Creasing inspection device and method thereof

A technology of inspection device and indentation, applied in the direction of measuring device, instrument, electrical components, etc., can solve problems such as difficult inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

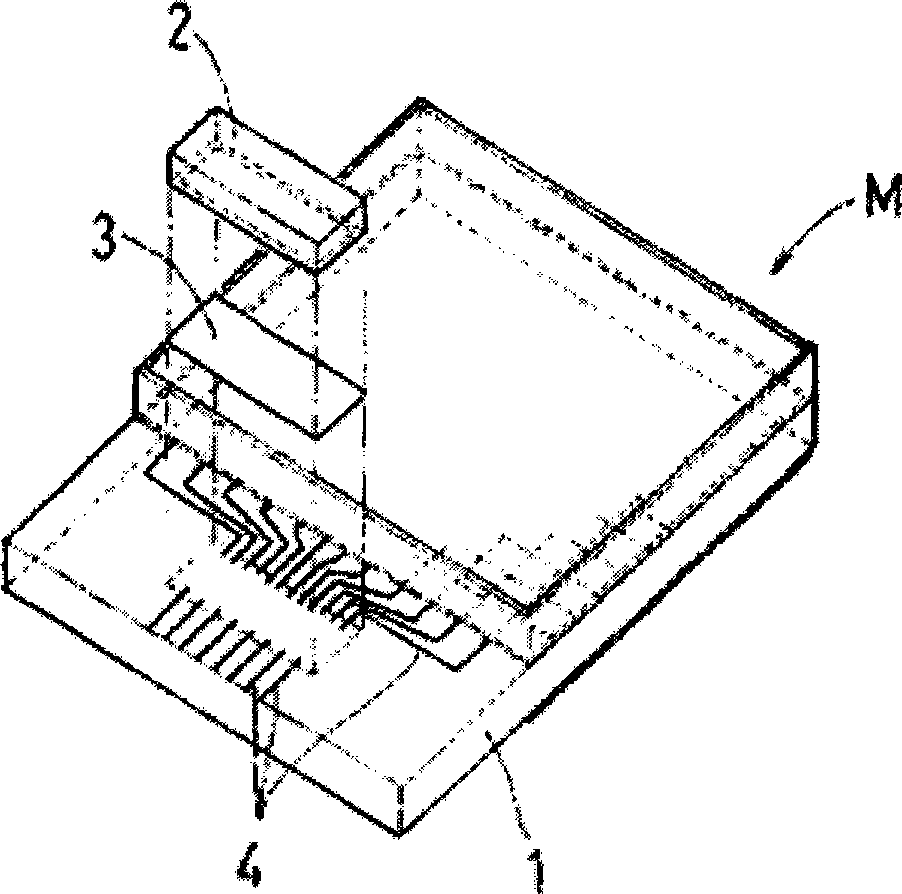

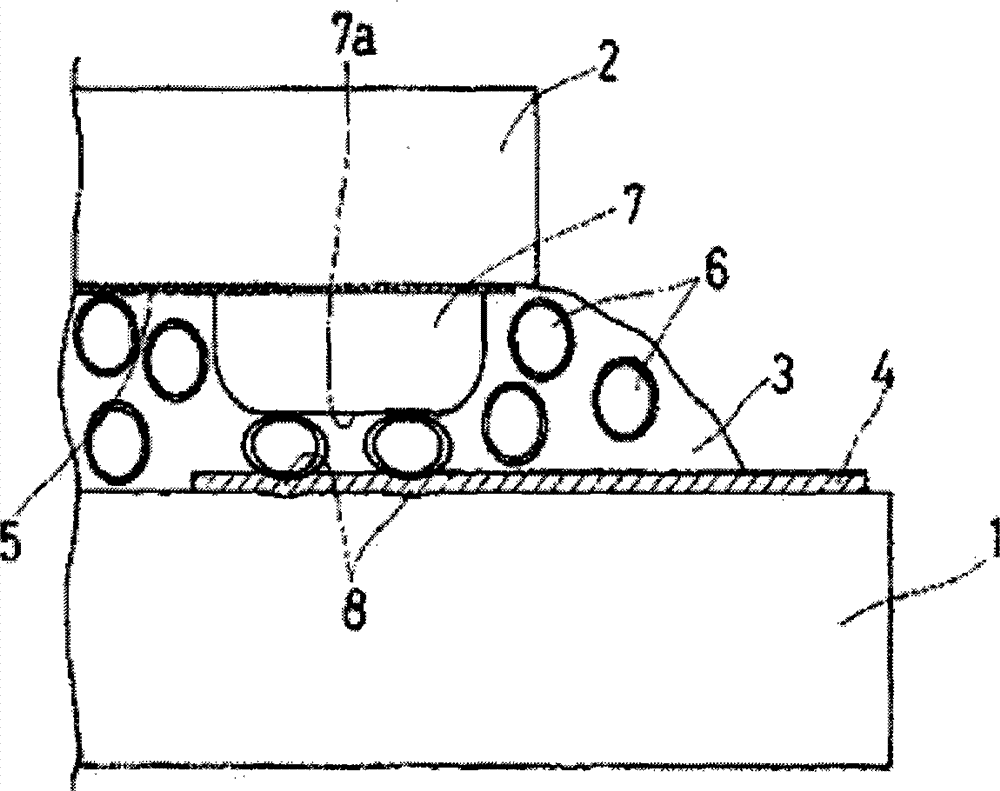

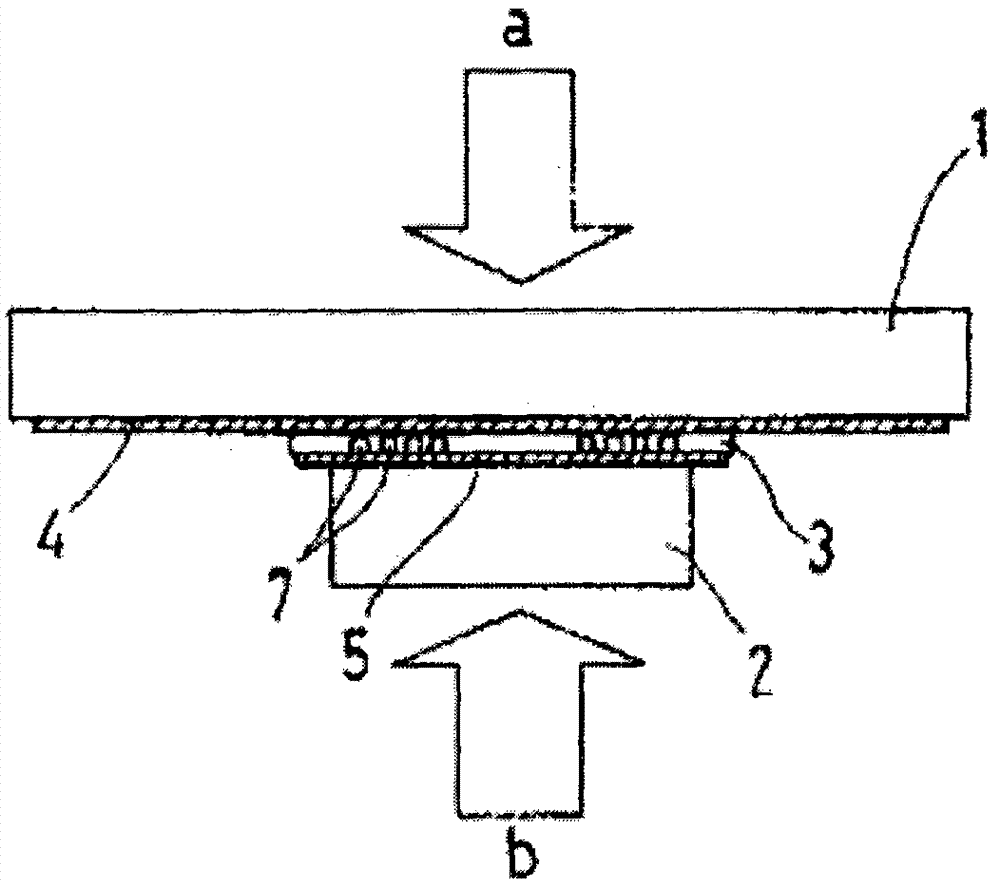

[0026] Hereinafter, an indentation inspection device and a method thereof according to preferred embodiments of the present invention are explained with reference to the accompanying drawings.

[0027] Take, for example, a flat panel display panel employing only a COG method among various wireless bonding methods including chip-on-glass (COG), chip-on-film (COF), flexible printed circuit board (FPC), and tape carrier package (TCP).

[0028] Therefore, the substrate to be inspected is a glass substrate.

[0029] Figure 4 It is a configuration diagram schematically showing an indentation inspection device according to the present invention. Figure 5 is a block diagram showing an inspection portion of an indentation inspection device according to the present invention. Figure 6 A method for selecting the inspection area of the indentation inspection device according to the present invention is schematically shown. Figure 7 A method for inspecting indentations by the inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com