Transfusion needle mechanical needle tube mounting technique and device thereof

A technology for infusion needles and needle tubes, which is applied to needles, hypodermic injection devices, and devices introduced into the body. It can solve problems such as low work efficiency, maintaining the direction of the needle surface, and contamination of infusion needle products, and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

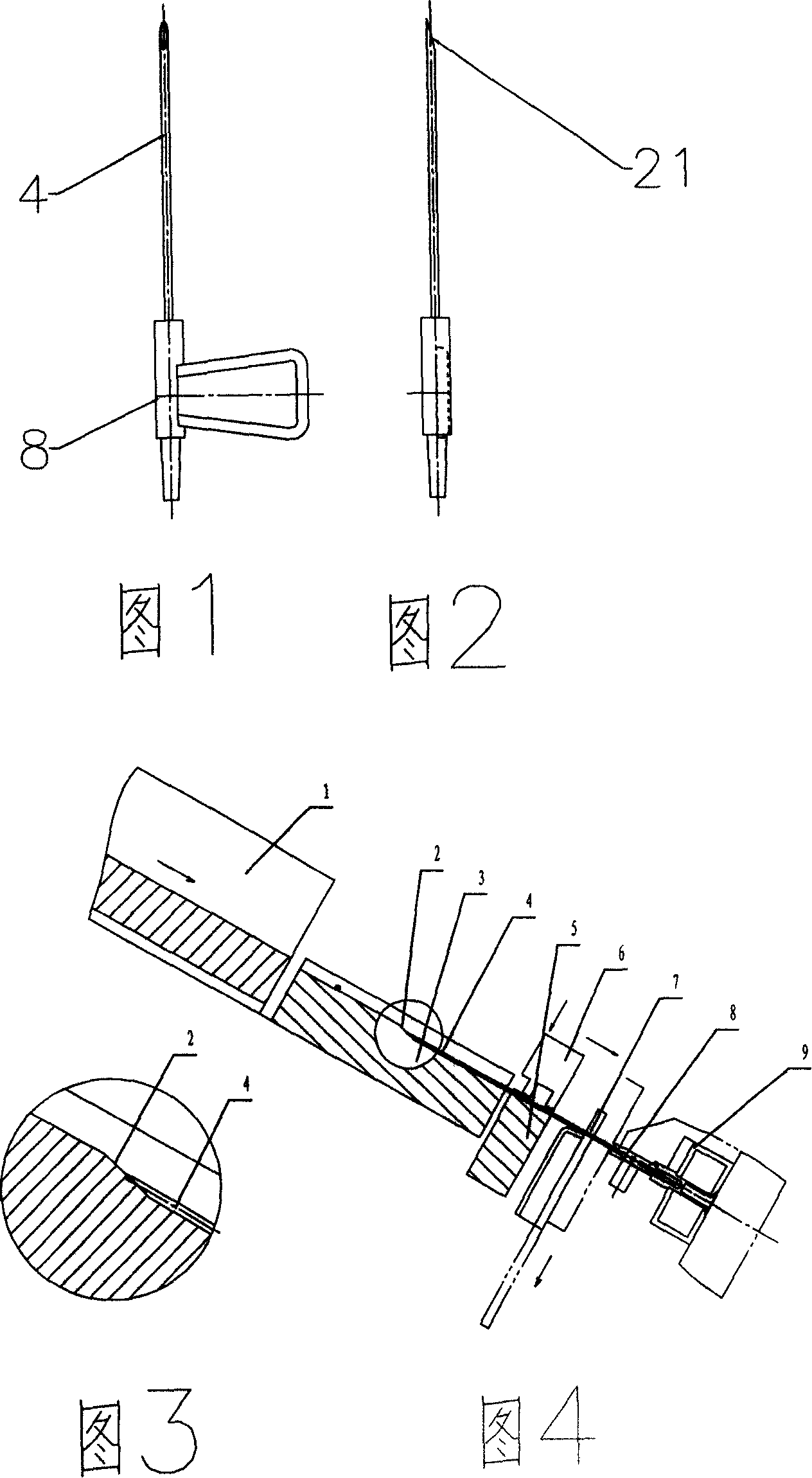

[0018] The mechanized needle loading technology for infusion needles described in this embodiment is to set up and control the orientation of the beveled surface of the needle head during the flow of the needle tube, so as to complete the oriented slope in which the beveled surface of the needle tip of the infusion needle is basically parallel to the wing surface of the needle seat. flat. The directional inclined plane contains continuous transitional inclined planes in the stepped parallel grooves, and the transitional inclined planes are made of materials containing metal or non-metal or a combination of metal and non-metal. After the needle tube slides down the groove, it rotates around its own axis due to vibration. When the inclined surface of the needle point and the oriented inclined plane meet, the needle tube no longer rotates, ensuring the orientation of the needle tube. The infusion needle is shown in Figure 1 and Figure 2.

