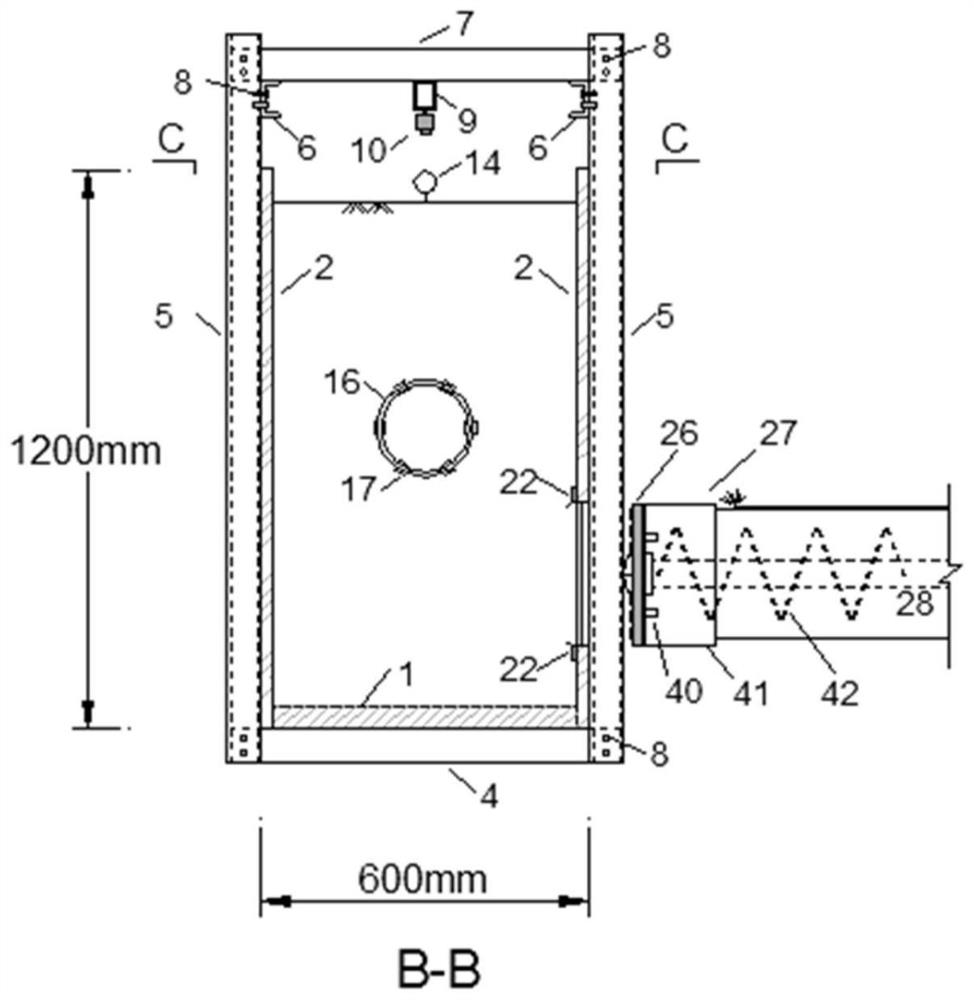

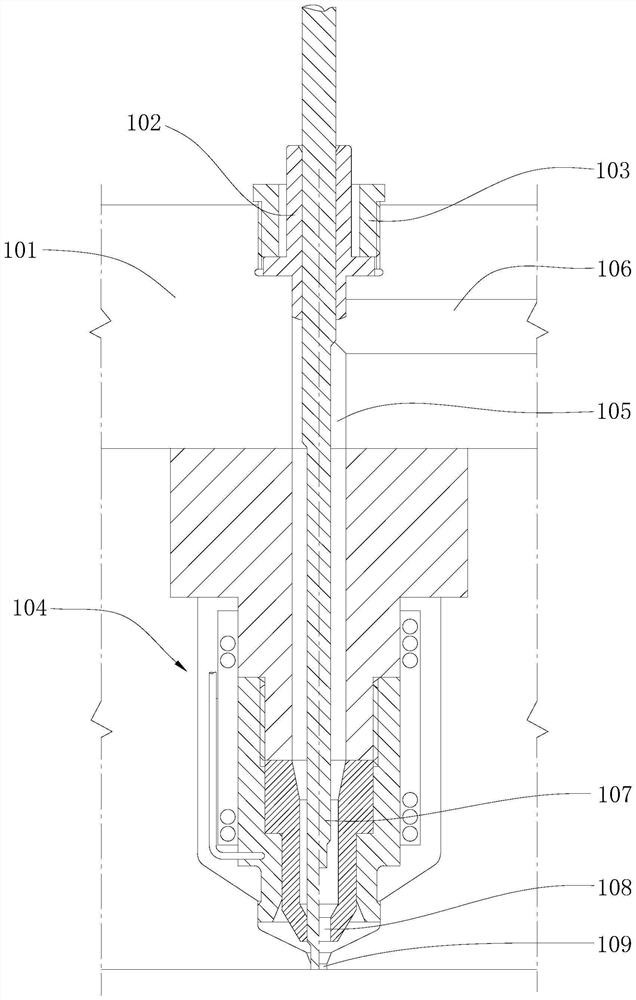

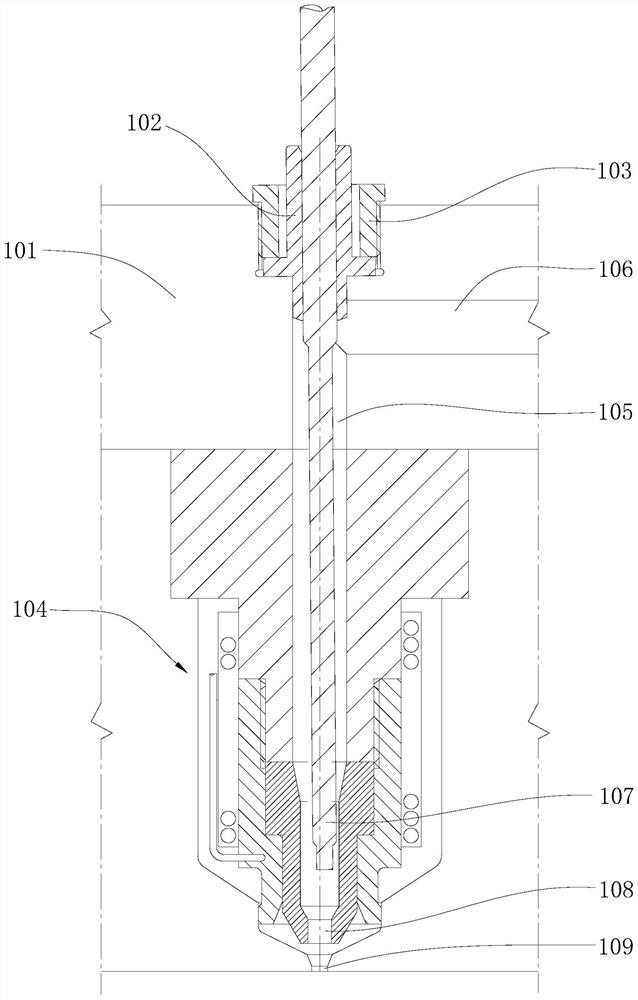

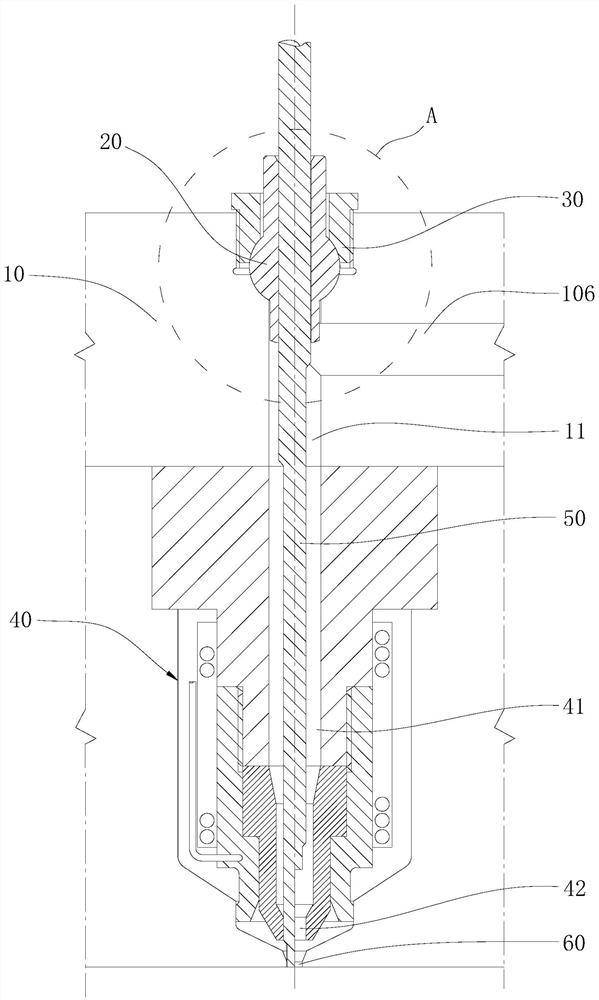

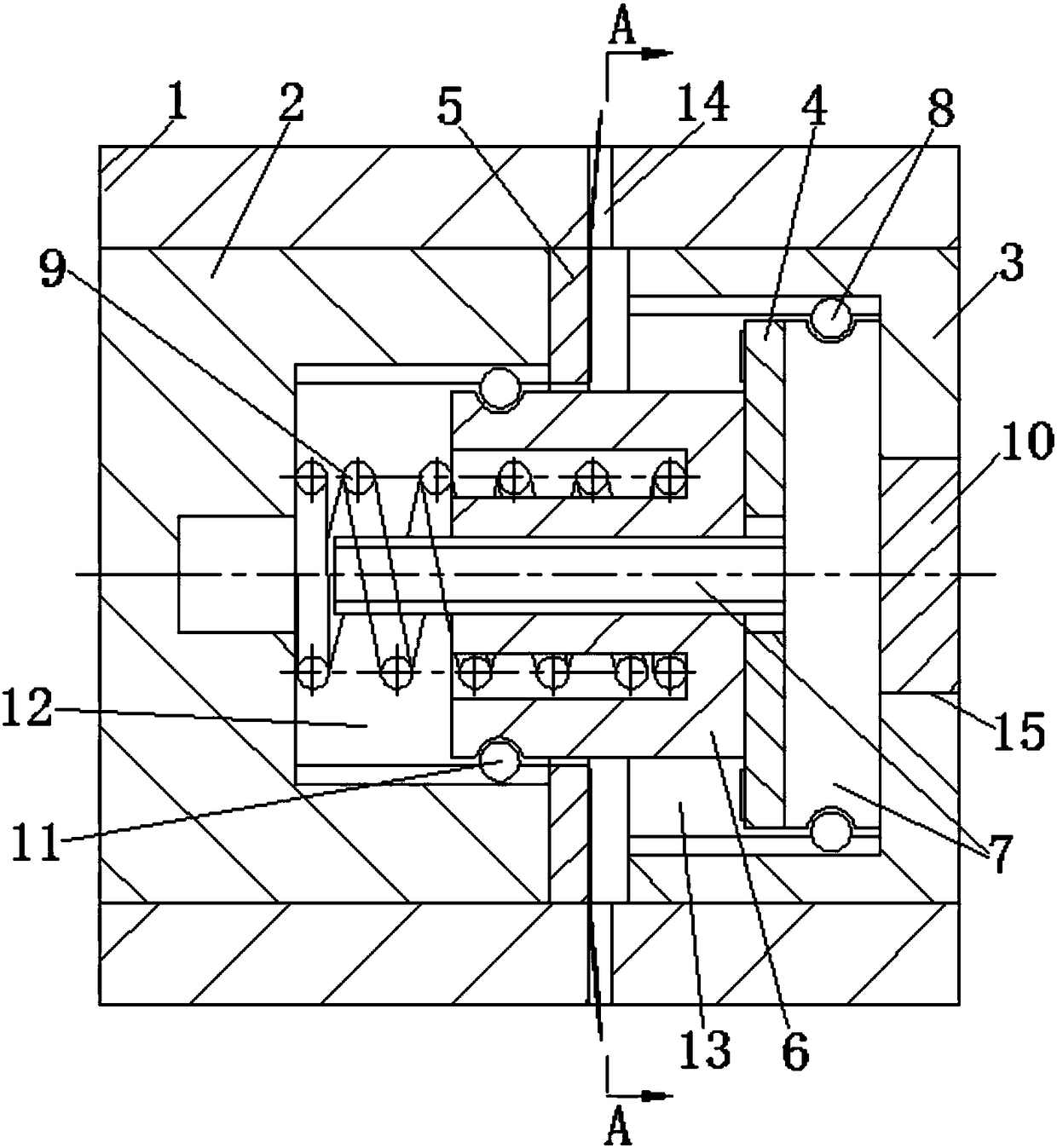

Valve needle guide structure, valve needle guide positioning method and injection mold

The invention relates to a valve needle guide structure, a valve needle guide positioning method and an injection mold. The valve needle guide structure comprises a splitter plate, a guide piece and a cover body, a through hole penetrating up and down is formed in the splitter plate, and a first annular groove is formed in the top of the through hole; the guide piece is of a rotary body structure with a center guide hole, the peripheral face of the guide piece is a protruding arc face, and the guide piece is partially contained in the first annular groove and can be axially deflected and adjusted through cooperation of the arc face and the first annular groove; the cover body is provided with a clearance hole penetrating up and down, a second annular groove opposite to the first annular groove is formed in the bottom of the clearance hole, and the cover body covers the guide piece and is fixedly connected with the splitter plate so as to limit axial deflection of the guide piece. The guide part can be quickly fixed to the position where the center guide hole and the ejection hole of the hot runner nozzle are located on the same center axis, the structure is simple, the requirement for machining precision is low, and installation is convenient and quick.

