Patents

Literature

58results about How to "Rotation doesn't happen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

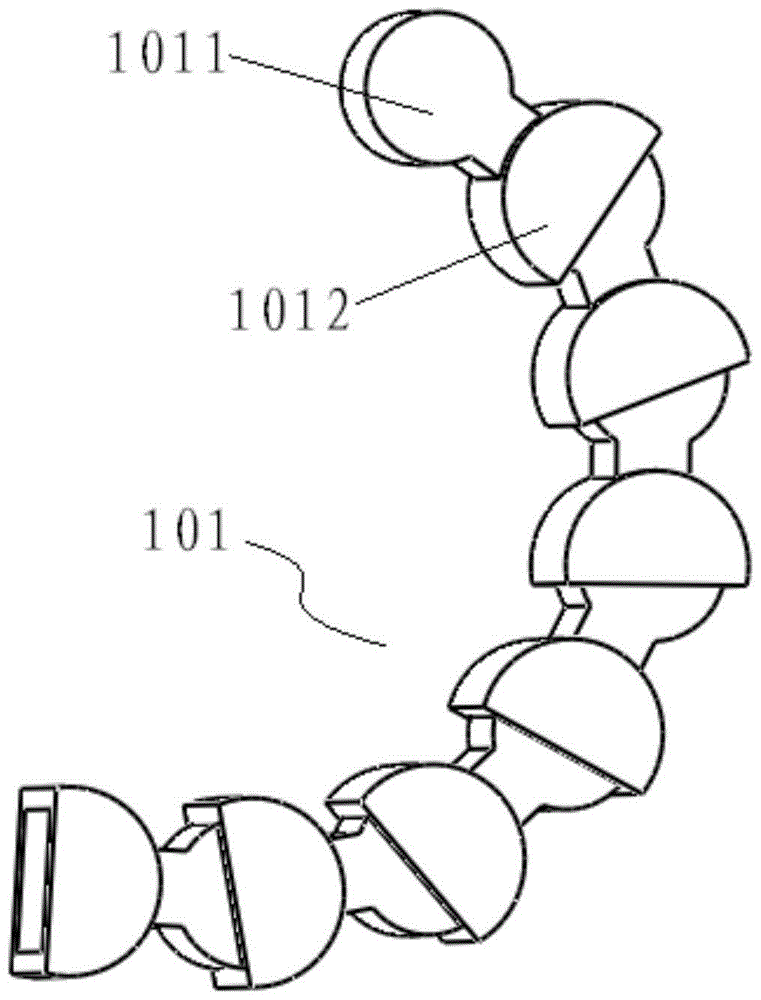

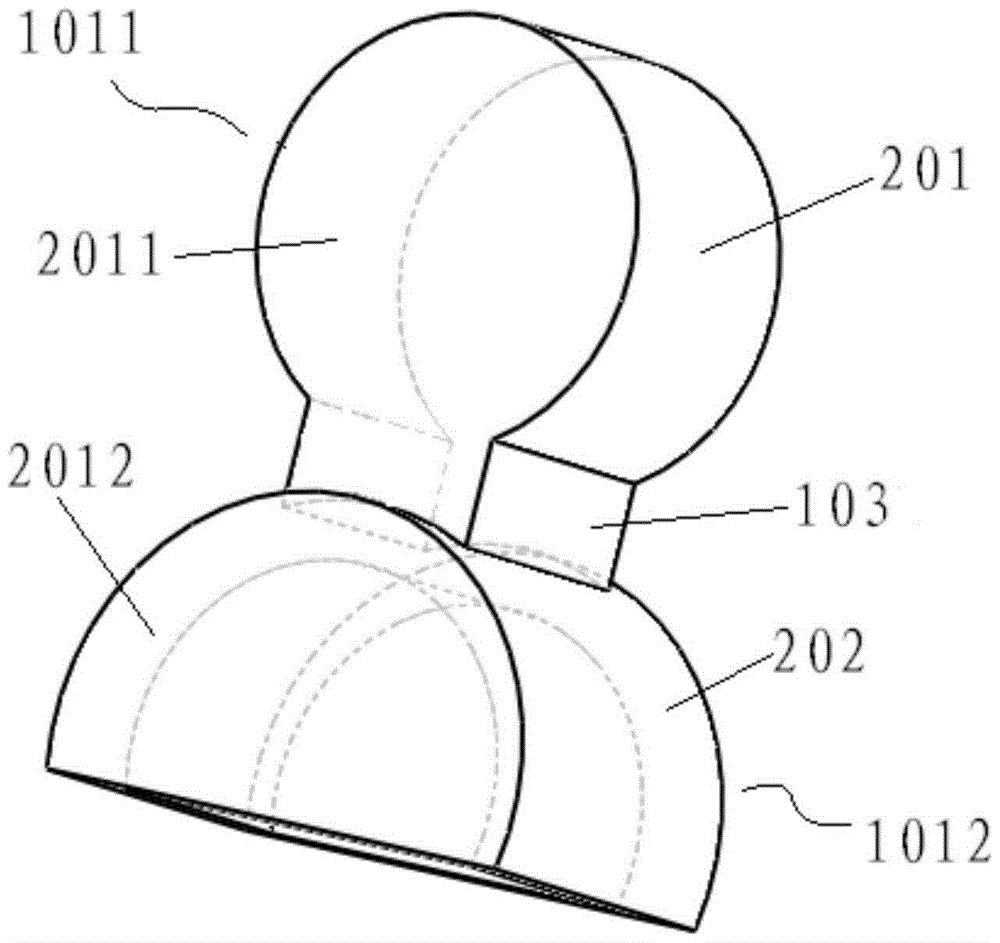

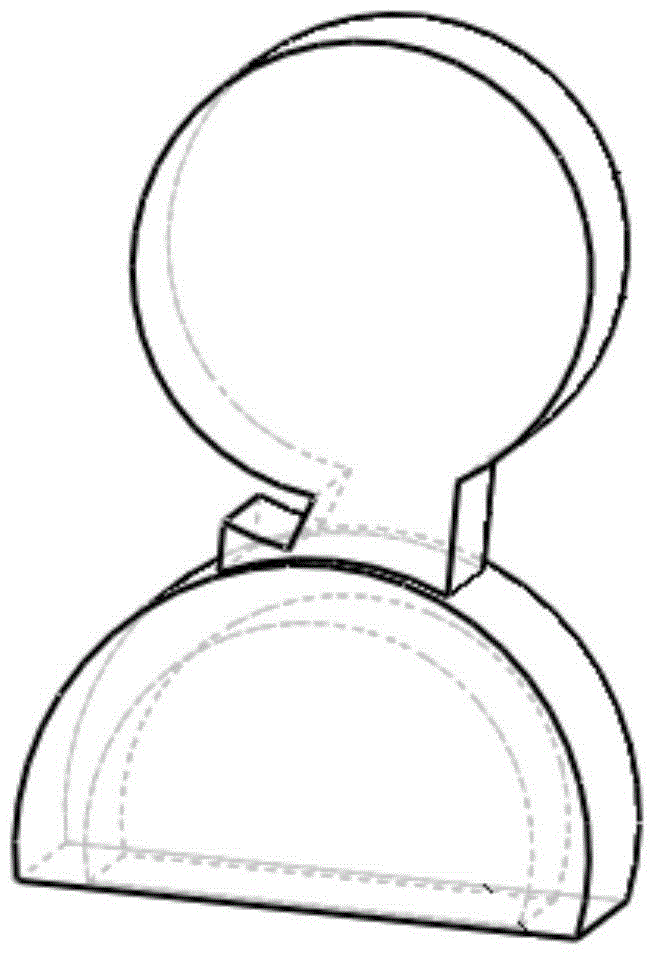

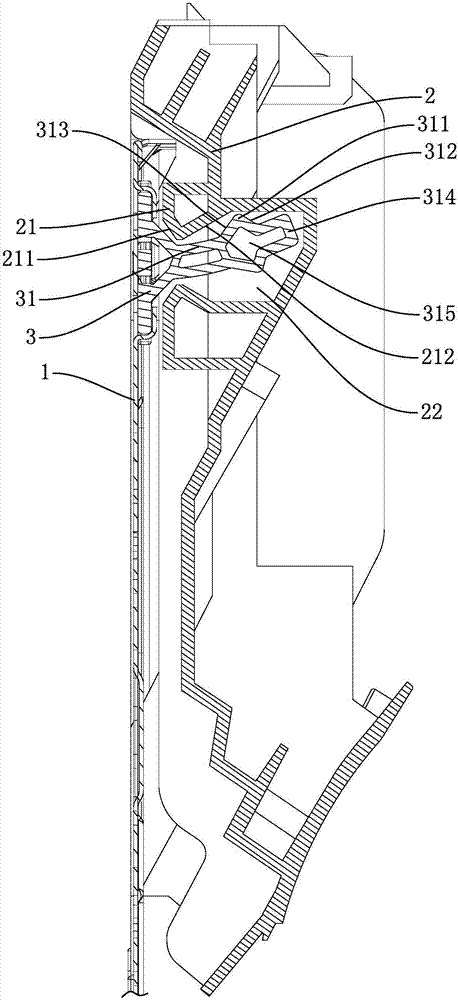

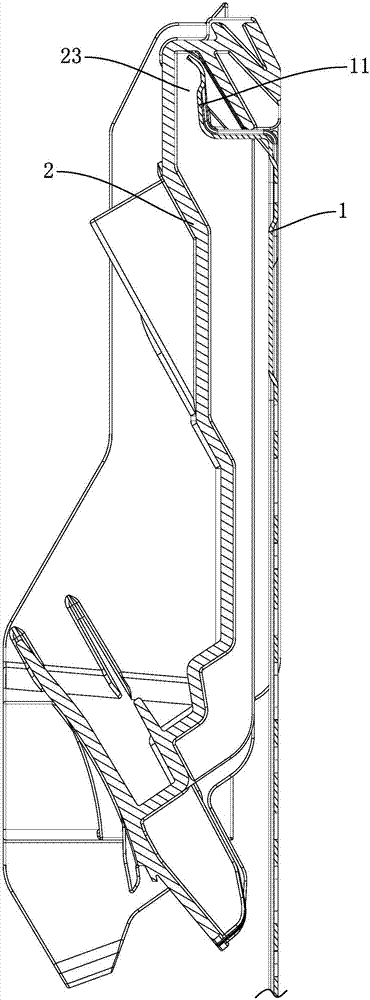

Flexible display device support device and flexible display

ActiveCN105185231AStable supportAvoid damageCasings with display/control unitsStands/trestlesComputer hardwareDisplay device

The invention provides a flexible display device support device and a flexible display. The support device comprises a framework chain connected by a plurality of framework units. Each framework unit comprises a head and a tail which are connected, wherein the head is provided with a first rotary face, the first rotary face is a cylindrical curved face or a spherical face; the tail comprises a cavity for accommodating the head of the adjacent framework unit, and the cavity is provided with a second rotary face matched with the first rotary face; the radius of the first rotary face is larger than that of the second rotary face, the second rotary face wraps part of the first rotary face of the adjacent framework unit to allow the head of the adjacent framework unit to be matched with the cavity of the tail and be capable of rotating relative to the cavity of the tail. The flexible display comprises a flexible display screen and is characterized by further comprising the flexible display device support device provided by optional one embodiment of the invention, and the flexible display screen is connected with the framework chain.

Owner:BOE TECH GRP CO LTD

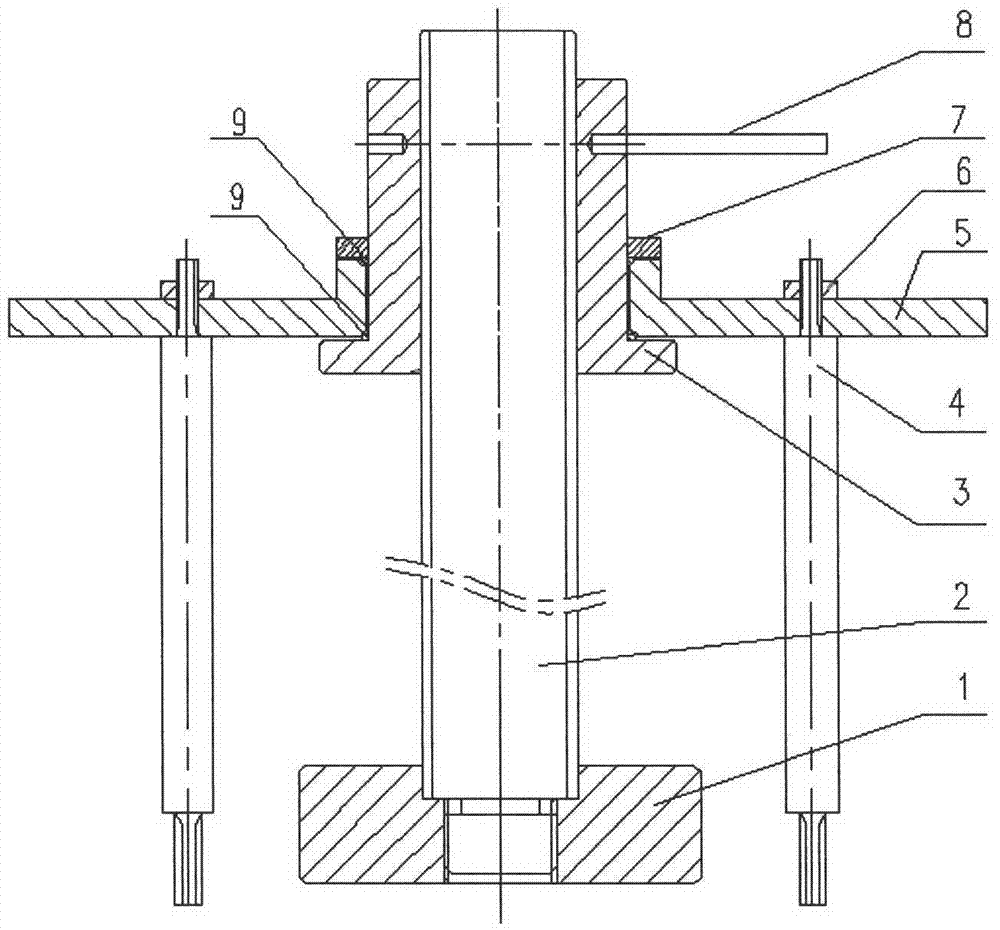

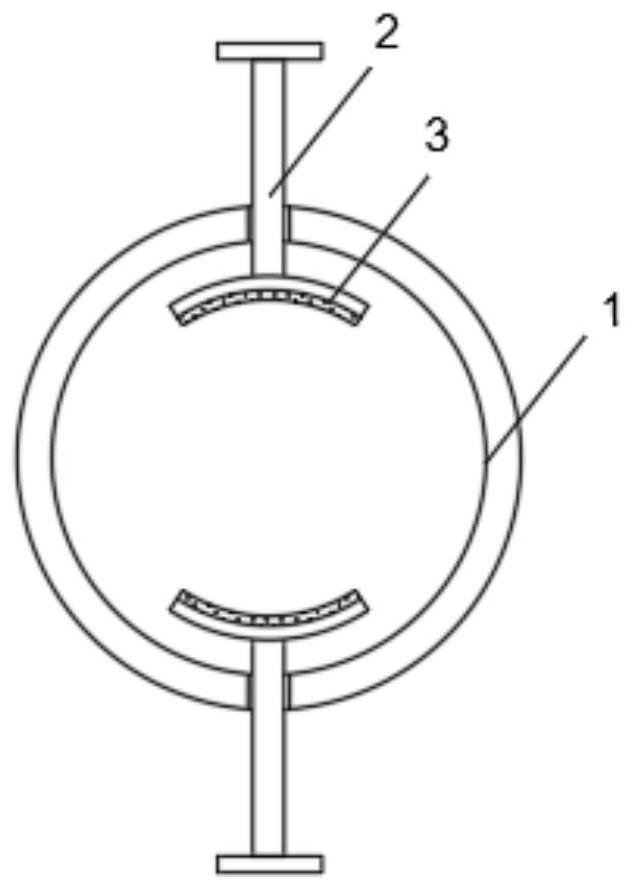

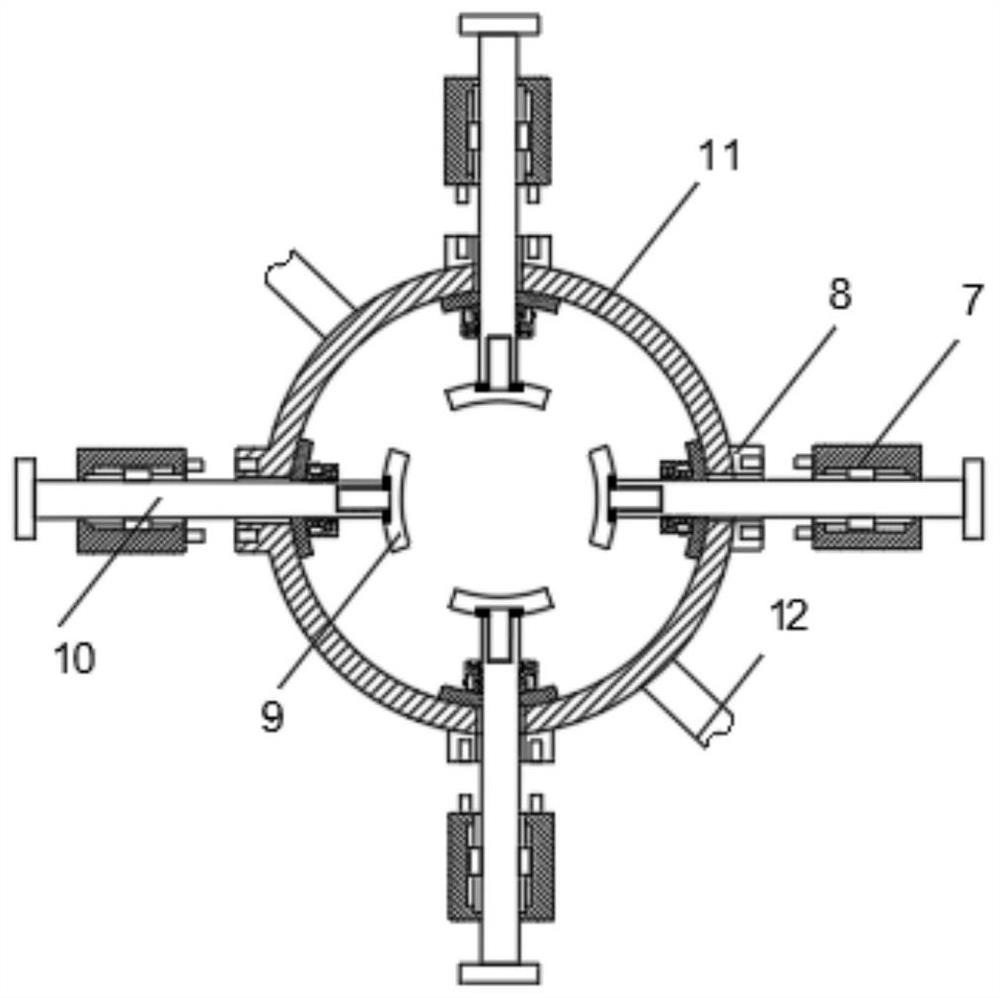

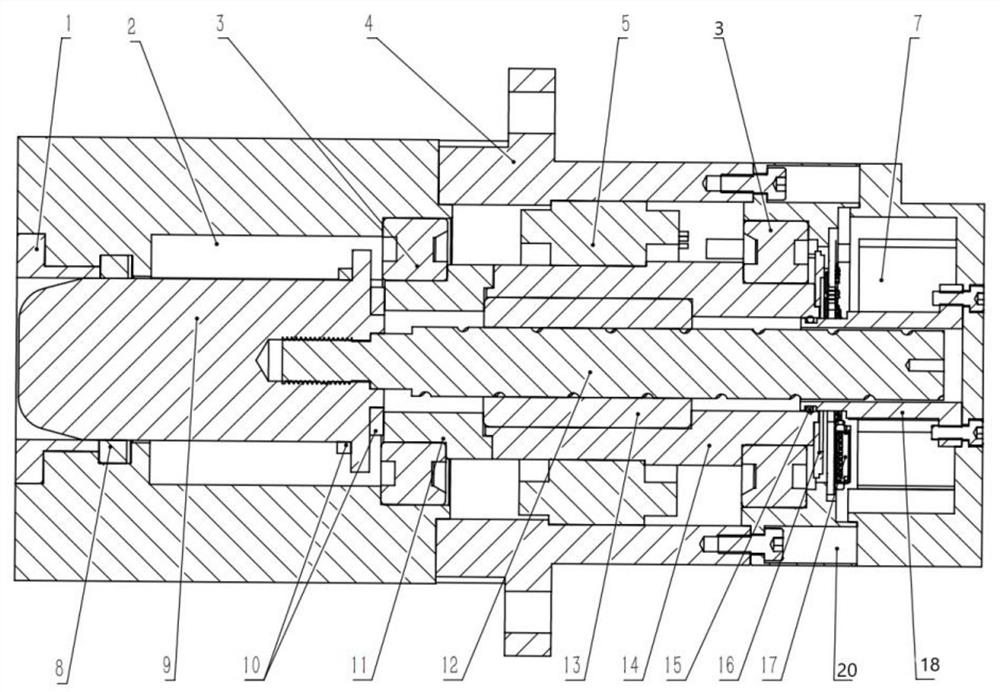

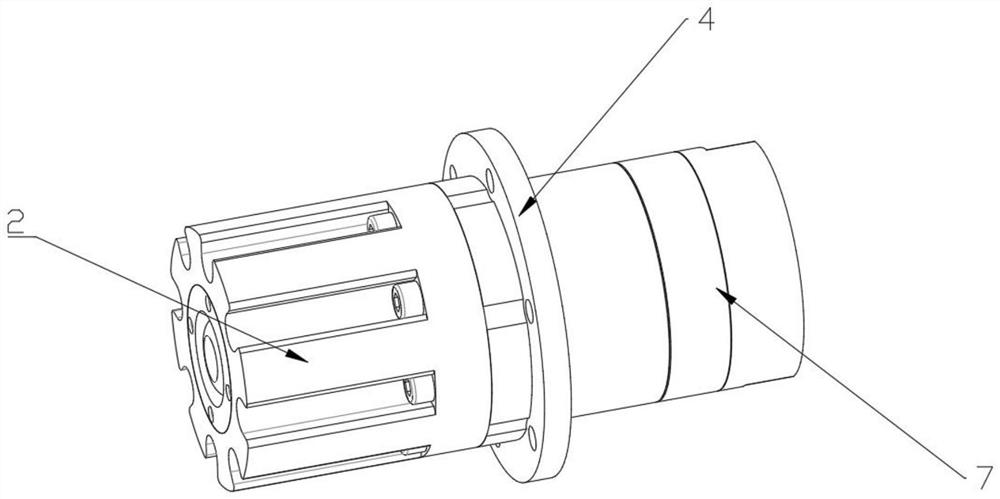

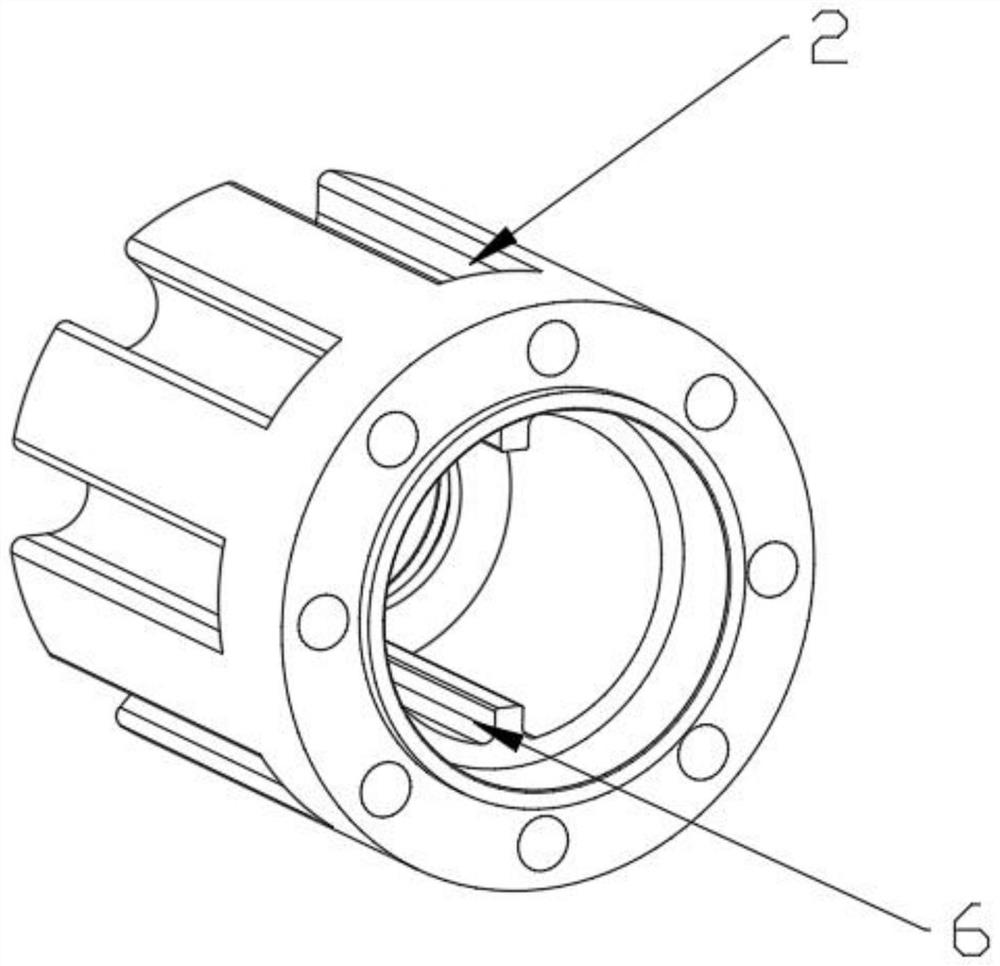

Tool for assembling photoelectric turntable motor

ActiveCN102780326ASolve assembly problemsRest assured to achieveManufacturing dynamo-electric machinesSteel ballEngineering

The invention discloses a tool for assembling a photoelectric turntable motor, which belongs to the technical field of mechanical assembling. The tool is mainly and technically characterized in that a centering mandrel is in matched connection with a dead axle sunken platform of a photoelectric turntable, a lifting lead screw is in matched connection with the centering mandrel, so a reference center is provided for the tool; the two ends of a central hole of a projection cylinder of a cross plate are respectively provided with a conical surface with a circle of steel balls, so the cross plate, the lifting lead screw, a lifting nut and a pressing ring form a rotating shaft system; and one ends of four draw bars are fixedly connected with four narrow plates of the cross plate, the other ends of the four draw bars are fixedly connected with a motor stator, one end of a lever is connected with the lifting nut, and the motor stator can be lifted and descended through pushing the lever to be accurately installed in a dead axle of the photoelectric turntable. The tool is used for solving the problems of conveniently and reliably mounting the photoelectric turntable motor, and has the characteristics of simple structure, convenience in carrying, high working efficiency and the like.