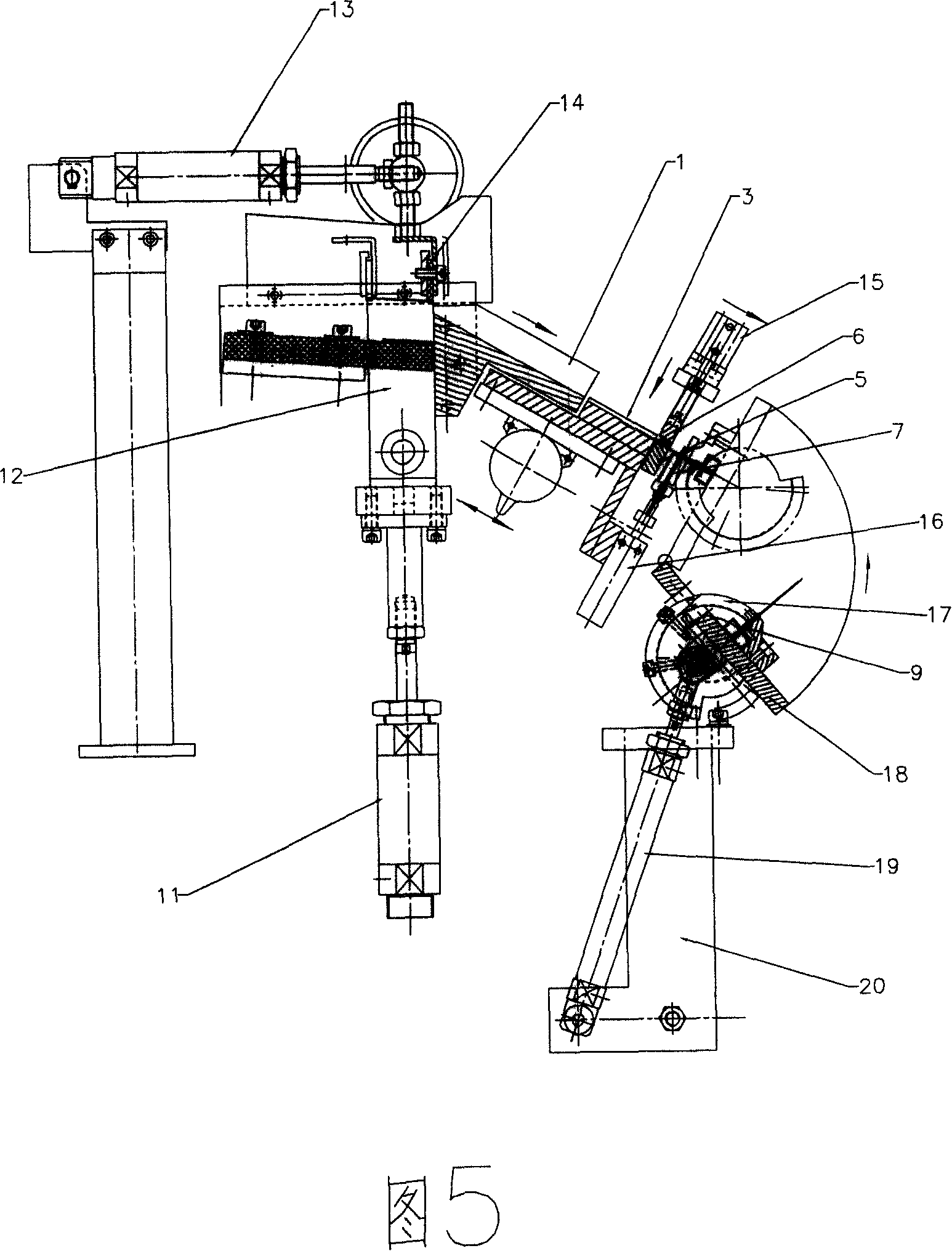

[0019] The device structure is shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com