Patents

Literature

41results about How to "Increase the output signal amplitude" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

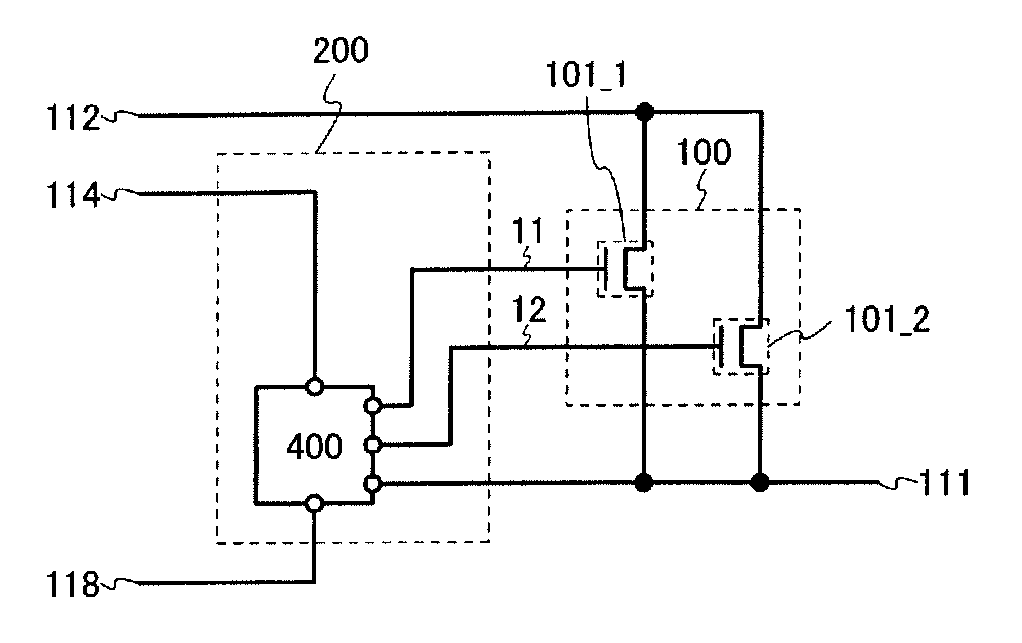

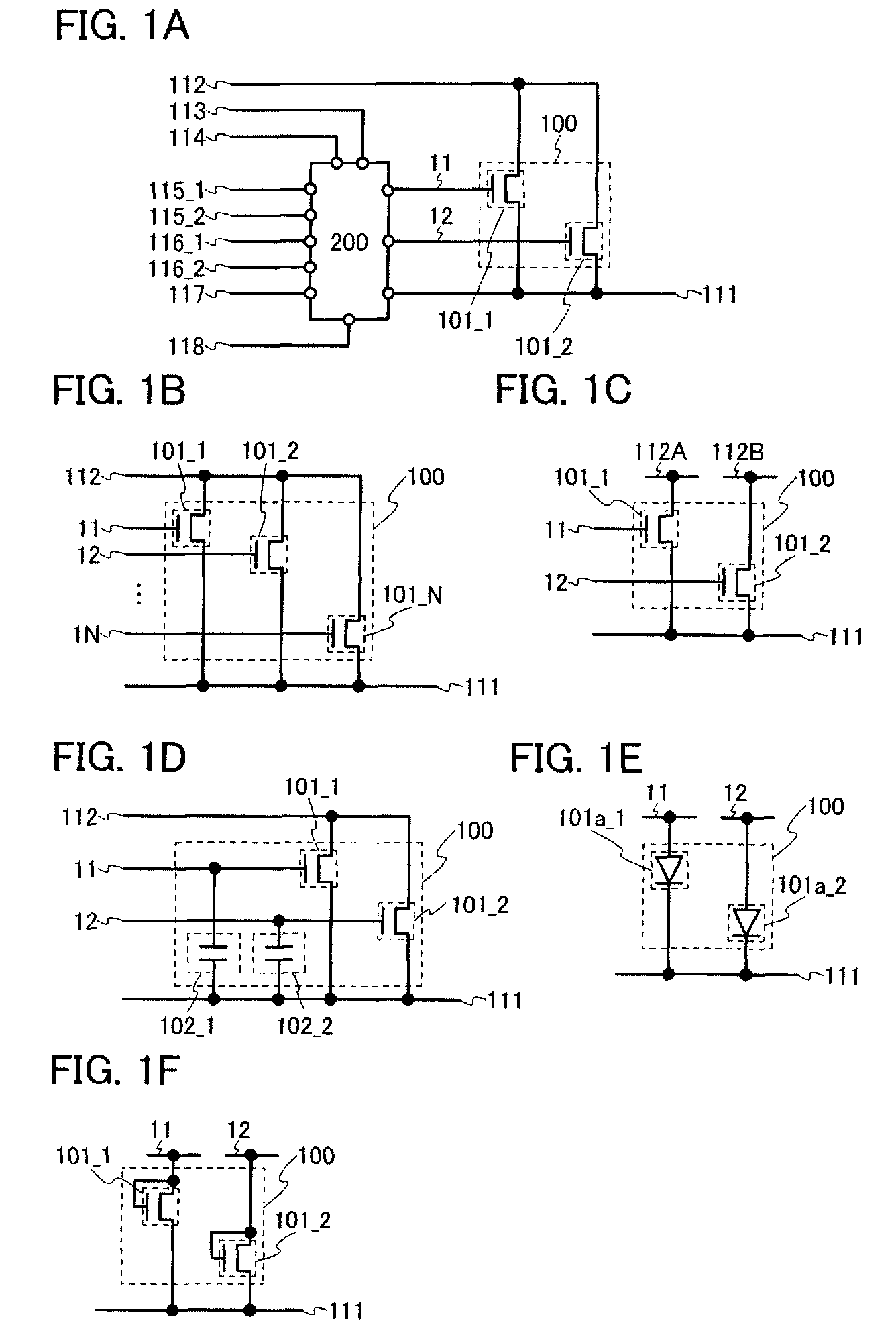

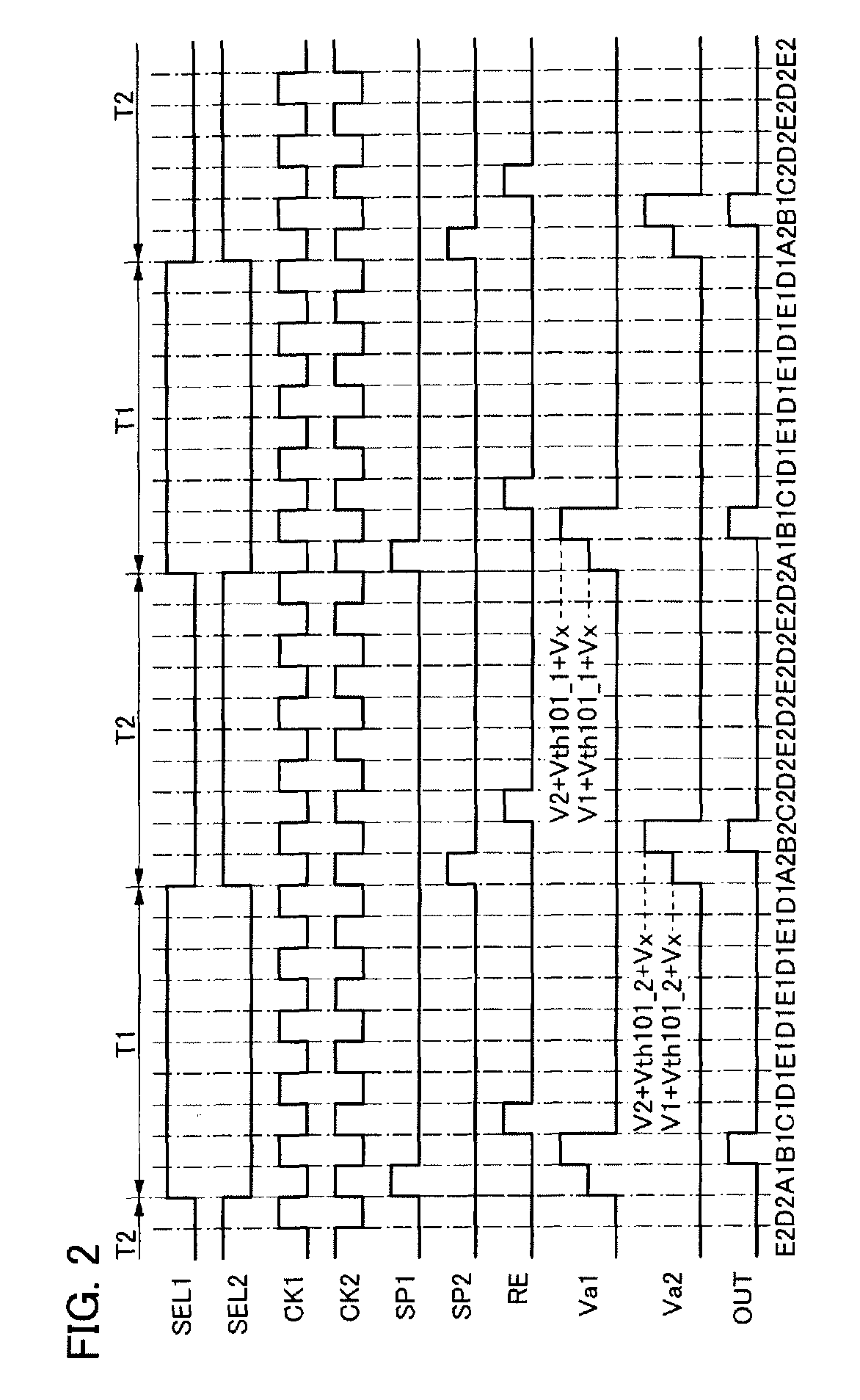

Semiconductor Device and Electronic Device Including Semiconductor Device

ActiveUS20100246750A1Suppress characteristicImprove the shortageTransistorStatic indicating devicesDriver circuitEngineering

