Wafer cutting tool and method for cutting wafer by using same

A technology for cutting tools and wafers, used in manufacturing tools, work accessories, stone processing equipment, etc., can solve the problems of difficulty in determining the position of the cutting line, inaccurate cutting, etc., to achieve diversified motion trajectories, low cost, and a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

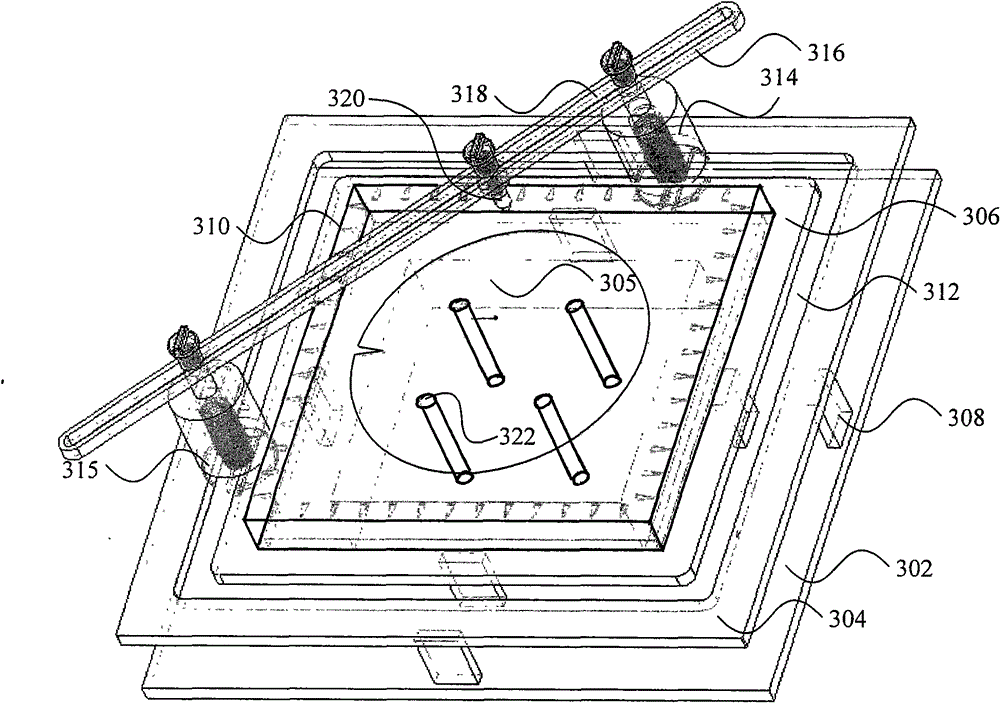

[0038] image 3 It is a schematic structural diagram of a wafer cutting tool according to an embodiment of the present invention. The wafer cutting tool includes: a tool base 302; a peripheral support 304 and a wafer carrier 306, which are respectively connected to the tool base 302 through pillars 308 , at least one of the peripheral bracket 304 and the wafer carrier 306 has a scale 310 around it, the peripheral bracket 304 surrounds the outer side of the wafer carrier 306, and leaves a gap between the wafer carrier 306 , as a slider track 312; sliders 314, 315 can slide along the slider track 312; a slider 316 has an inner groove 318, and the inner groove 318 is sleeved on the sliders 314, 315, so that the Slide bar 316 can slide on the line direction of two slide blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com