Owner:中国兵器工业第二0五研究所

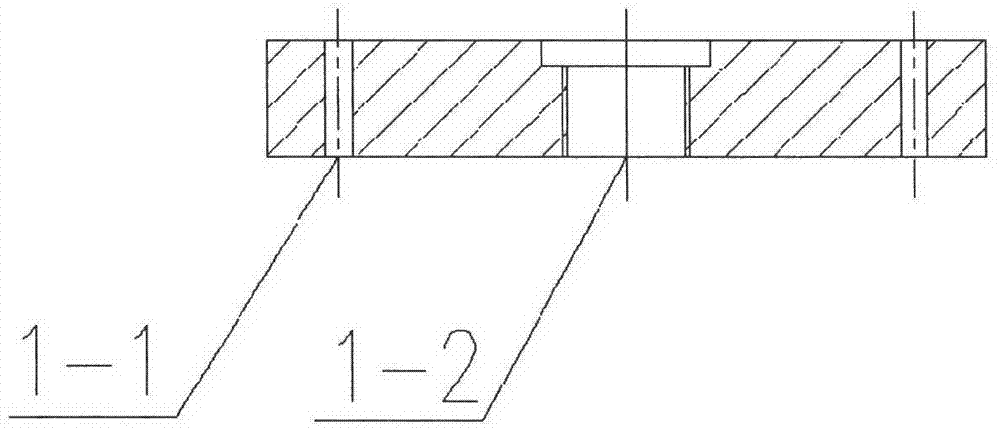

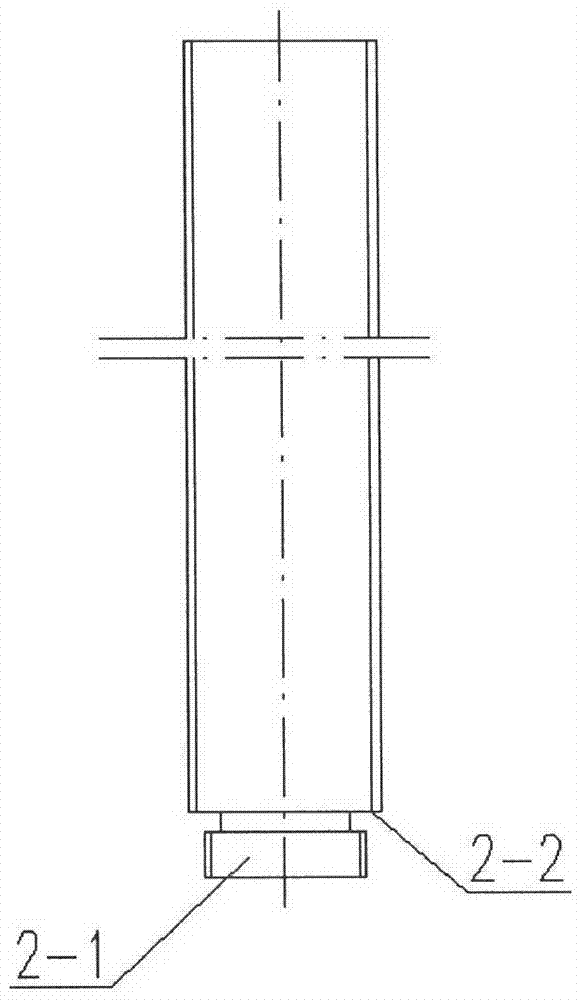

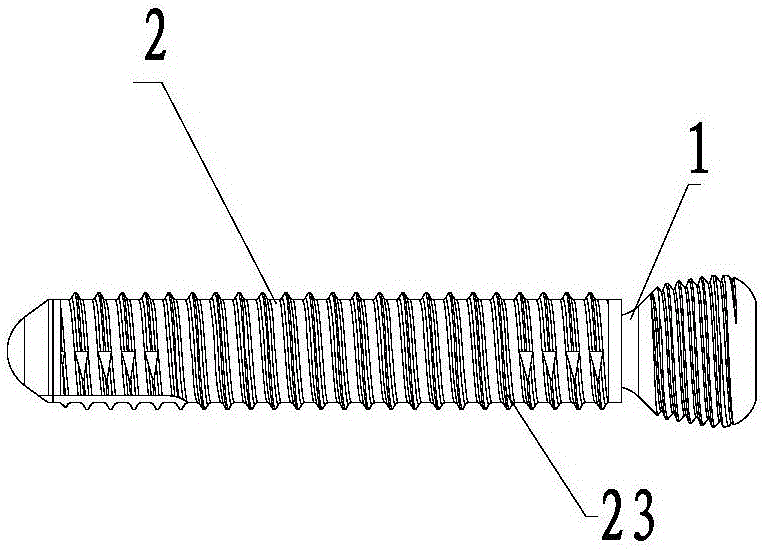

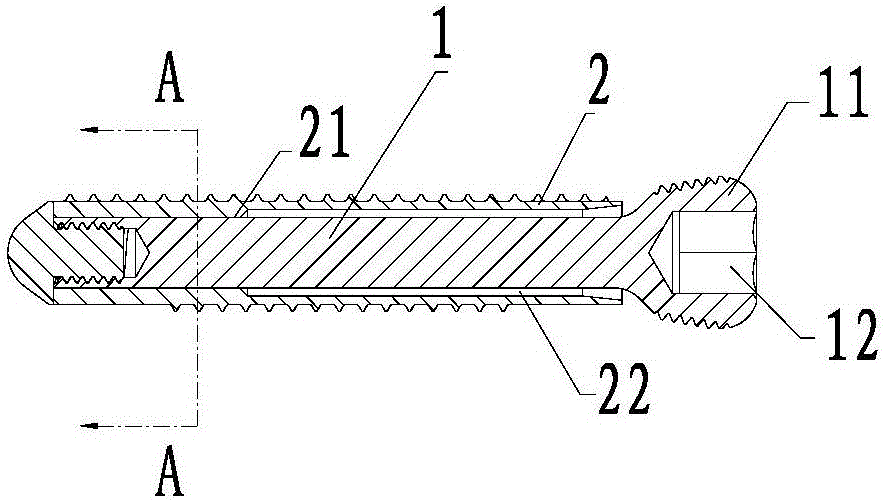

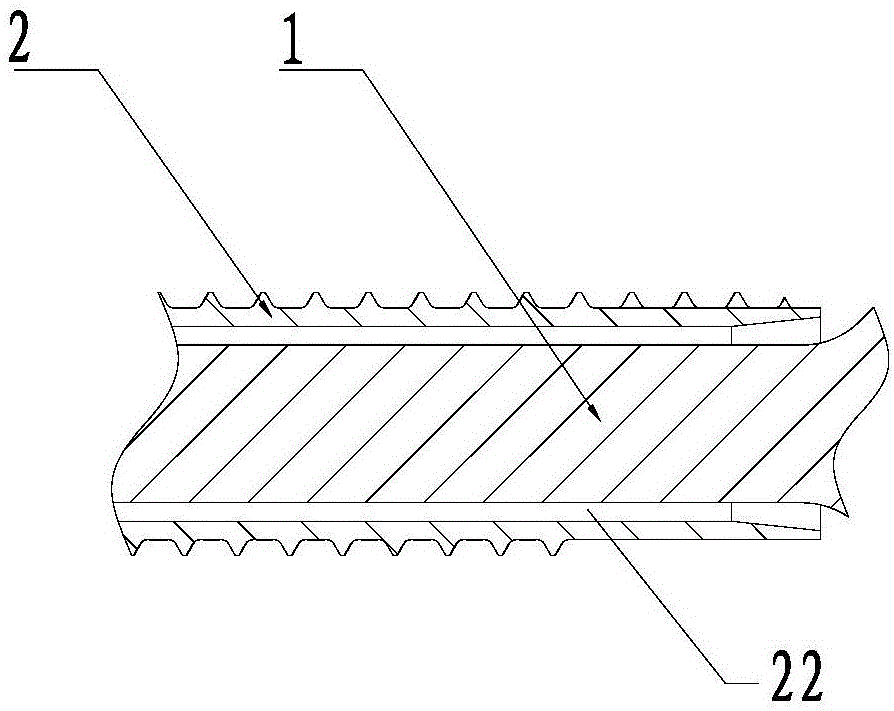

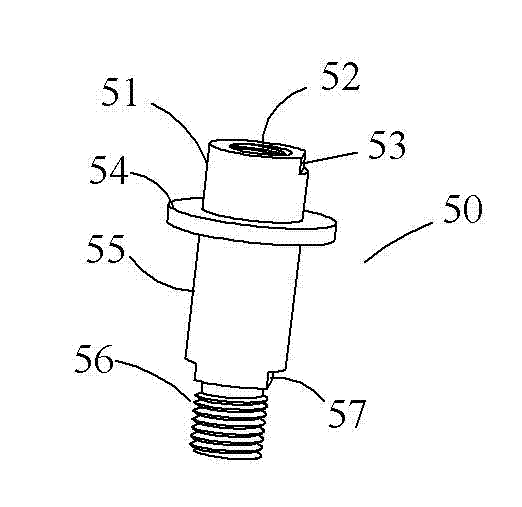

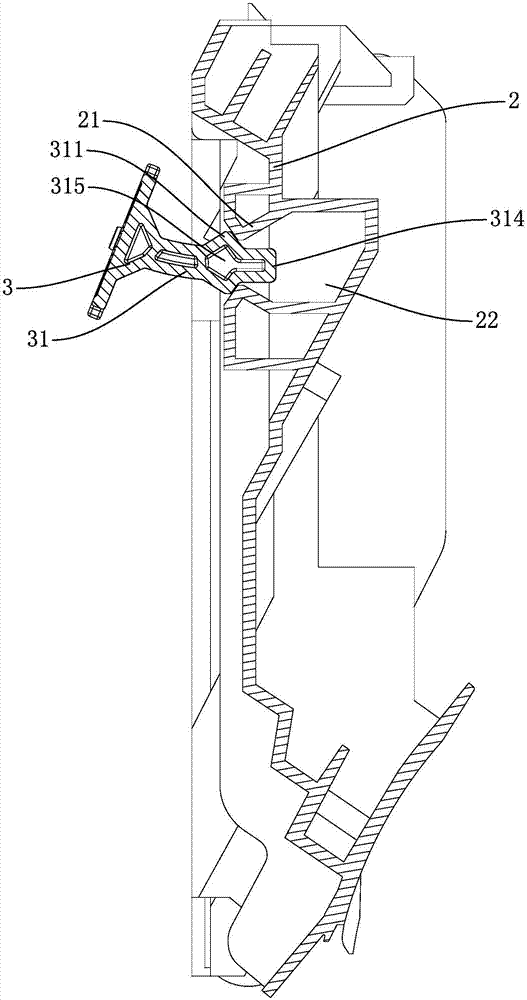

Elastic bone screw

The invention provides an elastic bone screw. At the position where an elastic rod and a limiting sleeve are fixedly connected, ribs distributed at intervals are arranged at the circumstantial direction, and the ribs protrude outward toward the direction close to the limiting sleeve; an inserting groove of the limiting sleeve forms concave grooves in the position corresponding to the ribs; when the elastic rod is fixedly connected to the limiting sleeve, the ribs and the grooves mesh in the rotating direction of the elastic rod to form a cooperatively limited helix resistance structure, and thus when the elastic rod rotates, no relative motion is conducted between the elastic rod and the limiting sleeve in the rotating direction; the elastic rod is inserted into the part of the limiting sleeve, and the tail end face of the part and the tail end face of the limiting sleeve are subjected to visual welding fixing. Through micro motion of the elastic bone screw, relative motion occurs between a locking plate and a connected bone in the direction parallel with the initial installing position, and healing of the bone is better promoted. Moreover, due to the use of the visual welding, the limiting sleeve and the elastic rod are welded, and the problems in the traditional blind welding process of pseudo soldering and solder skips can be effectively avoided.