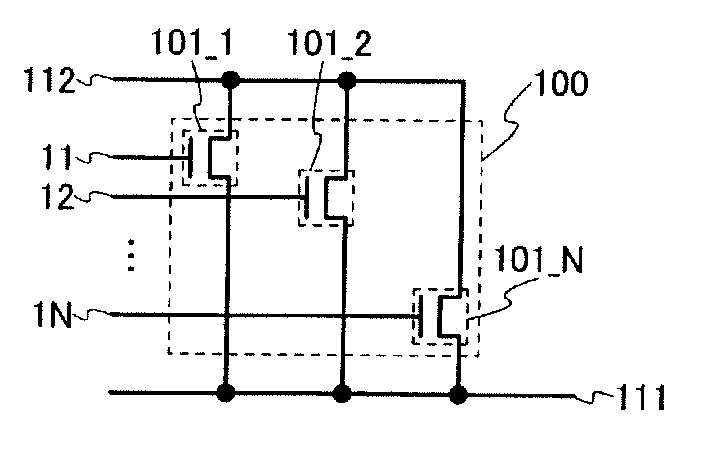

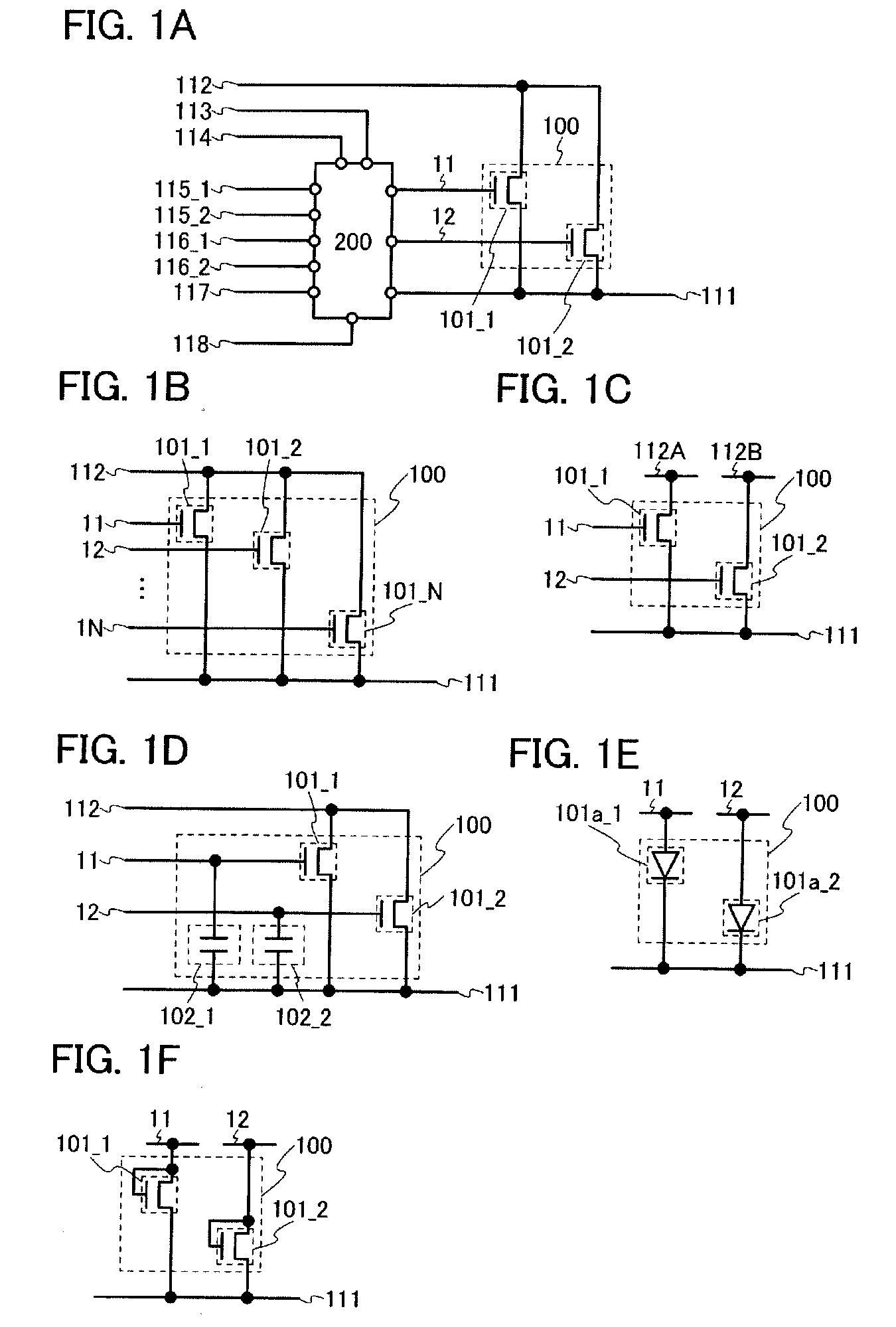

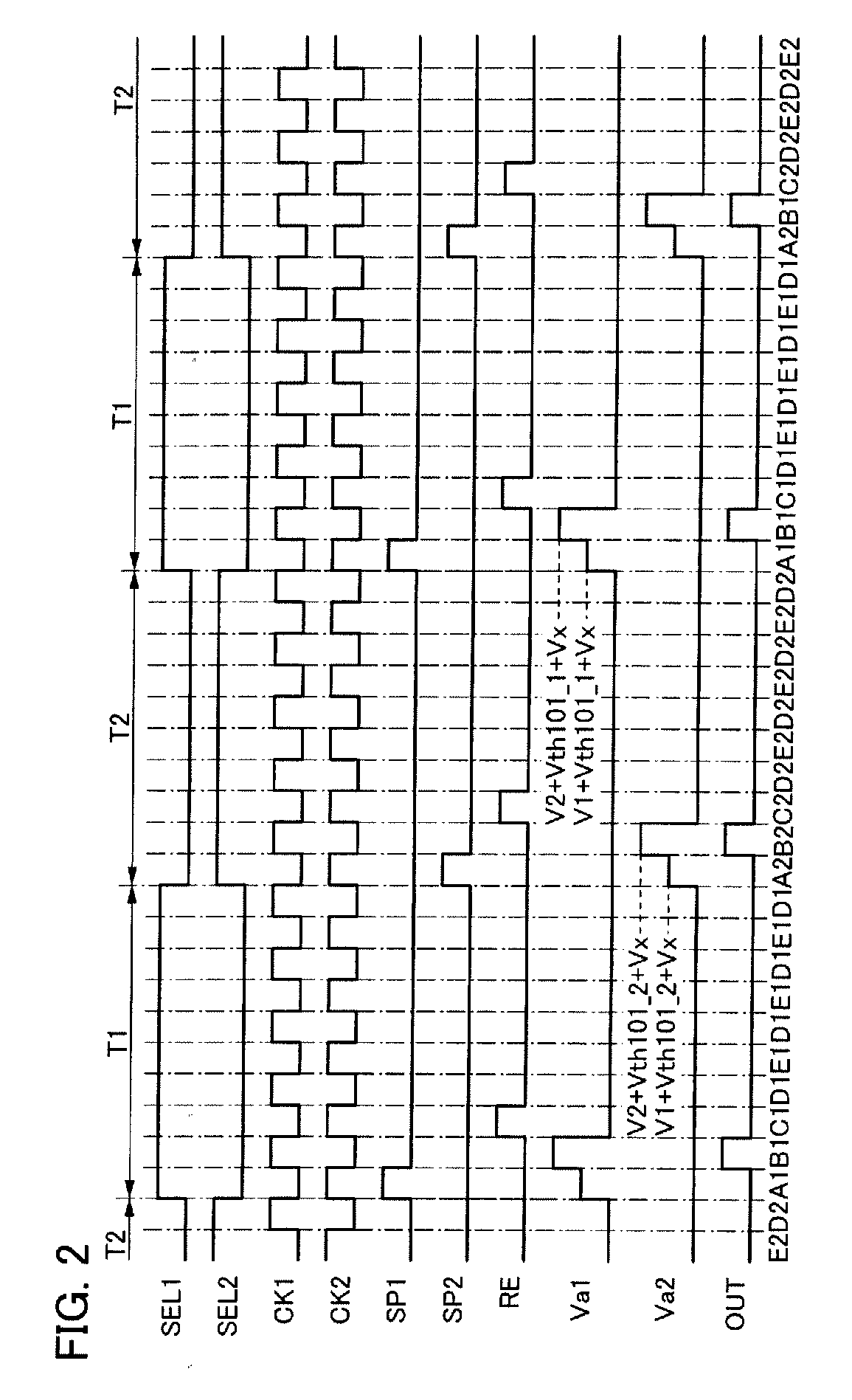

It is an object to suppress deterioration in characteristics of a transistor in a driver cricuit. A driver circuit includes a first transistor, a second transistor including a gate and one of a source and a drain to which a second signal is inputted, a third transistor whose gate is electrically connected to one of a source and a drain of the first transistor and which controls whether a voltage state of an output signal is set or not by being turned on / off, and a fourth transistor whose gate is electrically connected to the other of the source and the drain of the second transistor and which controls whether a voltage state of an output signal is set or not by being turned on / off.