Owner:EVERFINEST PRECISION MACHINERY SHENZHEN

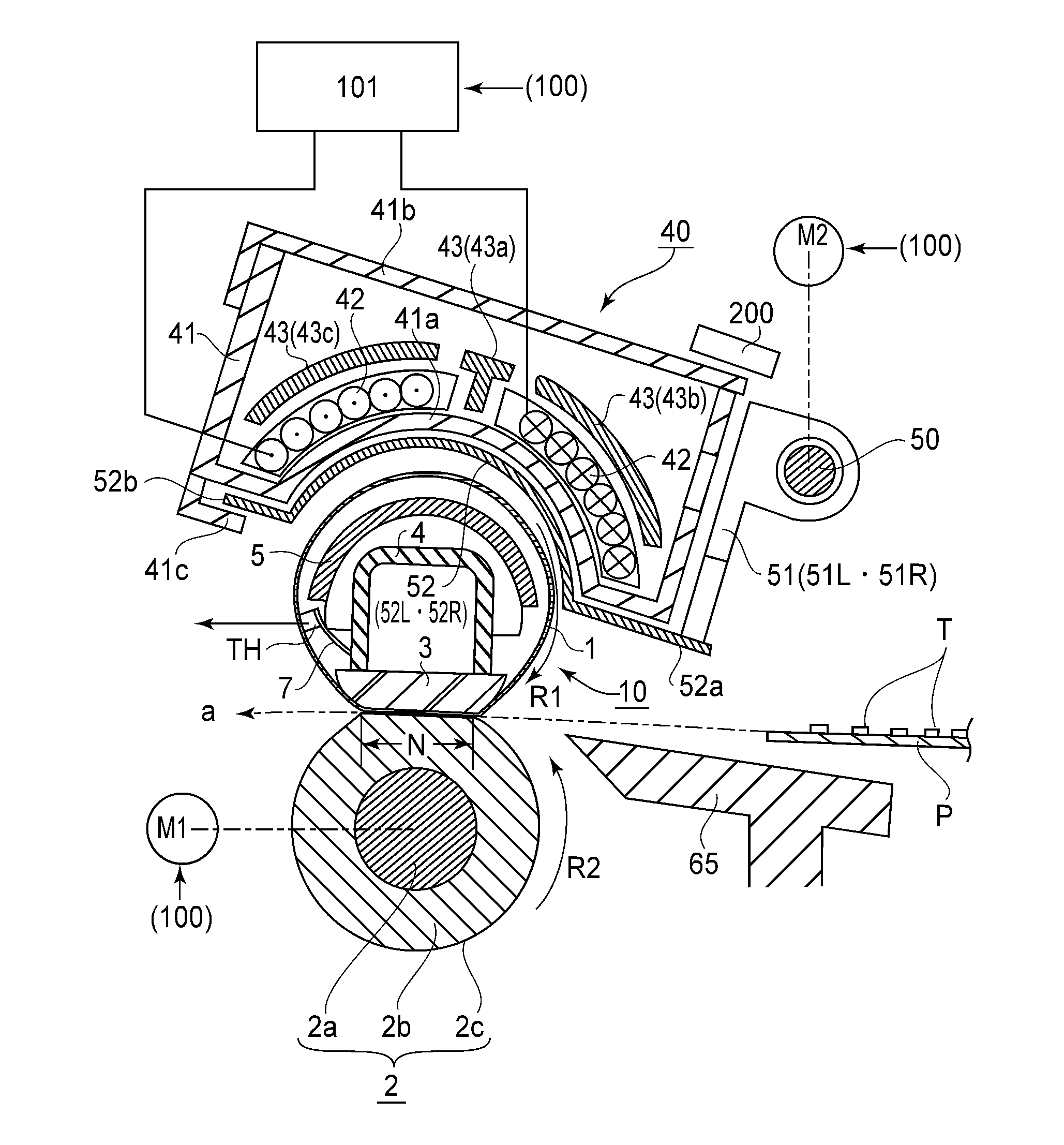

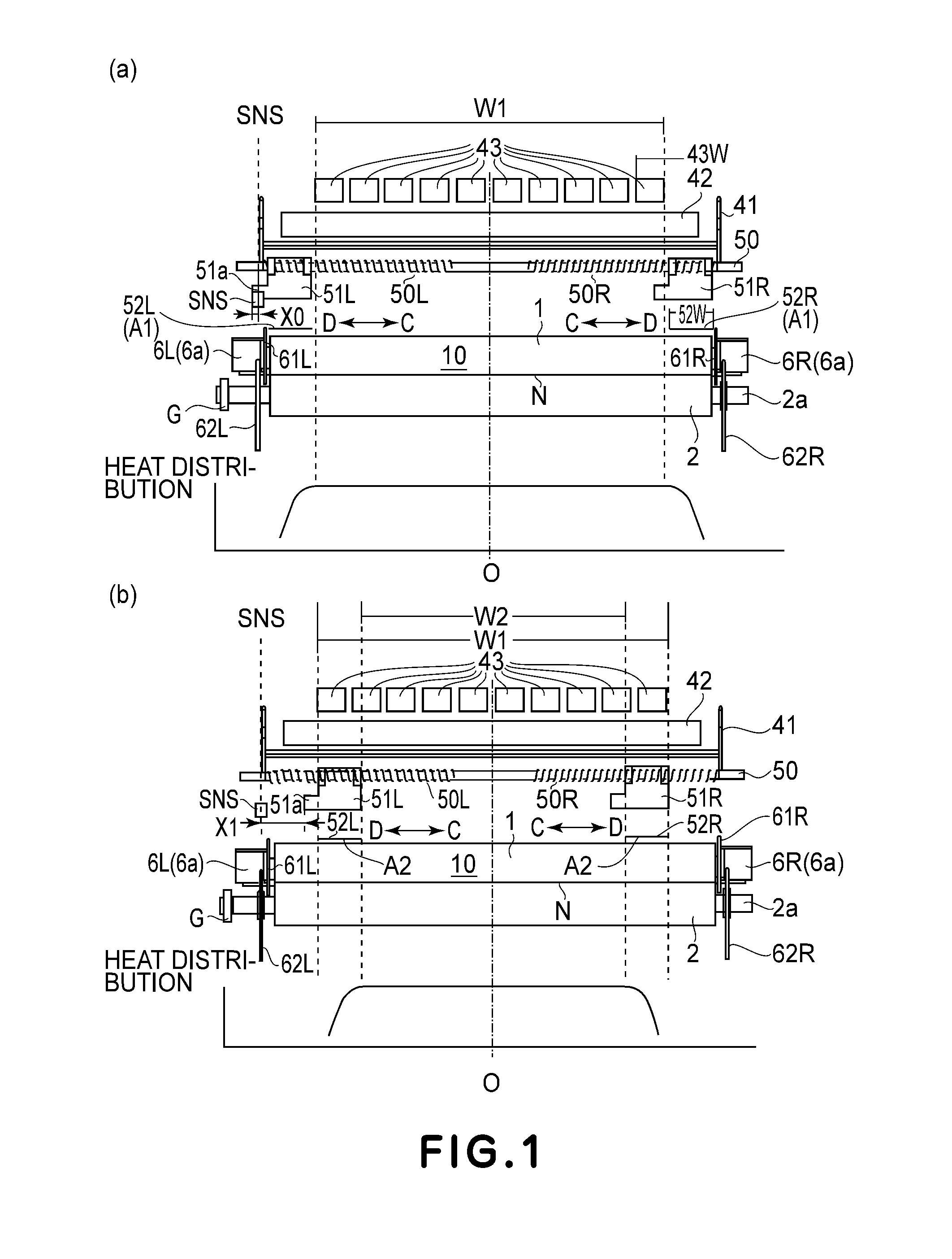

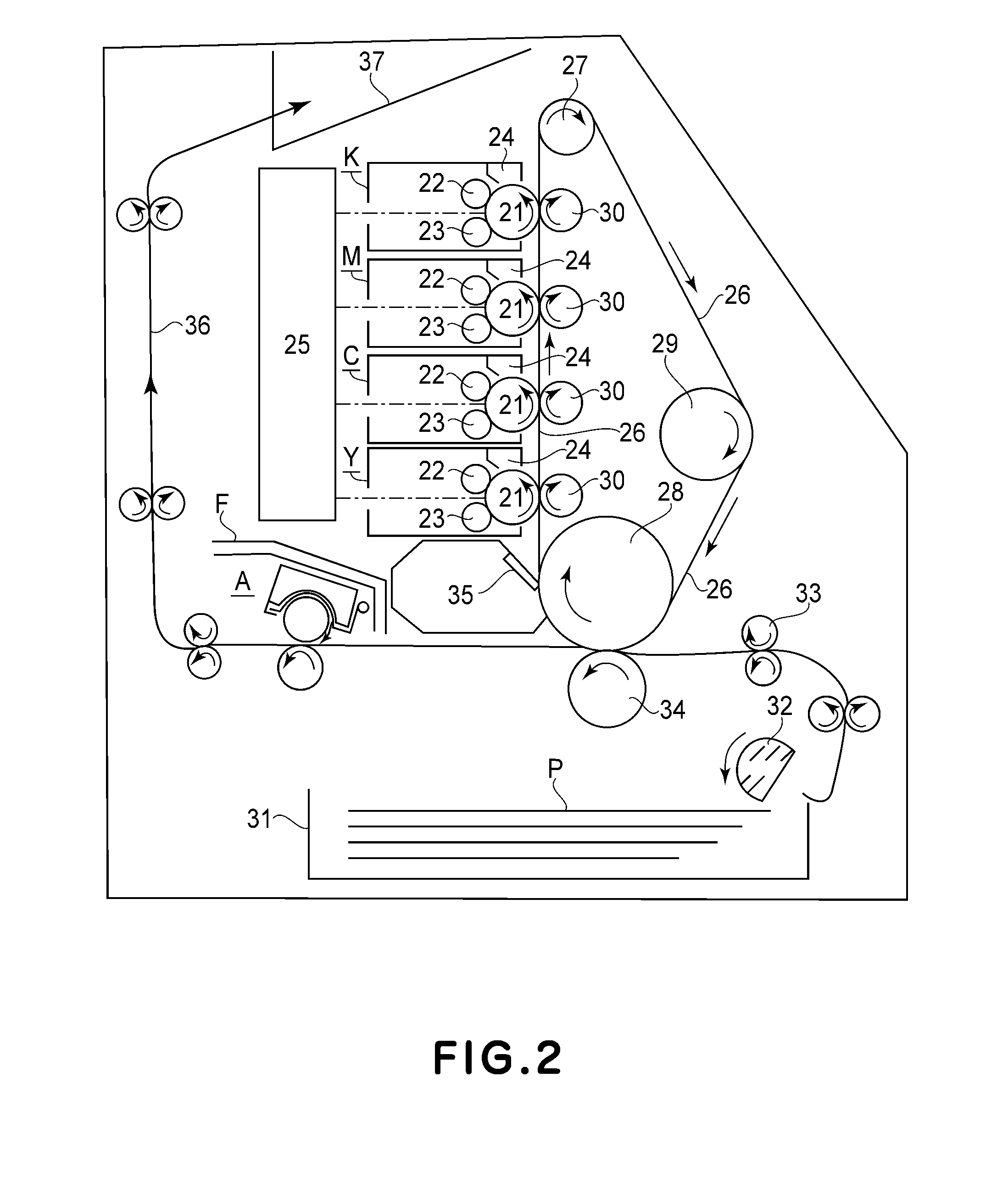

Image heating apparatus

An image heating apparatus includes: a heating member configured to heat a toner image formed on a sheet by using a toner containing a wax; an exciting coil; a magnetic flux suppressing member configured to suppress a part of magnetic flux actable from the exciting coil onto the heating member; a screw shaft configured to hold the magnetic flux suppressing member and configured to slide the magnetic flux suppressing member along a longitudinal direction of the heating member; and a controller configured to control a rotational movement operation of the screw shaft so that the magnetic flux suppressing member is moved to a position depending on a width of the sheet. The controller is, during non-image heating, capable of executing an operation in a mode in which the screw shaft is rotationally moved so that the magnetic flux suppressing member is reciprocated at least once in a predetermined range.

Owner:CANON KK

Surface marking device for machining mechanical parts

InactiveCN112265402APrecise slidingStable marking environmentEmbossing decorationsStructural engineeringMachine

The invention relates to the technical field of part machining, and discloses a surface marking device for machining mechanical parts. A marking mechanism is fixed to the telescopic end of a hydraulicpush rod, supporting plates are symmetrically fixed to the inner side of a conveying frame, printing supporting mechanisms are arranged on the inner sides of the supporting plates, transmission mainshafts are symmetrically connected to the positions, located at the two ends, of the inner side of a conveying frame, the outer sides of the transmission main shafts are connected with a conveying belt, and placing tables are fixed to the upper portion of the conveying belt. According to the surface marking device for mechanical part machining, supporting guide rods are subjected to double sleeving positioning through clamping rollers and pushing sliding sleeves in the marking mechanism, under transmission