Owner:DABO MEDICAL TECH CO LTD

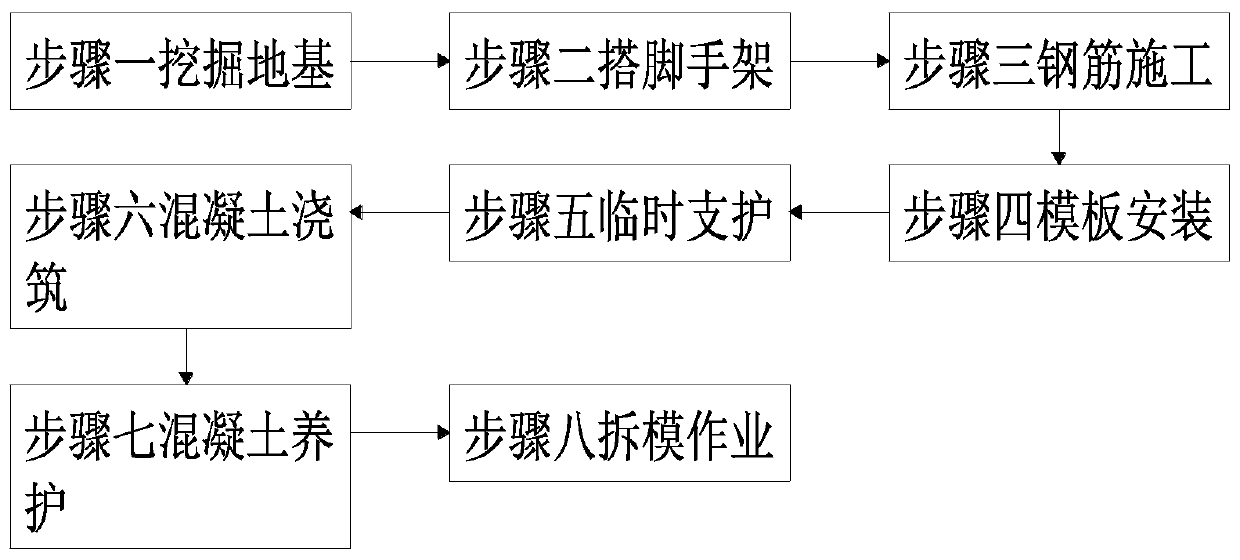

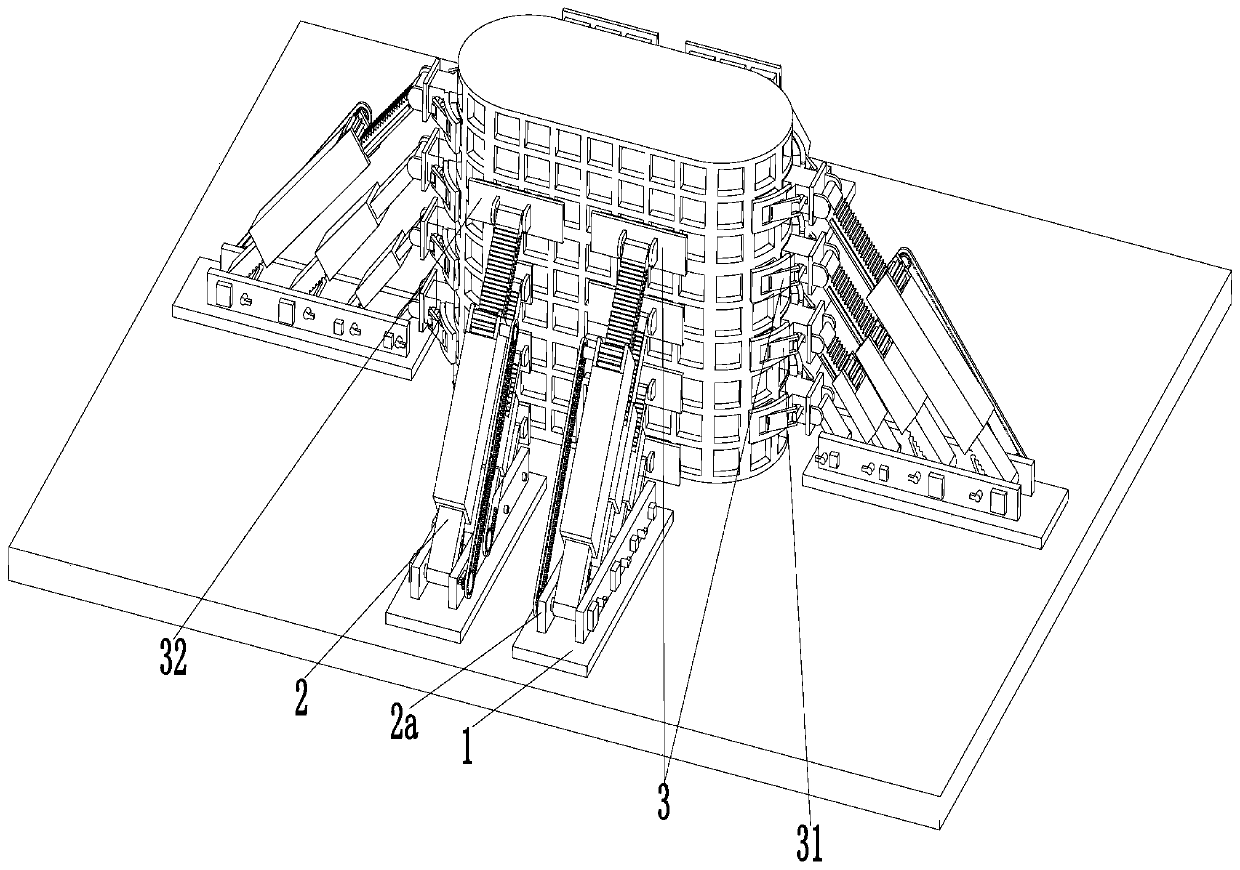

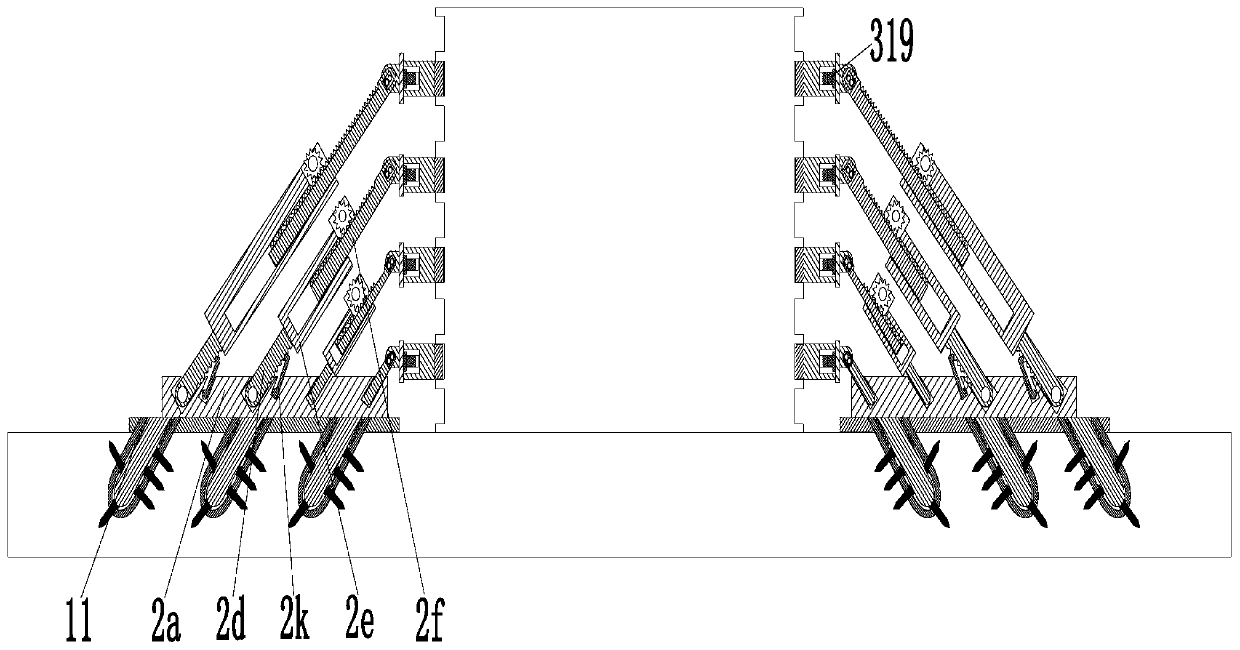

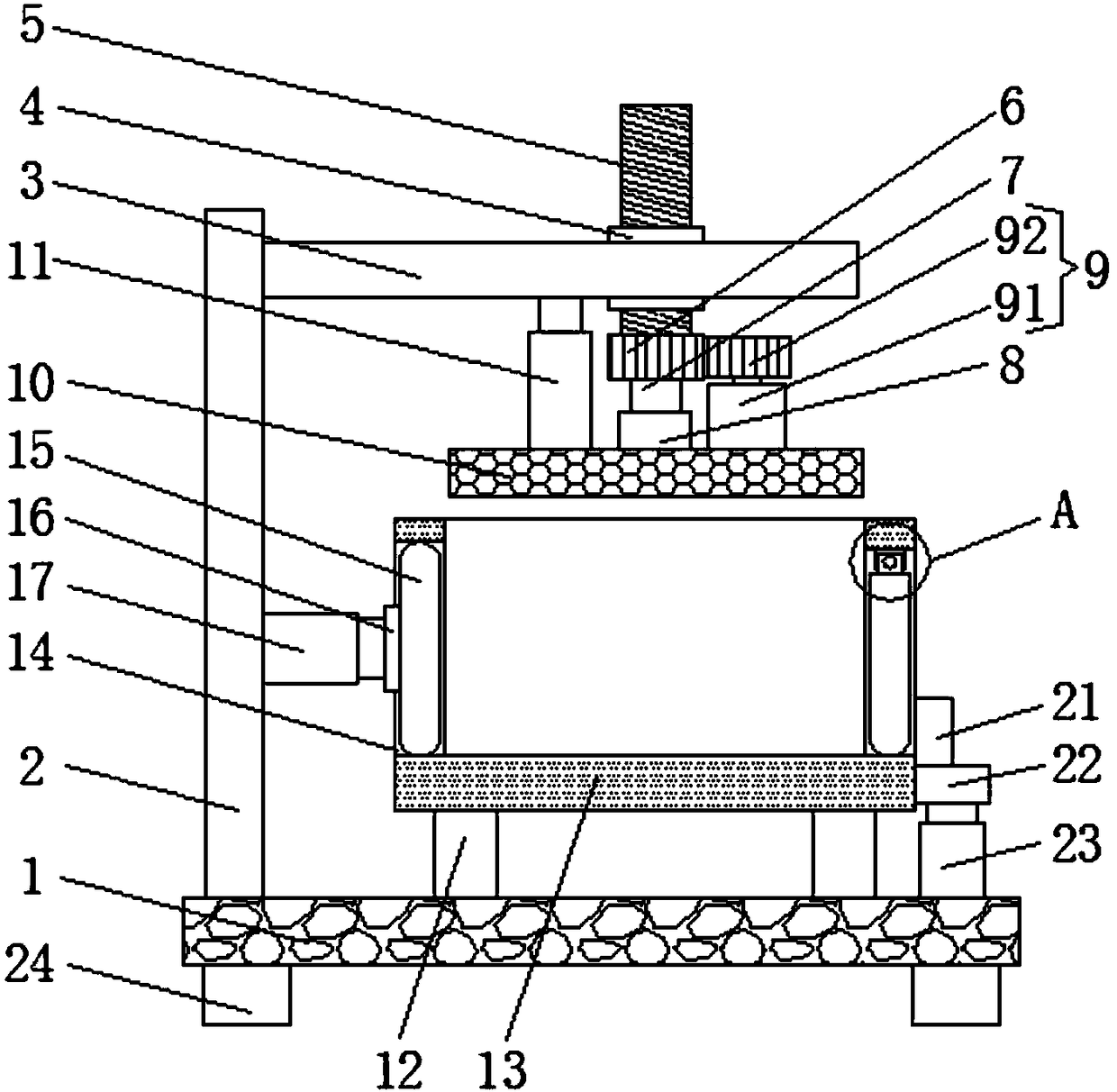

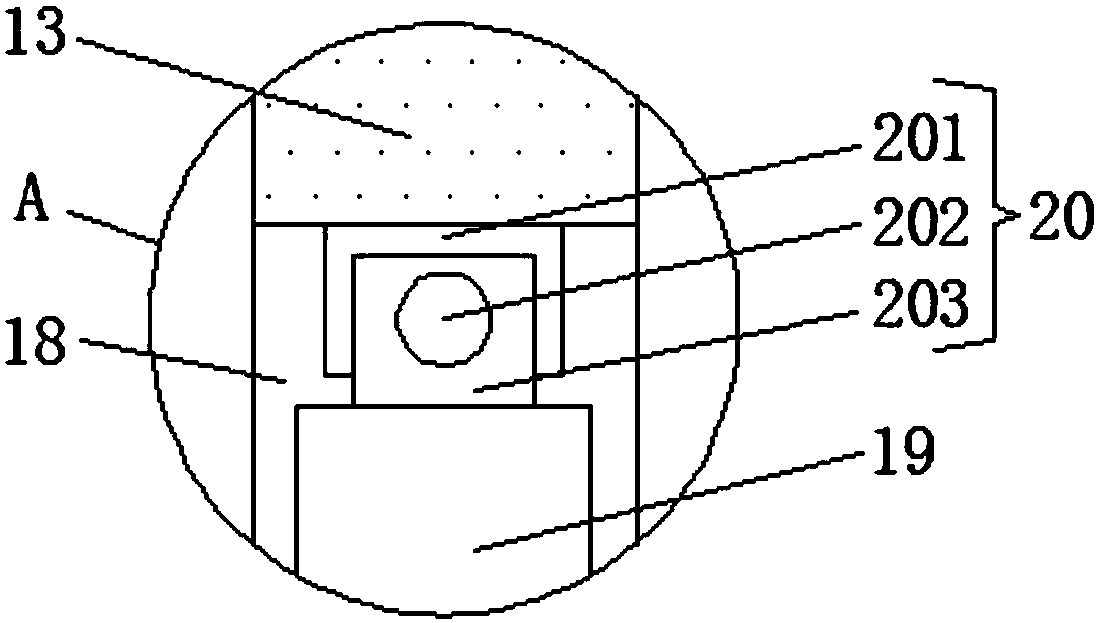

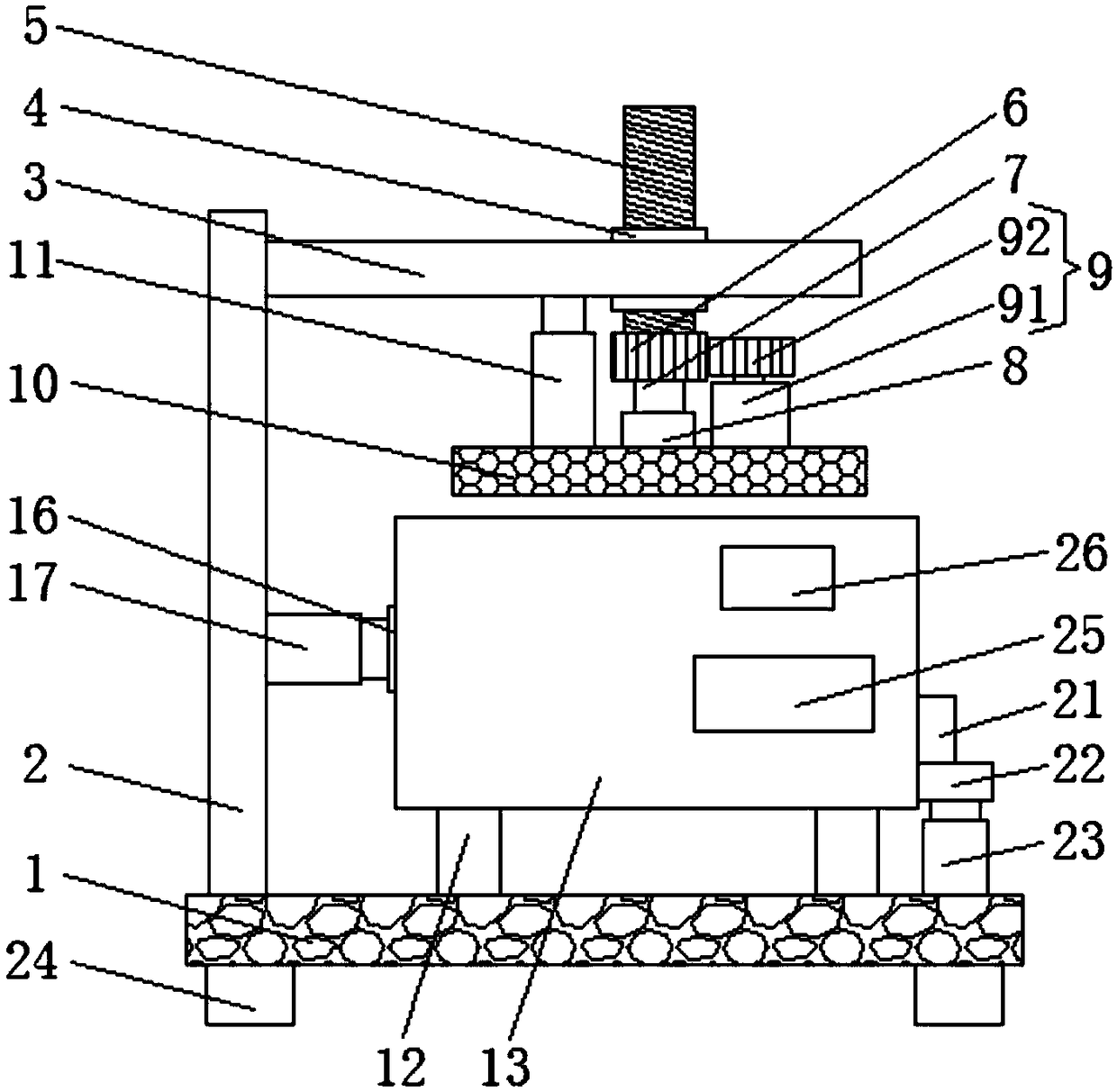

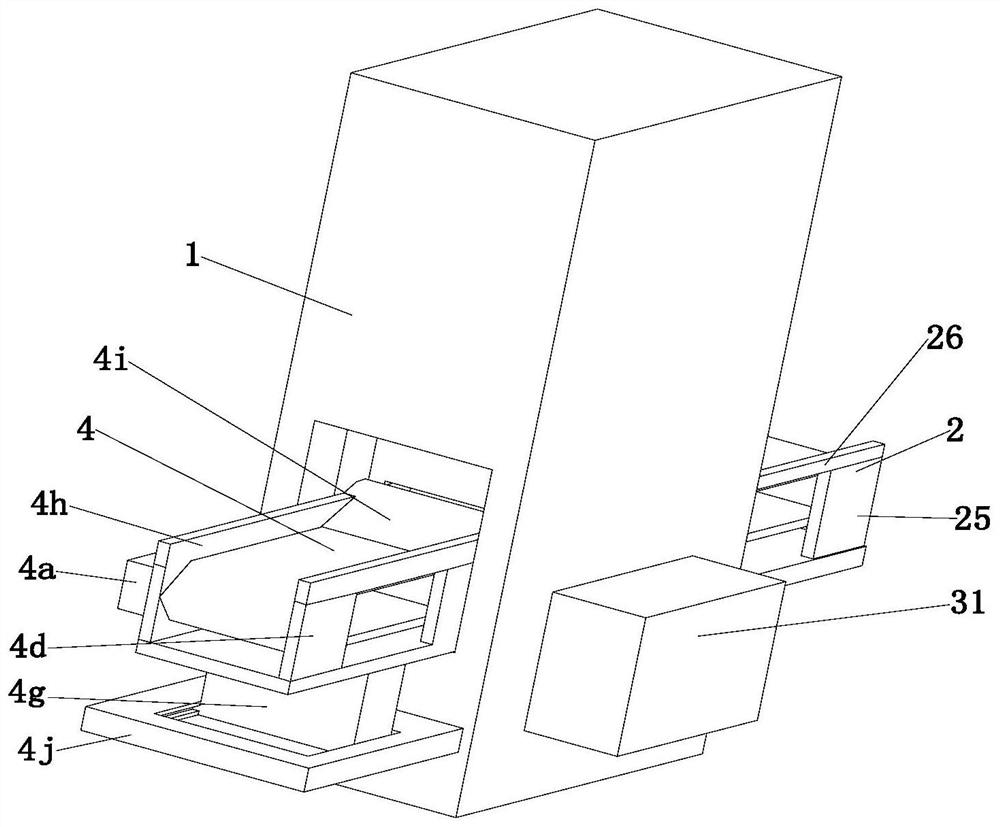

Viaduct pier construction method

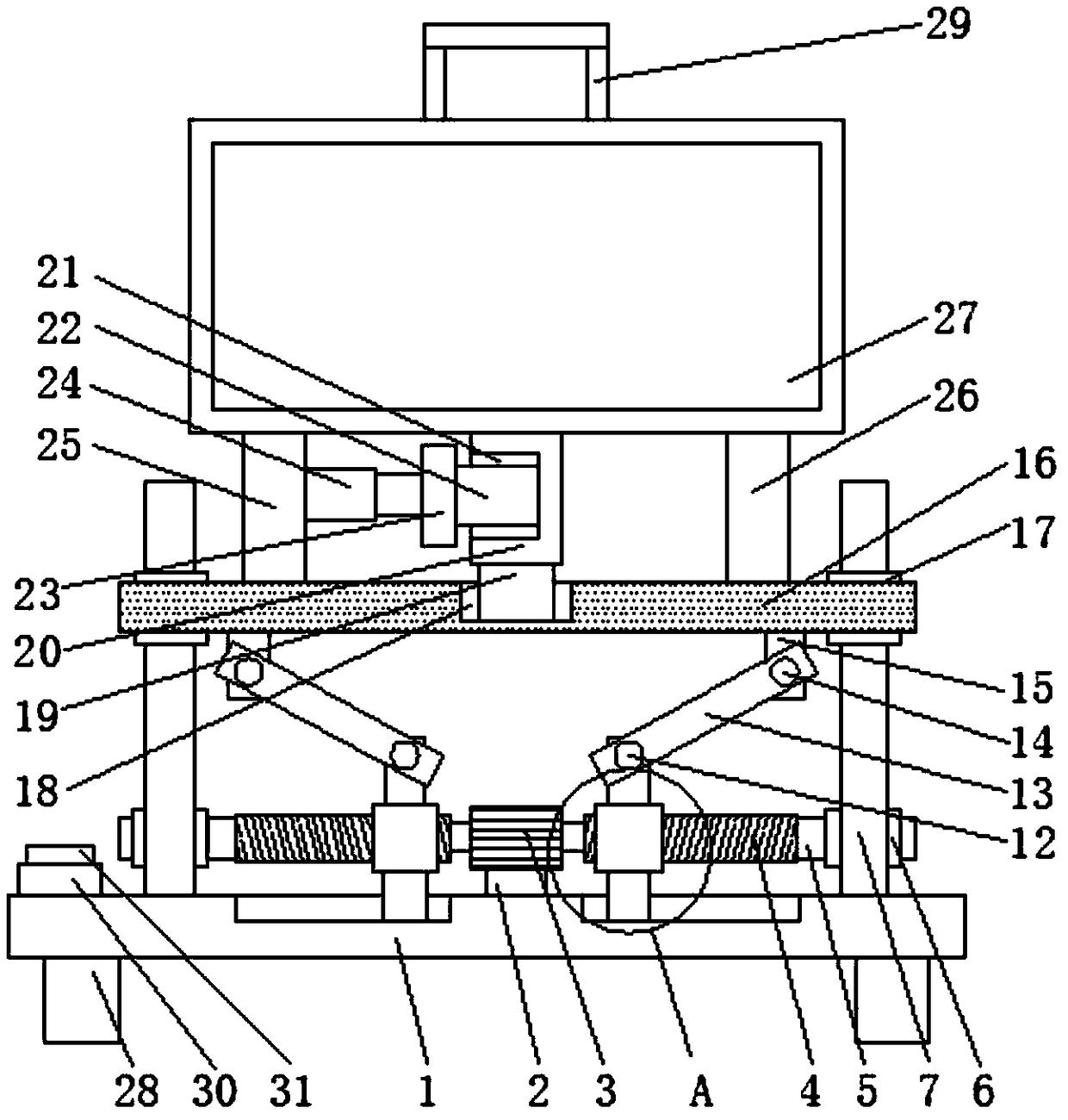

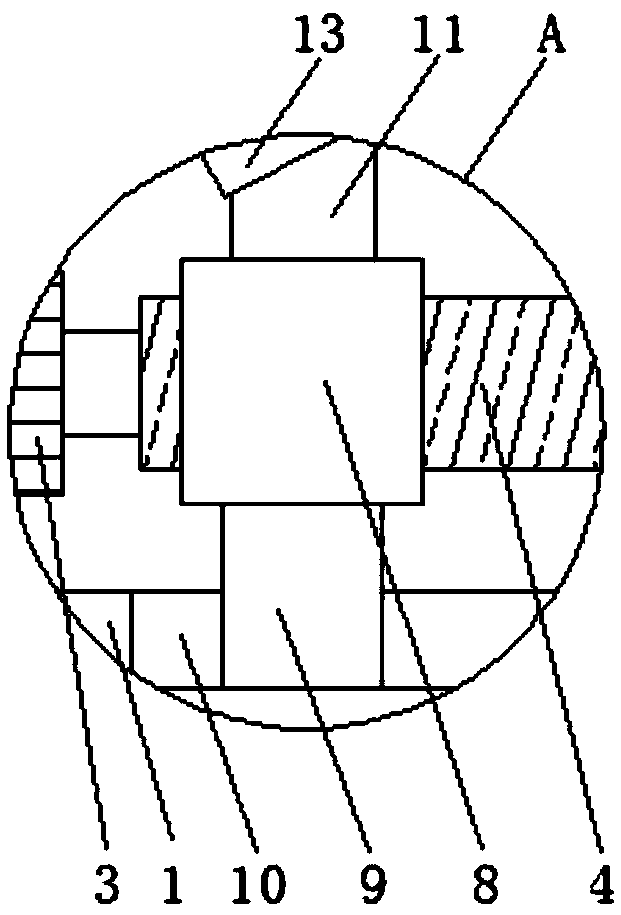

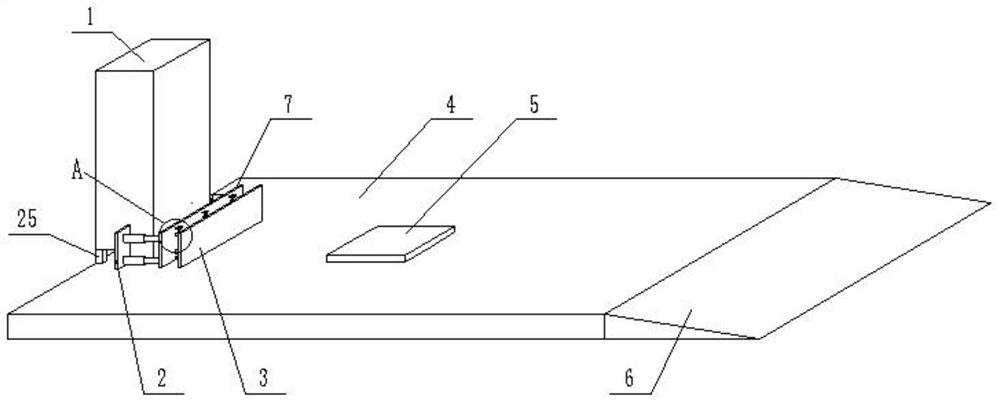

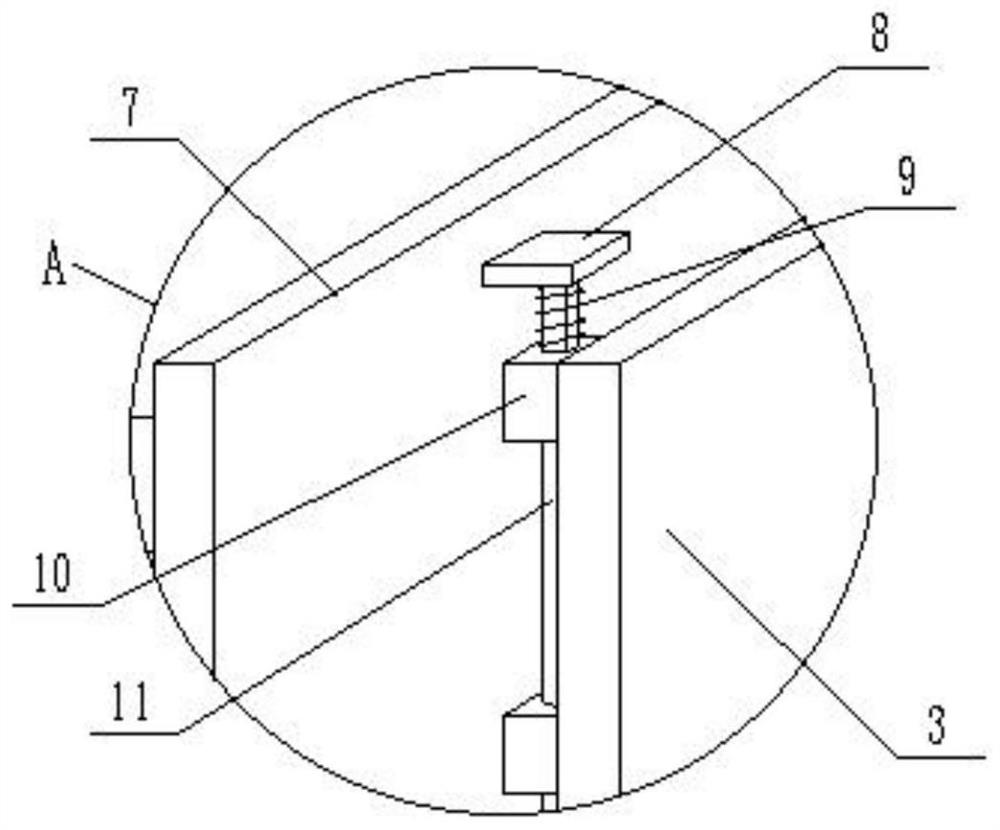

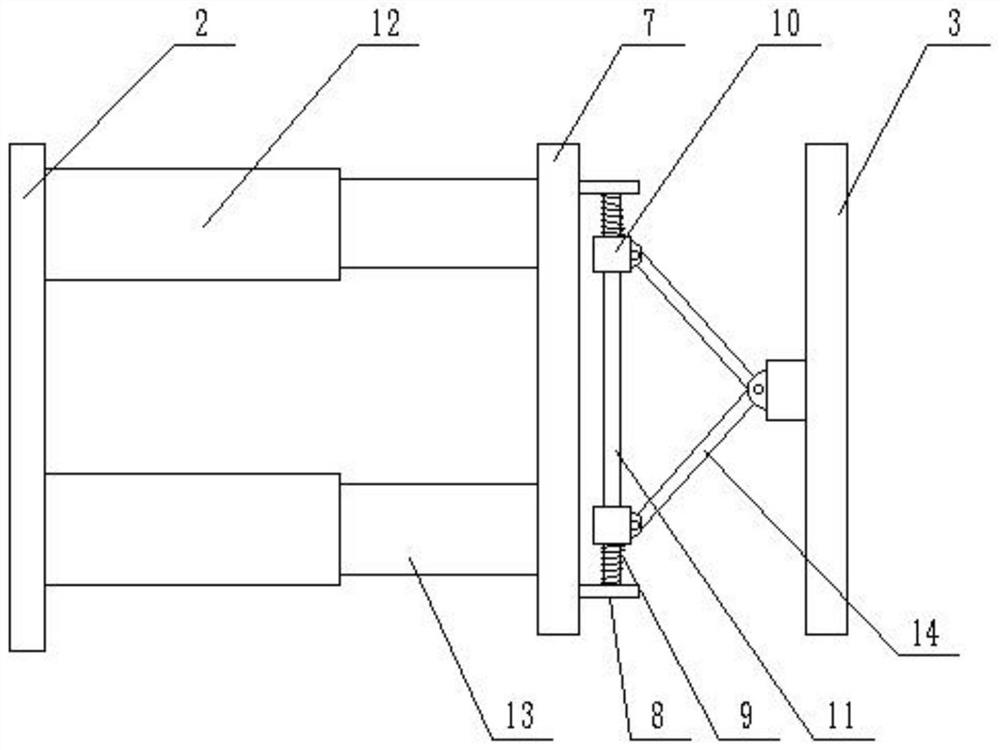

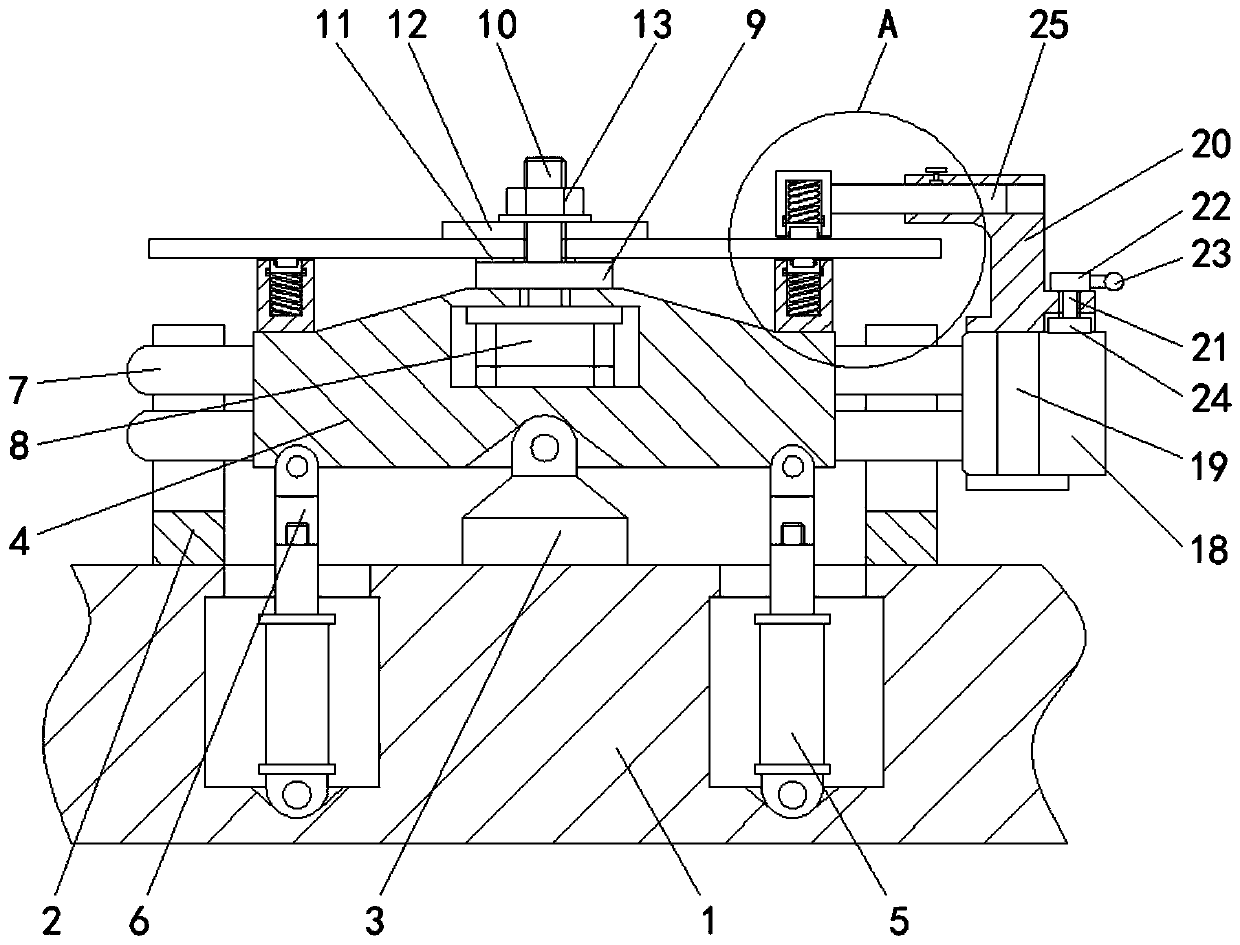

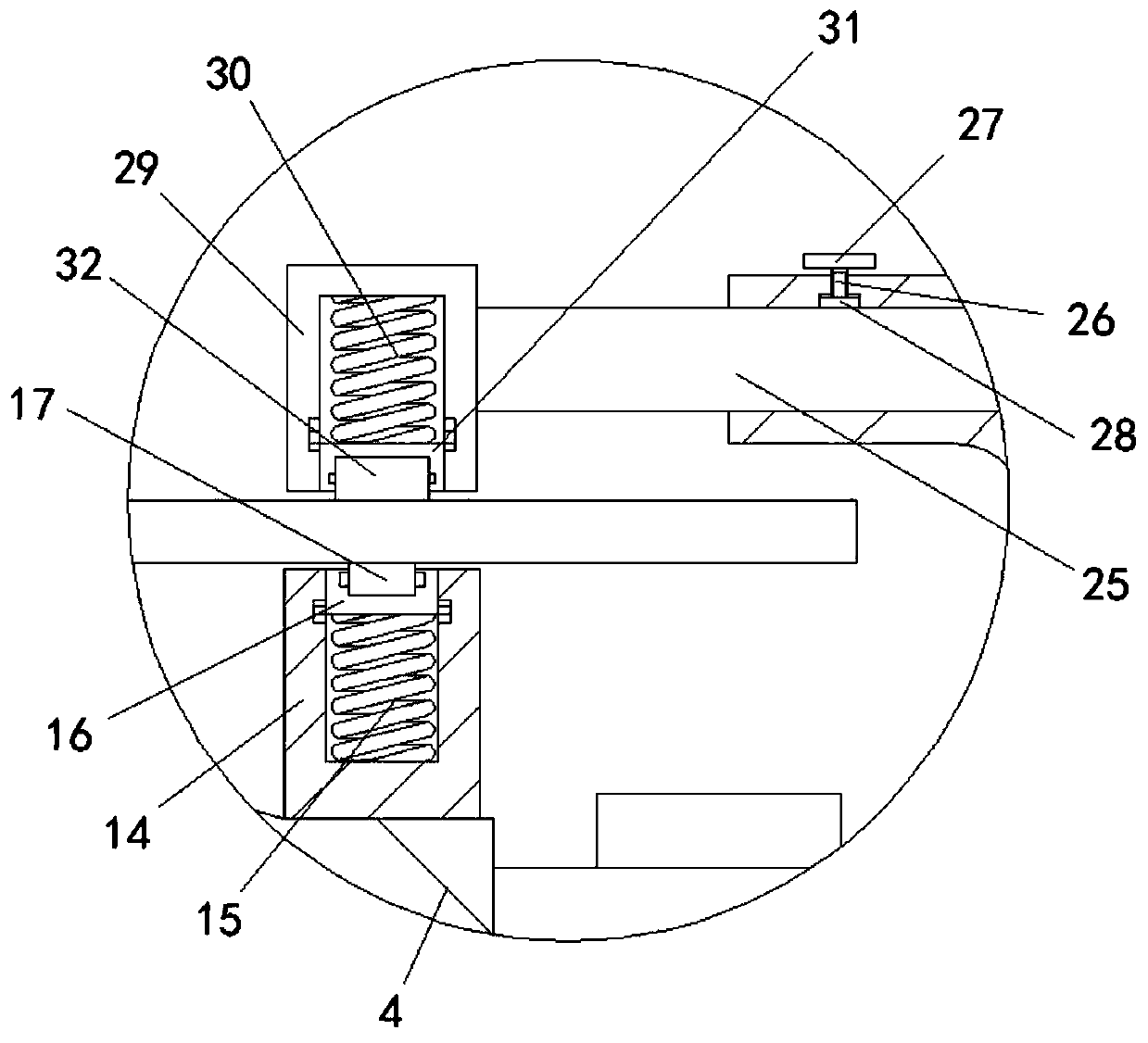

ActiveCN110952461ARotation doesn't happenGuaranteed stabilityBridge structural detailsForms/shuttering/falseworksFalseworkArchitectural engineering

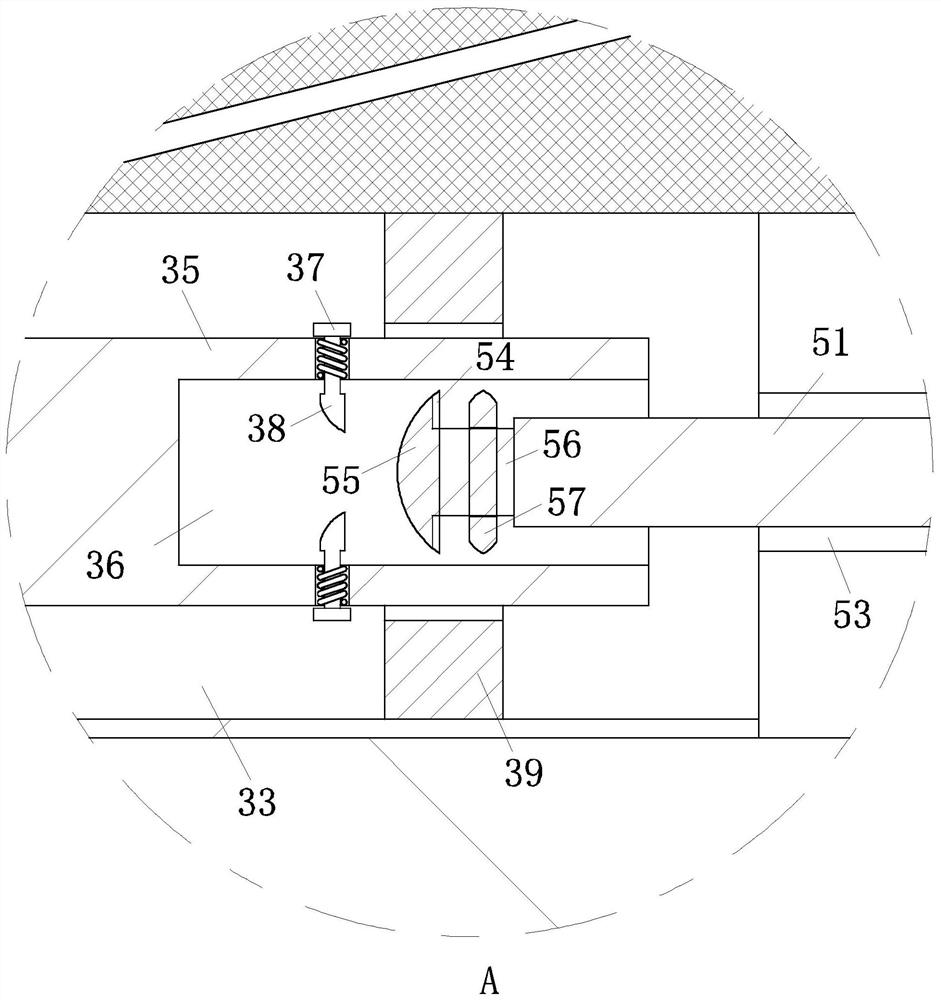

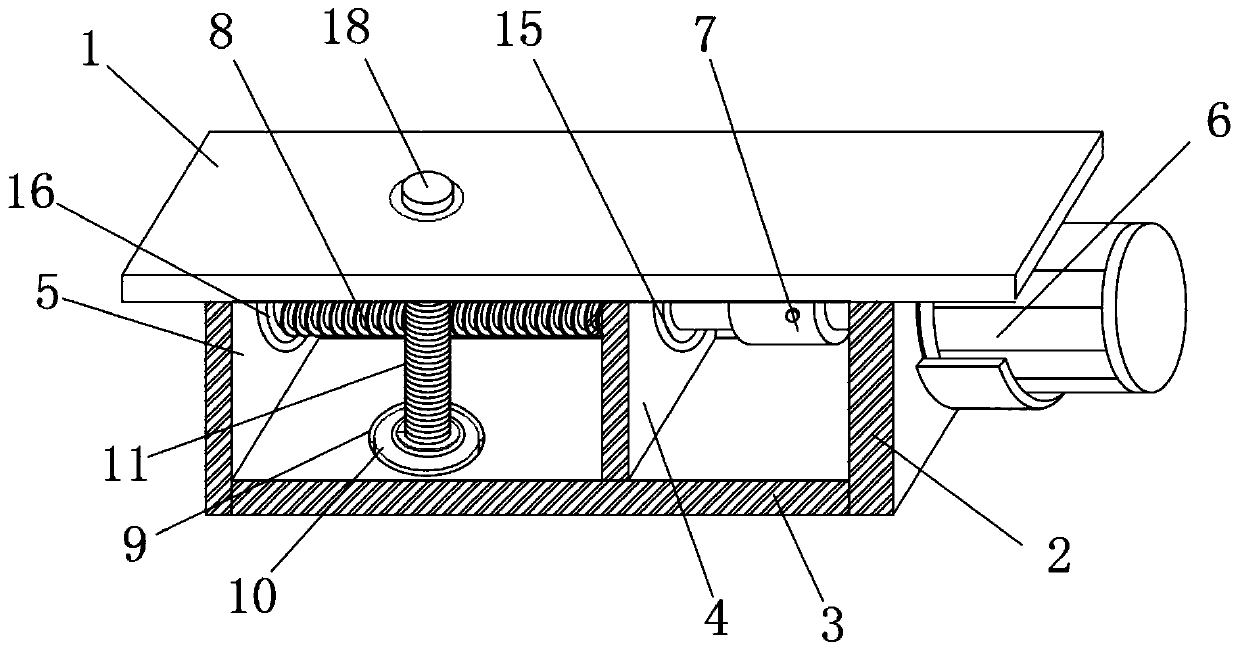

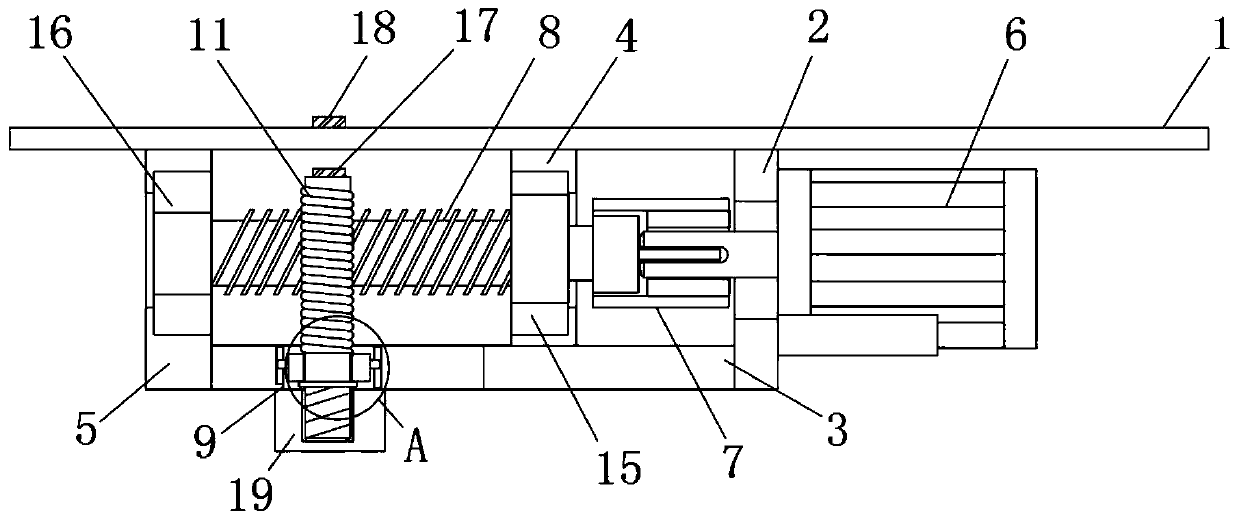

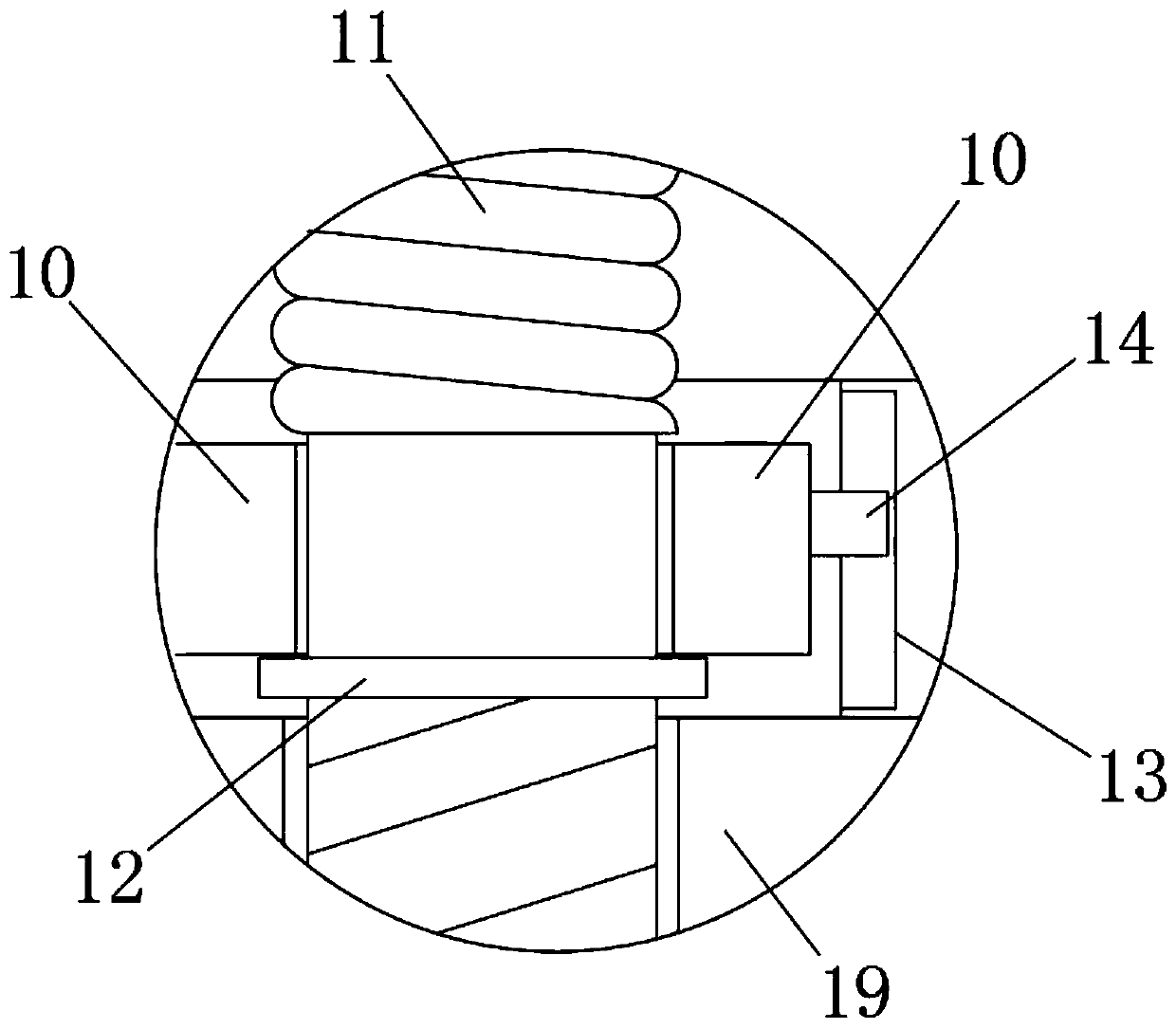

The invention relates to a viaduct pier construction method. The method mainly comprises the following steps: foundation excavation, scaffold building, steel bar construction, formwork installation, temporary supporting, concrete pouring, concrete curing, formwork removal operation and the like. The supporting equipment comprises a bottom plate, an angle adjusting device and an abutting device. According to the invention, the following problems existing in the existing template supporting process can be solved: when a traditional formwork is supported, a large number of inclined wood supportsneed to be arranged, generally, one end of each wood support abuts against the top end of a vertical keel, the other end of each wood support abuts against a foundation pit sheet pile, supporting at the top end and the bottom end is unstable, the occupied area is large, material transportation and observation of the solidification condition of concrete are inconvenient, and time and labor are wasted in the dismounting and mounting process; and b, a traditional supporting instrument easily generates lateral pressure on the formwork, so that the formwork is easily deflected, and when the formwork is erected on the ground with the complex terrain, the erecting cost is high, and the firmness cannot be effectively improved.