Owner:SEMICON ENERGY LAB CO LTD

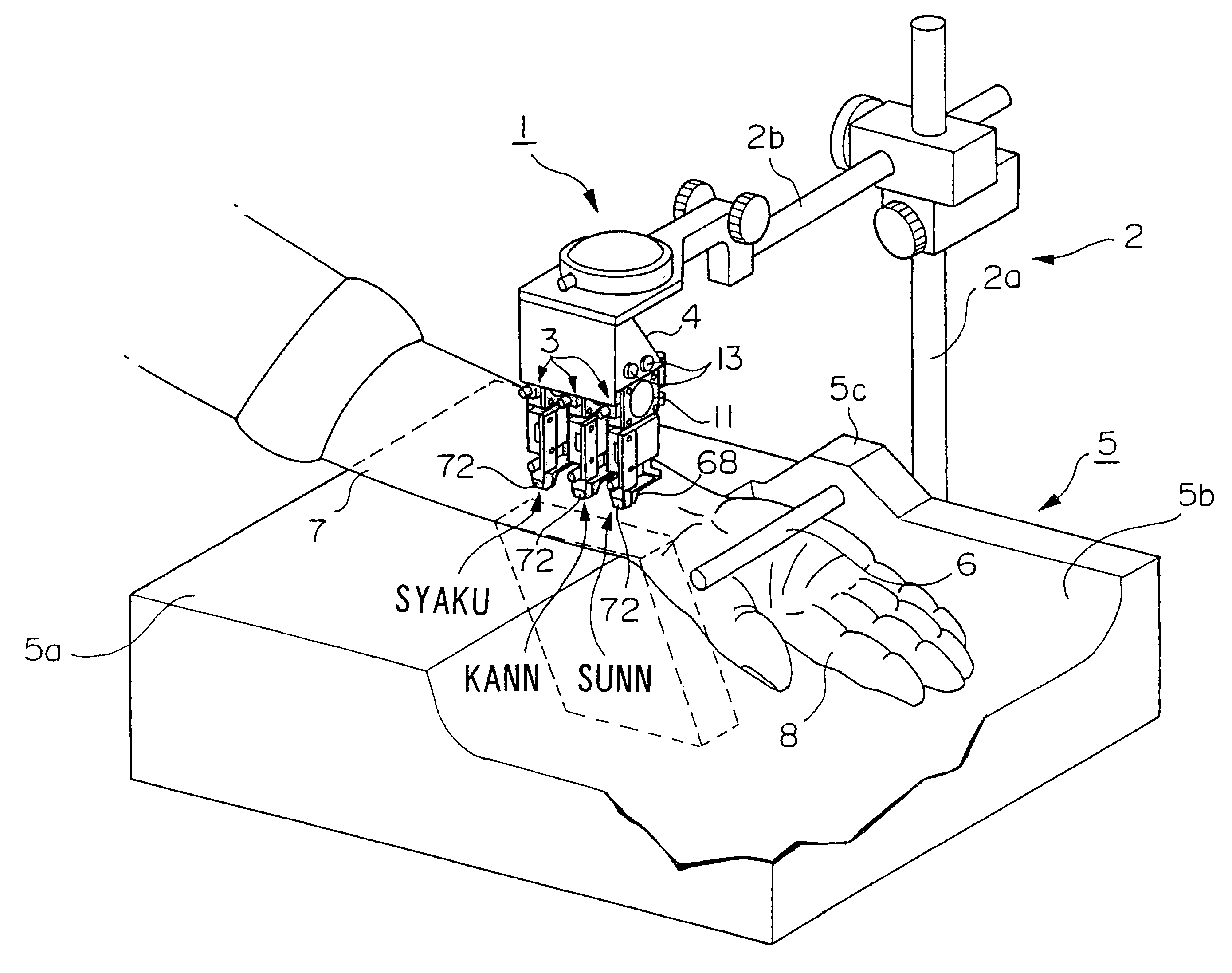

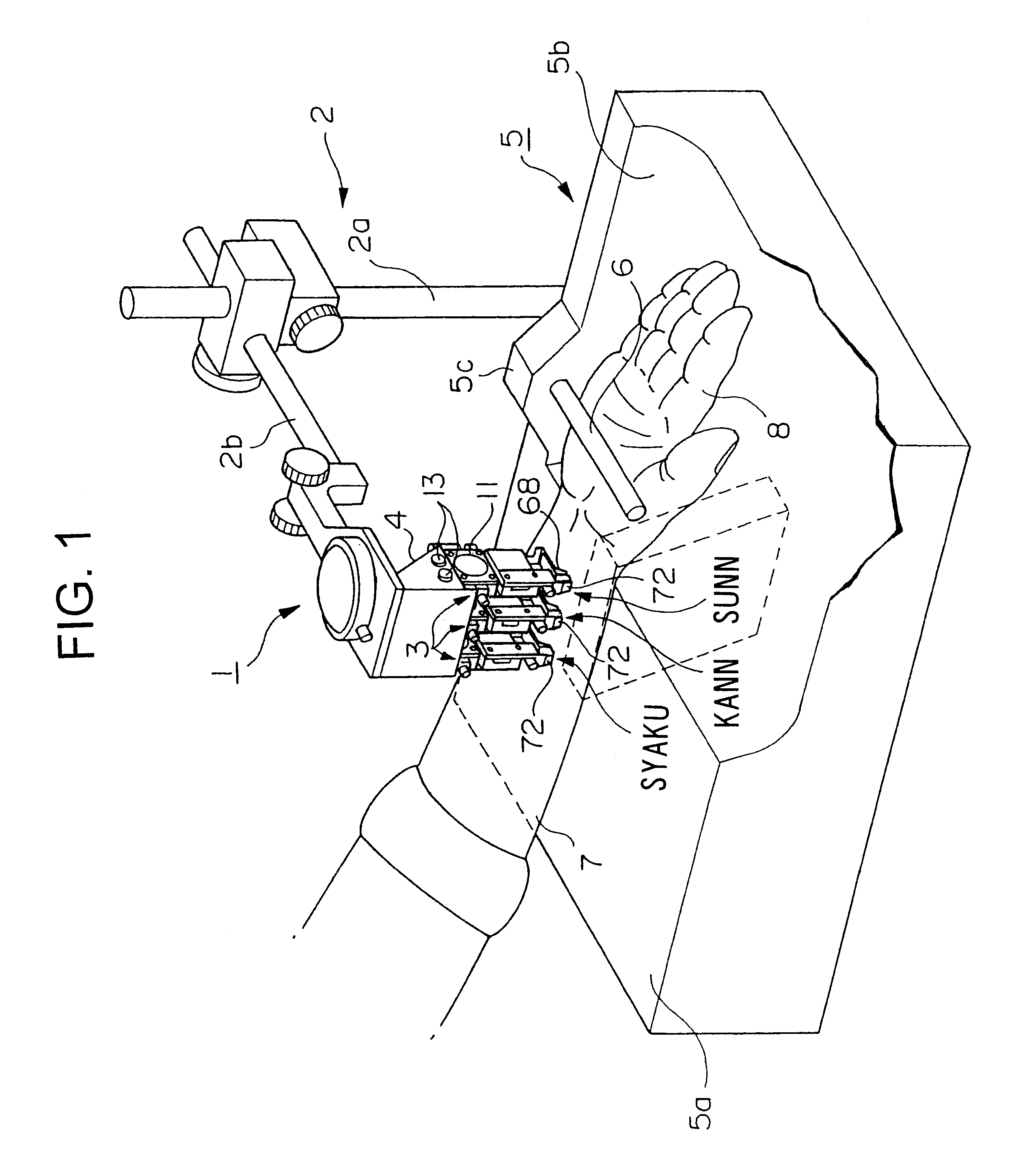

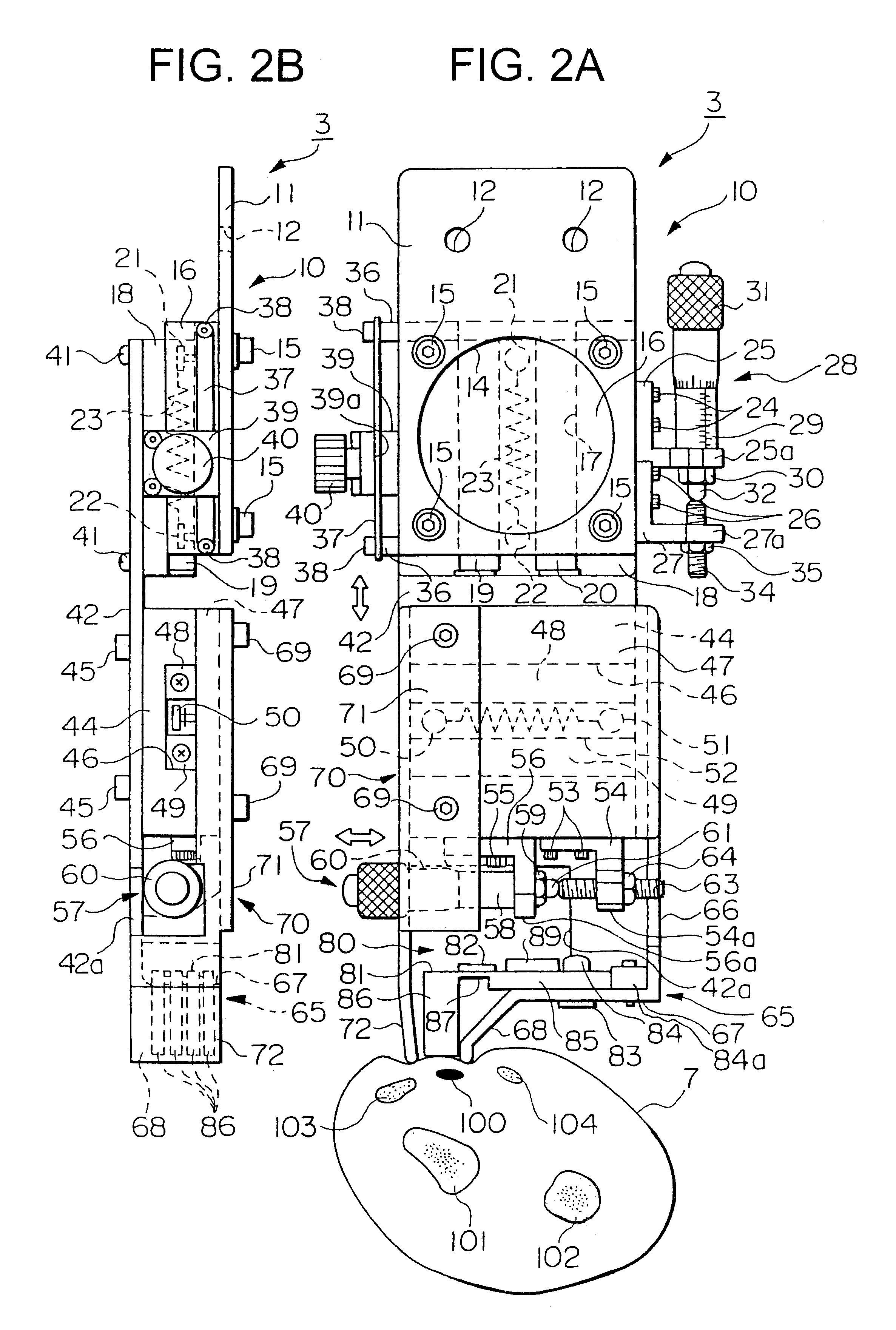

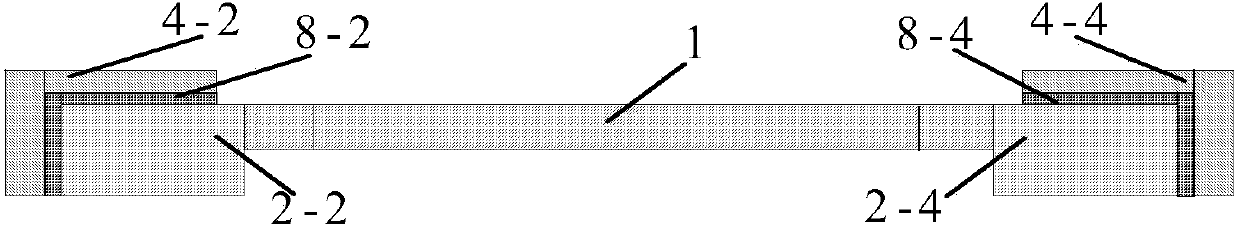

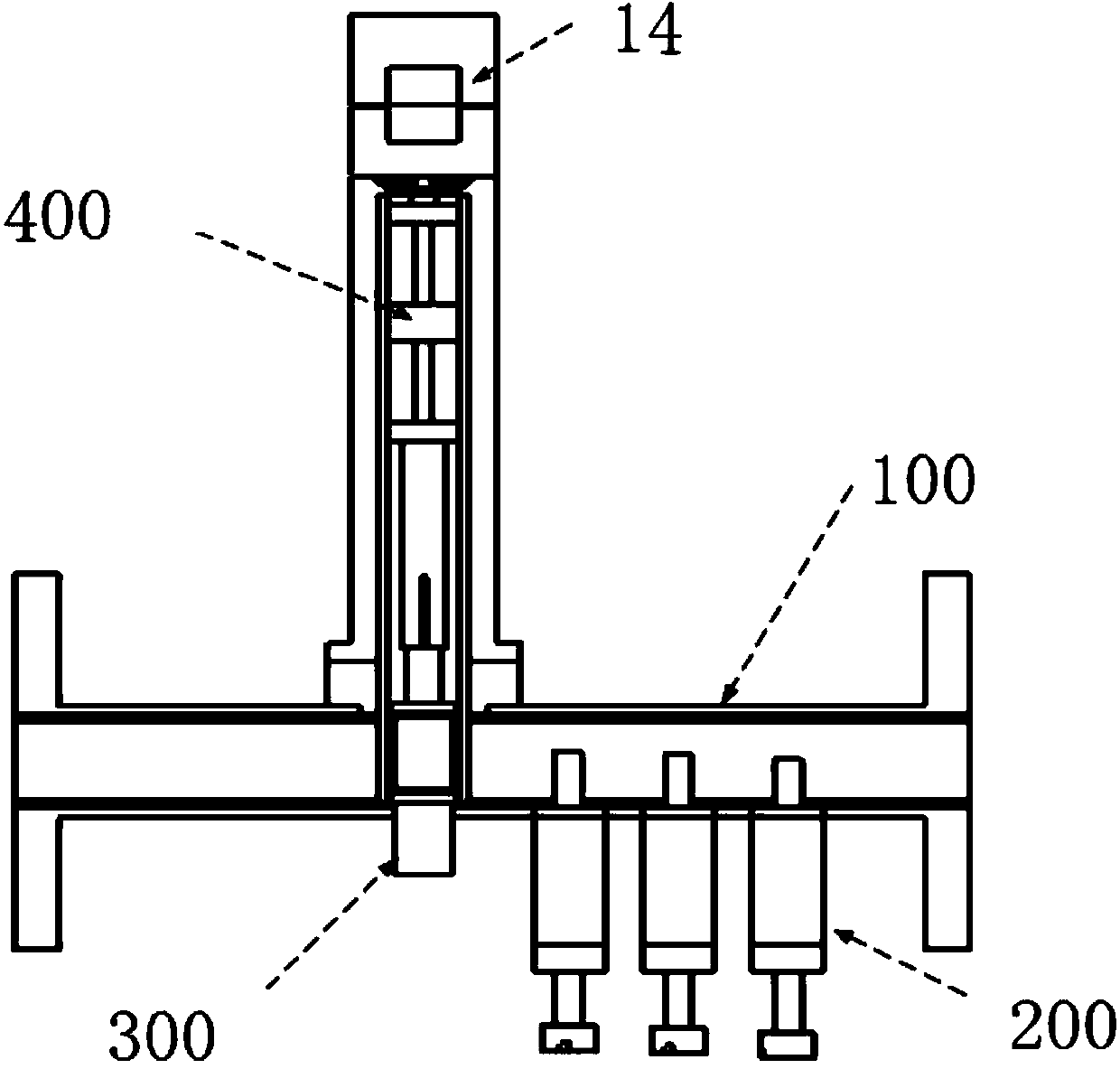

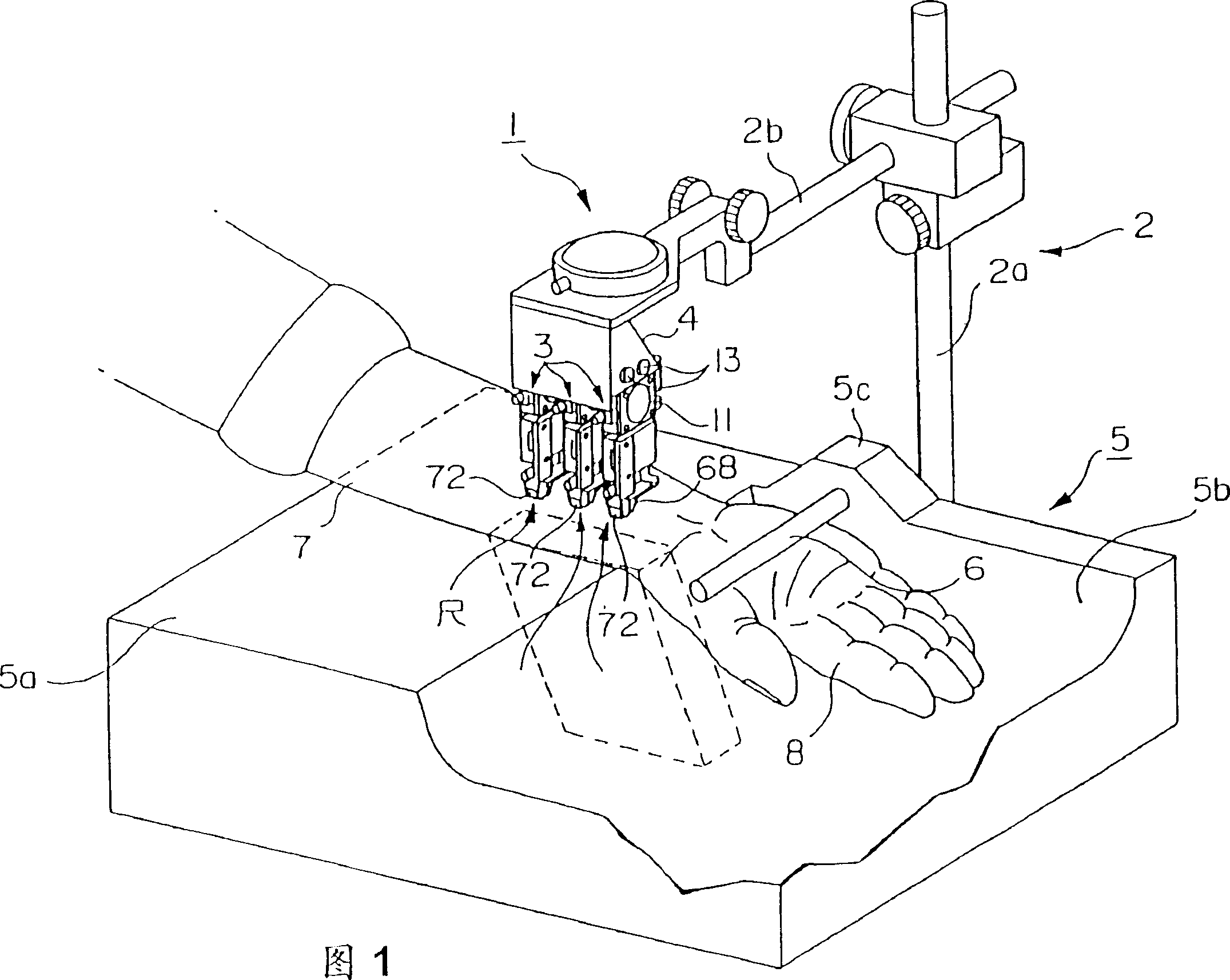

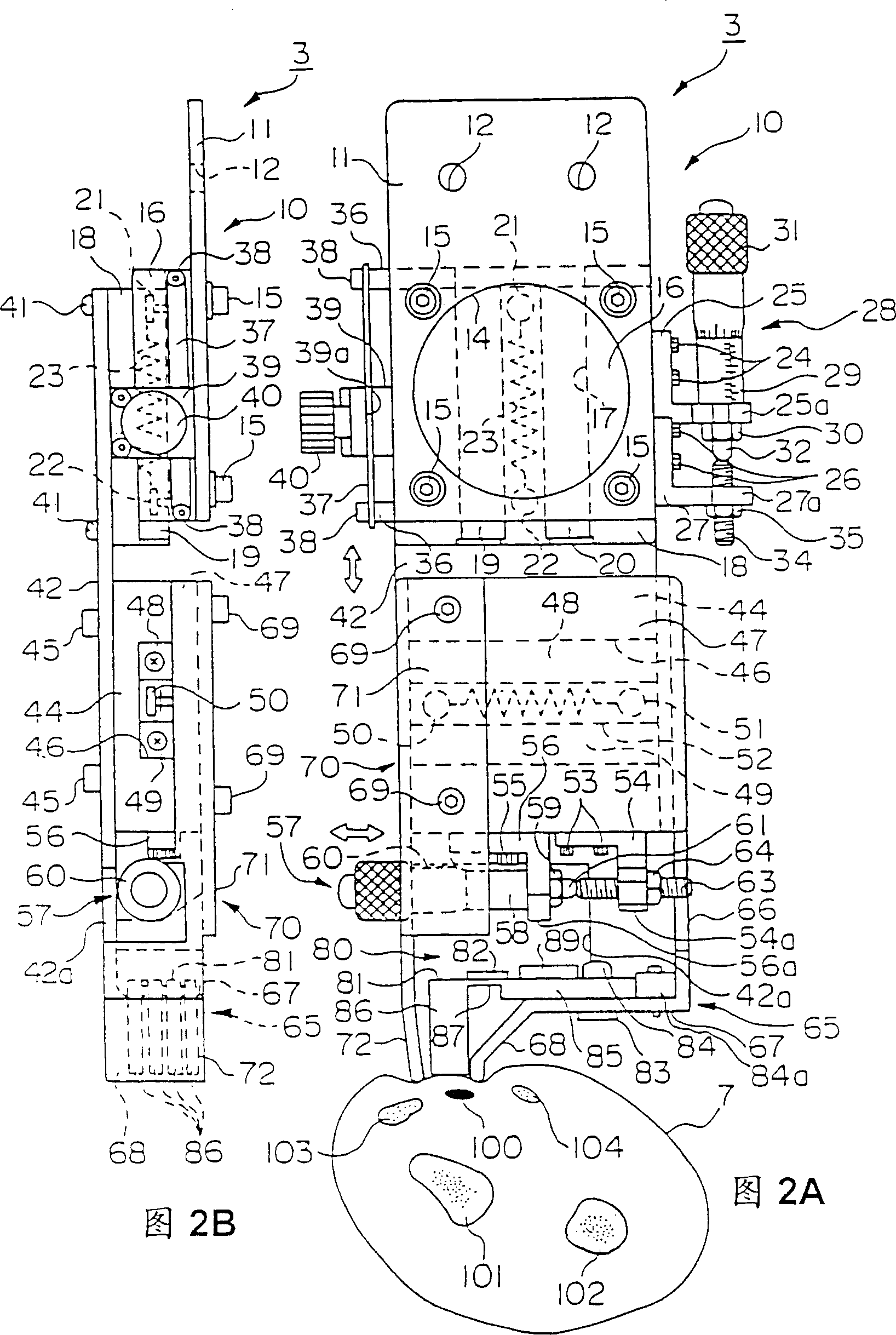

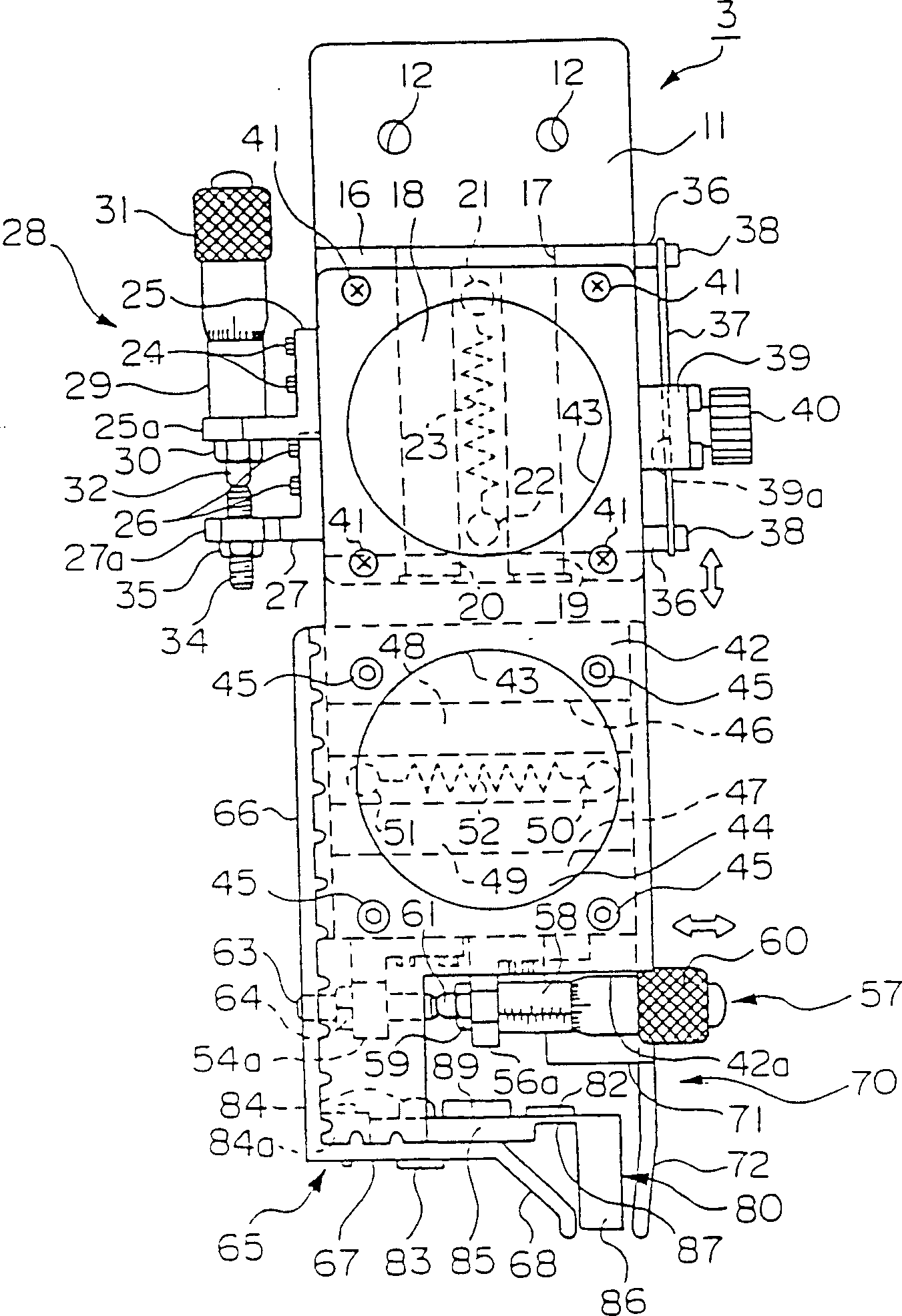

Blood pulse measuring device, pulsation measuring device, and pressure measuring device

A pulse wave measuring device is provided with a plurality of pulse wave measuring units. Each pulse wave measuring unit has a supporting member to which a beam of a pressure measuring device is attached. Contact portions at the distal end of the beam is in contact with the patient's arm, so that piezoelectric elements mounted on the beam measures the stress variation according to pulsation of the patient's radial artery. The supporting member has two pressing legs between which the contact portions of the beam are situated. The distal ends of the pressing legs are also pressed against the patient's arm. The pressing legs are harder than the radial artery. The interval between the pressing legs can be altered by handling a micrometer head. The contact portions are situated back from the distal ends of the pressing legs.