conveying of transmission toothed belts, printing needle heads can be driven to stably and accurately slide, the situations of dislocation and shaking in the marking process are avoided, the placing tables are mechanically conveyed through the conveying belt in the marking process, and under the supporting and lifting of the printing supporting mechanisms, the mechanical parts can be in a stable marking environment.

Owner:邱海姑

Full-automatic curve bending machining equipment

ActiveCN108838683APrecise processingIncrease processing costShearing machinesOther manufacturing equipments/toolsEngineeringTower

The invention discloses a full-automatic curve bending machining equipment. The equipment comprises a main body, wherein a feeding assembly, a folding arm chuck tower assembly, a universal folding head assembly, a shearing assembly and a control assembly are arranged on the main body; the clamping pliers are arranged on the feeding assembly, and the clamping pliers are used for clamping and driving the metal raw materials to drive the metal raw materials to slide to the folding arm chuck tower assembly; a folding arm chuck which is matched with the metal raw material is arranged on the foldingarm chuck assembly, the clamping pliers drive the metal raw materials to slide, and one end of the clamping pliers penetrates through the folding arm chuck to be fixed; the universal folding head assembly is provided with a universal folding head, and the universal folding head assembly drives the universal folding head to rotate, the universal folding head is located on one side of the metal rawmaterial stretching out of the folding arm chuck, and the metal raw material is located on the rotation path of the universal folding head; a shearing assembly is arranged on the shearing assembly, ashearing knife head is arranged on the shearing assembly, and the bent metal raw materials are sheared by the shearing cutter head; and each assembly is controlled to work by the control assembly. The full-automatic curve bending machining equipment has the characteristics of full-automatic operation, no need of manual turnover, high processing precision, simplicity in operation and the like.