Owner:武汉市市政工程机械化施工有限公司

A convenient warning board for road rescue

InactiveCN109208500AEasy to useImprove warning effectTraffic signalsRoad signsEngineeringThreaded rod

Owner:宣雪祥

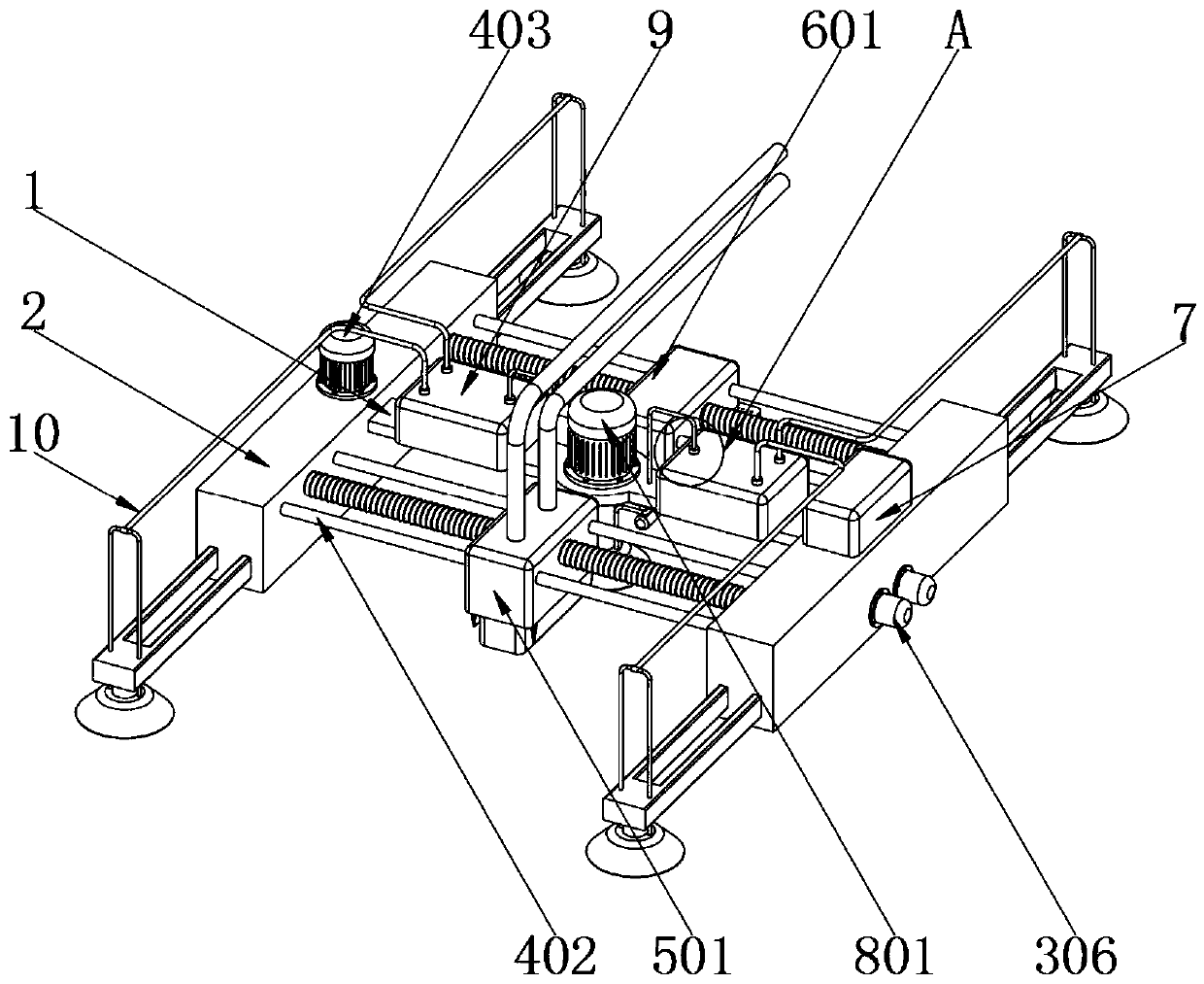

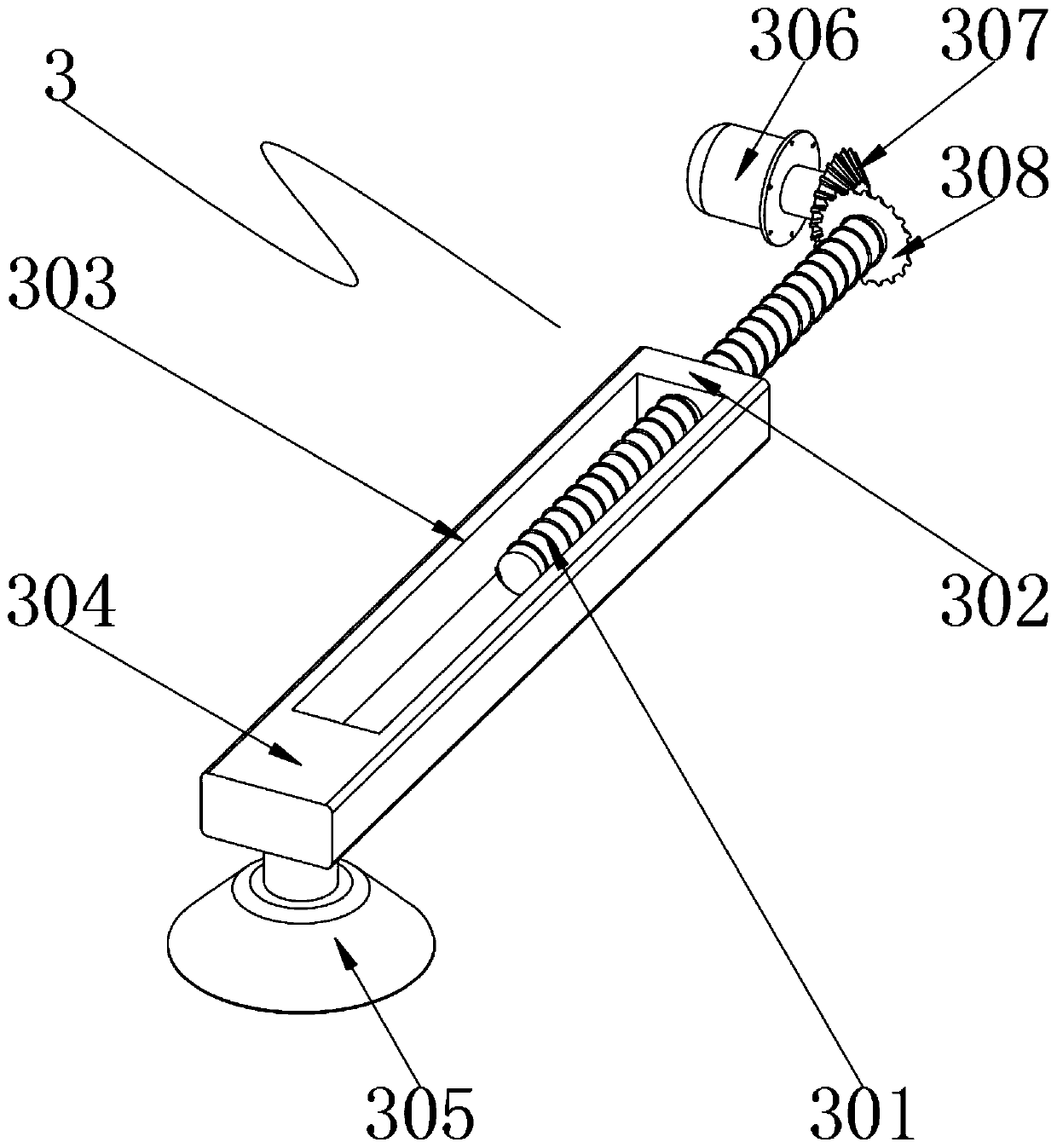

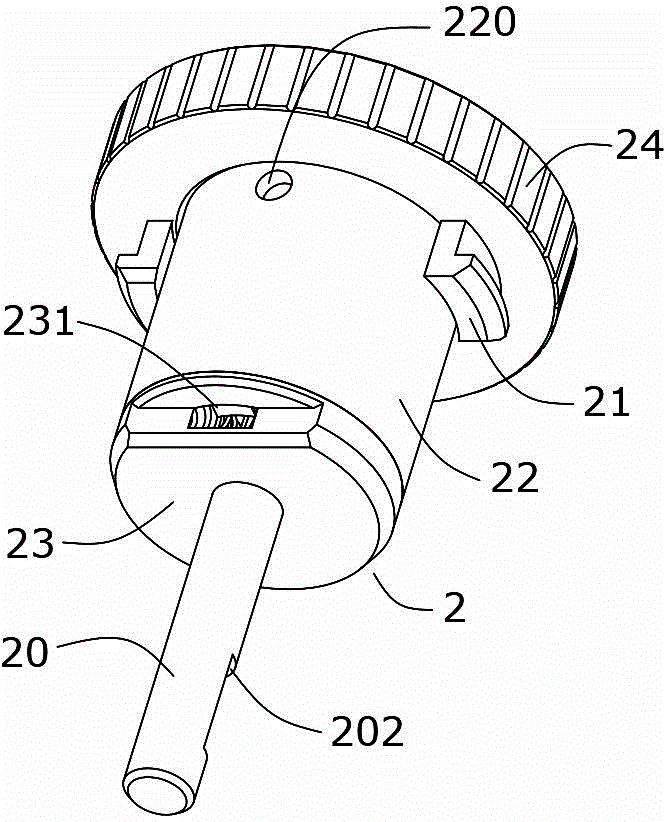

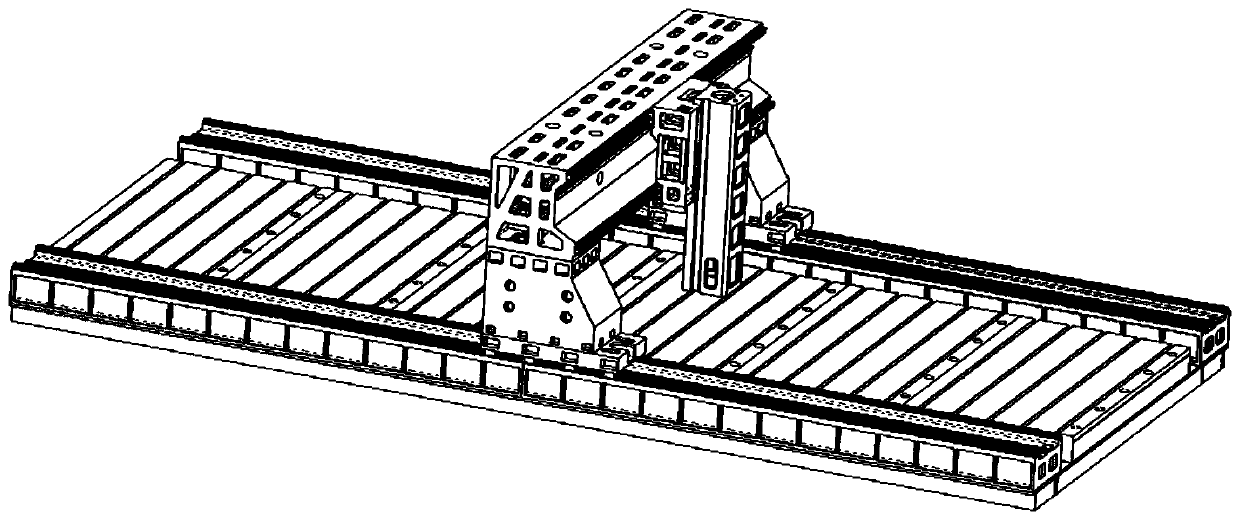

Intelligent curtain wall glass cleaning device for smart building

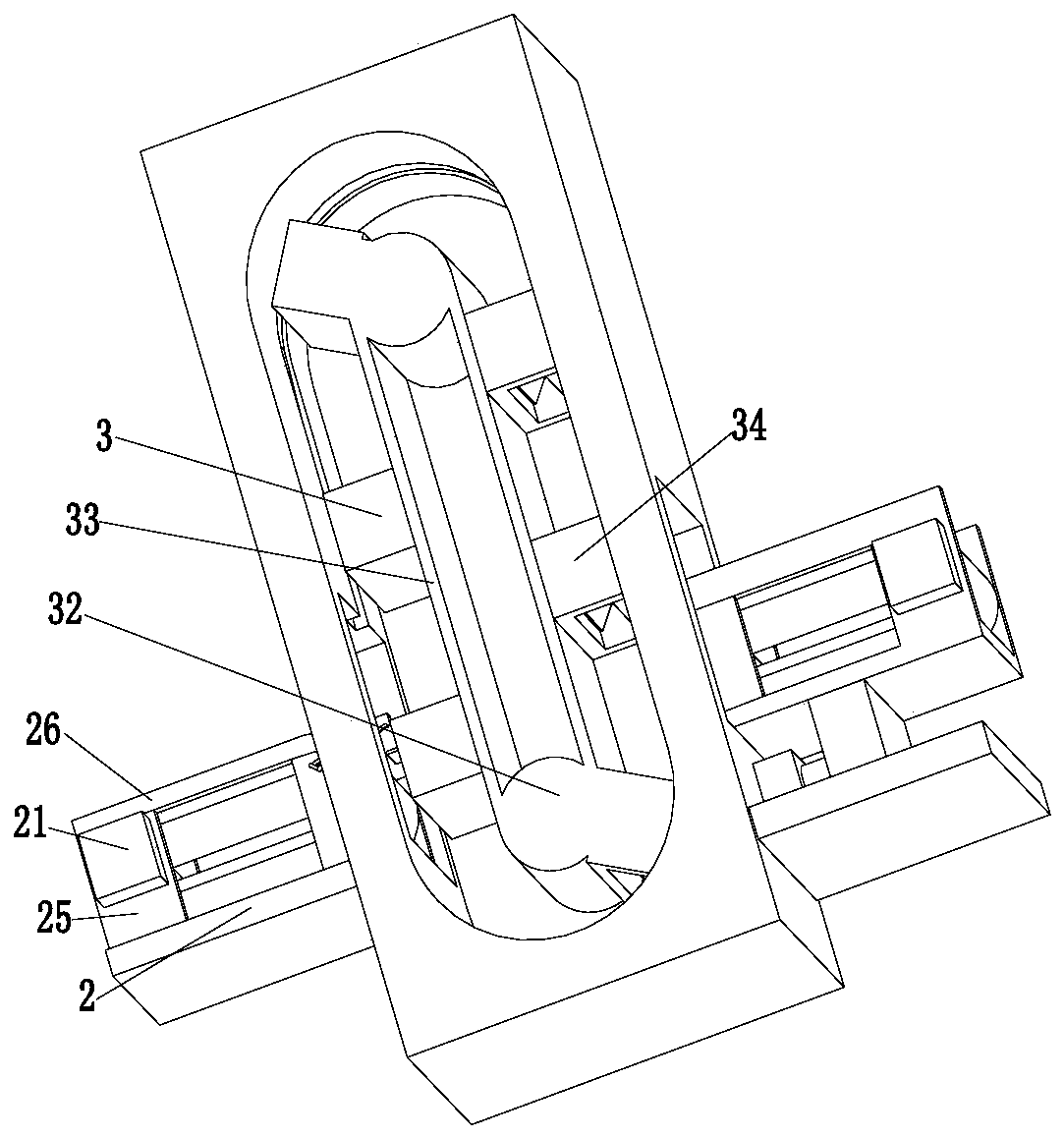

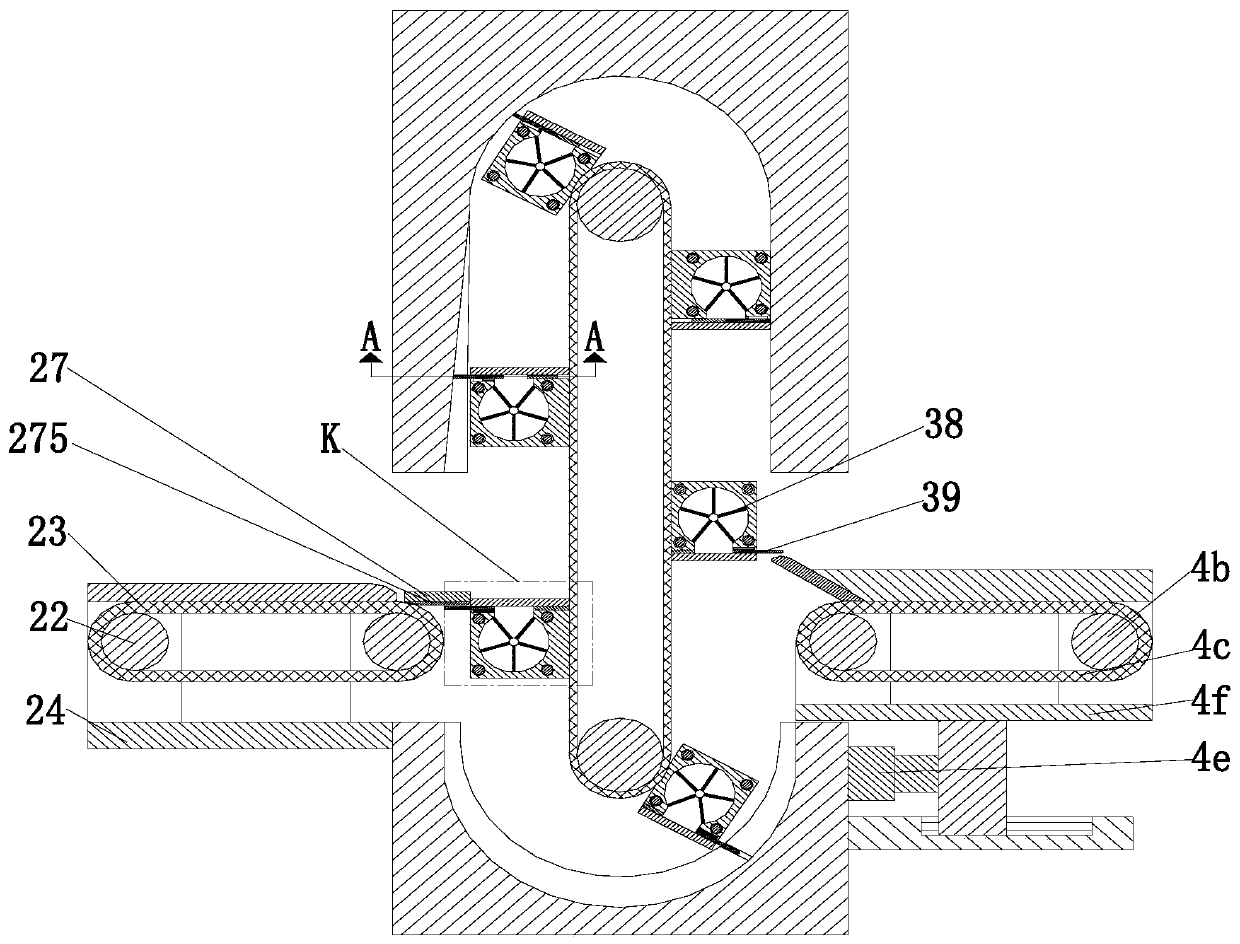

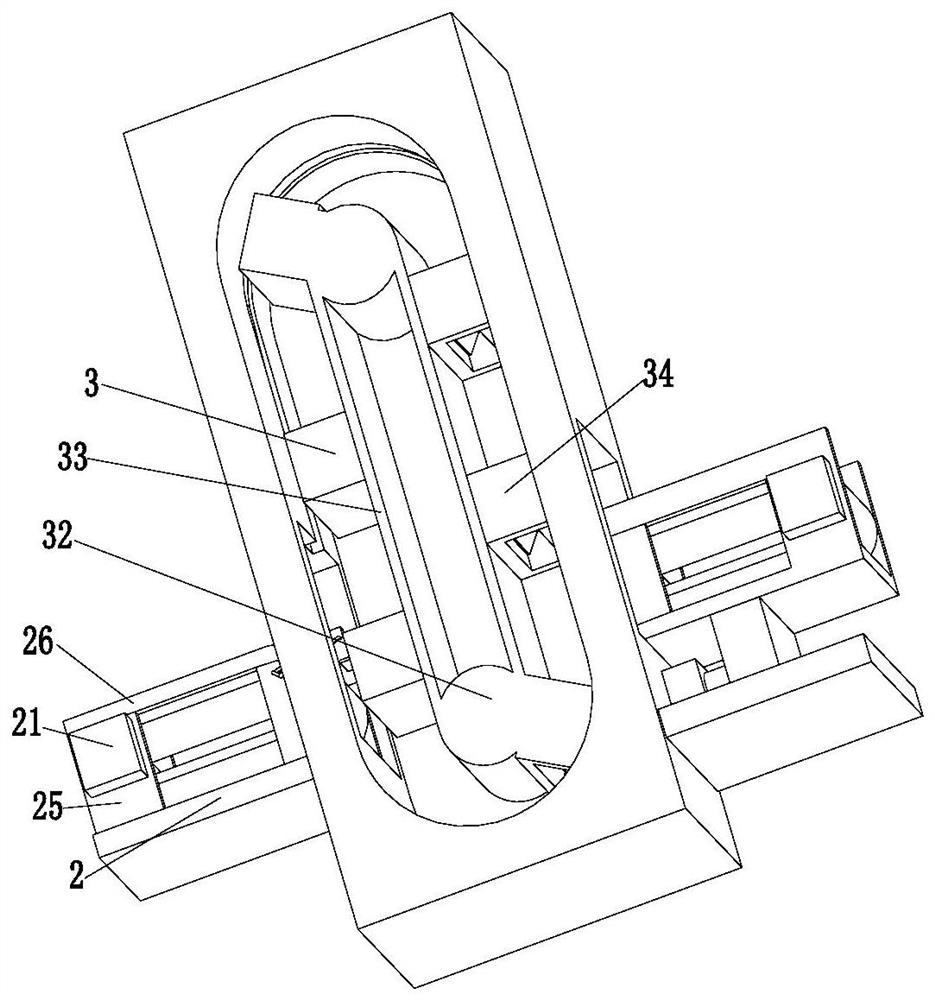

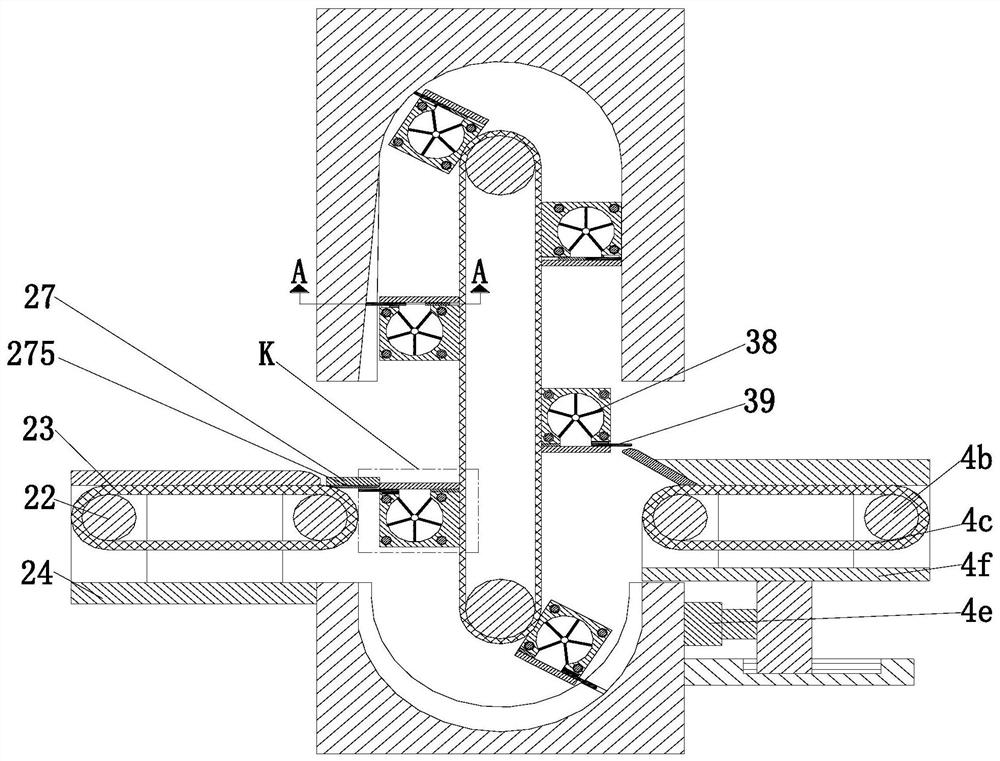

ActiveCN110934529ARealize all-round cleaningImprove cleaning efficiencyCarpet cleanersFloor cleanersArchitectural engineeringMechanical engineering

The invention belongs to the technical field of curtain wall cleaning, and especially relates to intelligent curtain wall glass cleaning device for a smart building. The device comprises a main supporting plate, and main supporting columns are fixedly installed at the two ends of the supporting plate. Walking mechanisms are installed at the two ends of the main supporting columns. Driving mechanisms are mounted on the two sides of the main supporting plate and located between the main supporting columns; a cleaning mechanism is mounted on the outer side of one driving mechanism, and a wiping mechanism is mounted on the outer side of the other driving mechanism. According to the invention, the device is scientific and reasonable, and is safe and convenient to use. Through the walking mechanisms, the automatic walking of the cleaning device outside the curtain wall glass can be realized; only setting commands need to be achieved, and manual guarding is not needed, so convenience and rapidness are achieved, and labor force is greatly reduced; meanwhile, by means of the rotating mechanism, the cleaning device can automatically change the direction outside curtain wall glass, omnibearing cleaning of the curtain wall glass is achieved, the curtain wall glass cleaning efficiency is higher, and the cleaned curtain wall glass is cleaner.