Owner:SEIKO EPSON CORP

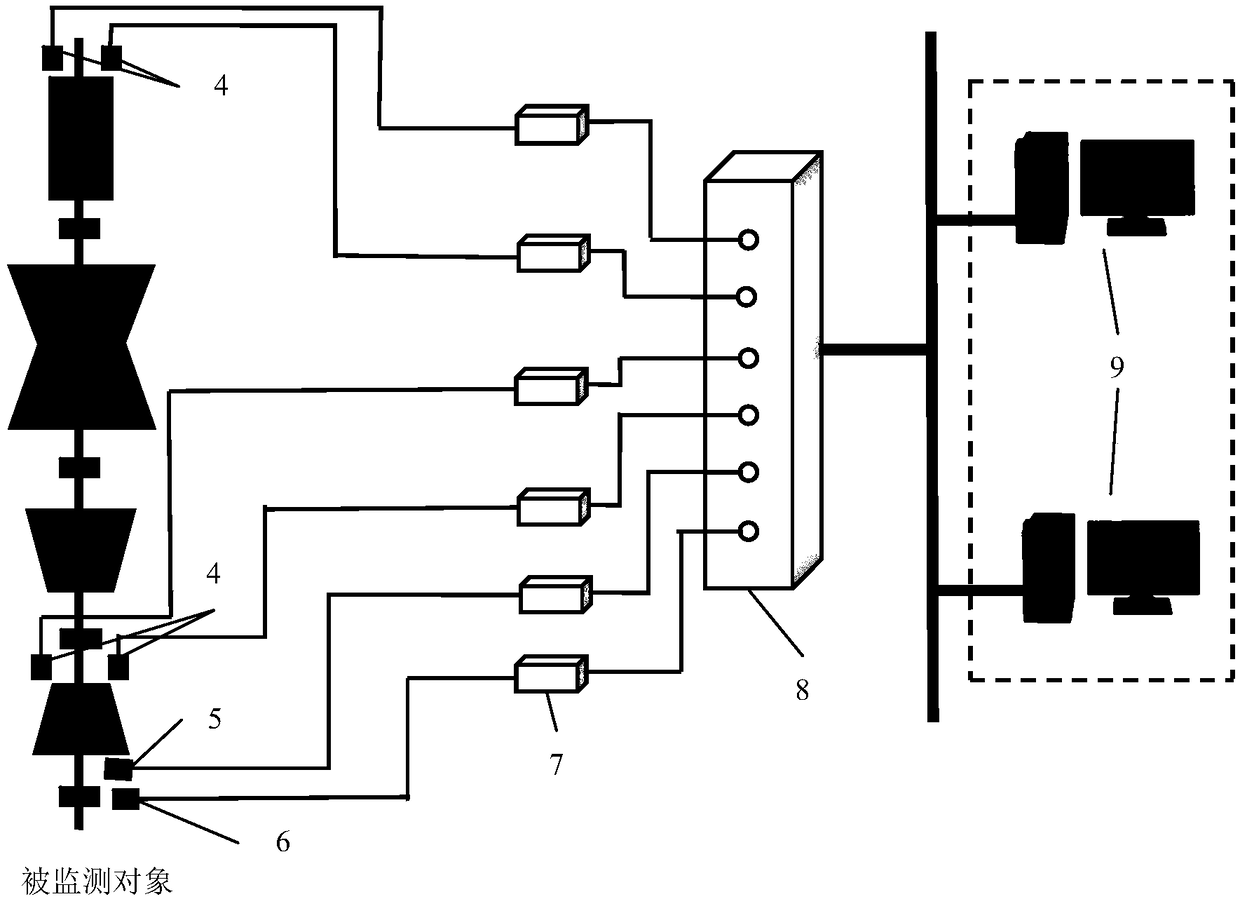

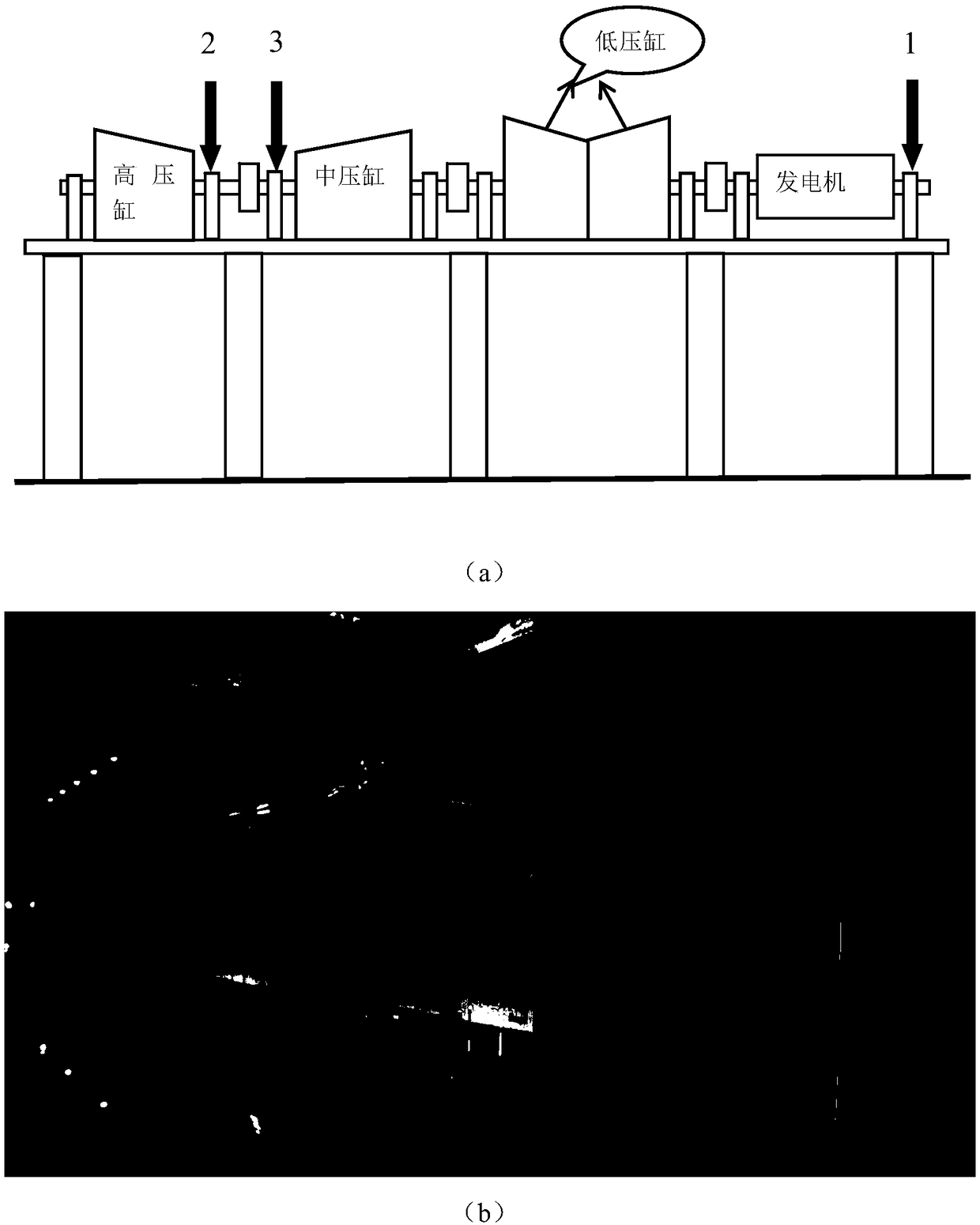

Torsional vibration error monitoring method for shaft system of steam turbine generator unit, monitor and system

ActiveCN108716989AWon't breakWill not affect normal operationMachine gearing/transmission testingFrequency spectrumVibration acceleration

The invention discloses a torsional vibration error monitoring method for a shaft system of a steam turbine generator unit, a monitor and a system. The method includes the steps of S1, collecting output signals of rotation speed sensors, key phase sensors and bearing base vibration acceleration sensors on the steam turbine generator unit; S2, conducting Fourier transform on the collected output signal of each bearing base vibration acceleration sensor to obtain vibration spectrum signals; S3, extracting an amplitude value in the vibration spectrum signal of each bearing base vibration acceleration sensor under the corresponding rotation frequency; S4, obtaining the types of to-be-detected frequencies and separately extracting the corresponding amplitude value and phase under each type of to-be-detected frequency from the vibration spectrum signal of each bearing base vibration acceleration sensor to serve as feature parameters; S5, on the basis of a judgment principle and the extractedfeature parameters, judging whether or not torsional vibration errors of the shaft system occur in the steam turbine generator unit. By means of the method, real-time online monitoring of the torsional vibration errors of the shaft system is achieved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

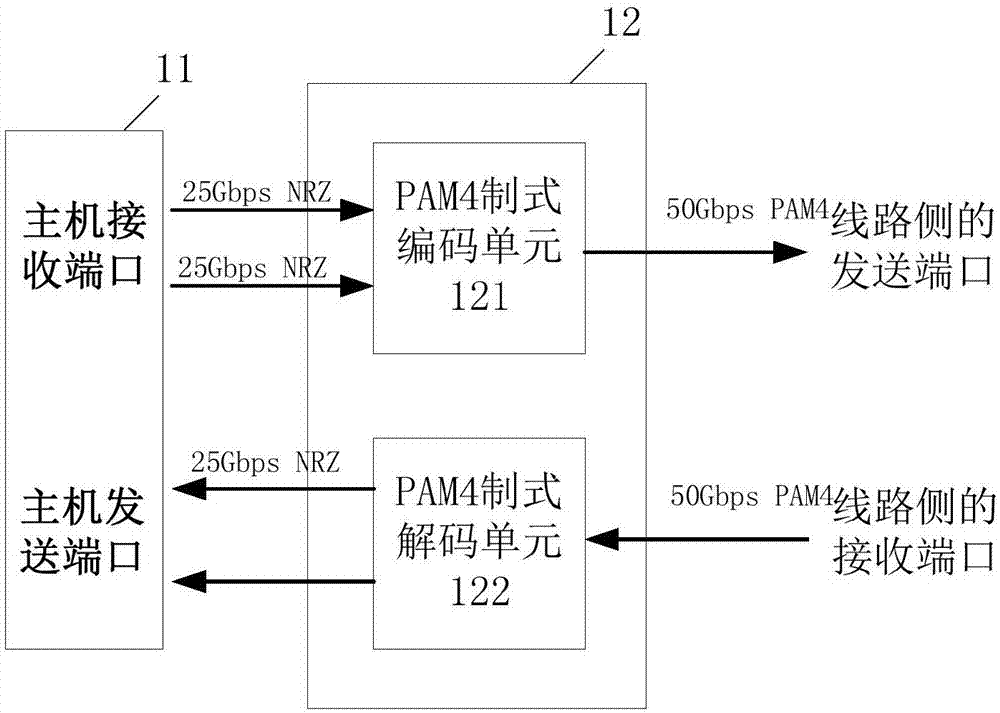

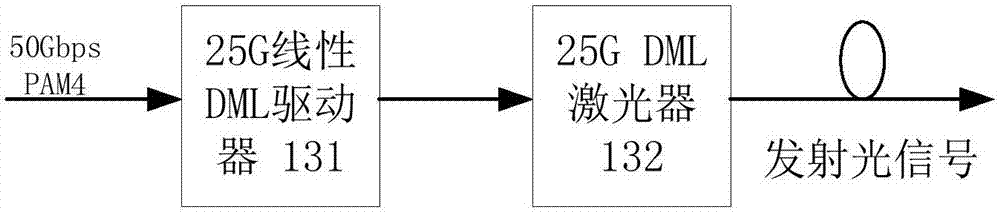

DML-based high speed PAM4 light transceiver module

InactiveCN107124225AReduce volumeLow costElectromagnetic transmittersElectromagnetic receiversElectricityTransceiver

The invention relates to the technical field of light modules, and provides a DML-based high speed PAM4 light transceiver module. The light transceiver module comprises an interface unit, a PAM4 system conversion unit, a DML light transmitting unit, and a light receiving unit. The interface unit is connected with the PAM4 system conversion unit and is used for transmitting an NRZ electric signal of a first code rate transmitted through the interface unit to the PAM4 system conversion unit. The PAM4 system conversion unit is also connected with the DML light transmitting unit and the light receiving unit. The PAM4 system conversion unit is also used for receiving an electric signal of a second PAM4 modulation code format generated by the light receiving unit. Due to adoption of the module of the PAM4 modulation mode, 50G bit of signal transmission rate can be reached by using only a path of 25G of transmitting component and a path of 25G of receiving component, so that compared with a module of an NRZ modulation mode of the same rate, the module of the PAM4 modulation mode has advantages of simple structure, small volume and low cost.

