Core pulling machine for plastic electric-fusing pipe

An electrofusion pipe fitting and core pulling machine technology is applied in the field of machines for processing plastic electrofusion pipe fittings, and can solve the problems of troublesome operation, high manufacturing cost, complex manipulator structure and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

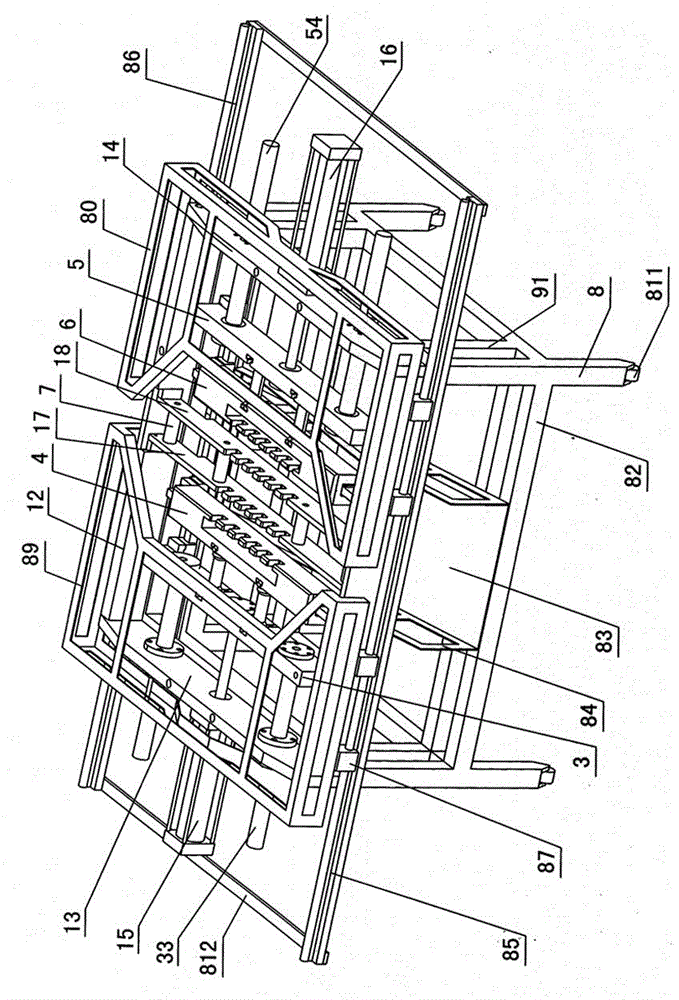

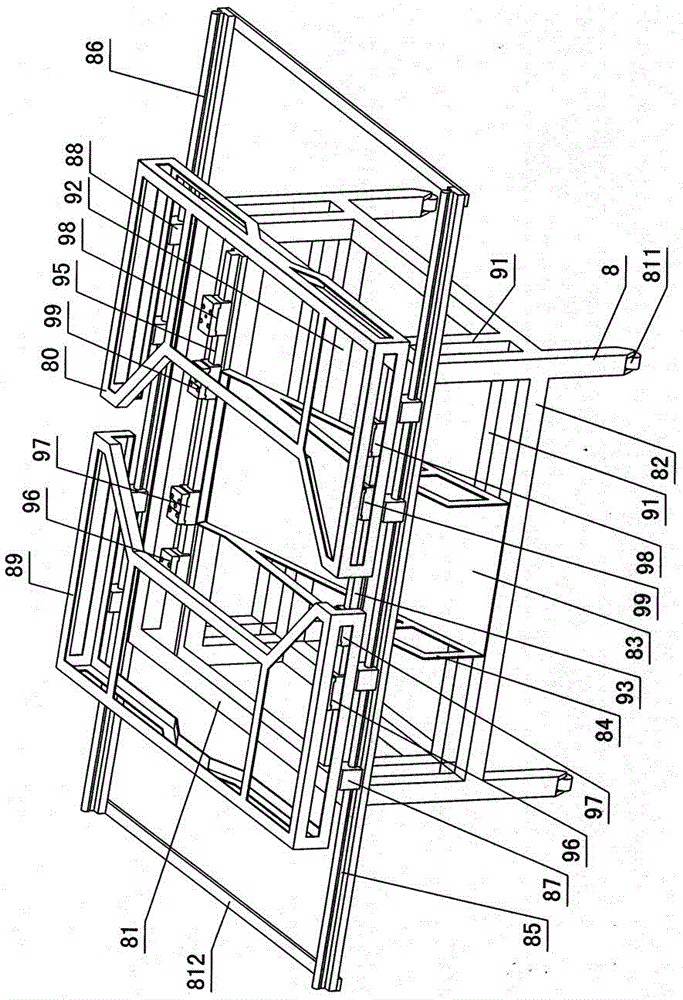

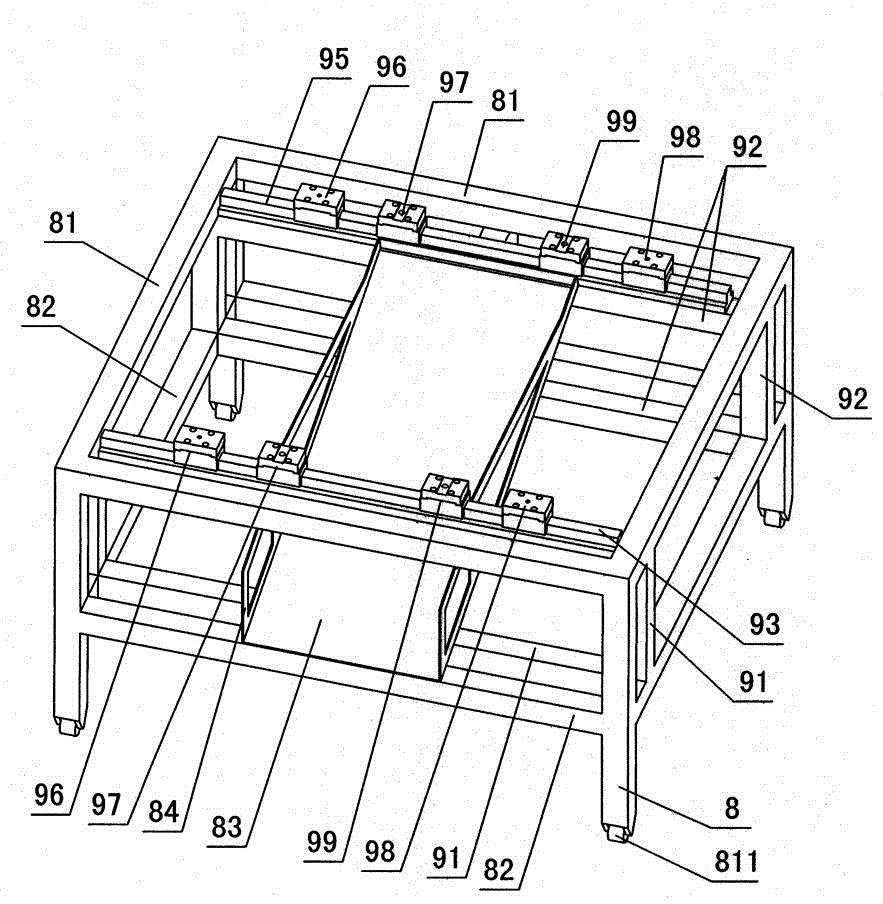

[0016] The invention relates to a core pulling machine for plastic electrofusion pipe fittings, such as figure 1 — Figure 9As shown, it is characterized in that it includes a fixed frame and a core-pulling mechanism. The fixed frame includes a support foot 8, an upper bracket 81 and a lower bracket 82 are formed on the support feet, and a front bracket is formed between the upper and lower brackets. Mounting frame 91 and rear mounting frame 92, front slideway 93 is installed on the front mounting frame, rear slideway 95 is installed on the rear mounting frame, the first left slide block 96, the second left slide block 97, the second left slide block 97, respectively are installed on the front and rear slideways. The first right slide block 98 and the second right slide block 99, a blanking hopper 83 is installed between the front slideway, the rear slideway and the lower support 82, the left and right sides of the blanking hopper are shaped on a fixed plate 84, and the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com