Owner:浙江腾升建设有限公司

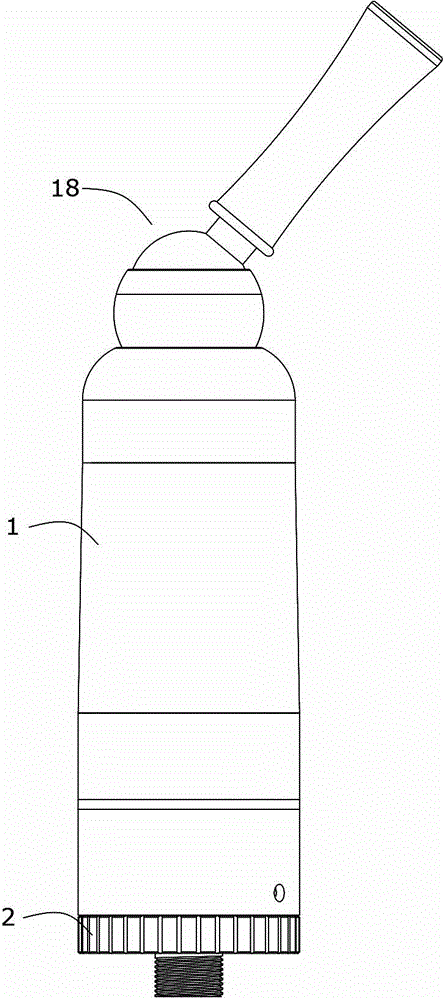

Electronic cigarette atomizer with function of regulating tobacco tar

ActiveCN104687255APrevent drynessRealize the function of adjusting the size of oil supplyTobacco pipesTobacco devicesTarEngineering

The invention discloses an electronic cigarette atomizer with the function of regulating tobacco tar. The electronic cigarette atomizer comprises a tobacco tar tube and an atomizer body which are connected in a rotating manner, wherein a sleeve tube is inserted in the tobacco tar tube, the ends of the sleeve tube are closed, a first opening is formed in the lateral wall of the sleeve tube, an inner tubular sleeve plug is fixed in the sleeve tube, and a second opening is formed in one side, close to the first opening, of the inner sleeve plug; an insertion tube in which an oil guide rope is arranged is arranged on the atomizer body, the ends of the insertion tube are closed, a third opening is formed in the lateral wall of the insertion tube, and the insertion tube is arranged in the inner sleeve plug of the sleeve tube. Through the adoption of the electronic cigarette atomizer disclosed by the invention, the problem that the tobacco tar is dry or is leaked during transportation and storage before electronic cigarettes are received by users is solved; the amount of the tobacco tar can be regulated to smoke amount and taste, which satisfy demands of the users; the electronic cigarette atomizer has the advantages of being firm and reliable, being rapid to assemble, being stable and flat in connection, and being simple in structure.

Owner:深圳市天士力神通本草技术开发有限公司

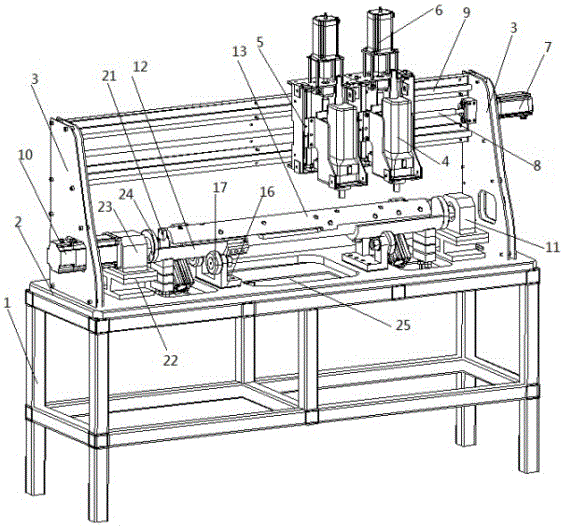

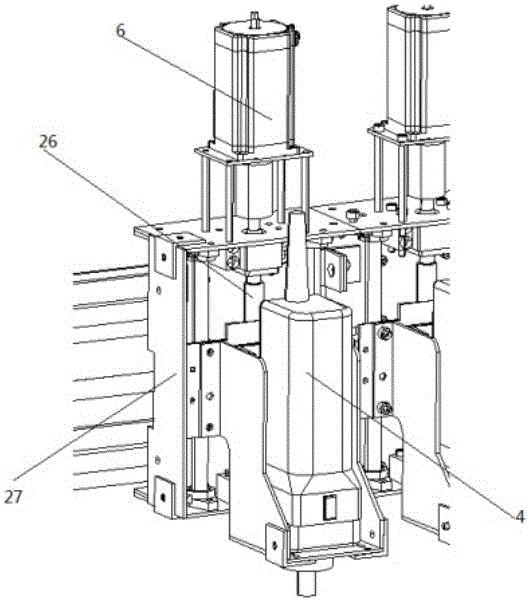

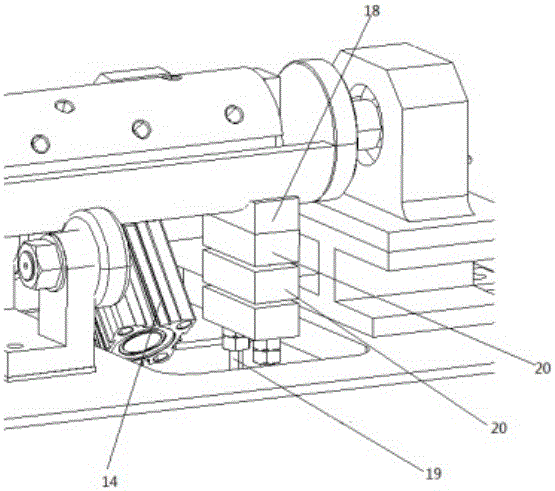

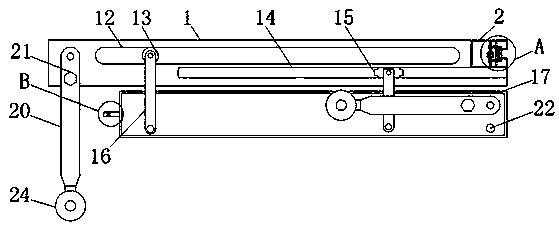

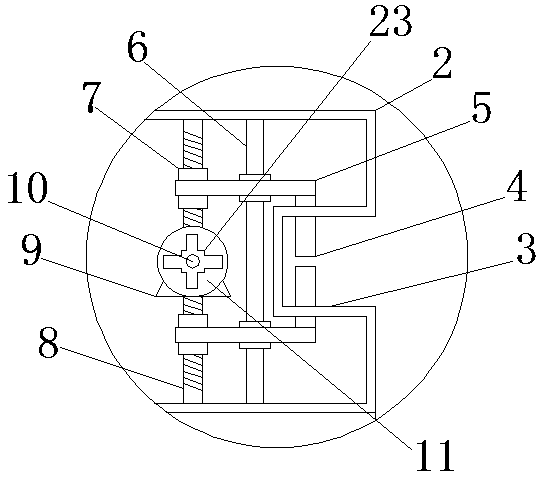

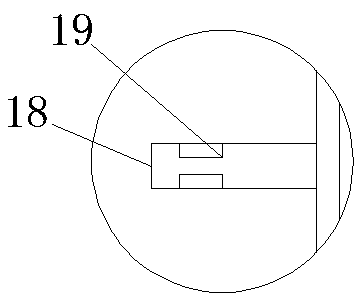

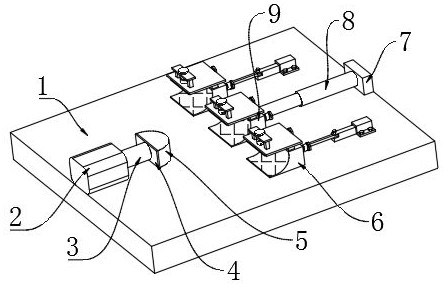

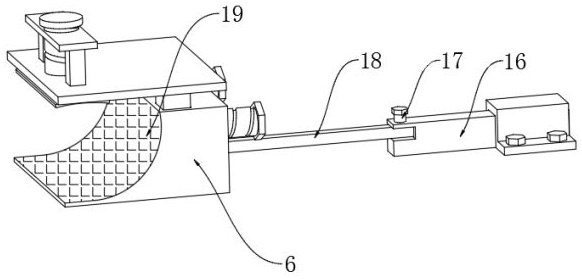

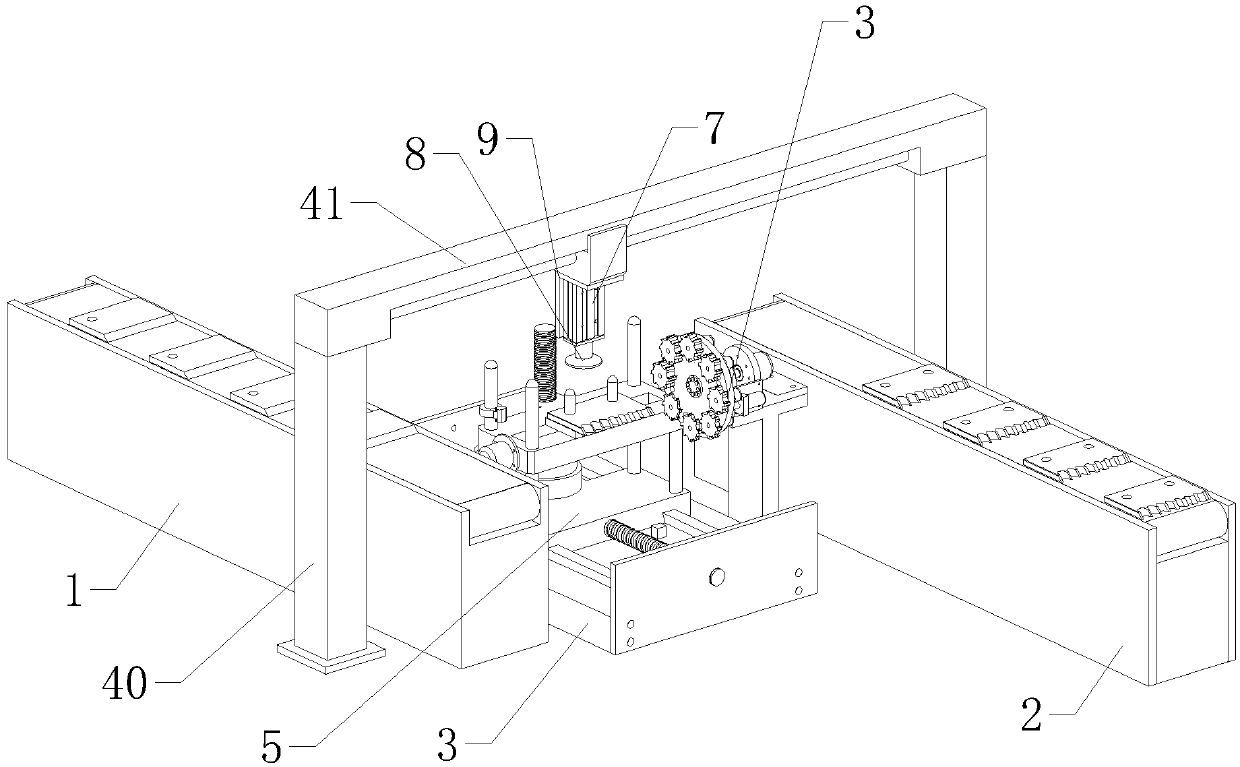

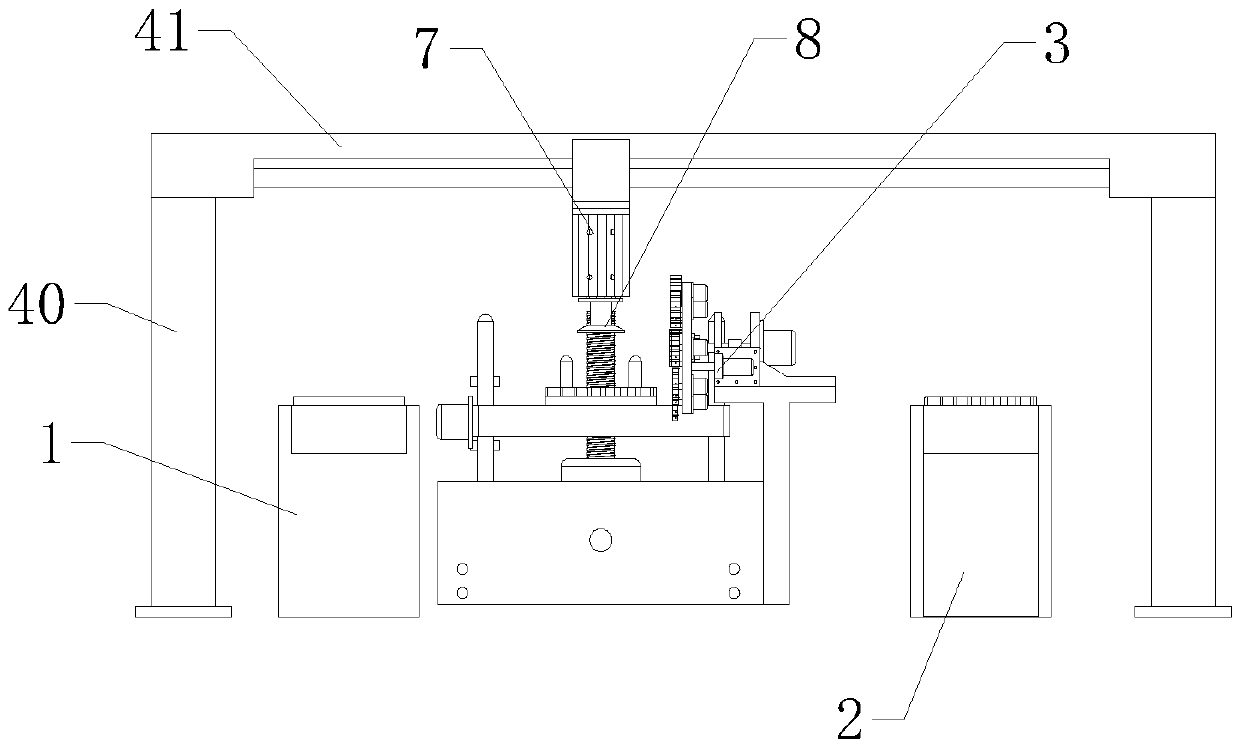

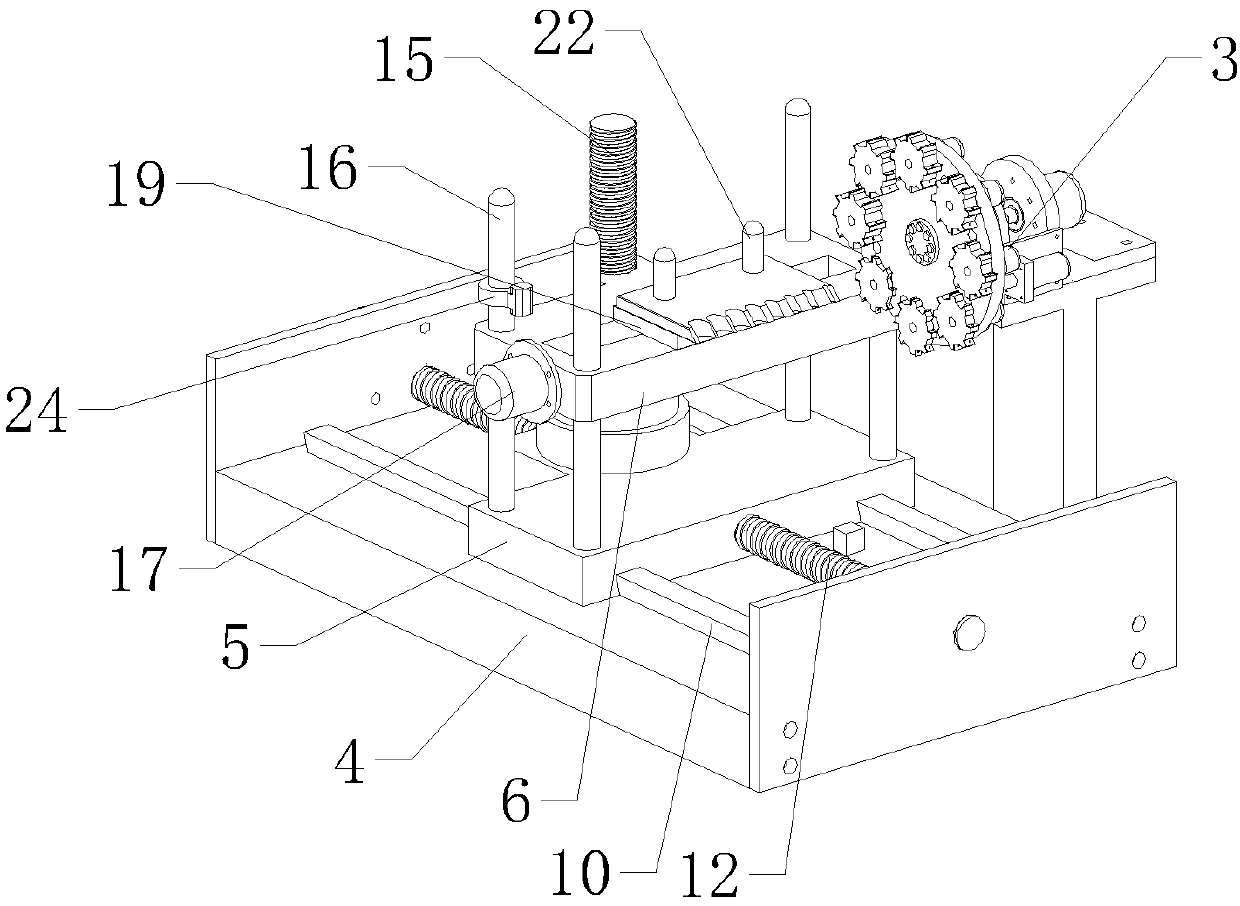

Cross beam pipe punching equipment in automobile fitting

PendingCN106736766APrecise slidingRotation doesn't happenWork clamping meansPositioning apparatusElectric machineryDrilling machines

The invention provides cross beam pipe punching equipment in an automobile fitting. The cross beam pipe punching equipment comprises a rack, wherein the rack is provided with a worktable; the worktable is provided with two supporting plates; the two supporting plates are arranged on two sides of the worktable respectively; a punching mechanism and a positioning mechanism are arranged between the two supporting plates; the punching mechanism comprises a drilling device and a sliding device; the drilling device is movably connected with the sliding device; the drilling device comprises a drilling machine, a connecting device and a servo motor A; the drilling machine is connected with the servo motor A through the connecting device; the sliding device comprises a servo motor B, a sliding rod and a sliding rail; and the servo motor B is connected with the sliding rod and is used for driving the sliding rod.

Owner:河北科斯特自动化科技有限公司

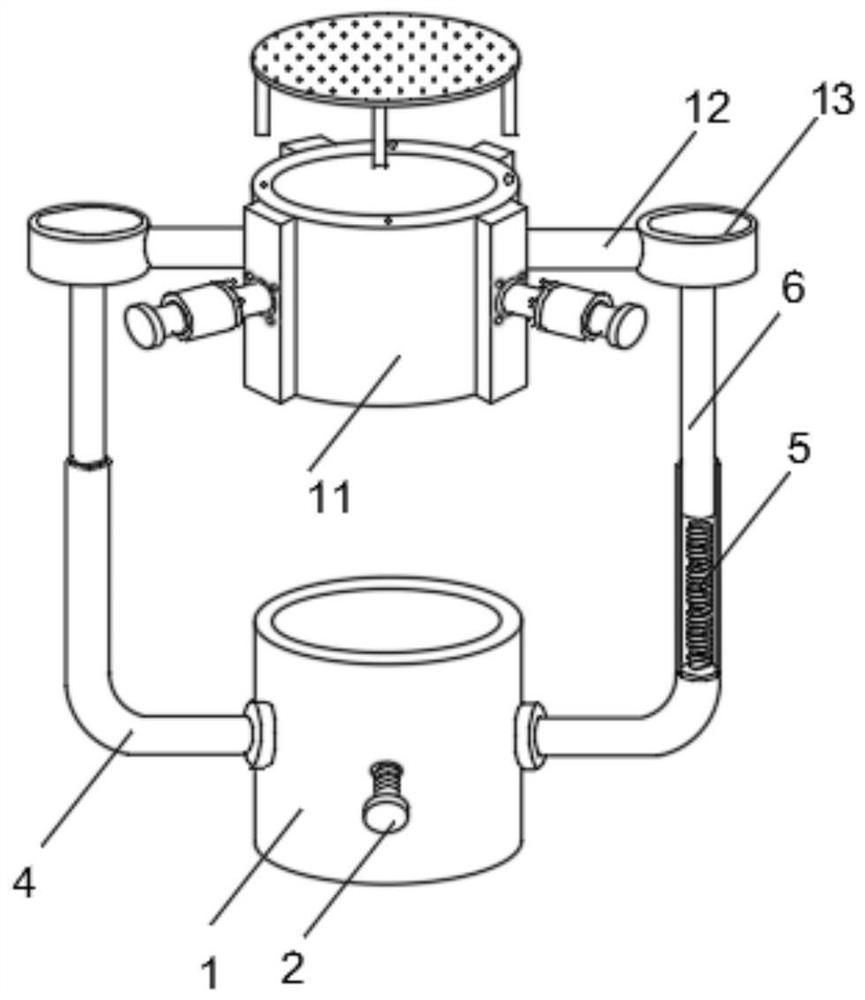

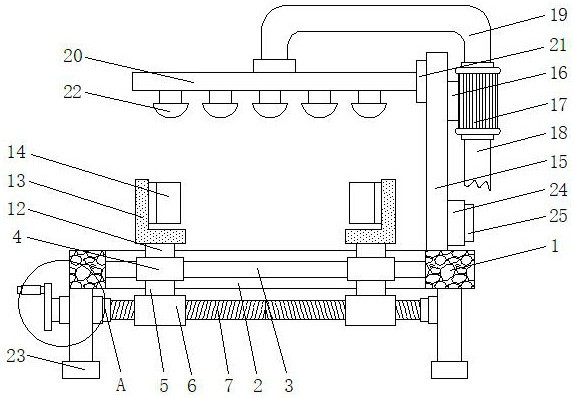

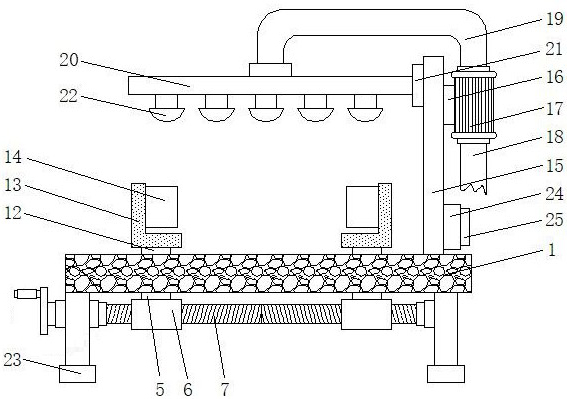

Drying and dehydrating system for preparing biomass fuel from crop straws

ActiveCN111006491AAvoid wasting resourcesNo dropBiofuelsSolid fuelsAgricultural scienceAgricultural engineering

The invention relates to a drying and dehydrating system for preparing biomass fuel from crop straws. The system comprises a straight plate, a feeding device, a transmission drying device and a discharging device, the feeding device is mounted on the outer wall of the left end of the straight plate, the discharging device is mounted on the outer wall of the right end of the straight plate, and thetransmission drying device is mounted in the straight plate. According to the system, the following problems during drying and dehydration of crop straws can be solved: 1, at present, domestic crop straws are basically dried and dehydrated on an open-air platform, the straws are dehydrated and aired in an airing mode, the airing effect and the airing time of the straws can be affected by changesof weather, and the straws can be damped again in the airing process; and 2, an existing crop straw drying and dewatering device basically conducts dewatering operation on straws through rotation of adewatering barrel, the dewatering barrel rotates generally to only spin-dry moisture on the outer surface of the straws, and the moisture in the straws is difficult to spin out directly.

Owner:国电建三江前进生物质发电有限公司

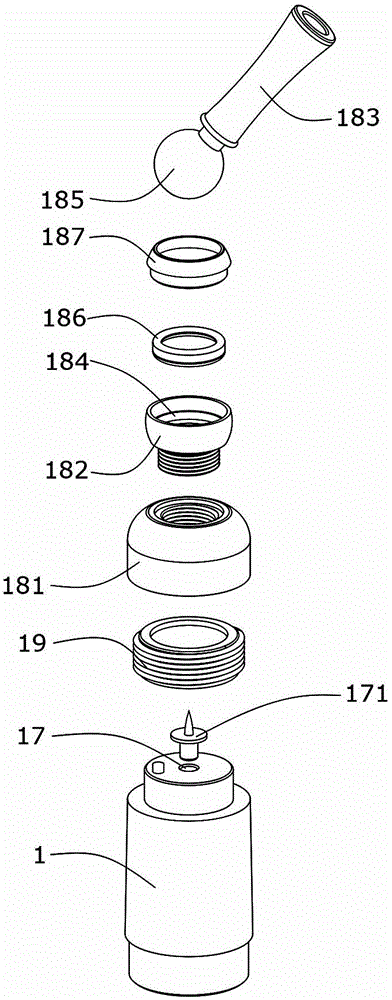

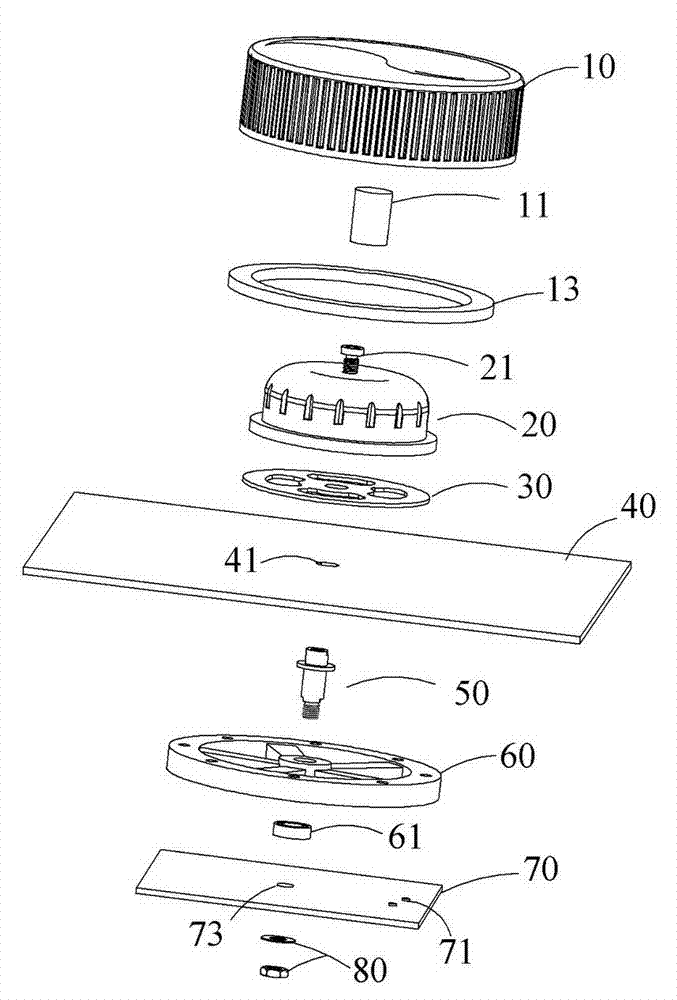

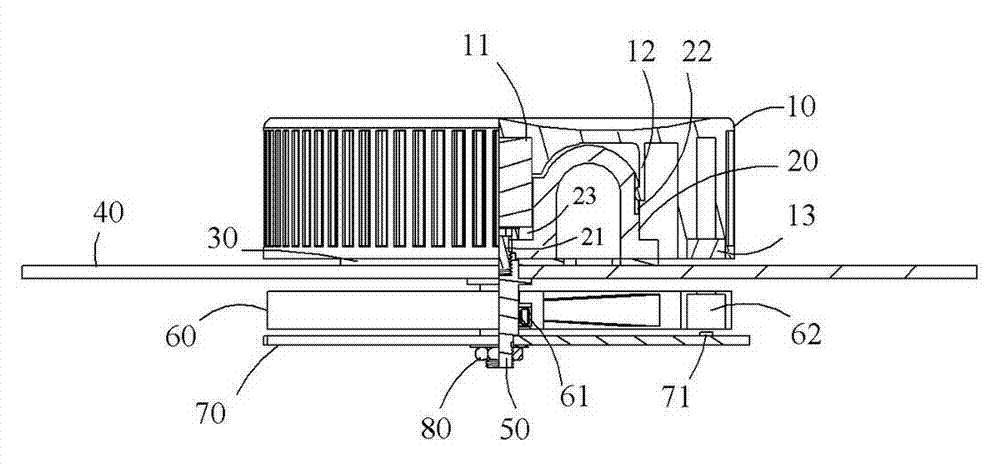

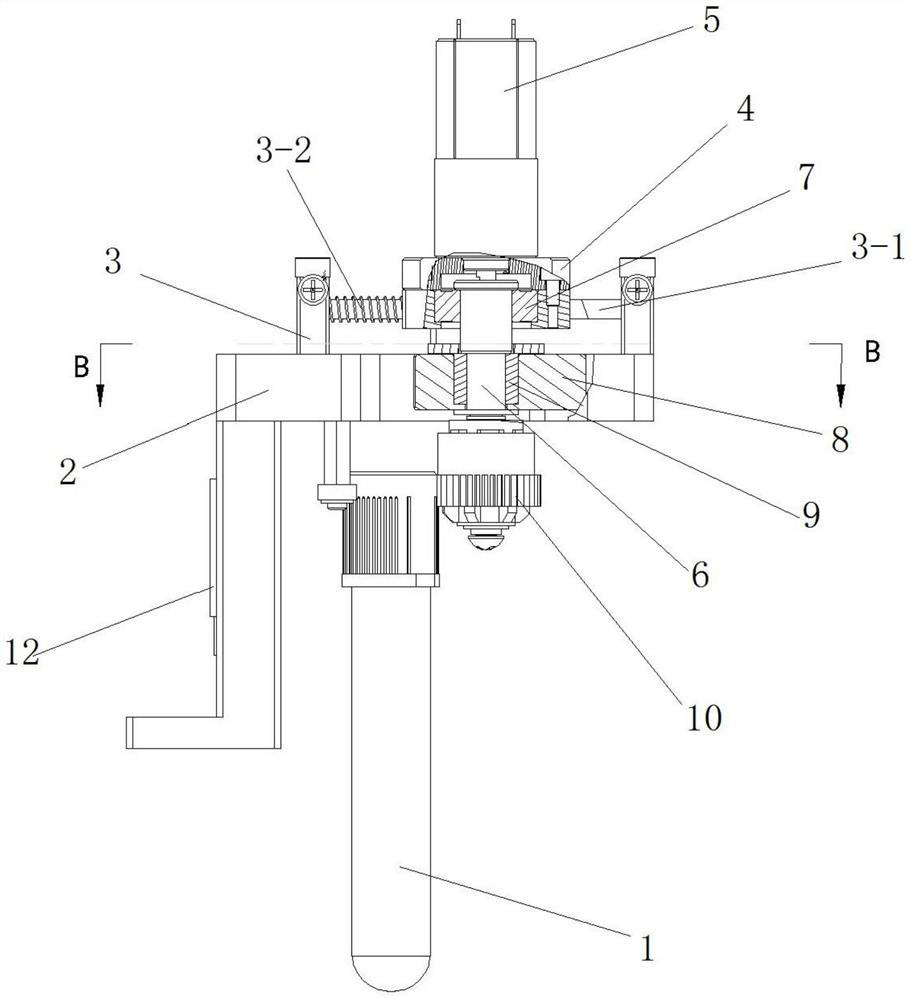

Waterproof coding device having built-in magnet disc

InactiveCN103591969ARotation doesn't happenIncrease the output signal amplitudeMeasurement apparatus componentsUsing electrical meansEngineeringMagnet

The invention relates to a waterproof coding device having a built-in magnet disc. The waterproof coding device having the built-in magnet disc comprises the magnet disc, a turn button with a shaft, an induction circuit board, a positioning shaft, and a circular support seat, wherein an inner top face of the turn button is provided with an elastic positioning sheet, a port portion of an annular chamber at an outer wall of the turn button is provided with a magnetic guide ring, the magnet disc is mounted at a central portion of the positioning shaft, the induction circuit board is fixed at a tail portion of the positioning shaft, an outer circumferential wall of the circular support seat is provided with a positioning groove, a central portion of the circular support seat is provided with a shaft sleeve, the circular support seat is on a panel, a head portion of the positioning shaft penetrates through a mounting hole of the panel, thread connection with the positioning shaft is realized through a screw, the turn button is mounted on the support seat, the shaft is in moving matching with the shaft sleeve in the support seat, and the magnetic guide ring is attracted by a magnet of the magnet disc to realize synchronous rotation of the magnet disc and the turn button. The magnet disc is arranged in the casing panel, axial positioning of the turn button is realized through magnetic force of the magnet disc, the waterproof coding device has advantages of compact structure, waterproof performance, anti-shock performance and low cost and is especially applicable to use in a high wet environment or an easy shocking occasion.