Owner:浙江中雁机械制造有限公司

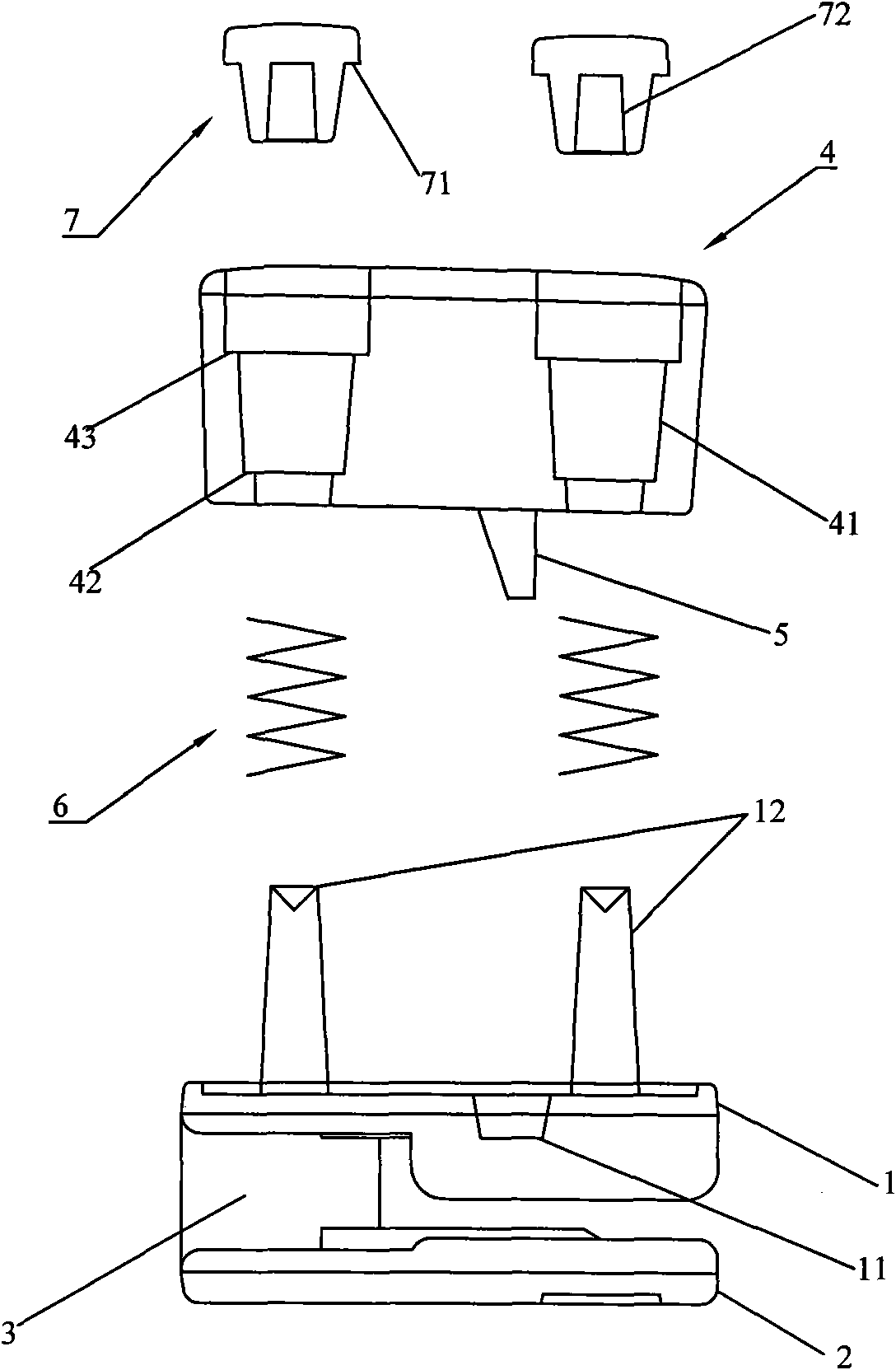

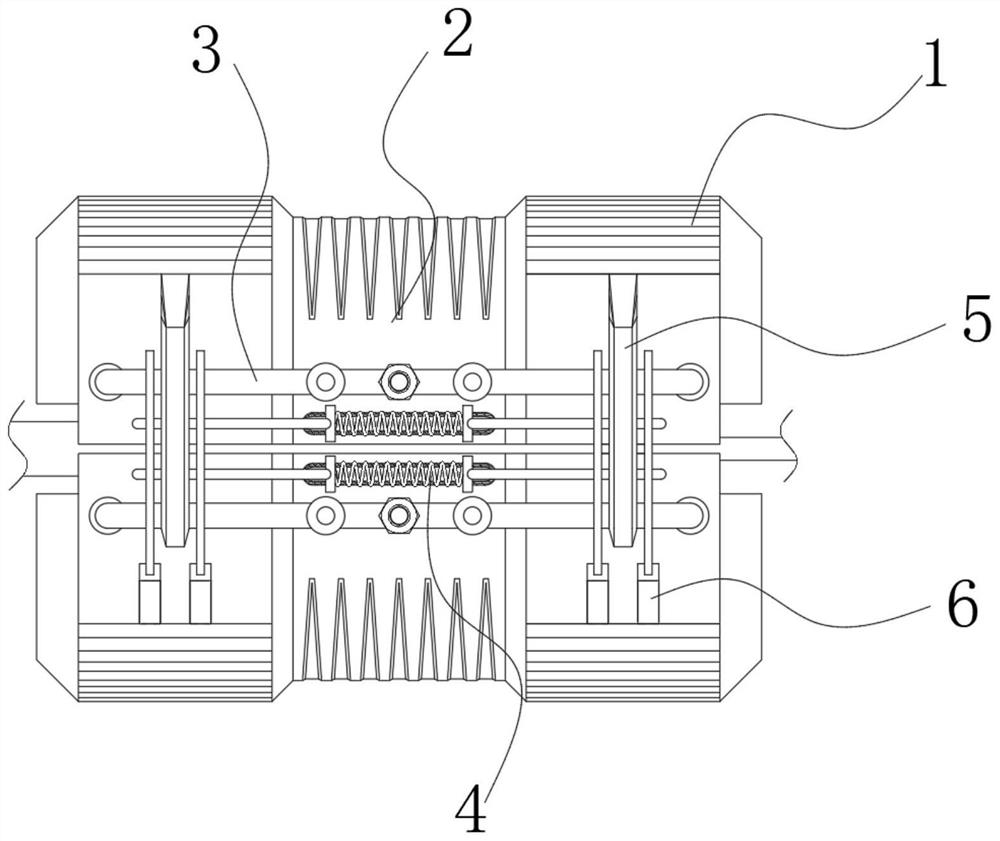

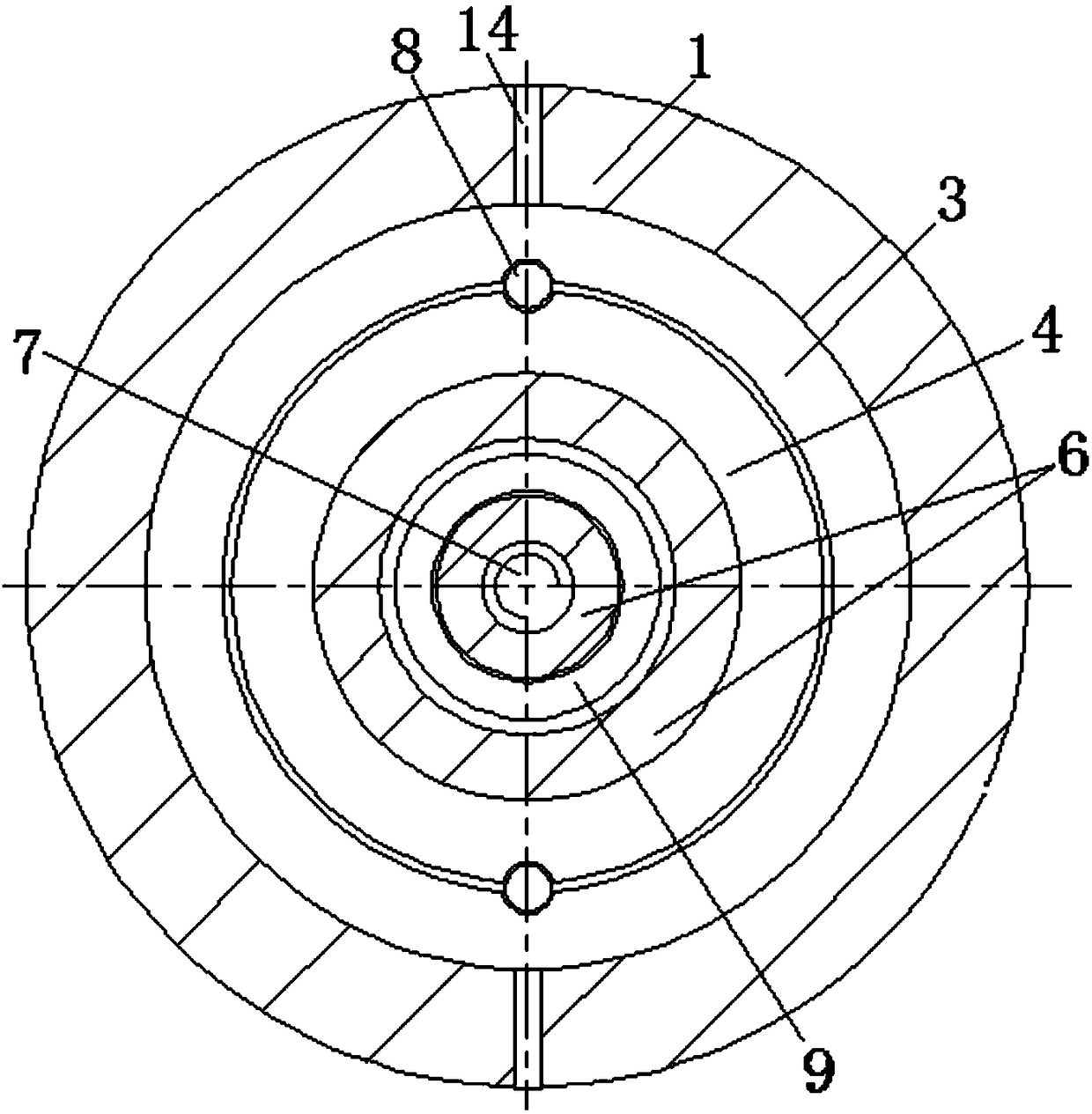

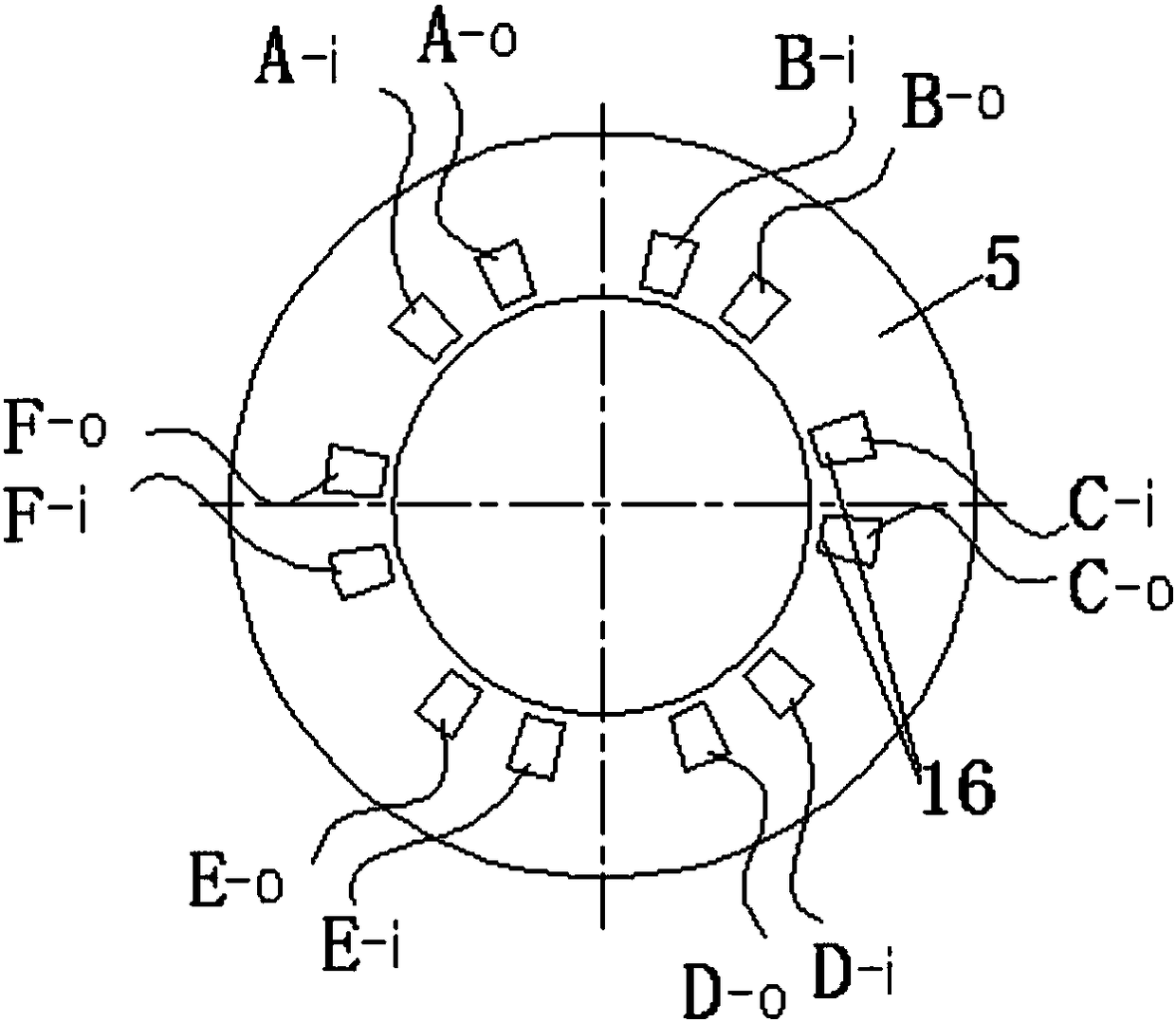

Multichannel mechanical acceleration switch

ActiveCN108183047AControl on-off stateEliminate waste and consumptionElectric switchesEngineeringMechanical engineering

The invention provides a multichannel mechanical acceleration switch. The acceleration switch is arranged on a centrifugal rotating part, and the axial direction is consistent with the radial direction of the centrifugal rotating part. The multichannel mechanical acceleration switch concretely comprises a shell, a stationary electrode plate, a slide body and a spring. The shell has a cylindrical or square tubular structure. A T-shaped chute formed by an external radius base and an internal radius base is formed in the shell. The shell is provided with at least one wiring hole. The stationary electrode plate of the insulator is fixed on the end surface of the external radius base, and the surface is provided with multiple sets of conductive electrodes. The slide body is mainly composed of aT-shaped screw, a slide electrode plate and a spring sleeve which are combined together. Multiple sets of conductive electrodes are arranged in the area, which is radially exposed out of the edge ofthe spring sleeve, of the slide electrode plate of the insulator. The spring is axially arranged in the chute. The axial position of the slide electrode plate maintains to be spaced from the stationary electrode plate under the effect of the spring. The spring is compressed by the slide body which axially slides to the outside in the centrifugal acceleration process so that the correspondingly matched conductive electrodes of the slide electrode plate and the stationary electrode plate are enabled to be contacted and conducted.

Owner:DONGFANG TURBINE CO LTD

Movable lifting auxiliary device for building wall building and using method thereof

PendingCN113006447AStable handlingReduce contact areaScaffold accessoriesBrickArchitectural engineering

