Rotary roller elevator capable of achieving stable transmission

A rotary and elevator technology, applied in the direction of lifting frames, conveyor objects, lifting devices, etc., can solve the problems of large height difference, high cost, low manual handling efficiency, etc., and achieve the effect of facilitating automatic feeding and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

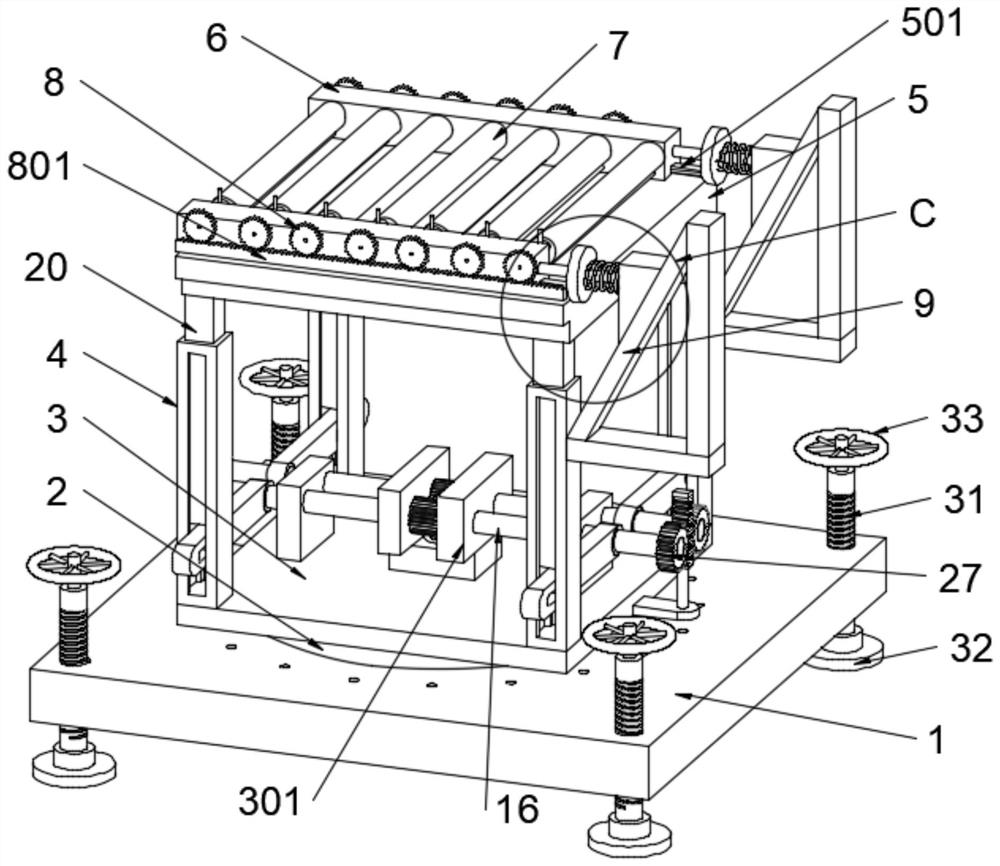

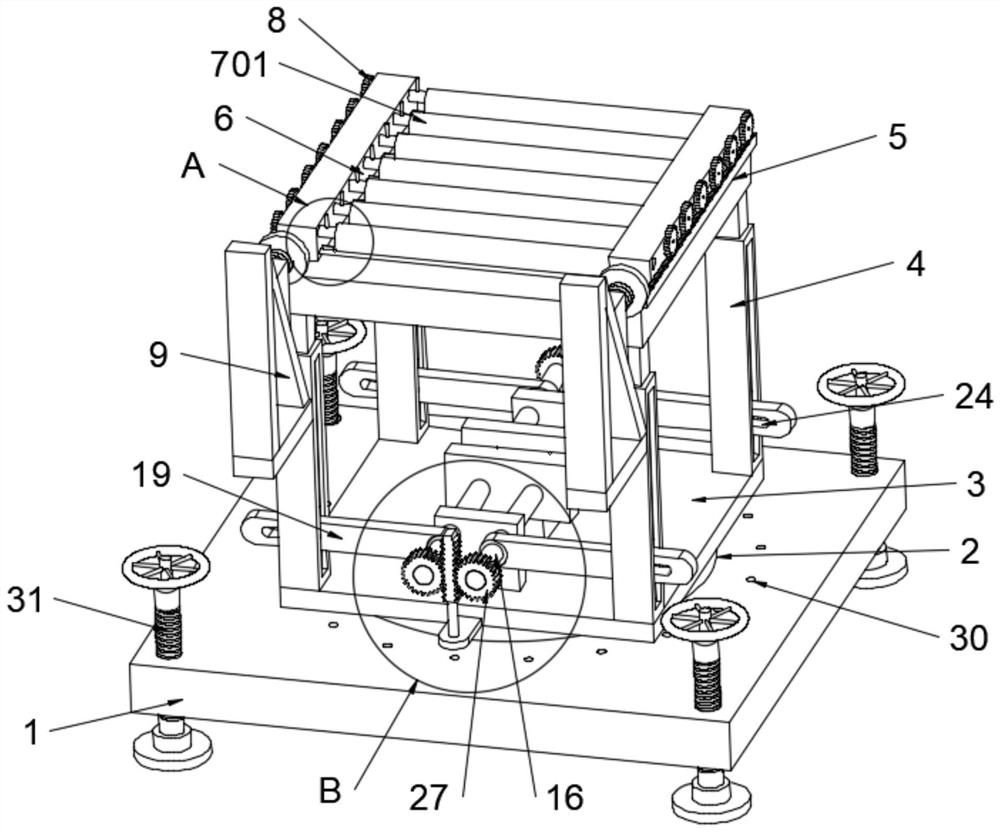

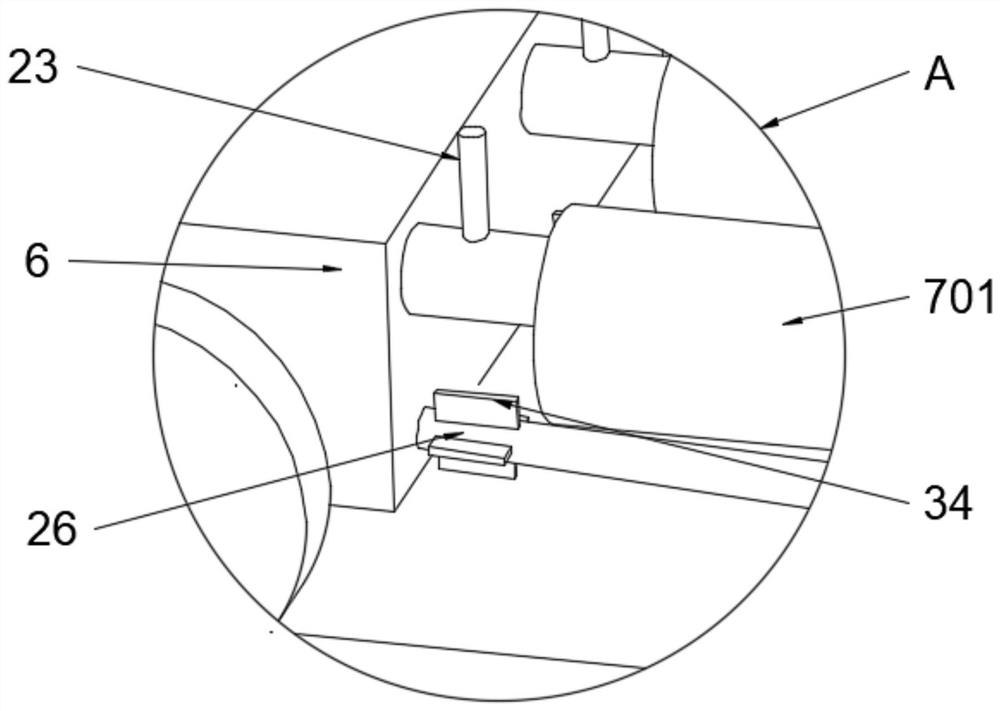

[0029] see Figure 1 to Figure 9 , the present invention provides a technical solution: a rotary drum lift capable of stable transmission, comprising a base 1, the upper surface of the base 1 is provided with a rotating table 2 that rotates at a fixed axis, and the upper surface of the rotating table 2 is fixedly connected with an installation platform 3, The four corners of the upper surface of the installation platform 3 are fixedly connected with the limit column 4, and the lift platform 5 is arranged directly above the limit column 4. The upper surface of the lift platform 5 is symmetrically provided with a guide rail 501, and the guide rail 501 is provided with a conveying platform 6. On the conveying platform 6 A feeding mechanism is provided, and the feeding mechanism includes several eccentric rollers 7 rotating on the inner wall of the conveying platform 6 with fixed axes. 8 intermeshed tooth plates-801, one side of the limit column 4 is fixedly installed with an incl...

Embodiment 2

[0044] Such as Figure 1 to Figure 10 As shown, on the basis of the first embodiment, the difference is that the eccentric roller one 7 is replaced by the second eccentric roller 701, and the specific replacement method is that the material mechanism includes the second eccentric roller 701, and the second eccentric roller 701 is provided with several, several eccentric rollers The two 701 intervals are distributed on the inner wall of the conveying platform 6. The output shafts at both ends of the eccentric roller 7 run through the inner wall of the conveying platform 6 and are fixedly connected with the gear 1 8.

[0045] By setting the eccentric roller 2 701 with the eccentric lower axis distributed up and down on the inner wall of the conveying platform 6 at intervals, the shaking frequency of the goods on the conveying platform 6 can be increased, and the dust accumulated on the surface of the goods can be quickly shaken off by increasing the shaking frequency .

[0046]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com