Owner:王嘉 +2

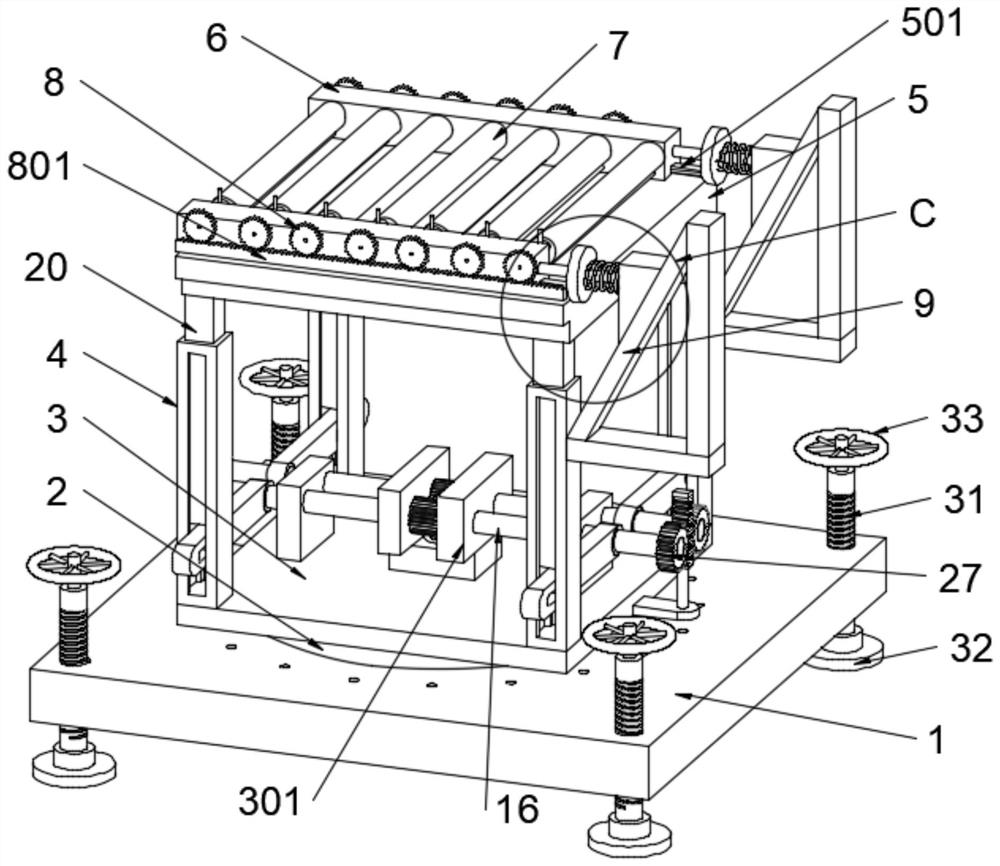

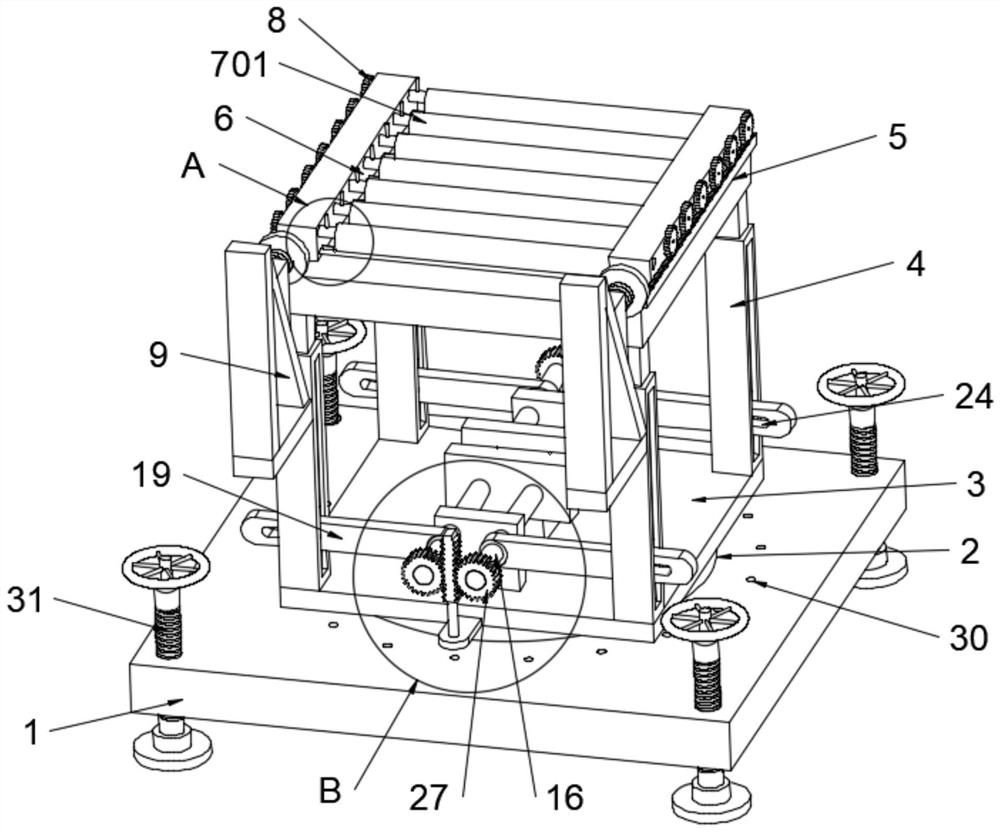

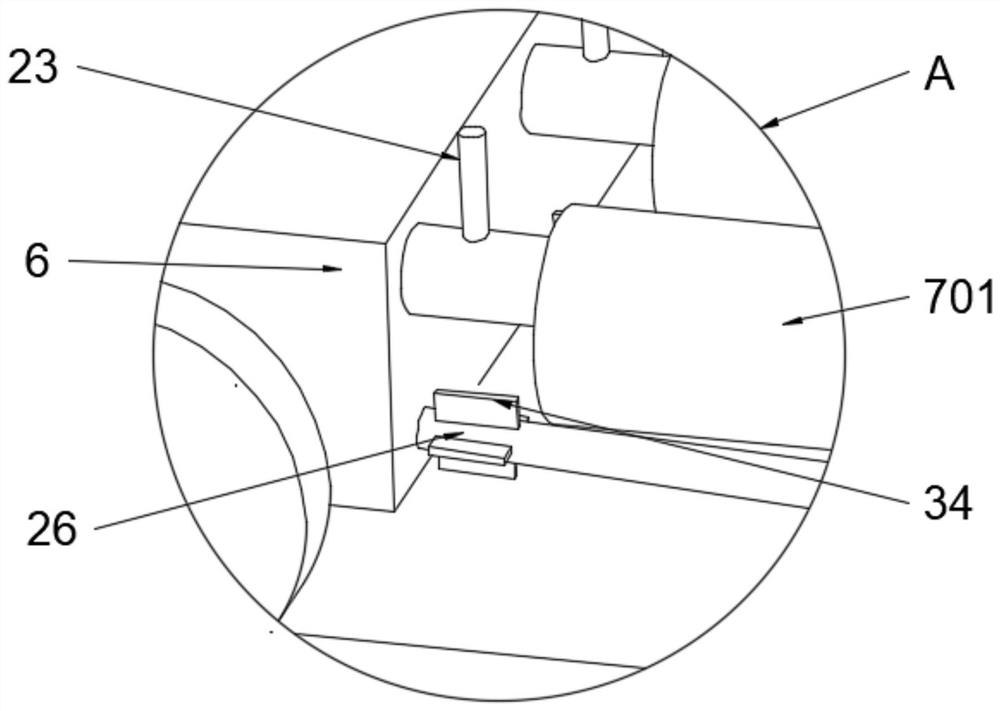

Rotary roller elevator capable of achieving stable transmission

PendingCN113830490AGuarantee stabilityConvenient automatic feedingCleaningLifting framesRotary stageControl engineering

The invention discloses a rotary roller elevator capable of achieving stable transmission, which comprises a base; a rotary table rotating around a fixed axis is arranged on the upper surface of the base; a mounting platform is fixedly connected to the upper surface of the rotary table; limiting columns are fixedly connected to the four corners of the upper surface of the mounting platform; a lifting platform is arranged directly above the limiting columns; guide rails are symmetrically arranged on the upper surface of the lifting platform; a conveying platform is arranged on the guide rails; a feeding mechanism is arranged on the conveying platform, and the feeding mechanism comprises a plurality of eccentric rollers I rotating around a fixed axis on the inner wall of the conveying platform, and output shafts of the eccentric rollers I penetrate through the outer wall of the conveying platform and are fixedly connected with gears I; toothed plates I meshed with the gears I are arranged at the bottoms of the gears I; an inclined plate is fixedly mounted on one side of each limiting column; and push rods for feeding of the eccentric rollers I are symmetrically arranged on the side, close to the inclined plate, of the conveying platform. The rotary roller elevator capable of achieving the stable transmission provided by the invention has the advantages of being convenient to feed, safe and stable, and the problems in the background technology are solved.

Owner:江苏历漠智能装备有限公司

Medical stretcher capable of being folded and stored

InactiveCN108652837ARealize the function of collapsible storageRotation doesn't happenStretcherArchitectural engineeringSlide plate

The invention discloses a medical stretcher capable of being folded and stored. An inserting groove is formed in the right side of a connecting head, and positioning rods are separately connected to the top and bottom of an inner cavity of the inserting groove in a penetrating mode. Sliding plates are separately and fixedly connected to the sides, opposite to each other, of the two positioning rods, and a sliding rod is connected to the middle portions of the sliding plates in a penetrating mode. Threaded sleeves are connected to the left sides of the sliding plates in a penetrating mode, anda threaded rod is connected to inner cavities of the threaded sleeves in a threaded mode. A driven conical gear is connected to the middle portion of the outer side of the threaded rod in a sleeving mode, and a rotating shaft is connected to the middle portion of the front face of the connecting head in a penetrating mode. The back face of the rotating shaft penetrates through the connecting headto be fixedly connected to a driving conical gear, and a first sliding groove is formed in the upper portion of the front face of a first bottom plate. An inserting plate is fixedly connected to the left side of a second bottom plate, and positioning grooves are formed in the left sides of the top and the bottom of the inserting plate. The medical stretcher is convenient to fold and store throughthe arrangement of the inserting plate, the positioning rods, the threaded rod, the threaded sleeves, the first sliding groove, a positioning bolt and positioning holes.

Owner:谢博

Grafting device for nursery stock planting

InactiveCN112449892AImprove grafting efficiencyImprove operational safetyGraftingRootstockAgricultural engineering

The invention discloses a grafting device for nursery stock planting. The device comprises a fixed shell, a working mechanism is arranged on the fixed shell, and the working mechanism comprises threaded rods, limiting plates, a first connecting rod, a spring, a second connecting rod, a mounting protrusion, a cutting blade, an adjusting rod, a barrel, a handle and a connecting block. The threaded rods are connected to the outer circle face of the front side and the outer circle face of the rear side of the fixed shell in a threaded penetrating mode. The ends, extending into the fixed shell, ofthe threaded rods are fixedly connected with the limiting plates. Cutting of multiple connectors can be completed simultaneously, compared with the prior art that connector cutting needs to be conducted one by one, the grafting efficiency is improved, the cutting blade conducts cutting inside the barrel, a user holds the handle with hands, the user does not need to make contact with the blade, andthe operation safety is improved. Besides, the cutting blade can be adjusted through the adjusting rod according to the thickness degree of a rootstock, and the universality of the device is improved.

Owner:阜阳市艺凯农业科技有限公司

Supporting structure of base for air conditioner and air conditioner

ActiveCN107152779AAvoid the phenomenon of falling out of the chuteImprove stabilityLighting and heating apparatusSpace heating and ventilation detailsEngineeringMechanical engineering

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

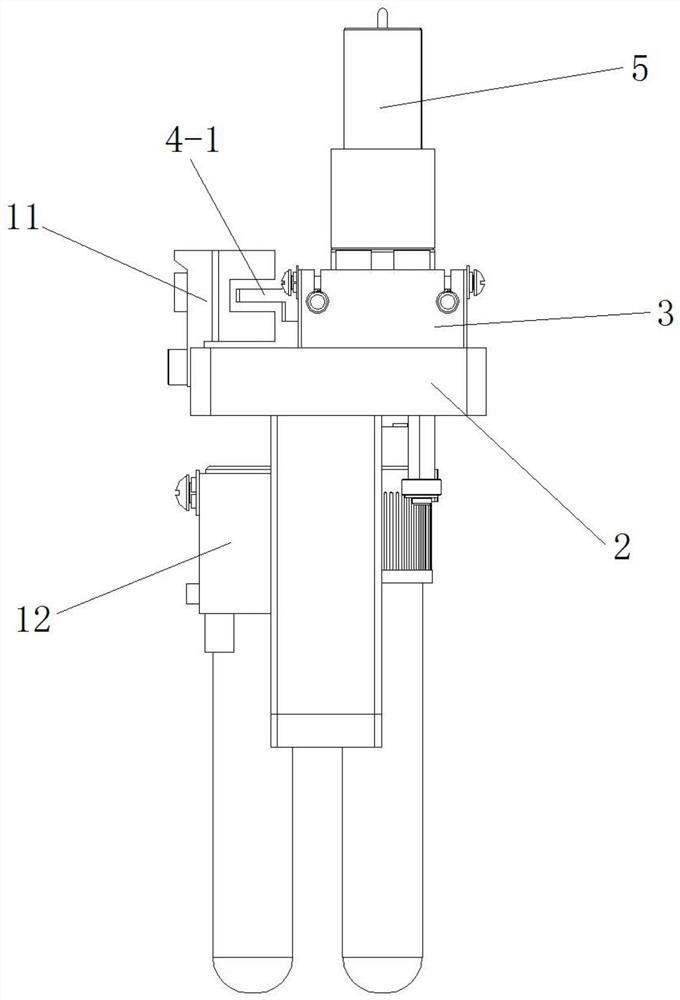

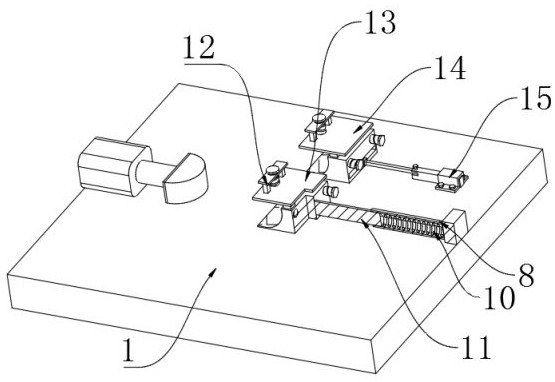

Test tube rotating mechanism and test tube rotating code-scanning device

PendingCN112149437APrecise clampingReliable rotationLaboratory benches/tablesSensing by electromagnetic radiationDrive shaftElectric machine

The invention relates to the technical field of medical instruments and provides a test tube rotating mechanism which comprises a fixing block, a clamping rotating assembly and a cam groove are arranged on the fixing block, the clamping rotating assembly comprises a motor, a driving shaft, a cam, a one-way bearing and a rotating gear, the motor drives the driving shaft to rotate, and the driving shaft drives the rotating gear to rotate. The driving shaft is connected with the cam through a one-way bearing and drives the cam to rotate, a cam flange is arranged on the cam groove, and the circumferential face of the cam makes contact with the cam flange all the time. The driving shaft drives the cam to rotate through the one-way locking characteristic of the one-way bearing, the cam drives the driving shaft to get close to the sample test tube and enables the rotating gear to clamp the sample test tube, then the cam does not rotate along with the driving shaft through the bearing effect of the one-way bearing, and the driving shaft drives the rotating gear to clamp the sample test tube and drive the sample test tube to rotate. A sample test tube can be accurately clamped and driven torotate without an electromagnet.

Owner:宁波美康盛德生物科技有限公司

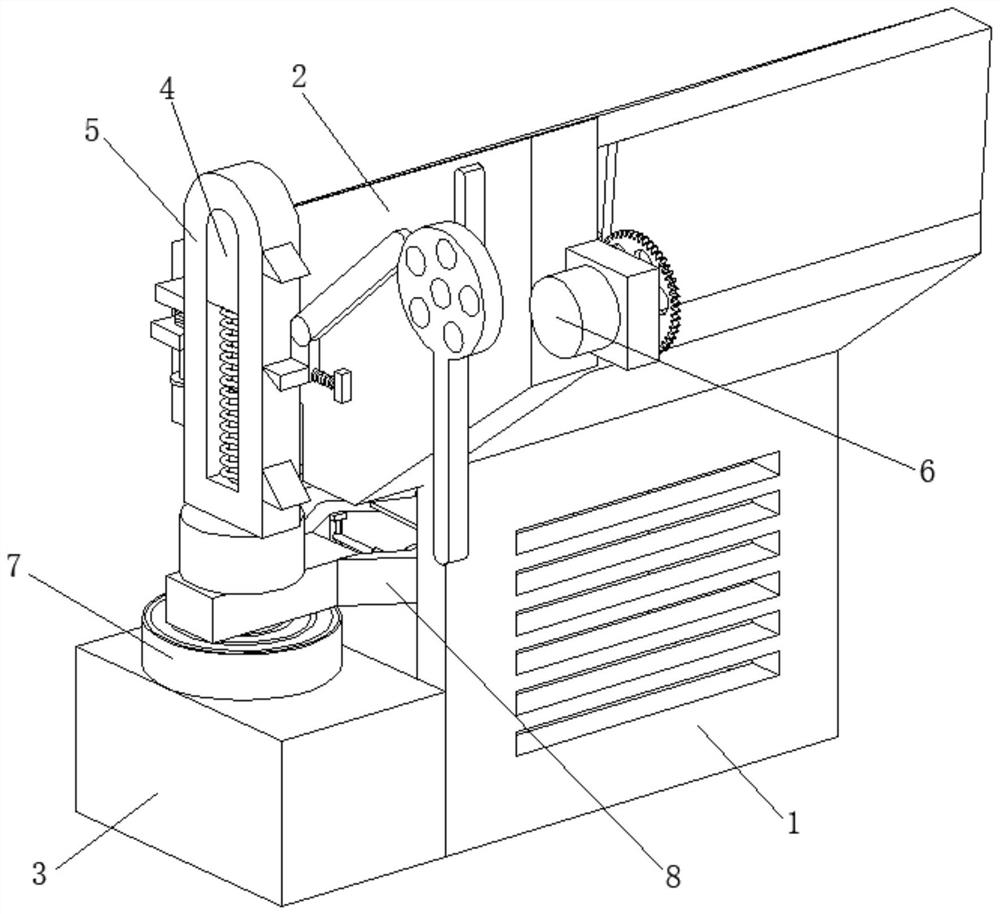

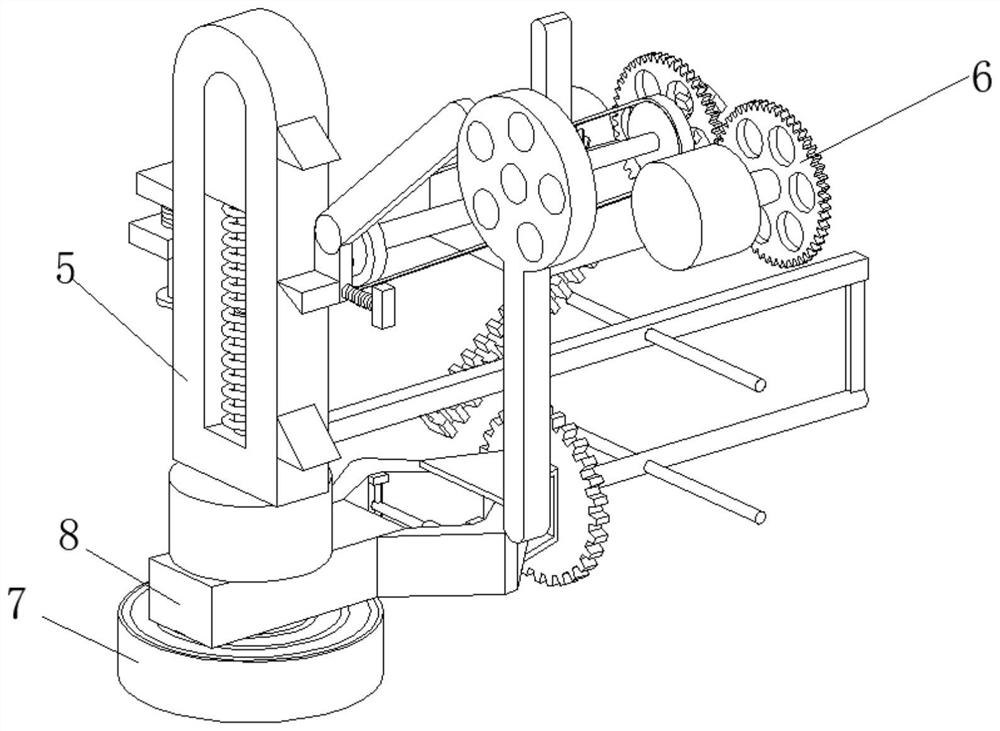

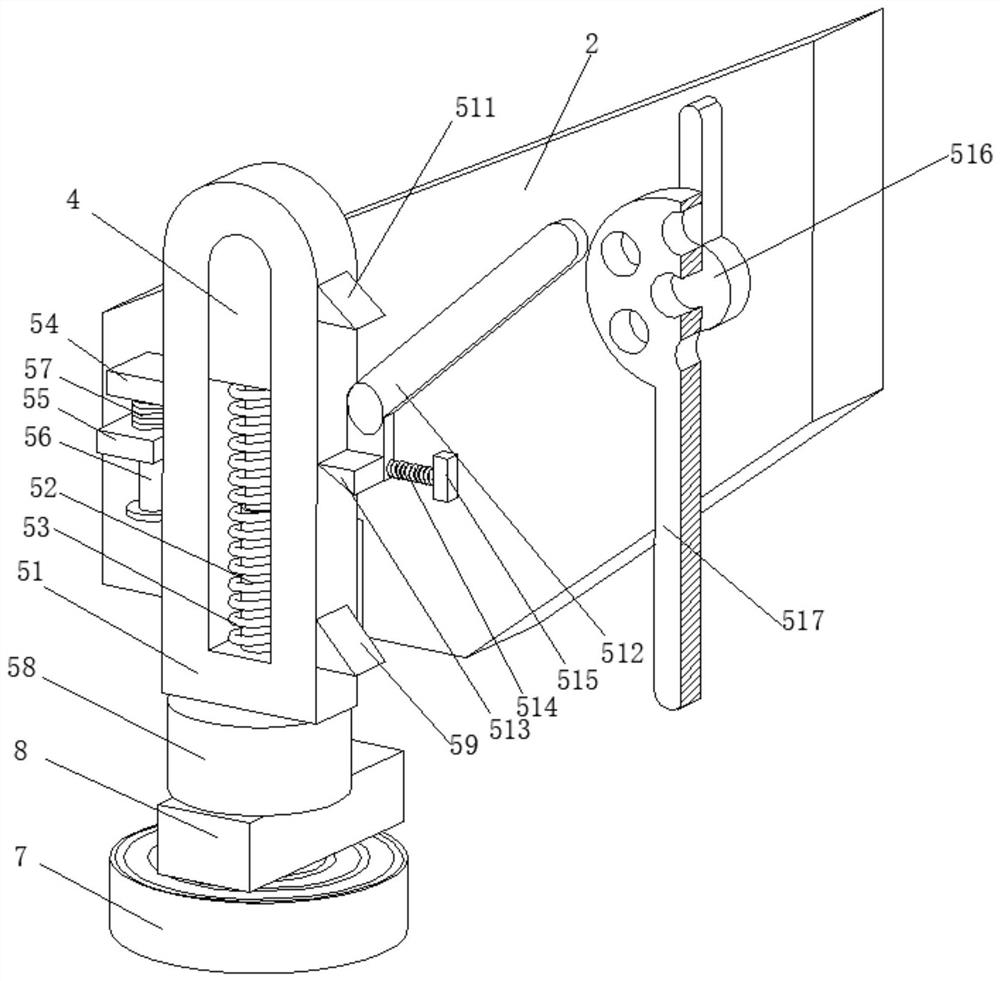

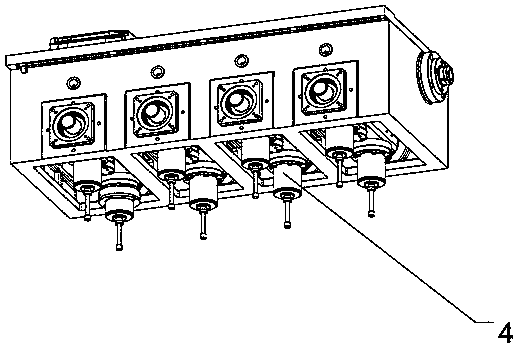

Full-automatic metal forging forming equipment

InactiveCN112475169AReduce the burden onExtended service lifeDrop hammersHammer drivesFully automaticBolt connection

The invention relates to the technical field of forging forming, and discloses full-automatic metal forging forming equipment. The full-automatic metal forging forming equipment comprises a box body,wherein a mounting plate and a supporting box are respectively welded to the front part of the box body; a limiting block is welded to the front part of the mounting plate, and a forging mechanism isarranged on the surface of the limiting block; a transmission mechanism is arranged on the right side of the mounting plate; a placing plate is connected to the top of the supporting box through bolts; and a clamping mechanism is arranged at the top of the containing plate. Through cooperative operation of the transmission mechanism, the forging mechanism and the clamping mechanism, steel can be automatically clamped and overturned while forging is conducted, therefore manual overturning of workers is not needed, the labor intensity of the workers is reduced, and the situation that the workingefficiency becomes low and even safety accidents are caused by fatigue due to long-time work of the workers is prevented. The steel can rotate intermittently through the transmission mechanism, therefore the steel cannot rotate during forging, the steel and a hammer head are prevented from interfering with each other, and the device cannot be damaged.