Owner:杨建勋

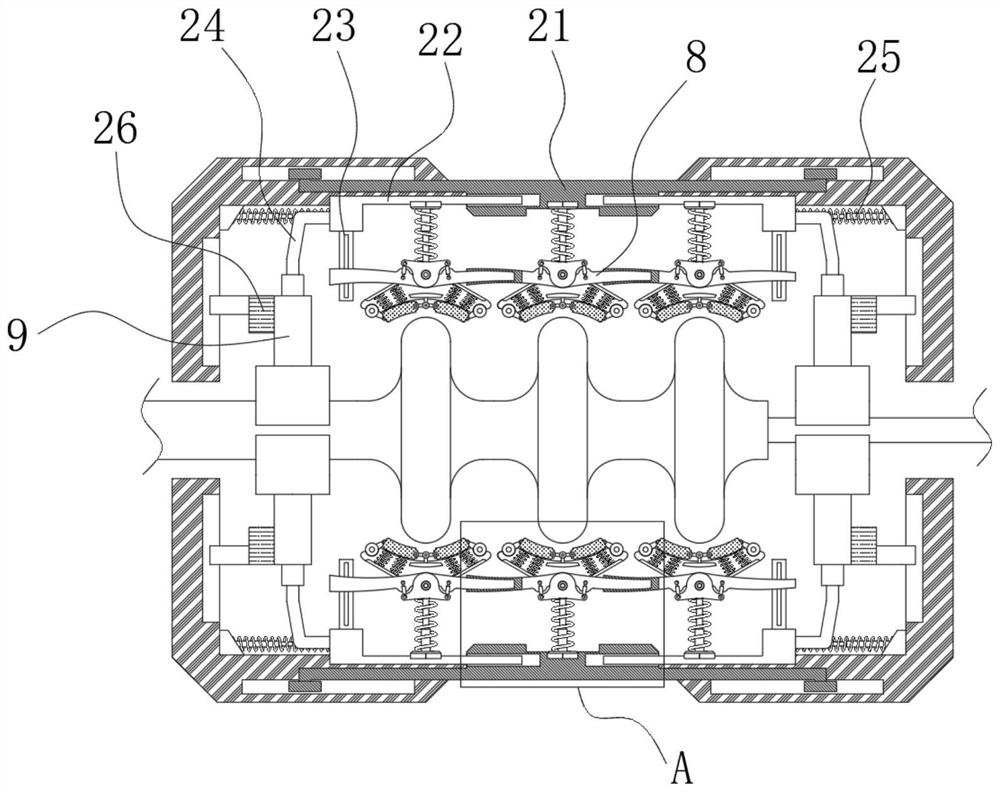

Automatic classification device for classifying archives according to IoT

ActiveCN110479640APrecise slidingMaximize the conversion rate of mechanical energySortingGear wheelThe Internet

The invention discloses an automatic classification device for classifying archives according to IoT (Internet of Things). The automatic classification device comprises a body; a driven roller is rotationally arranged at the front side of a driving roller; another driven roller is rotationally arranged at the rear side of the driving roller; a first rotating shaft can be driven to rotate by starting a first motor, and then a main belt wheel is driven by the first rotating shaft to rotate so as to drive a first belt to rotate to enable the archives after paging to move to the right. According to the automatic classification device, and a sheet-shaped transportation space is formed by two vertically symmetrical belt wheels to page the archives; and the information of the internet of things is on the file is scanned by a scanner, an electric signal is sent to control the steering of the motor, and when the motor for controlling the rollers is started, the positions of classification frames can be controlled by the gears sliding in a linkage manner, so that the classified archives are accurately slid into the frame of the same category.

Owner:SHENZHEN ZHIHE CHUANGXING SCI & TECH

Core pulling machine for plastic electric-fusing pipe

The invention relates to a core pulling machine for a plastic electric-fusing pipe. The core pulling machine comprises a fixed stander and a core pulling mechanism, wherein the fixed stander comprises support legs, wherein an upper bracket and a lower bracket are arranged on the support legs, front mounting frames and rear mounting frames are mounted between the upper bracket and the lower bracket, a front runner is mounted on the front mounting frames, a rear runner is mounted on the rear mounting frames, first and second left sliding blocks and first and second sliding blocks are respectively mounted on the front runner and the rear runner, a blanking hopper is mounted among the front runner, the rear runner and the lower bracket, a front sliding rail and a rear sliding rail are mounted on the upper bracket, front guiding blocks and rear guiding blocks are respectively arranged on the front sliding rail and the rear sliding rail, and a left protection cover and a right protection cover are respectively mounted on the front guiding blocks and the rear guiding blocks; the core pulling mechanism comprises a front mounting plate, a rear mounting plate, a left mounting plate and a right mounting plate, a left air cylinder and a rear air cylinder are respectively arranged on the left mounting plate and the right mounting plate, a left baffle and a right baffle are mounted between the front mounting plate and the rear mounting plate, left core pulling holes and right core pulling holes are respectively formed in the left baffle and the right baffle, a left connecting plate is mounted on the first left sliding block, a left connecting sleeve and a left connecting pin are arranged on the left connecting plate, a left clamping plate is mounted on the second left sliding block, a left clamping trough and a left core trough are formed in the left clamping plate, a left core support plate is clamped in the left clamping trough, a left core is inserted into the left core support plate, a right connecting plate is mounted on the first right sliding block, a right connecting sleeve and a right connecting pin are arranged on the right connecting plate, a right clamping trough and a right core trough are formed in the right clamping plate, a right core support plate is clamped in the right clamping trough, a right core is inserted into the right core support plate.

Owner:YONGGAO CO LTD

Cold roll forming equipment of single board

ActiveCN103028638APrevent deviationLow costMetal-working feeding devicesPositioning devicesRoll formingEngineering

The invention discloses cold roll forming equipment of a single board. The cold roll forming equipment comprises a machine platform, a cold roll forming device, a control device, a guide platform, a detection device, a pushing mechanism, an electromagnetic sucking disk and a guide seat, wherein the single board is put on the guide platform; the machine platform is provided with at least one guide rail and one fixing baffle plate, the guide platform is connected to the machine platform in a sliding way, the guide seat and the guide rail are matched, and the guide platform slides along the direction of the guide rail through the matching of the guide seat and the guide rail; and the control device is also in signal connection with the electromagnetic sucking disk, a position detection device and the pushing mechanism, and the control device can be used for controlling the electromagnetic sucking disk to adsorb the single board or release the adsorption, judging whether deviation needs to be corrected or not according to single board position data obtained by the position detection device and controlling the pushing mechanism to push the single board so that the single board can be leaned against the fixing baffle plate for correcting the deviation. The cold roll forming equipment disclosed by the invention has the following advantages that automatic deviation correcting and feeding is adopted before the forming of the single board, and accurate follow-up guide is adopted during the forming of the single board.

Owner:XIAMEN ZHENGLIMING METALLURGICAL MACHINERY

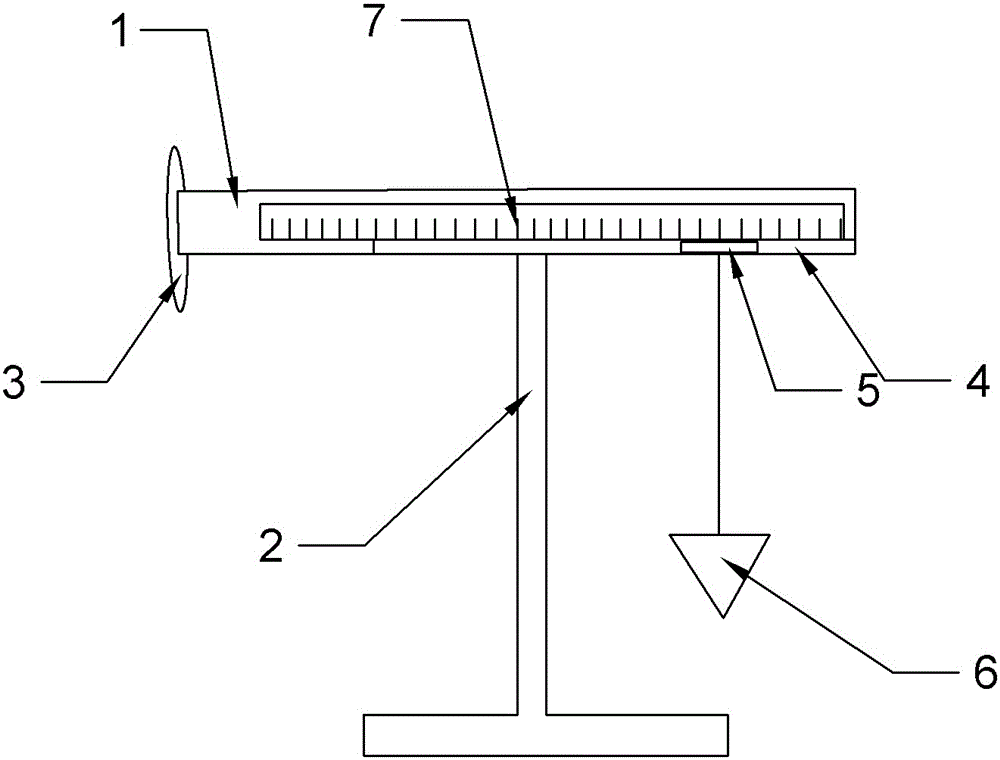

Detection measure of leaf spring

InactiveCN105115396AReduce labor intensityGuaranteed accuracyMechanical clearance measurementsPlumb lines for surveyingEngineeringLeaf spring

The invention belongs to the automobile detection field and relates to a detection measure of a leaf spring. The detection measure comprises a measure body; the measure body is rectangular on the whole; an end portion of the measure body is provided with a detachably-connected fixing disc; the center of the fixing disc is corresponding to the center hole of a wrapping eye; the diameter of the fixing disc is larger than the diameter of the wrapping eye; the lower edge of the measure body is provided with a plumb which is in sliding connection with the lower edge of the measure body; a side surface of the measure body is provided with a scale marking line plate; and the starting point of the scale marking line plate is located at the joint of the fixing disc and the measure body. According to the detection measure of the invention, the center of the leaf spring is determined accurately through the plumb, so that the accuracy of detection results of the measure can be ensured.

