Tool for assembling photoelectric turntable motor

A photoelectric turntable and tooling technology, which is applied in the field of mechanical assembly, can solve the problems of being unable to carry freely, complicated operation process, and inability to realize assembly, etc., and achieve the effect of reducing labor intensity of workers, simple operation, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

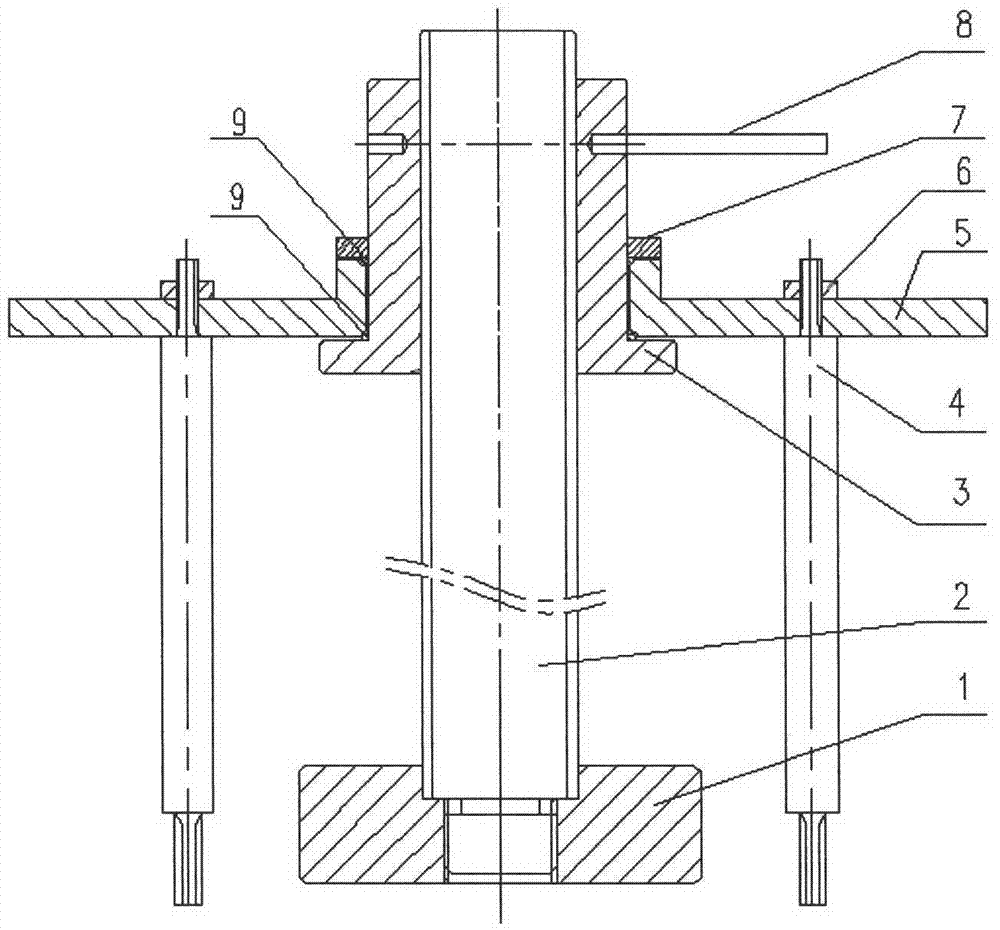

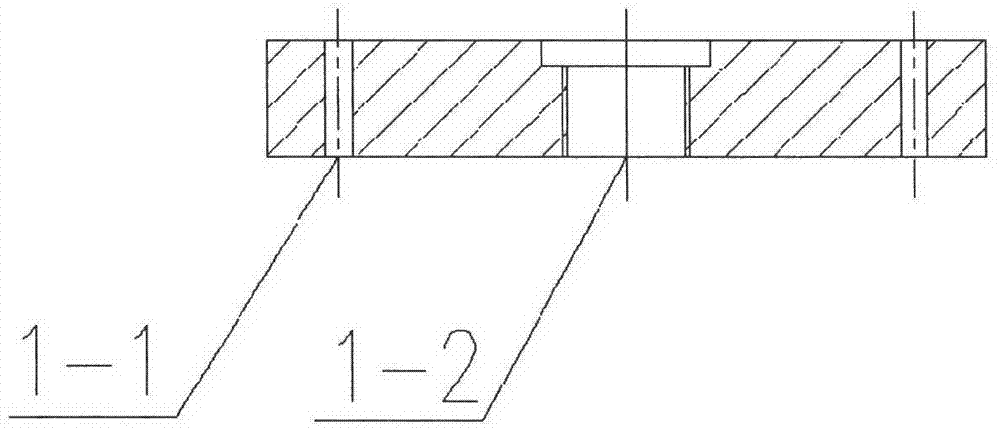

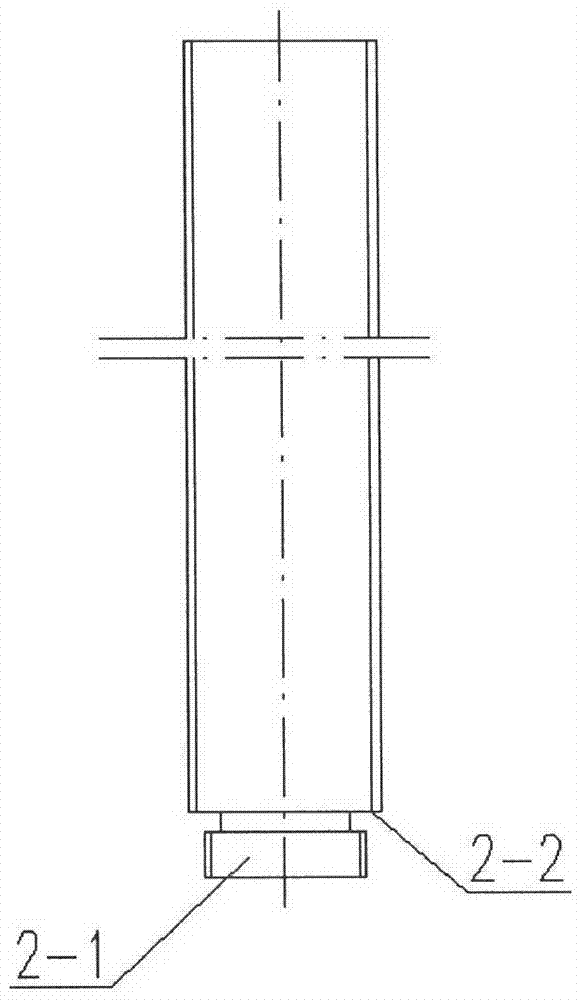

[0019] as figure 1 As shown, the tooling of the preferred embodiment of the present invention includes a centering mandrel 1, a lifting screw 2, a lifting nut 3, four pull rods 4, a cross plate 5, four nuts 6, a pressure ring 7, one or two spanners Bar 8, some steel balls 9. The centering mandrel 1 has four through holes 1-1 and a center hole 1-2 (see figure 2 ), the lower section of the center hole is a screw hole, and the upper port is an expanding diameter positioning platform. The four through holes 1-1 are evenly distributed on the circumference concentric with the center hole 1-2. The process wire holes on the static shaft correspond to each other. The outer diameter of the centering mandrel 1 matches the sinking platform of the static axis of the photoelectric turntable. The lifting screw 2 is a double-ended trapezoidal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com