Owner:谢娟

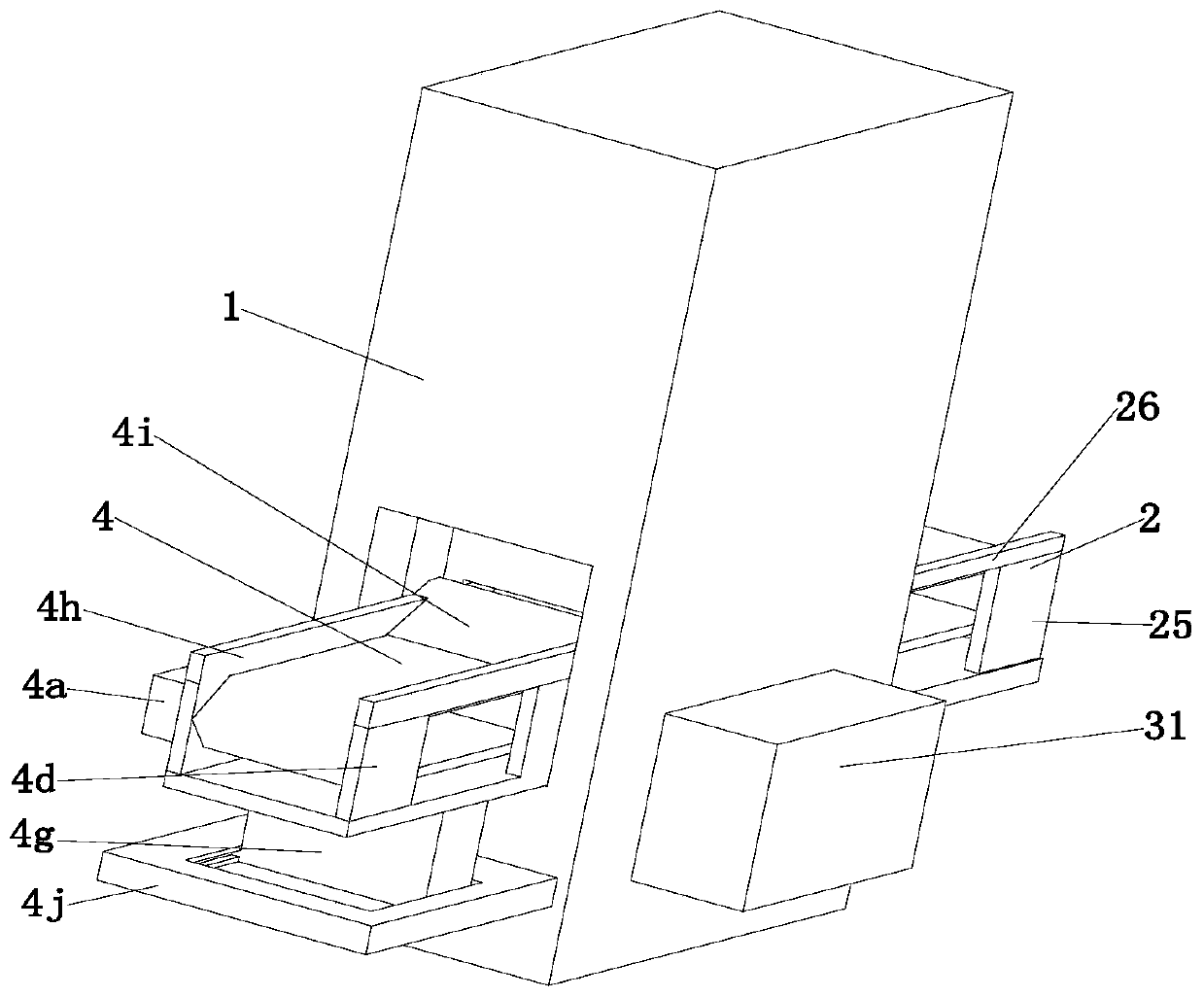

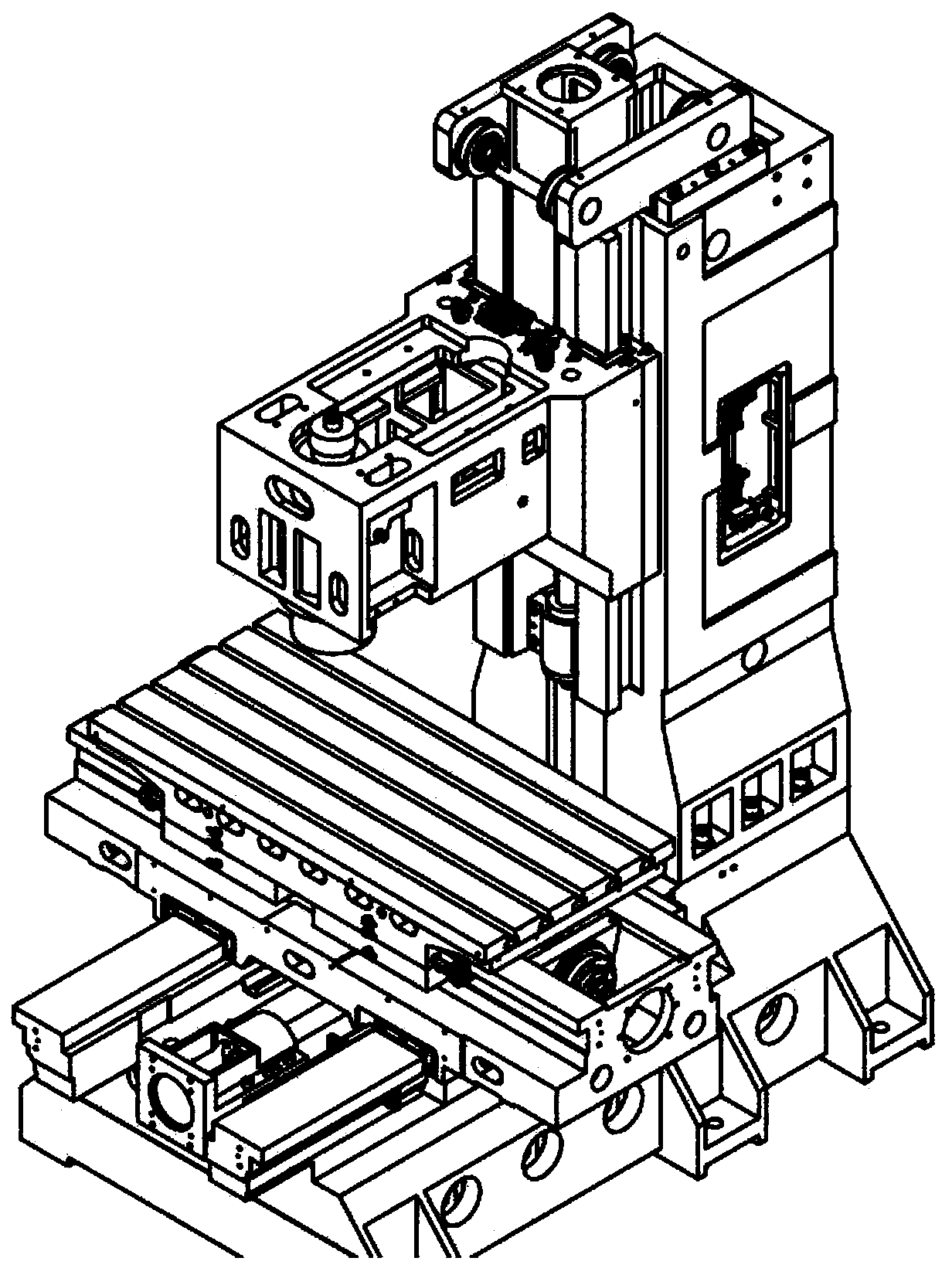

Vertical machining tool

ActiveCN111037315AEliminate the effects of movementWon't turnLarge fixed membersStructural engineeringMachine tool

The invention provides a vertical machining tool. The machine tool comprises a machine tool body and a Z-axis sliding table, two stand columns are fixedly connected to the machine tool bed. A Z-axis sliding rail is arranged on the stand columns. The two ends of the Z-axis sliding table are slidably connected with the Z-axis sliding rail. A main shaft is arranged in the middle of the Z-axis slidingtable; the main shaft is located below the Z-axis sliding table, a Y-axis sliding table is slidably connected to the machine tool bed through a Y-axis sliding rail, an X-axis sliding table is slidably connected to the Y-axis sliding table through an X-axis sliding rail, the Y-axis sliding rail and the X-axis sliding rail are horizontally arranged, the Y-axis sliding rail and the X-axis sliding rail are perpendicular to each other, and the included angle between the Z-axis sliding rail and the horizontal plane is 30-60 degrees. Through ingenious design of the vertical machining machine tool, the problem that in the prior art, a main shaft of a vertical machining machine tool rotates under the effect of torque is solved.

Owner:枣庄北航机床创新研究院有限公司

Angle-adjustable bending device for steel structure machining

The invention discloses an angle-adjustable bending device for steel structure machining, and relates to the technical field of steel structure machining and bending. The problem that the angle of steel structure machining and bending is inconvenient to adjust is solved. The bending device specifically comprises a workbench; a limiting baffle is arranged on the outer wall of the top end of the workbench; a fixed base is arranged on the outer wall of one side of the limiting baffle; a telescopic spring is arranged on the inner wall of one side of the fixed base; a telescopic connecting rod is arranged on the outer wall of one end of the telescopic spring; an active bearing block is arranged on the outer wall of one side of the telescopic connecting rod; and the peripheral outer wall of the telescopic connecting rod is movably connected to the inner wall of one side of the fixed base. By arranging a telescopic column composed of the fixed base, the telescopic spring and the telescopic connecting rod, after a pipeline is bent, the bent pipeline is automatically delivered out through the telescopic column, a worker can conveniently take out the bent pipeline, the flexibility of the device is improved, meanwhile, the telescopic spring can buffer pressure borne by the pipeline, a bent pipeline body is prevented from being damaged, and the device practicability is improved.

Owner:武汉市达人联盟房地产投资发展有限公司

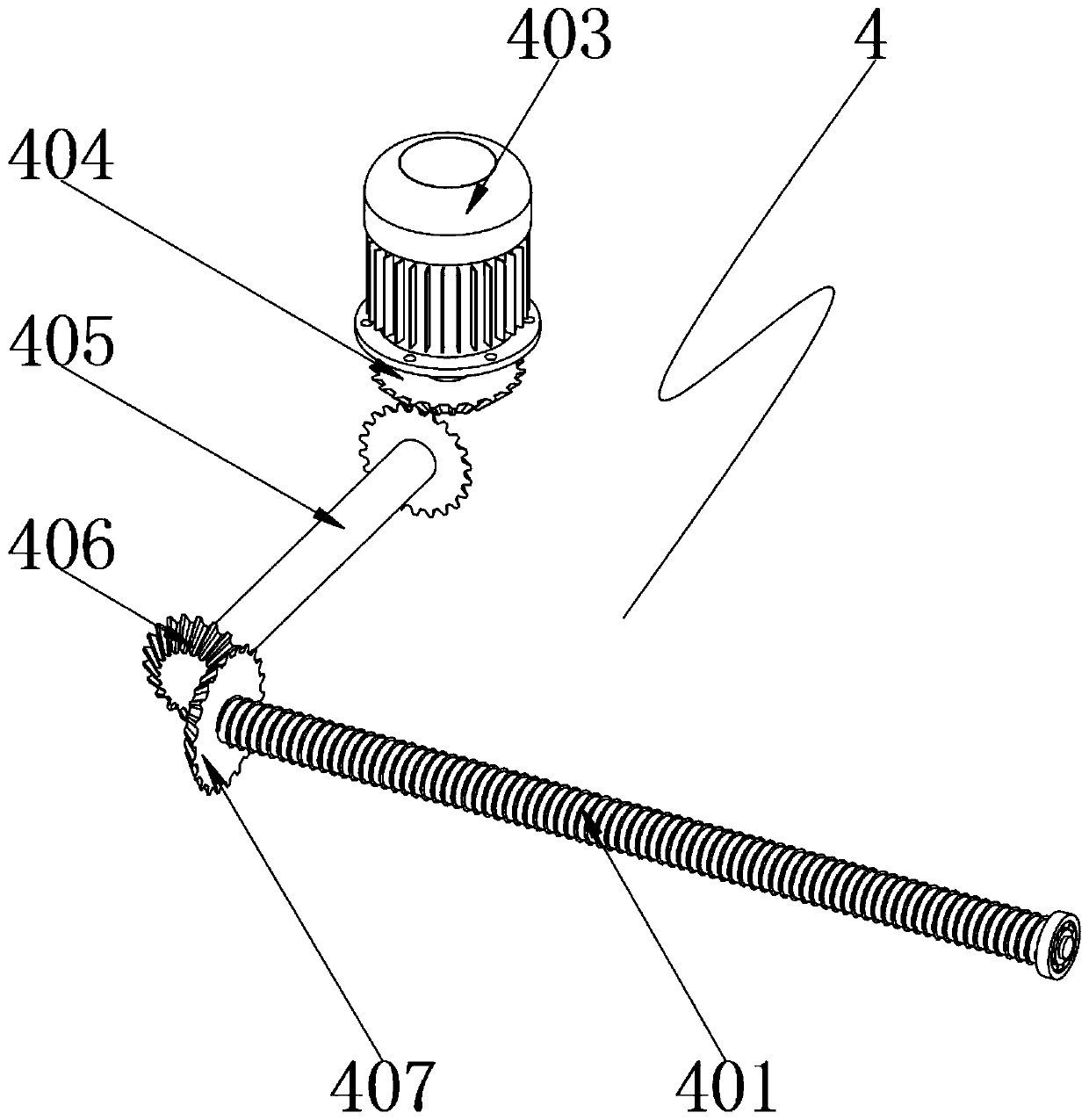

Wood waste centralized recovery device for wood processing

PendingCN108356709AEasy to recycleReduce bulkBark-zones/chip/dust/waste removalGrinding/polishing safety devicesGear drivePulp and paper industry

The invention discloses a wood waste centralized recovery device for wood processing. The wood waste centralized recovery device comprises a bottom plate, the upper surface of the bottom plate is fixedly connected with a supporting rod, the supporting rod is located on the left side of the upper surface of the bottom plate, and a supporting plate is fixedly connected to the upper portion of the right side face of the supporting rod; and a threaded cap is connected to the upper surface of the supporting plate in a clamped mode, and the internal thread of the threaded cap is in threaded connection with a threaded rod. According to the wood waste centralized recovery device for wood processing, by arranging a driving device, an output shaft of a motor in the driving device rotates forwards todrive a driving gear to rotate, the driving gear drives a driven gear to rotate, the threaded rod can be driven to move downwards by rotating in the threaded cap, and thus an extruding plate can be directly driven to move downwards; and the extruding plate moves downwards so that waste in a box can be compressed directly, thus filling power of the waste can be reduced, the occupied space of the waste during recovery can be reduced, and convenience is provided for people during recovery treatment of the wood waste.

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

Wireless charging pile for electric vehicle

PendingCN113547940AHeight adjustableAdjustable distanceHybrid vehiclesCharging stationsStructural engineeringElectric vehicle

The invention relates to the field of charging piles and discloses an electric vehicle wireless charging pile. The charging pile comprises a bottom plate, wherein a transmitting end is arranged on the bottom plate, a charging coil is arranged in the transmitting end, a lifting device is arranged at a lower end of the transmitting end, a mounting box is fixedly connected to a lower end of the bottom plate, and the lifting device is arranged in the mounting box; an opening is formed in an upper end of the bottom plate, the opening is communicated with the mounting box, the opening is matched with the transmitting end, a charging pile control box is fixedly connected to the left side of the bottom plate, a control panel is arranged on the charging pile control box, and an anti-collision device is arranged on the charging pile control box. The charging pile is advantaged in that a problem that an existing wireless charging pile is not provided with an anti-collision protection device and is prone to damage due to accidental collision is effectively solved, and meanwhile a problem that a charging coil in the existing charging pile is inconvenient to adjust is solved.

Owner:举视(深圳)新能源科技有限公司

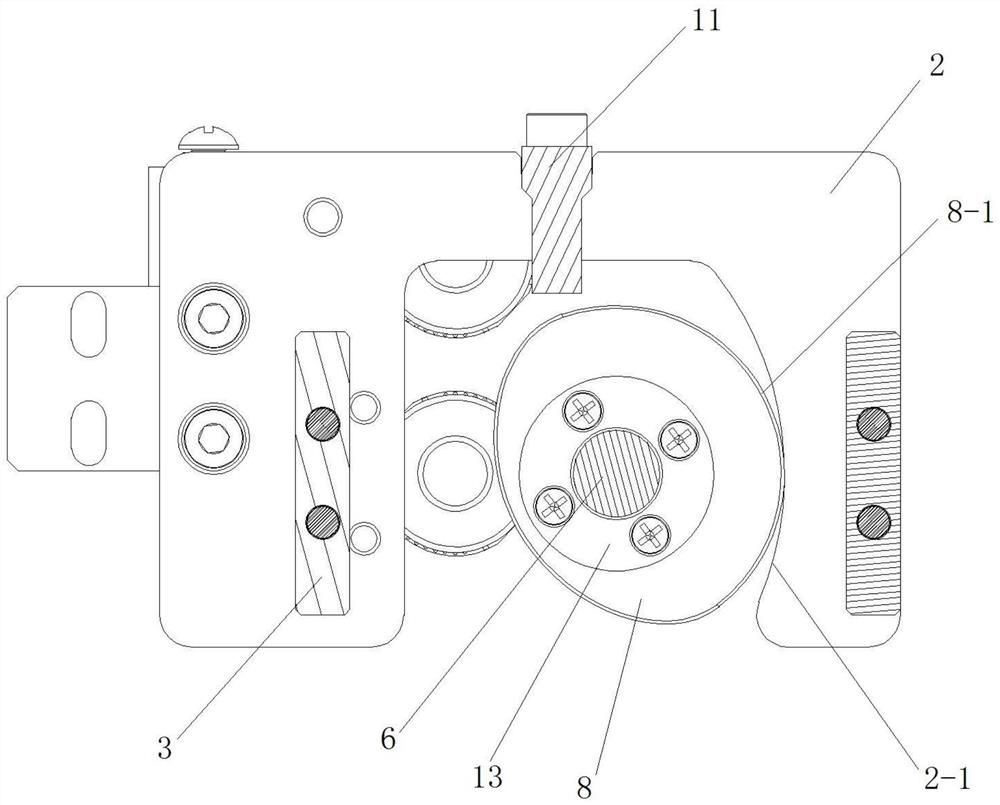

Cutting and milling mechanism of automatic machining equipment of wire stripping blade and control method of cutting and milling mechanism

ActiveCN108672778AWith self-locking functionAdd locking componentsMilling equipment detailsMetal working apparatusMilling cutterRotating disc

The invention relates to the field of automatic machining, in particular to a control method of a cutting and milling mechanism of automatic machining equipment of a wire stripping blade. A mounting base, a rotating switching assembly and a locking assembly are included. The rotating switching assembly comprises a rotary motor, a rotating disc and eight milling cutters of different specifications.The rotating disc is vertically arranged on the side, away from the rotary motor, of a supporting frame. The center of the rotating disc is fixedly connected with an output shaft of the rotary motor.The eight milling cutters are evenly distributed on the edge of the side, away from the rotary motor, of the rotating disc. Eight cutting and milling motors are arranged on the side, close to the rotary motor, of the rotating disc and are fixedly connected with the eight milling cutters in one-to-one correspondence. The locking assembly locks the rotating disc through lock holes in the rotating disc. According to the cutting and milling mechanism of the automatic machining equipment of the wire stripping blade, wire stripping grooves of different specifications can be automatically cut and milled out, the trouble of replacing the milling cutters by shutdown is omitted, and the production efficiency is improved.

Owner:台州孚亚电机有限公司

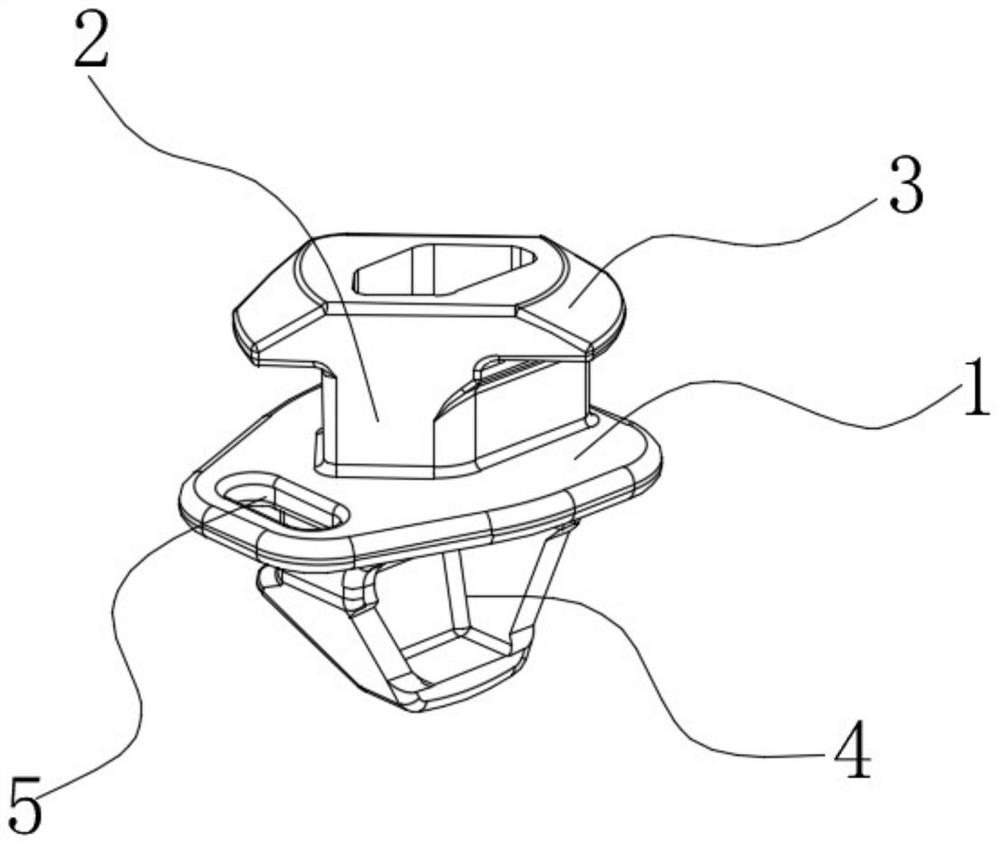

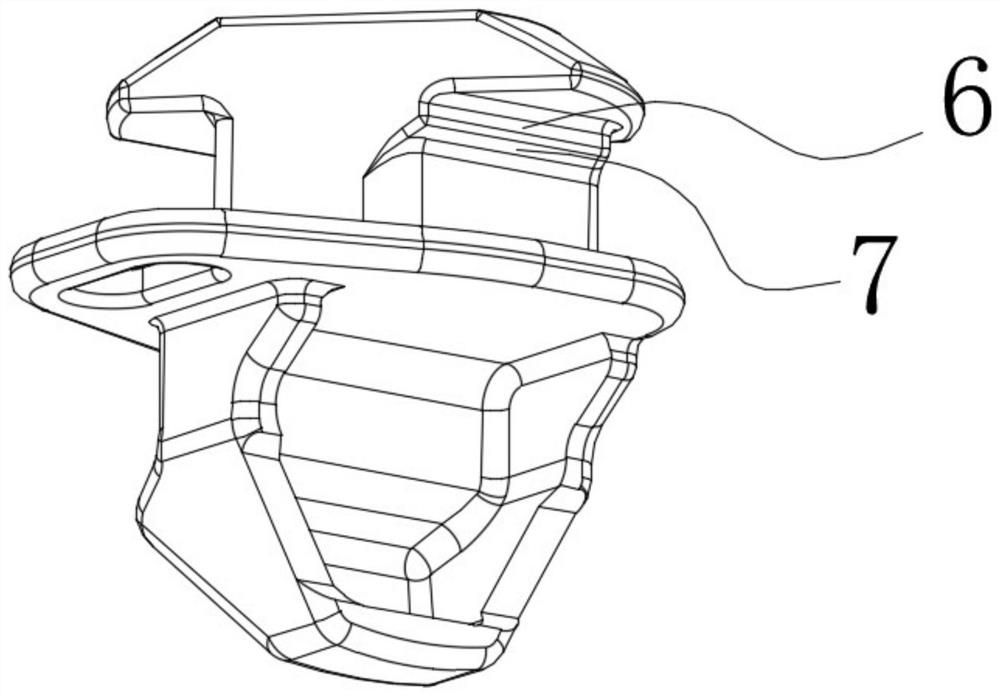

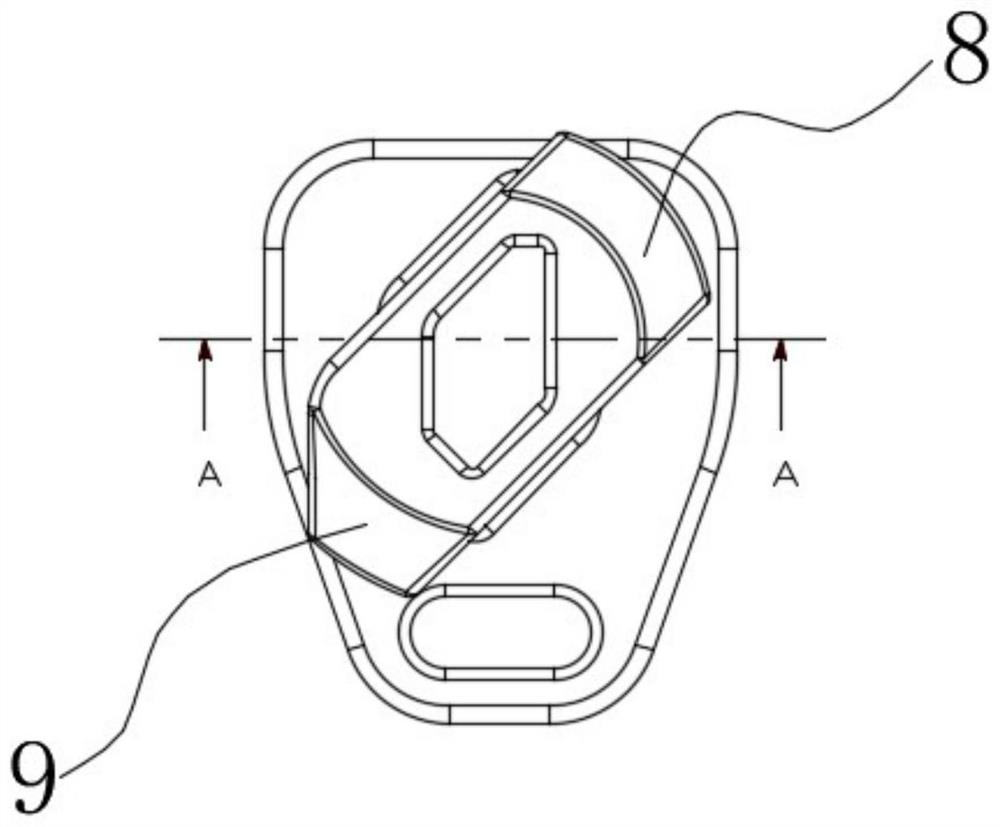

Automatic central lock for container

The invention discloses an automatic central lock for a container. The automatic central lock comprises a lock plate. A lock body and a lock hook are disposed on the upper side and the lower side of the lock plate correspondingly. Convex lugs are disposed at the two ends of the top of the lock body. A limiting step is disposed at the position, connected with the convex lug, of the side wall of oneside of the lock body. The automatic central lock for the container realizes an anti-rotation function by its limiting structure instead of original rocker arm, pin and other mechanical connection type limiting structures and is easy to operate.