Owner:WUHAN TELECOMM DEVICES

Semiconductor device having interconnected transistors and electronic device including semiconductor device

ActiveUS8319528B2Suppresses characteristic deteriorationReduce widthStatic indicating devicesDigital storagePower semiconductor deviceDriver circuit

Owner:SEMICON ENERGY LAB CO LTD

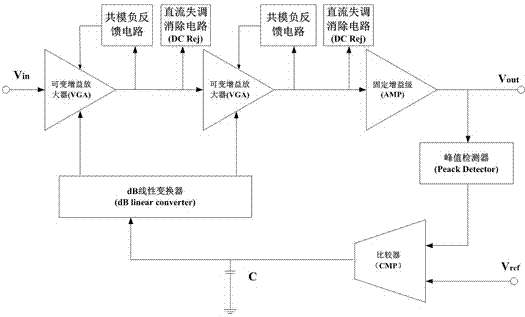

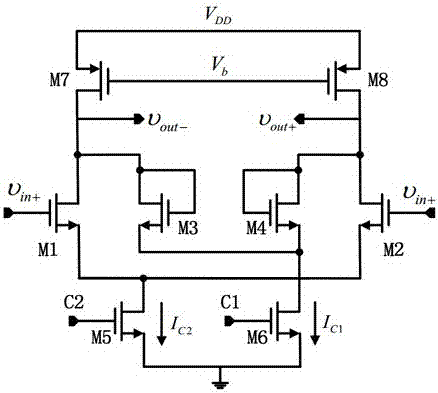

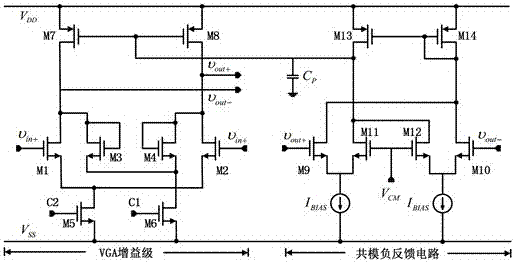

CMOS automatic gain control circuit for NEXT series product

InactiveCN107276548AReduce overheadThe output signal amplitude is stableGain controlCMOSSoi cmos technology

The invention discloses a NEXT series product CMOS automatic gain control circuit. The automatic gain control circuit is composed of a variable gain amplifier, a fixed gain stage, a peak detector, and a comparator. The variable gain amplifier includes: a VGA main body amplification unit, Common mode negative feedback circuit, DC offset elimination circuit, dB linear converter; variable gain amplifier as the main channel of the intermediate frequency signal, based on CMOS technology, adopts two-stage VGA structure, and connects DC offset elimination circuit after each stage; fixed gain The stage is linked with the variable gain amplifier in one direction, the input transconductance stage adopts a fully differential structure, and the source negative feedback is introduced to provide the absolute value of the gain for the automatic gain control circuit; the peak detector is connected with the output terminal of the circuit and the fixed gain stage, It is used for real-time detection and judgment of signal strength; one end of the comparator is connected to the peak detector and the comparison voltage at the same time, and the other end is connected to the dB linear converter for signal judgment.

Owner:JIANGXI CRYSTAL BIOSENSOR TECH

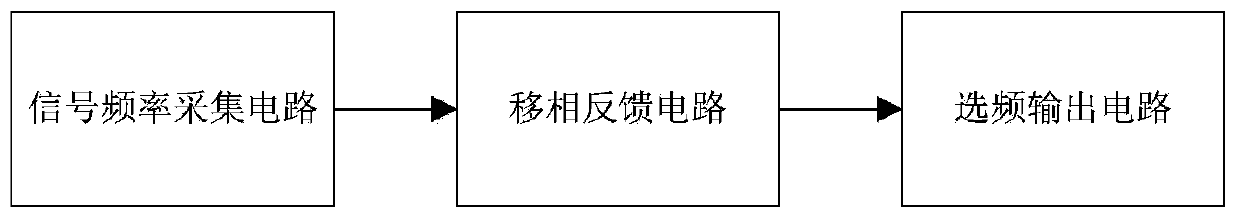

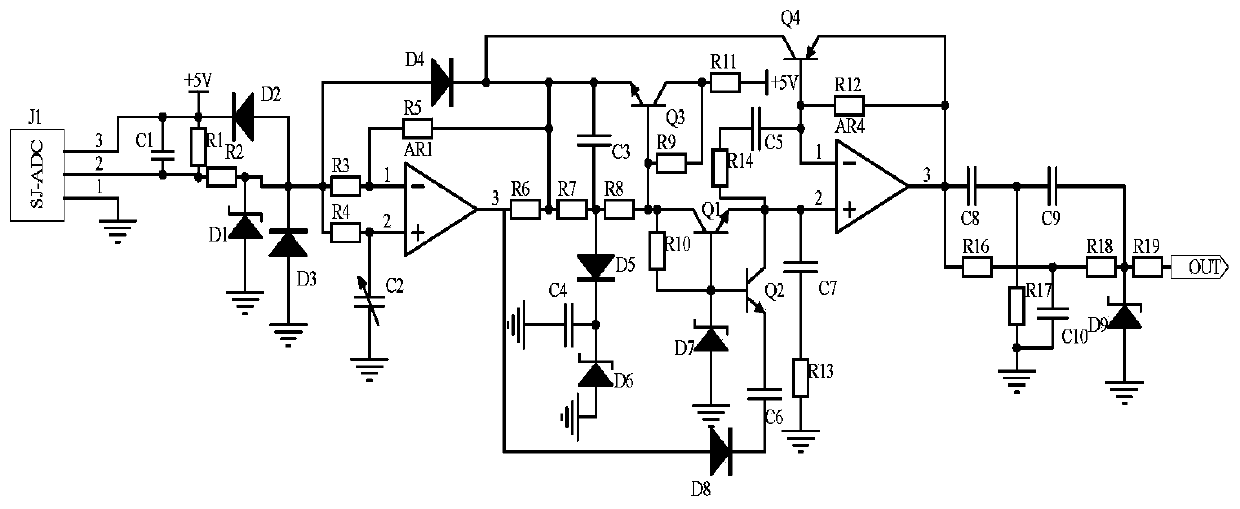

Power transmission real-time monitoring system

ActiveCN109905088APhase shiftingFilter out abnormal waveformsModulation transferenceAngle modulation detailsCapacitanceElectric power transmission

The invention discloses a power transmission real-time monitoring system, which comprises a signal frequency acquisition circuit, a phase shift feedback circuit and a frequency selection output circuit, and is characterized in that the signal frequency acquisition circuit adopts an SJ-type; A signal frequency collector J1 of the ADC collects the frequency of a data signal received by a control terminal in the power transmission real-time monitoring system. The phase shift feedback circuit uses an operational amplifier AR1, resistors R5 to R8 and a capacitor C3. the capacitor C4 forms a phase shift circuit to adjust the signal pulse width; A triode Q1 and a voltage-regulator tube D7 are used for voltage stabilization and then input into the in-phase input end of an operational amplifier AR4, a triode Q2 and a capacitor C6 are used for feeding back signals to the base electrode of a triode Q3, a triode Q4 is used for feeding back signals to the emitting electrode of the triode Q3. Finally, the frequency selective output circuit uses a resistor R16-resistor R18 and a capacitor C8-capacitor C10 to form a frequency selective circuit to screen out a single frequency signal output., so that the frequency of a data signal received by a control terminal in the power transmission real-time monitoring system can be monitored in real time, and signal frequency modulation and voltage stabilization are carried out.

Owner:内蒙古皖能建筑安装工程有限公司

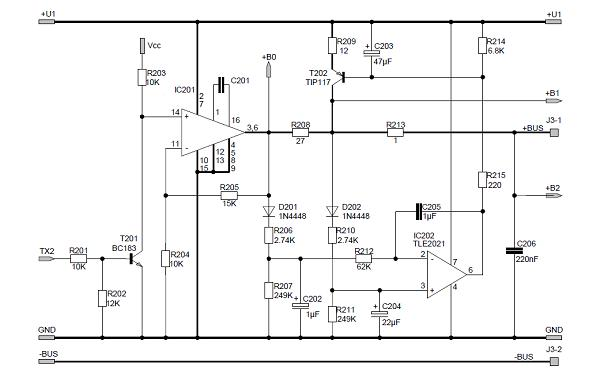

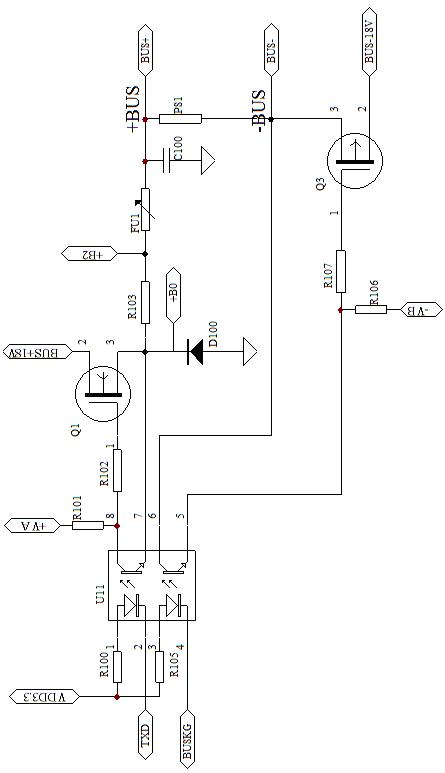

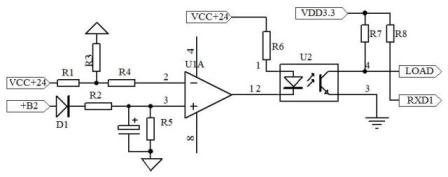

M-BUS (Meter-Bus) driving circuit

The invention relates to an M-BUS (Meter-Bus) driving circuit. A signal transmission circuit of the circuit comprises optocouplers, a first MOSFET (Metal-Oxide -Semiconductor Field Effect Transistor) and a second MOSFET, wherein a grid of the first MOSFET is connected with a collector of the first optocoupler, a drain of the first MOSFET is connected with an anode of a bus power supply, and a source of the first MOSFET is connected with an emitter of the first optocoupler and used as a positive output end of the signal transmission circuit; and a grid of the second MOSFET is connected with an emitter of the second optocoupler, a drain of the second MOSFET is connected with a cathode of the bus power supply, and a source of the second MOSFET is connected with a collector of the second optocoupler and used as a negative output end of the signal transmission circuit. In the invention, the signal transmission circuit and the power supply circuit are constructed by using the MOSFETs to provide power supply to a node on the M-BUS; and because the internal resistance of the MOSFETs is small and the load capacity is strong, an increasing number of terminal equipments can be hung on the M-BUS bus; meanwhile, the amplitude value of an output signal is increased, the influence from an interference signal is effectively avoided and the communication reliability is improved by using the circuit.

