Butt joint type automatic double-spindle numerical control machine tool for polygon turning

A CNC machine tool and docking technology, applied in the field of parts processing, can solve the problems of troublesome cleaning, pollution, serious pollution, etc., and achieve the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

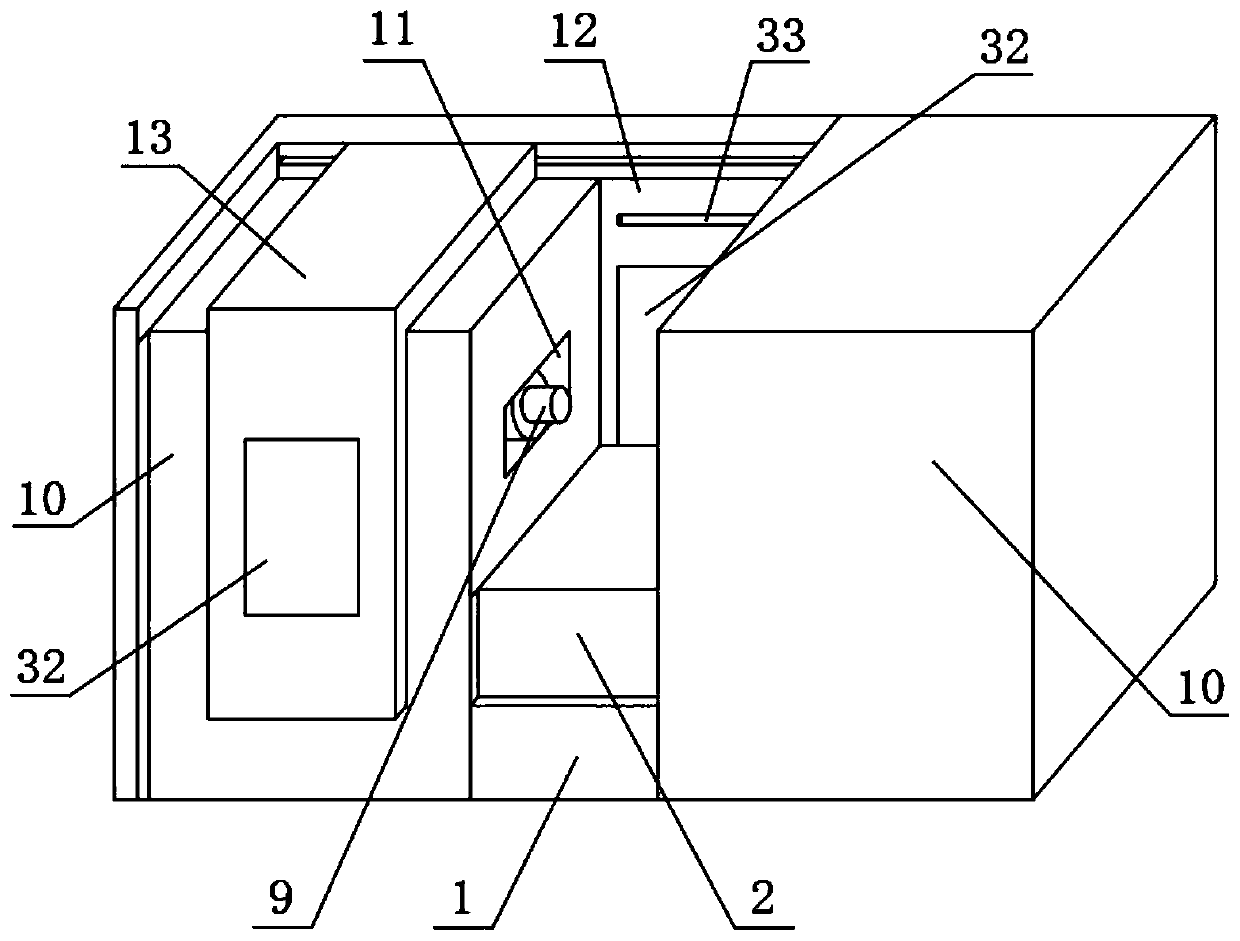

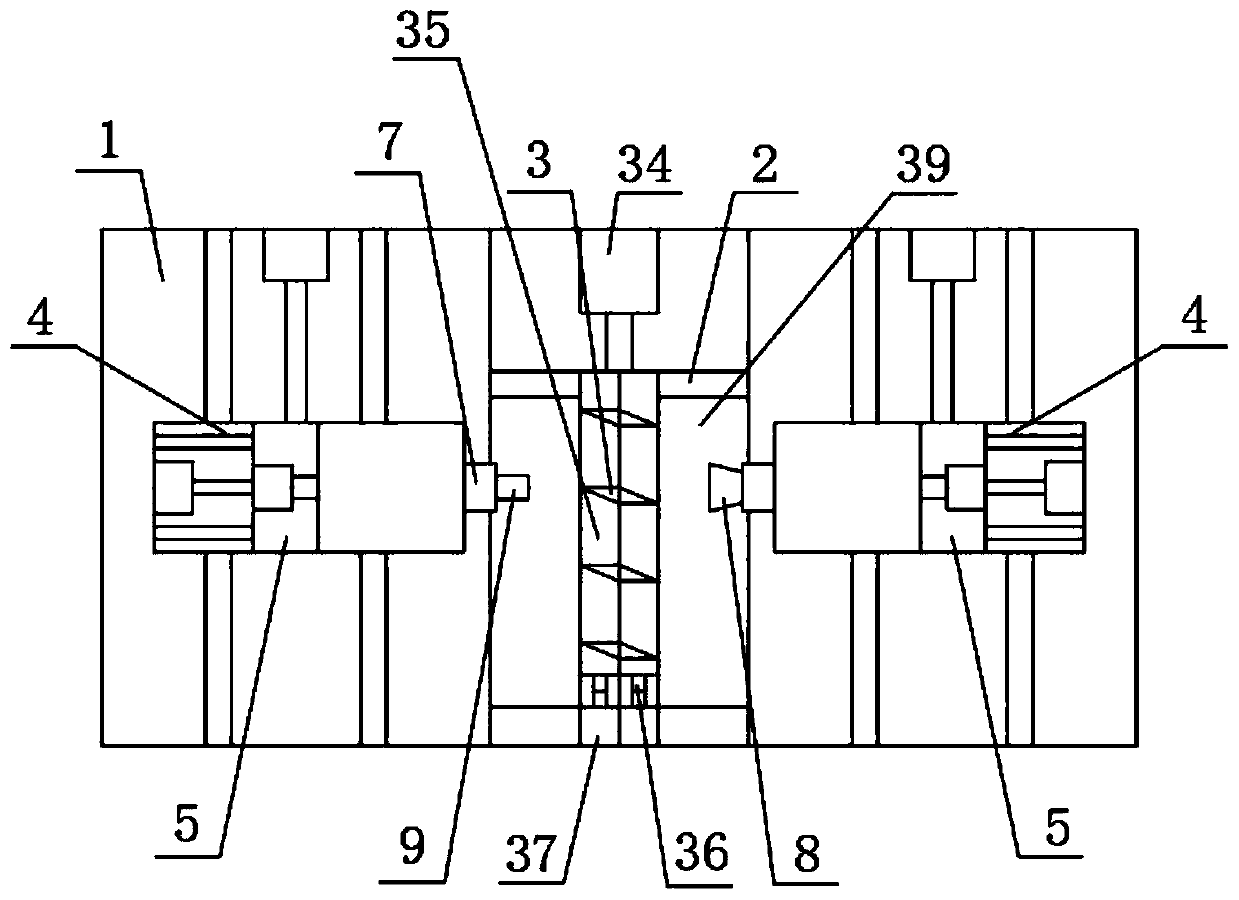

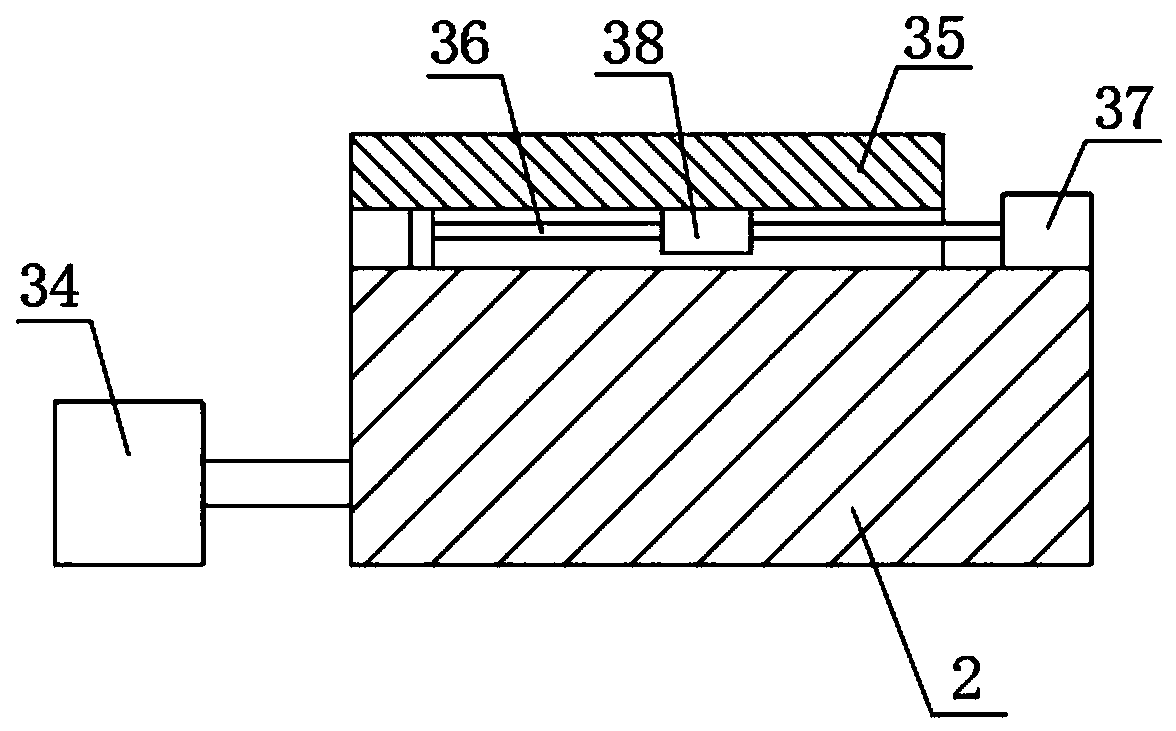

[0024] Example. Dockable automatic dual-spindle CNC machine tool for polygon turning, constituted as Figures 1 to 7 As shown, including the base 1, the middle part of the base 1 is provided with a knife row seat 2, and both sides of the top of the knife row seat 2 are fixed with a row of knives 3; Sliding seat 4, each horizontal sliding seat 4 is all horizontally slidably set with base 1, and the sliding direction of each horizontal sliding seat 4 is all parallel to row knife seat 2; Sliding seat 5, the sliding direction of each vertical sliding seat 5 is all perpendicular to row tool holder 2; One end of the tool holder 2 is respectively fixed with an outer chuck 8 and an inner support chuck 9; the base 1 is provided with an outer cover 10 at the positions corresponding to both sides of the row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com