Owner:上海中升科贸有限公司

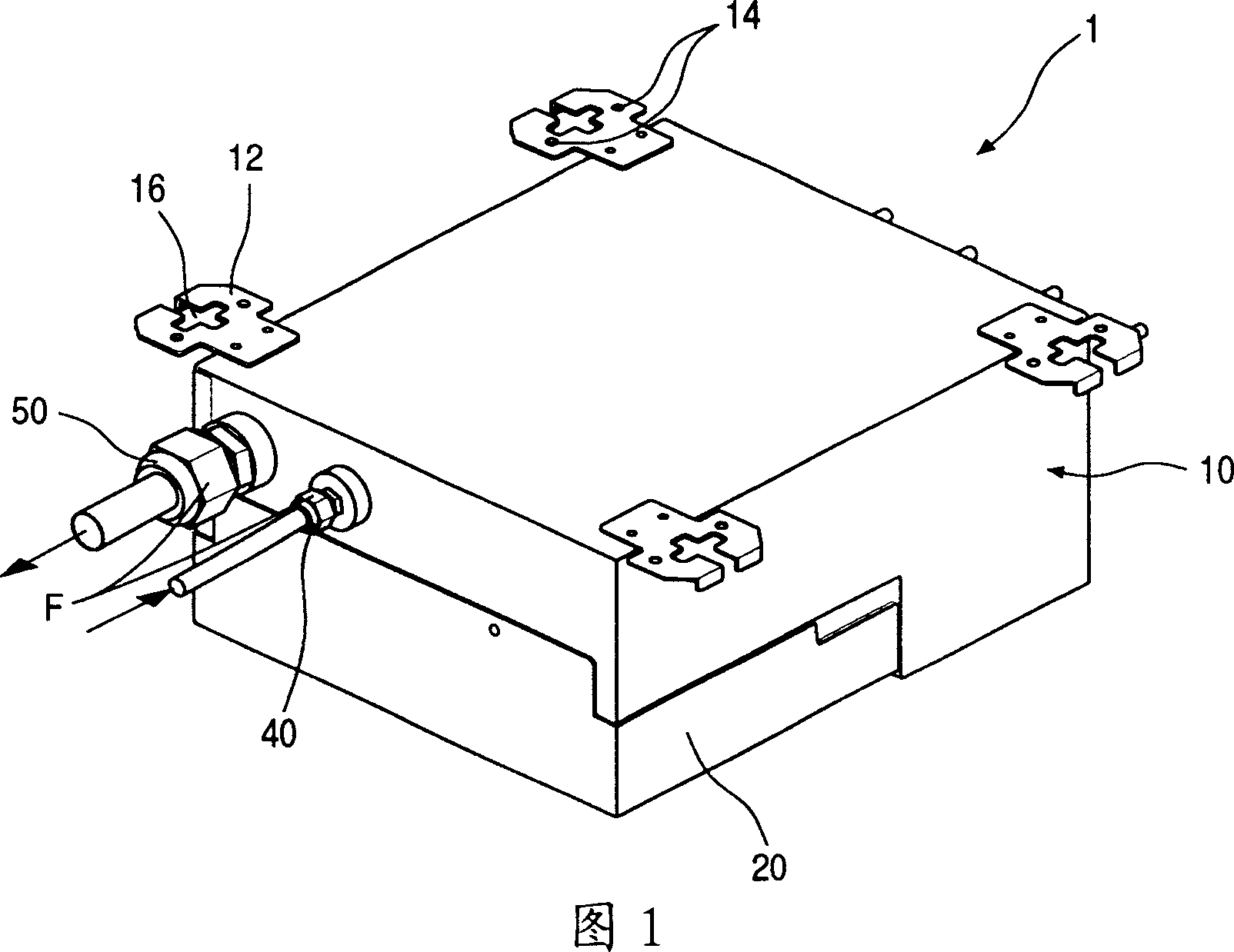

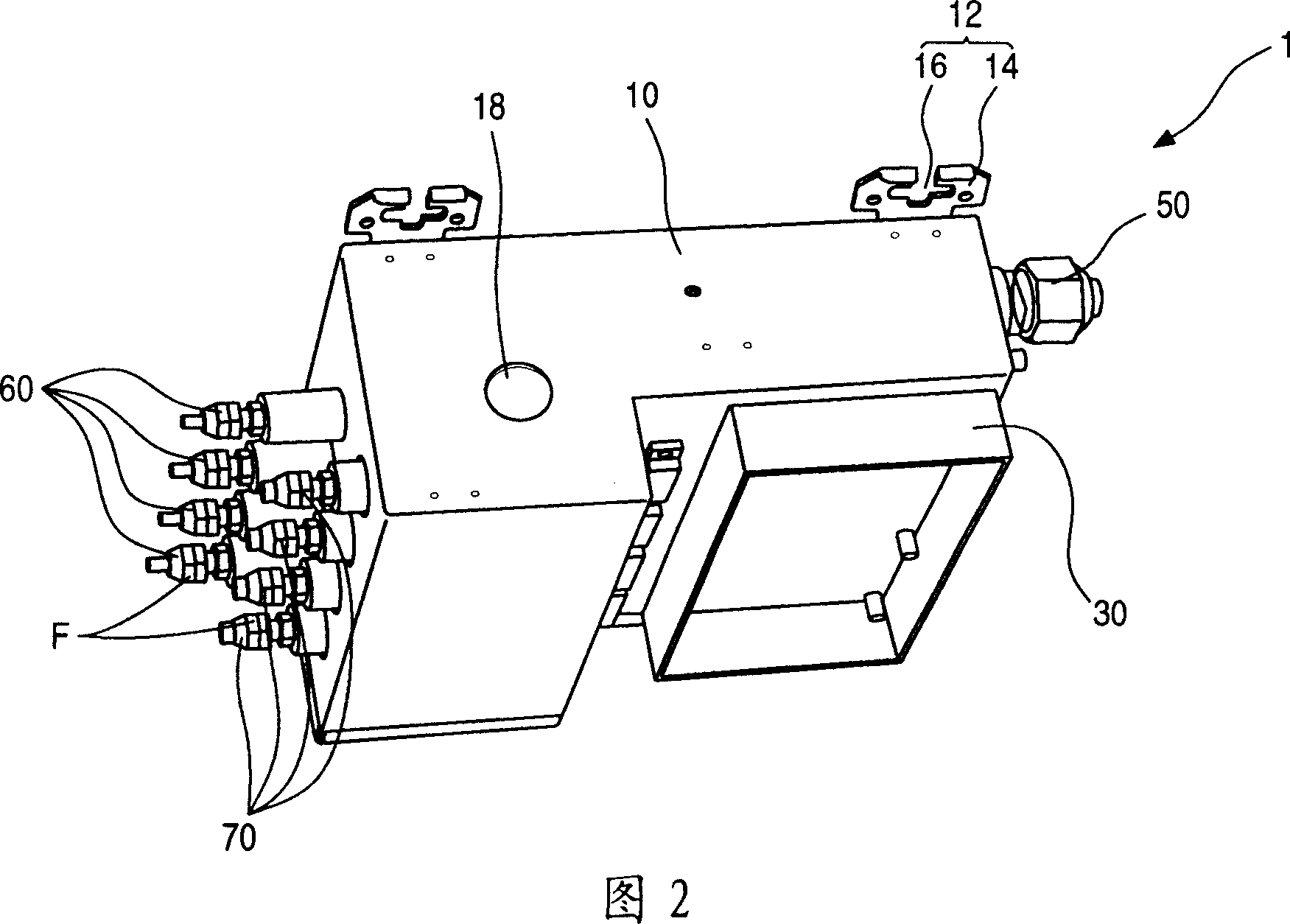

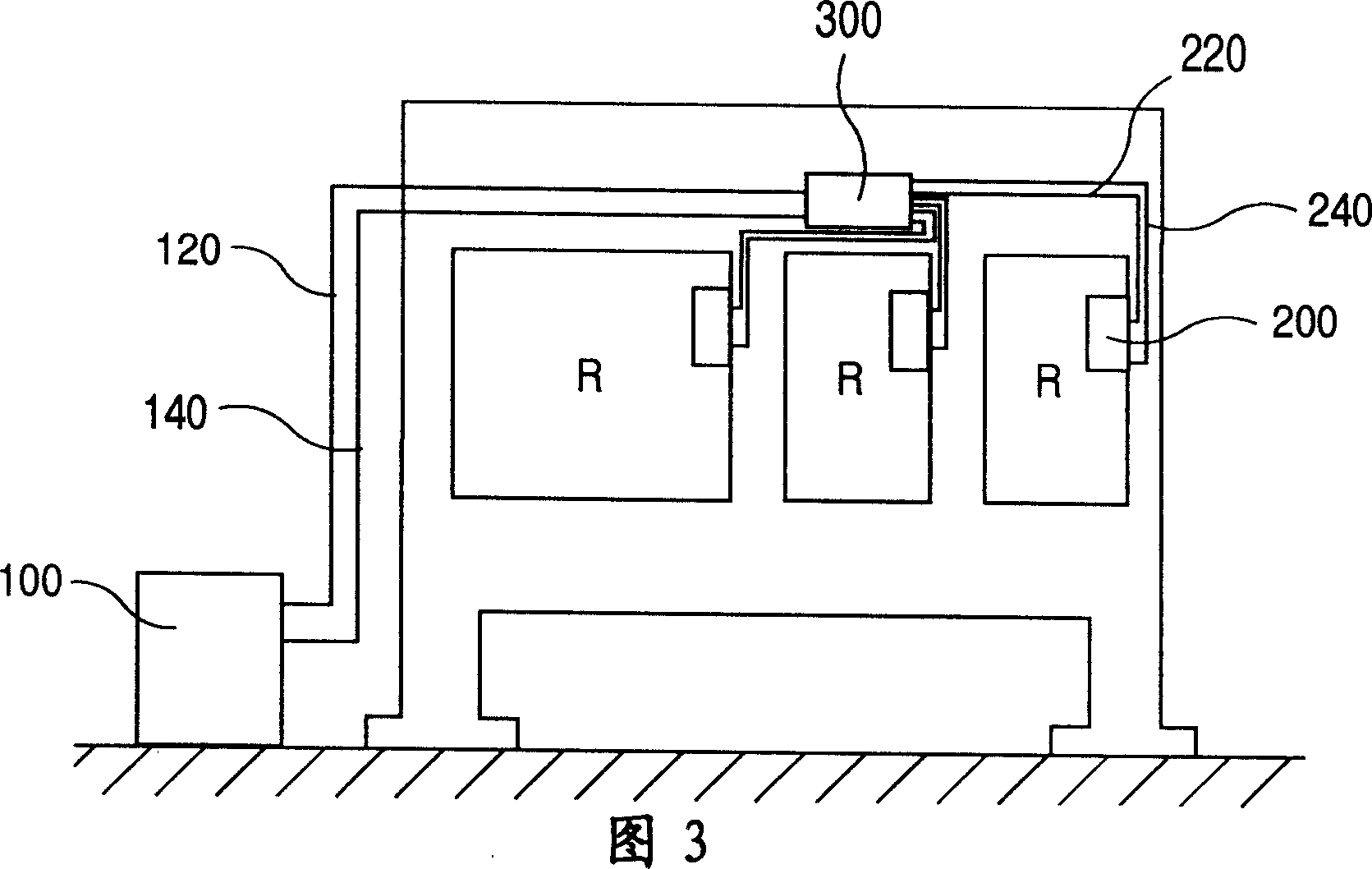

Distributor of combined type air conditioning equipment

InactiveCN1959308AAvoid contactAvoid damageFluid circulation arrangementRefrigeration safety arrangementLow voltageEngineering

A distributor of composite air-conditioner device consists of shell, indoor side high voltage socket set on shell and projected towards outside as well as used for leading refrigerant flowing in through outdoor unit to flow to indoor unit, indoor side low voltage socket for leading refrigerant being heat-exchanged through indoor unit to flow to internal of shell, setting one side of shell to be segment difference form to make two said sockets be set on shell in different vertical lines.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

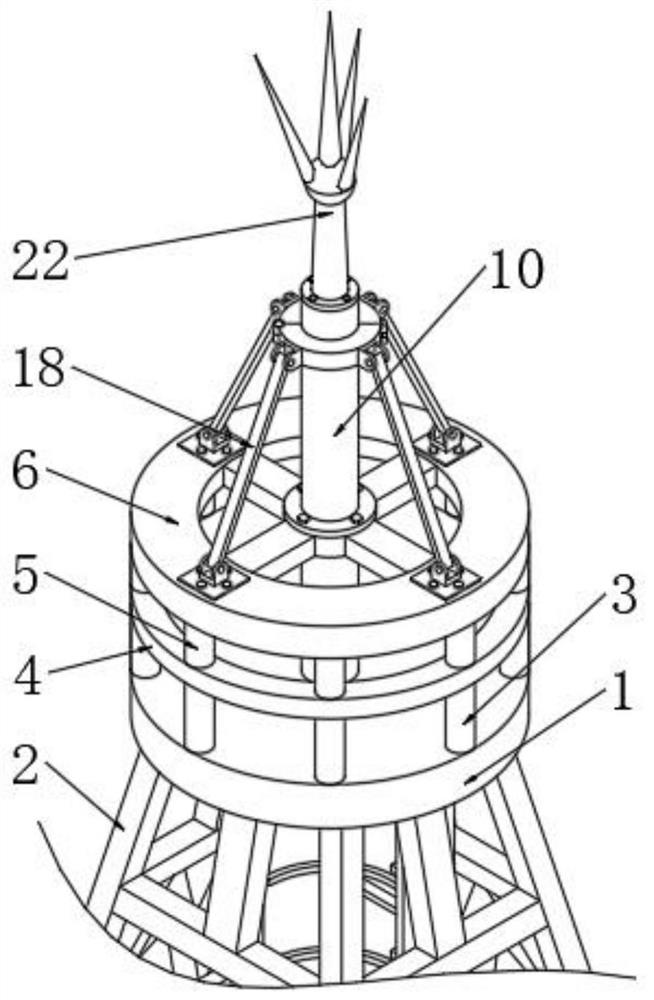

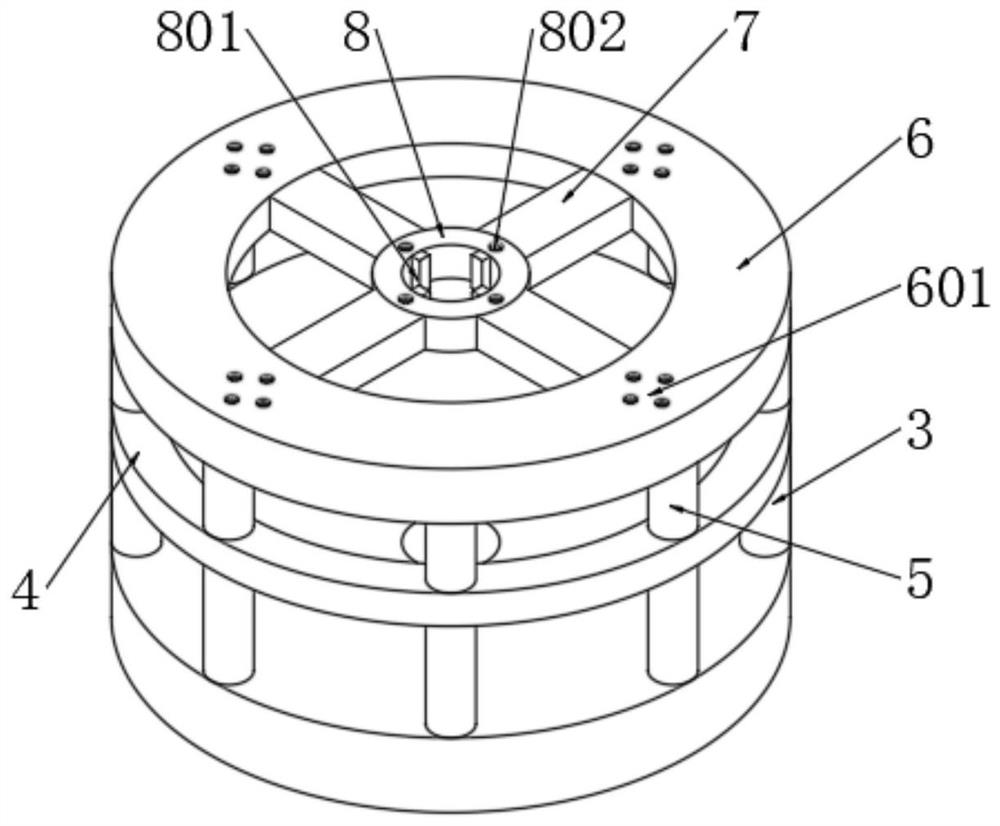

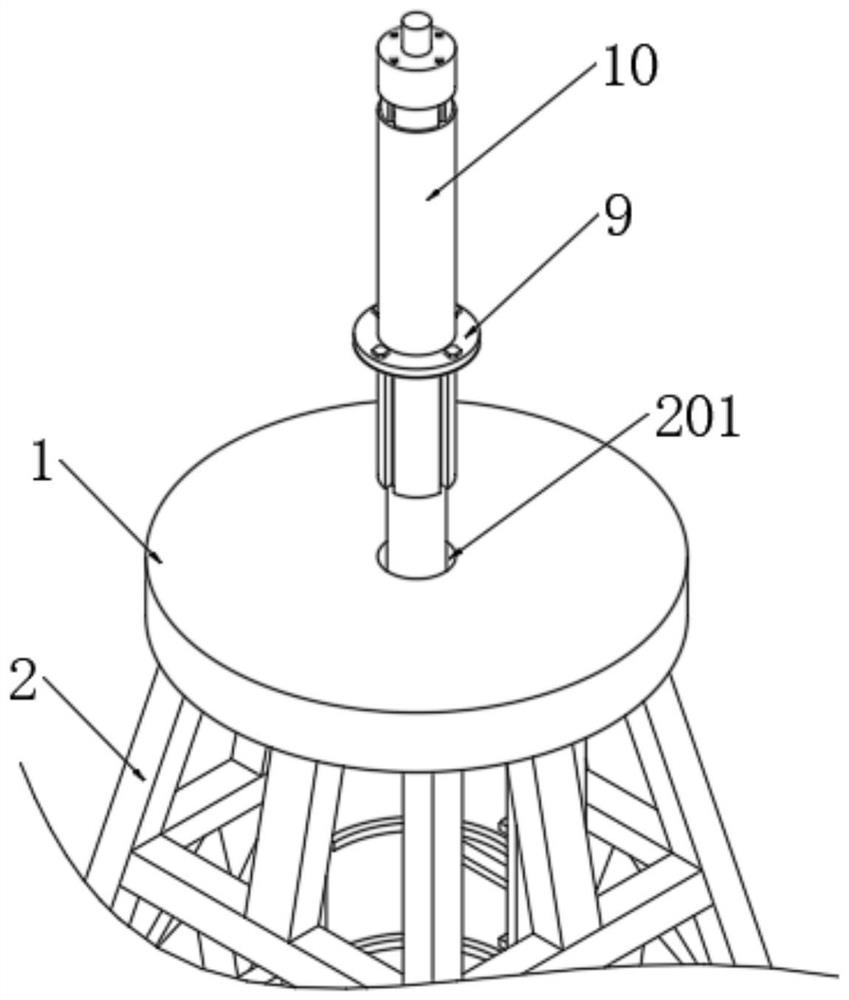

An easy-to-install lightning protection device for communication towers

ActiveCN112736651BAvoid direct installationReduce riskDischarge by conduction/dissipationCorona dischargeCircular discLightning rod

The invention discloses an easy-to-install lightning protection device for a communication tower. The top of the first support cylinder is fixedly connected with a first support ring, the top of the first support ring is fixedly connected with a plurality of second support cylinders around the top, and the tops of the plurality of second support cylinders are fixedly connected with a second support ring. The beneficial effects of the present invention are: the invention separates the main body of the lightning protection device into three parts: a circular connecting rod, a fixed cylinder and a conical circular platform, effectively avoiding the direct installation of the integrated device, and reducing the time required to transport the integrated lightning rod device to a communication tower at a high place Therefore, the four fixed bottom plates are sequentially fixed on the top of the second support ring, and the circular connecting rods are fixed by four support rods, so as to avoid the new type of shaking when the lightning protection device is used.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

A drying and dehydration system for making biomass fuel from crop straw

ActiveCN111006491BAvoid wasting resourcesNo dropBiofuelsSolid fuelsAgricultural scienceAgricultural engineering

The invention relates to a drying and dehydrating system for preparing biomass fuel from crop straws. The system comprises a straight plate, a feeding device, a transmission drying device and a discharging device, the feeding device is mounted on the outer wall of the left end of the straight plate, the discharging device is mounted on the outer wall of the right end of the straight plate, and thetransmission drying device is mounted in the straight plate. According to the system, the following problems during drying and dehydration of crop straws can be solved: 1, at present, domestic crop straws are basically dried and dehydrated on an open-air platform, the straws are dehydrated and aired in an airing mode, the airing effect and the airing time of the straws can be affected by changesof weather, and the straws can be damped again in the airing process; and 2, an existing crop straw drying and dewatering device basically conducts dewatering operation on straws through rotation of adewatering barrel, the dewatering barrel rotates generally to only spin-dry moisture on the outer surface of the straws, and the moisture in the straws is difficult to spin out directly.

Owner:国电建三江前进生物质发电有限公司

A alloy saw blade processing fixture with stable clamping and multi-angle adjustment

ActiveCN110153745BStable clampingEasy to installPositioning apparatusMetal working apparatusHydraulic cylinderElectric machinery

The invention relates to the technical field of alloy saw web machining and discloses an alloy saw web machining clamp capable of achieving stable clamping and multi-angle adjustment. The alloy saw web machining clamp comprises a base. A limiting plate is fixedly mounted at the top of the base. A support plate is fixedly mounted at the top of the base. A movable seat is movably mounted at the topof the support plate. A hydraulic cylinder is movably mounted inside the base, wherein the hydraulic cylinder extends to the top of the base. Connecting rods are fixedly mounted at the top of the hydraulic cylinder, wherein the connecting rods are located at the bottom of the movable seat. Limiting rods are fixedly mounted at the left side and the right side of the movable seat correspondingly, wherein the limiting rods penetrate the limiting plate and extend to the side, away from the movable seat, of the limiting plate. A motor is fixedly mounted inside the movable seat. A first fixing plateis fixedly mounted at an output shaft of the motor, wherein the first fixing plate is located at the top of the movable seat. By means of the alloy saw web machining clamp capable of achieving stableclamping and multi-angle adjustment, the angle of an alloy saw web can be adjusted, and a user can use the alloy saw web machining clamp more conveniently under different circumstances.

Owner:高邮市翔宇机械制造有限公司

Bolt propeller

InactiveCN113531075AReduce volumeRotation will notGearingMechanical energy handlingTorque motorElectric machinery

The invention discloses a bolt propeller which comprises a motor shell. A frameless torque motor is arranged in the motor shell, a nut and a nut adapter are arranged in the frameless torque motor, the nut is in transmission connection with the frameless torque motor through the nut adapter, and a lead screw matched with the nut is arranged in the nut. The bolt propeller further comprises a guide pushing column arranged a the extending end of the lead screw. According to the structural design, a driving rod in a traditional motor is omitted, the lead screw is directly installed in the motor, utilization of the length space in the motor is achieved, and therefore the size of the device is greatly reduced.

Owner:苏州卓誉电气技术有限公司

Convenient-to-use cleaning device for centrifugal wind wheel of oven fan

InactiveCN112024505AEasy to useEasy to use Oven Fan Centrifugal Wind Wheel Easy to cleanCleaning using liquidsStructural engineeringMechanical engineering

The invention discloses a convenient-to-use cleaning device for a centrifugal wind wheel of an oven fan. The cleaning device comprises a bottom plate, wherein a through hole is formed in the middle ofthe upper surface of the bottom plate, a sliding rod is arranged in the through hole, the left end and the right end of the sliding rod are fixedly connected to the left side face and the right sideface of the inner wall of the through hole respectively, the surface of the sliding rod is sleeved with two sliding sleeves, the two sliding sleeves are located on the left side and the right side ofthe surface of the sliding rod respectively, and first connecting blocks are fixedly connected to the lower surfaces of the two sliding sleeves respectively. According to the convenient-to-use cleaning device for the centrifugal wind wheel of the oven fan, by arranging a rotating device, rotary shafts, threaded rods, threaded caps, the sliding sleeves and extrusion plates, the two extrusion platesmove close to each other so that the centrifugal wind wheel to be cleaned can be fixed, therefore, the centrifugal wind wheel cannot move in the cleaning process, the centrifugal wind wheel is prevented from falling off and being damaged, and convenience is brought to people in the process of cleaning the centrifugal wind wheel of the oven fan.

Owner:刘闪闪

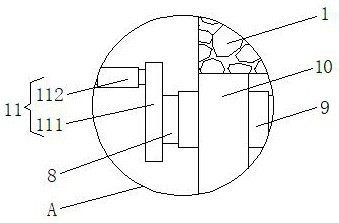

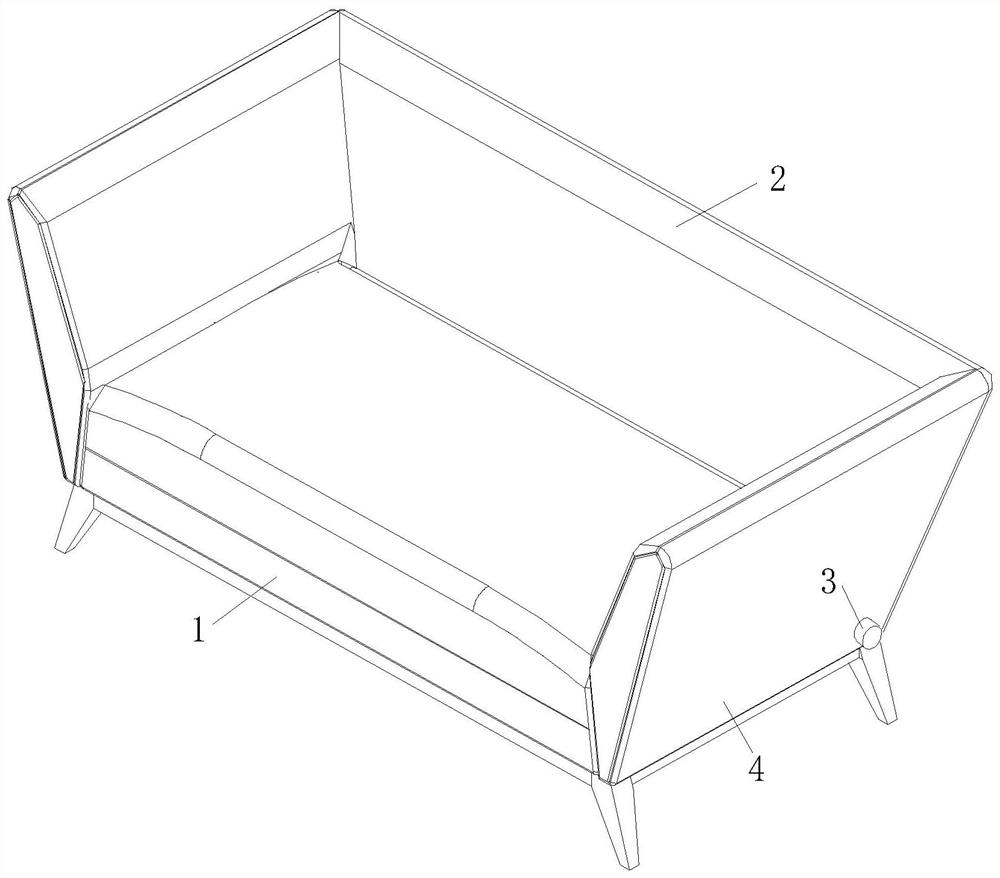

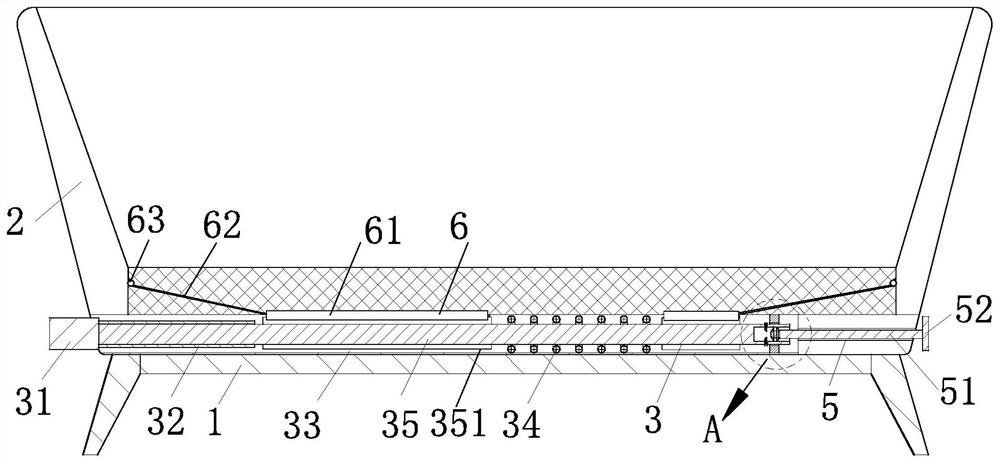

Multifunctional sofa based on Internet of Things

InactiveCN111616548ARotation doesn't happenFlipSofasCouchesCushionElectrical and Electronics engineering

The invention relates to the technical field of sofas, in particular to a multifunctional sofa based on Internet of Things. The multifunctional sofa comprises a bottom plate, a back cushion is movablyarranged on the side wall of the bottom plate, side baffles fixed on the bottom plate are arranged on the two sides of the back cushion, and a transmission mechanism is arranged on the bottom plate;an air outlet mechanism is mounted in the bottom plate; through the arranged transmission mechanism, a transmission rod can rotate to drive a threaded sleeve to rotate through rotation between the transmission mechanism and the threaded sleeve, therefore, the back cushion can be turned over, and the backrest sofa can be used as a lying bed; through cooperation of a limiting rod, a limiting block and a first spring, a circular clamping head on the clamping mechanism can be fixed through the limiting block, and therefore the function of firm clamping is achieved; and the transmission mechanism and the clamping mechanism are fixed, so that the transmission mechanism is limited, the transmission mechanism rotates to a required position, the transmission mechanism does not rotate, and the backcushion is stabilized.

Owner:董志刚

Lock motor with multi-gear positioning function

InactiveCN110365154ASolve problems with fewer optionsPrecise positioningSupports/enclosures/casingsCouplingIndustrial engineering

Owner:苏州克维拉通讯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com