Owner:AMPHENOL AORORA TECH (HUIZHOU) CO LTD

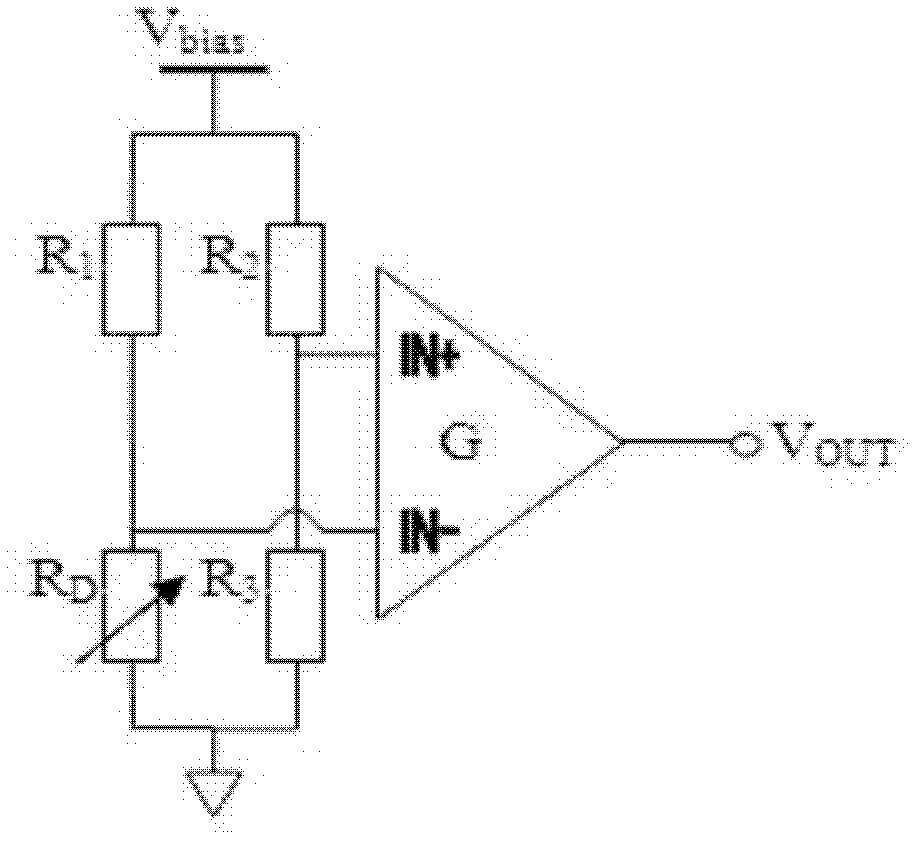

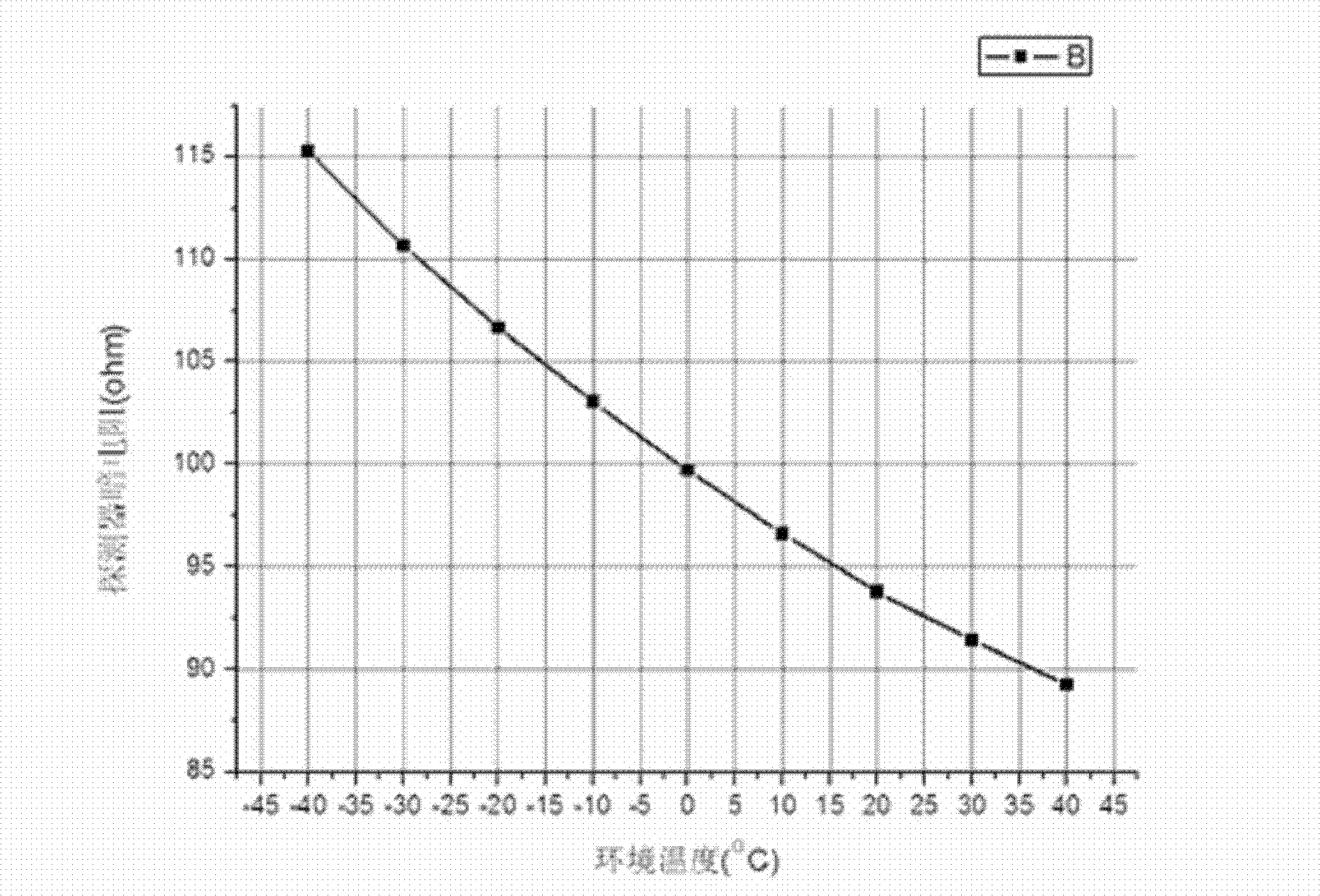

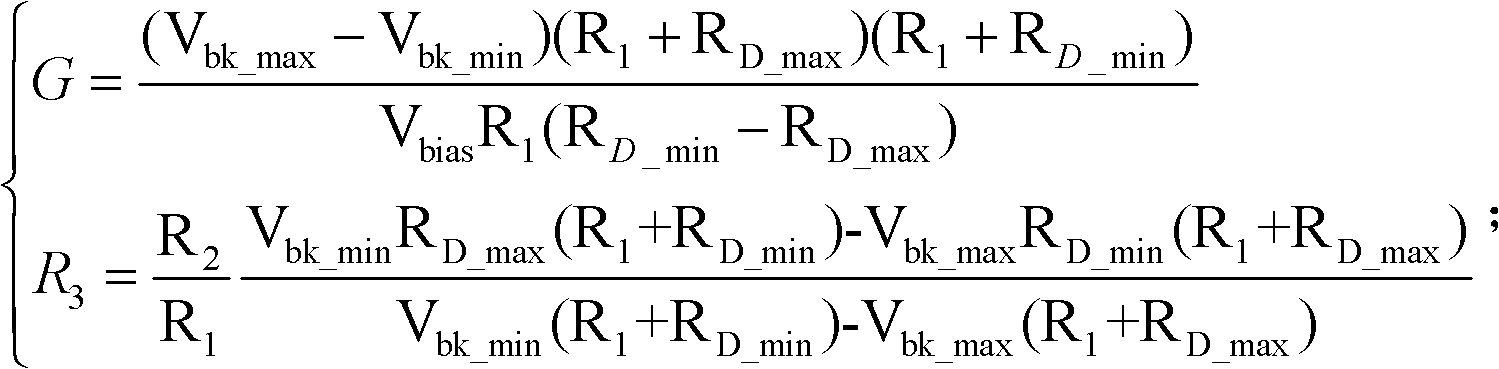

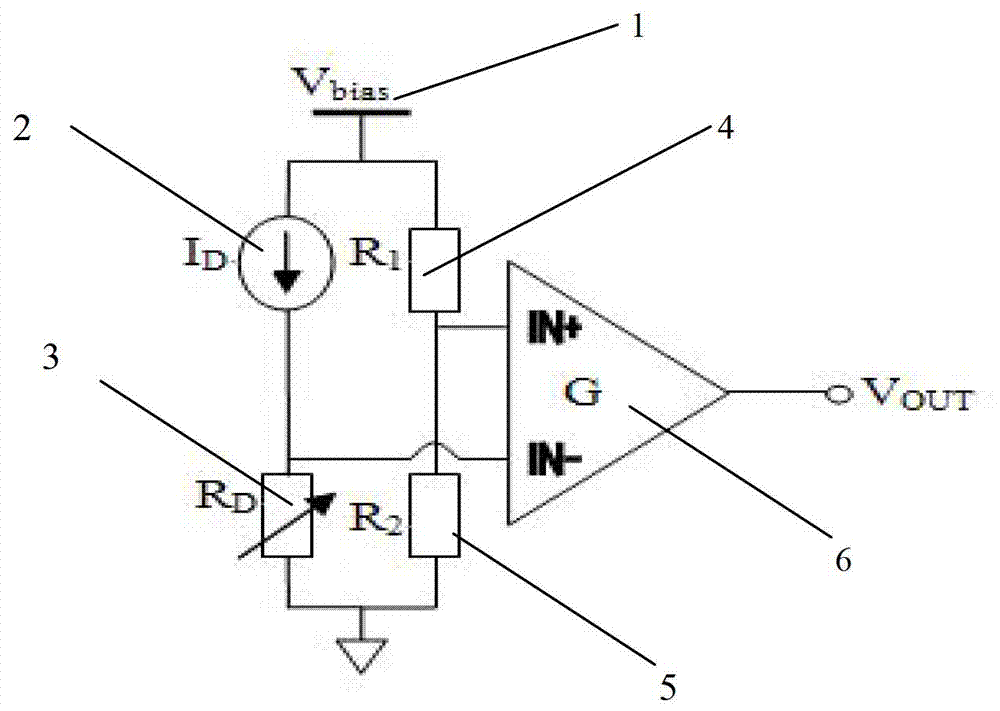

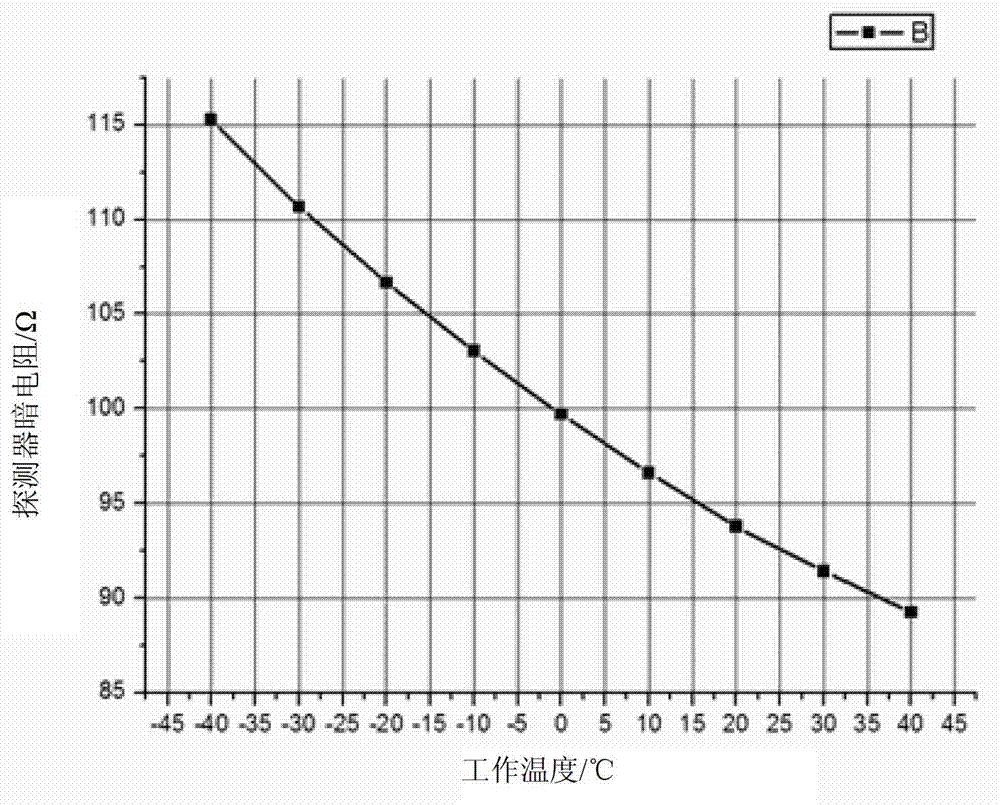

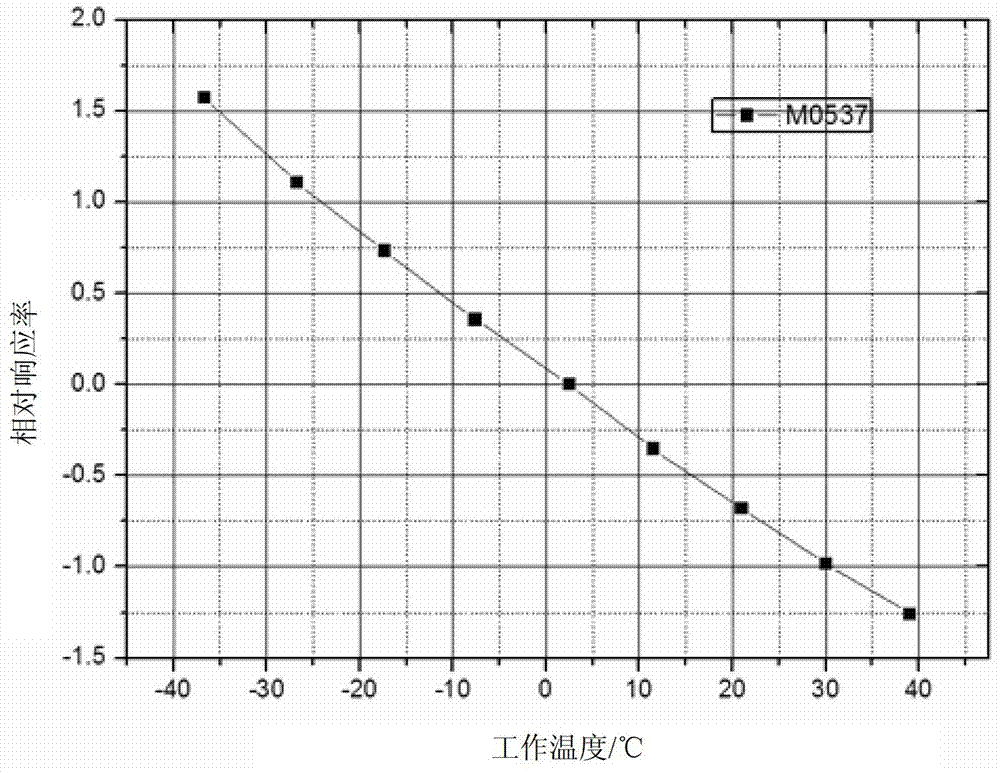

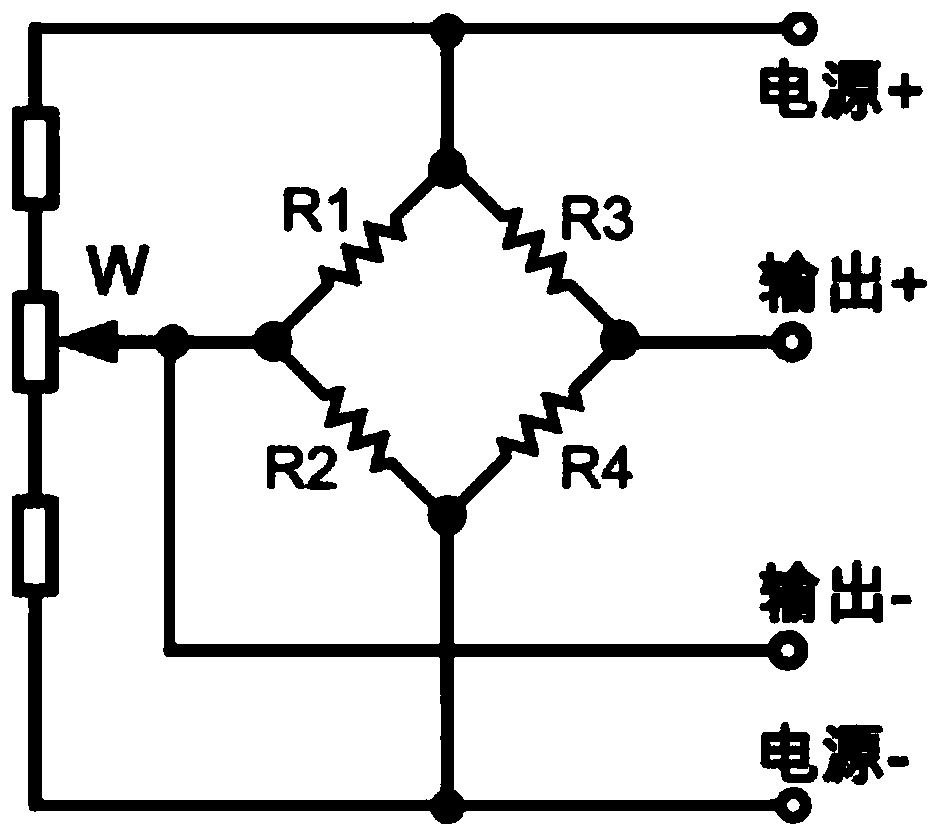

Mid-infrared detection circuit parameter design method based on bridge principle

InactiveCN102322950AIncrease the output signal amplitudeImprove measurement dynamic rangePhotometry using electric radiation detectorsVoltage amplitudeLower limit

The invention provides a mid-infrared detection circuit parameter design method based on a bridge principle. The method comprises the following steps: determining an upper limit and a lower limit of detector operating temperature, a corresponding background voltage allowable value and a maximal signal voltage amplitude allowed by an amplification circuit, determining resistance of a bias resistorand bias voltage of a bridge on