Owner:CHONGQING ZETIAN AUTO PARTS

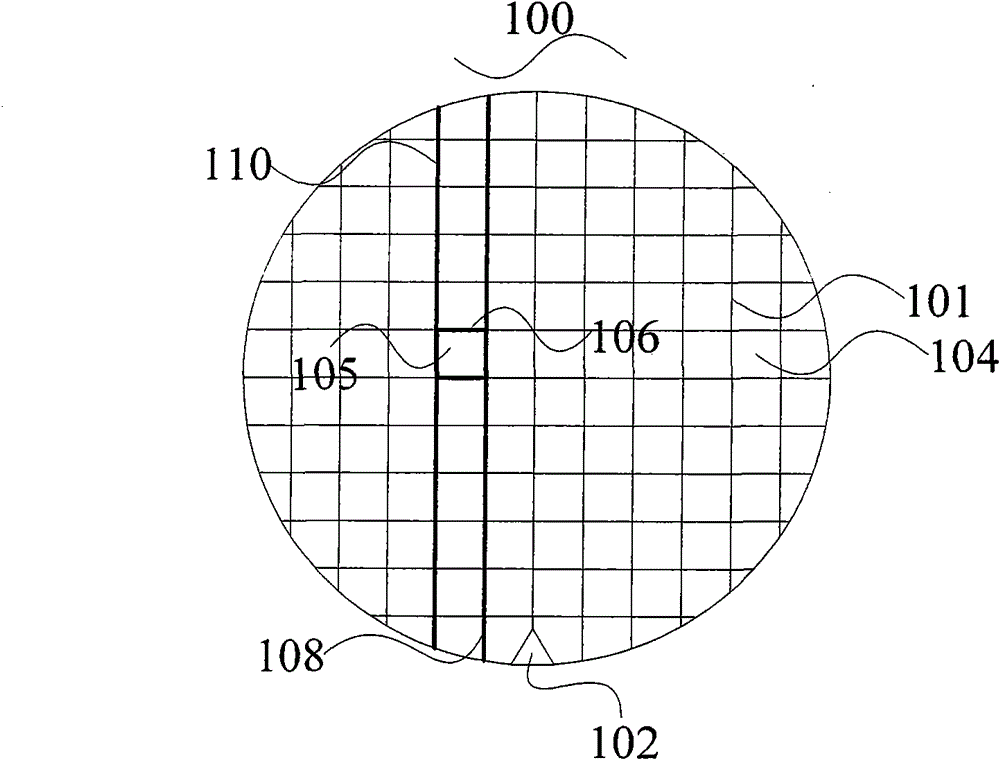

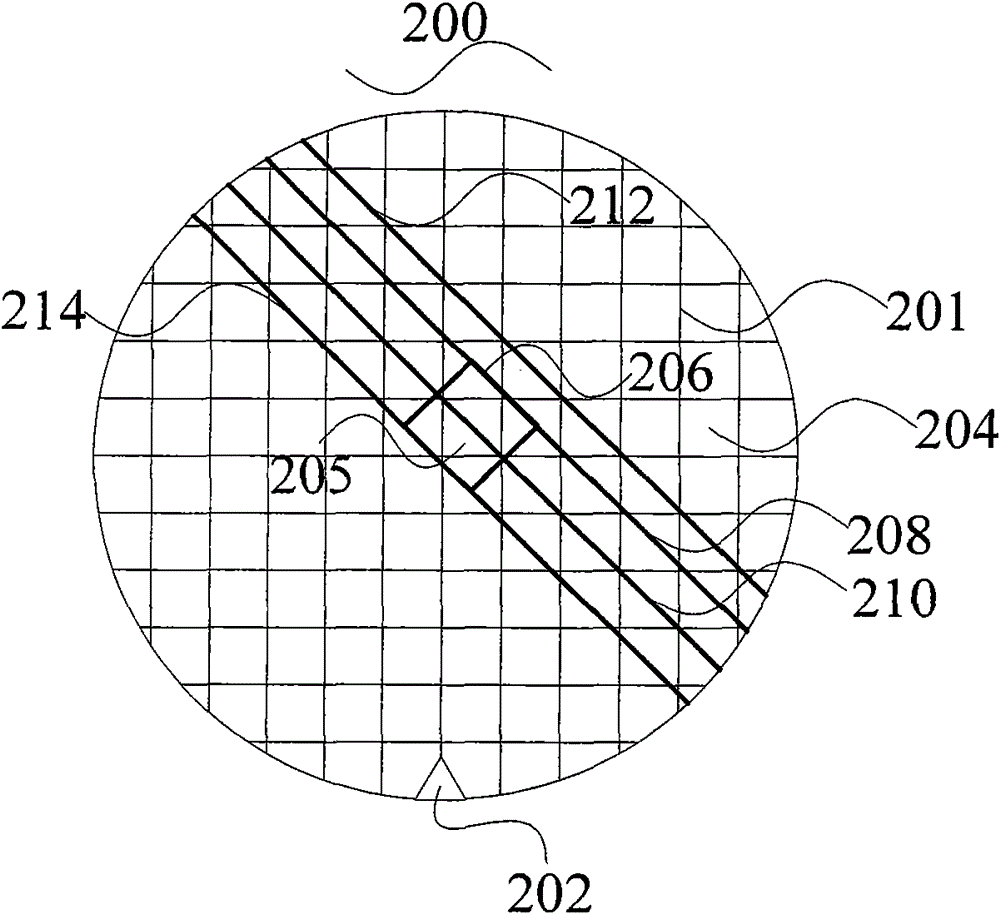

Wafer cutting tool and method for cutting wafer by using same

ActiveCN101992507BFast and precise determinationRich motion trackSemiconductor/solid-state device manufacturingWorking accessoriesMechanical engineering

The invention provides a wafer cutting tool. The wafer cutting tool comprises a peripheral bracket, a wafer bearing table, slide blocks, a slide rod and a cutter, wherein scales are carved on the circumference of at least one of the peripheral bracket and the wafer bearing table; the peripheral bracket surrounds the outer side of the wafer bearing table; a gap is reserved between the peripheral bracket and the wafer bearing table and serves as a slide block track; the slide blocks can slide along the slide block track; an inner groove is arranged in the slide rod and is sleeved on the slide block, so that the slide rod can slide in the connection line direction of the two slide blocks, and the slide rod has the length that each position of a wafer can be cut; the cutter is positioned between the two slide blocks on the slide rod and can slide along the inner groove of the slide rod to cut the wafer; and at least one of the slide rod and the cutter can be adjusted in the height direction. Correspondingly, the invention also provides a method for cutting the wafer. A cutting line position of an interested area on the wafer can be quickly and precisely determined and cut by the wafercutting tool.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com