a bridge detection arm, and resistance of a bias resistor on a bridge balancing arm, and solving an equation set to obtain a balancing resistance, an amplification multiple and check and correction of an amplification circuit amplification multiple. According to the invention, based on parameters of dark resistance, work voltage and the like of a wide temperature range end point of each detector, optimal solutions of the balancing resistance and the circuit amplification multiple are obtained, and an output signal amplitude and a measurement dynamic range of a bridge type mid-infrared detection circuit are raised. The method has the characteristics of concise step and convenient programming, and can be used for designing balancing resistance and circuit amplification multiple parameters of the mid-infrared detection circuit in quantities.

Owner:NORTHWEST INST OF NUCLEAR TECH

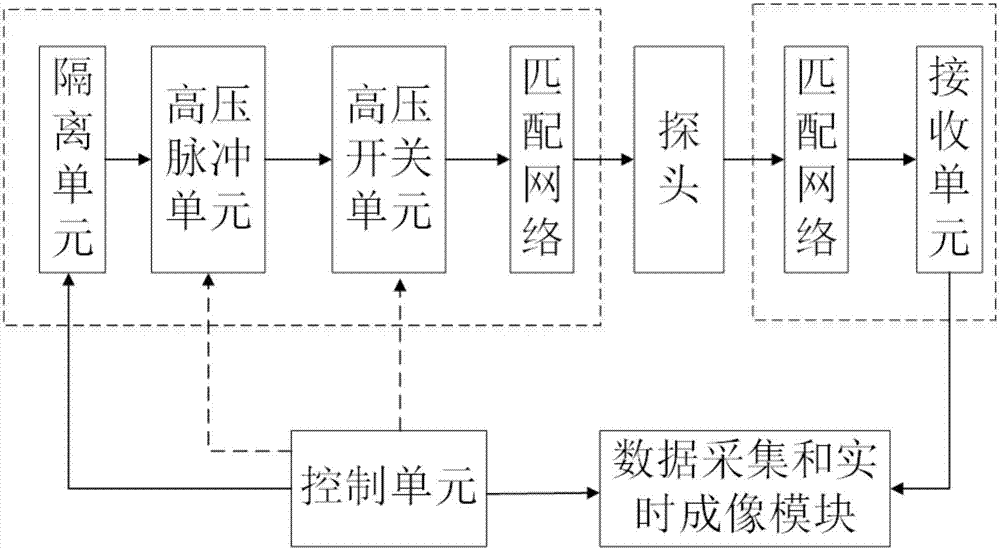

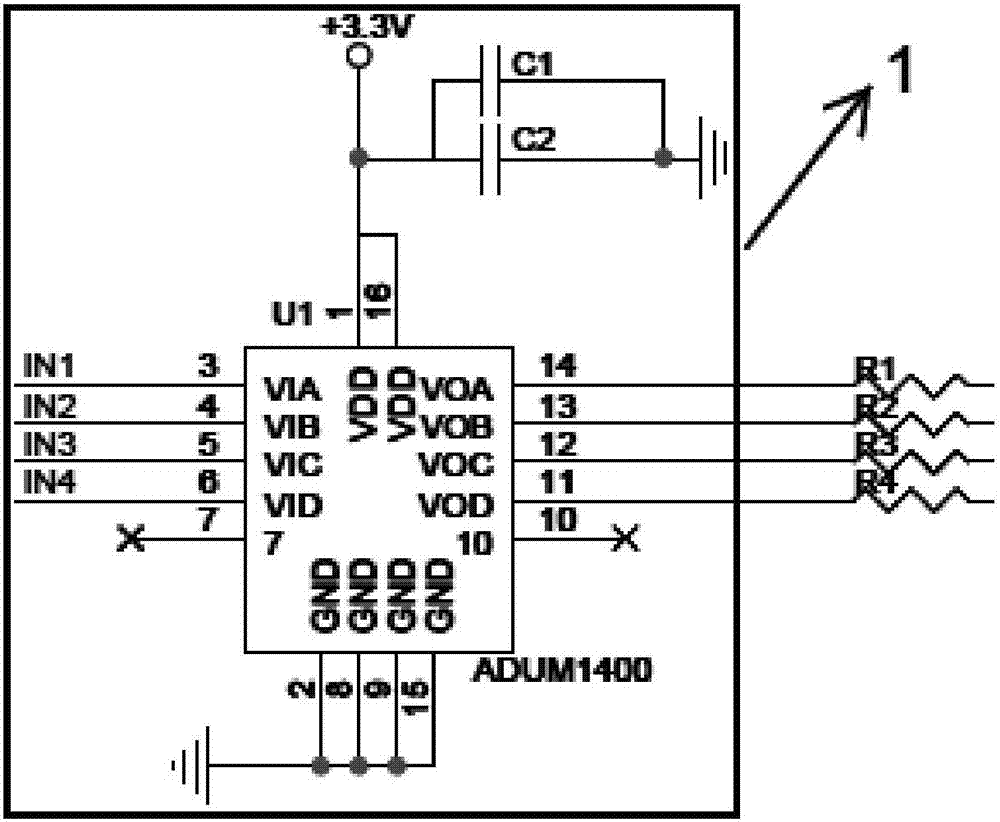

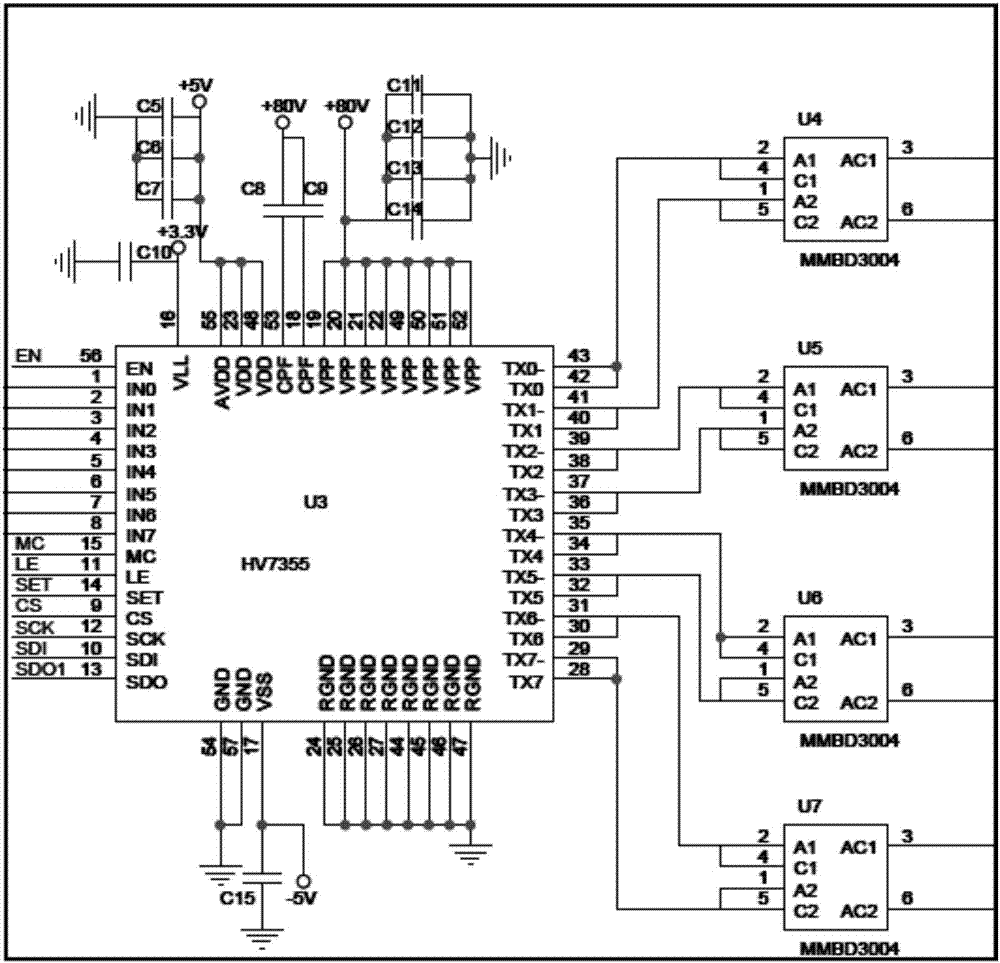

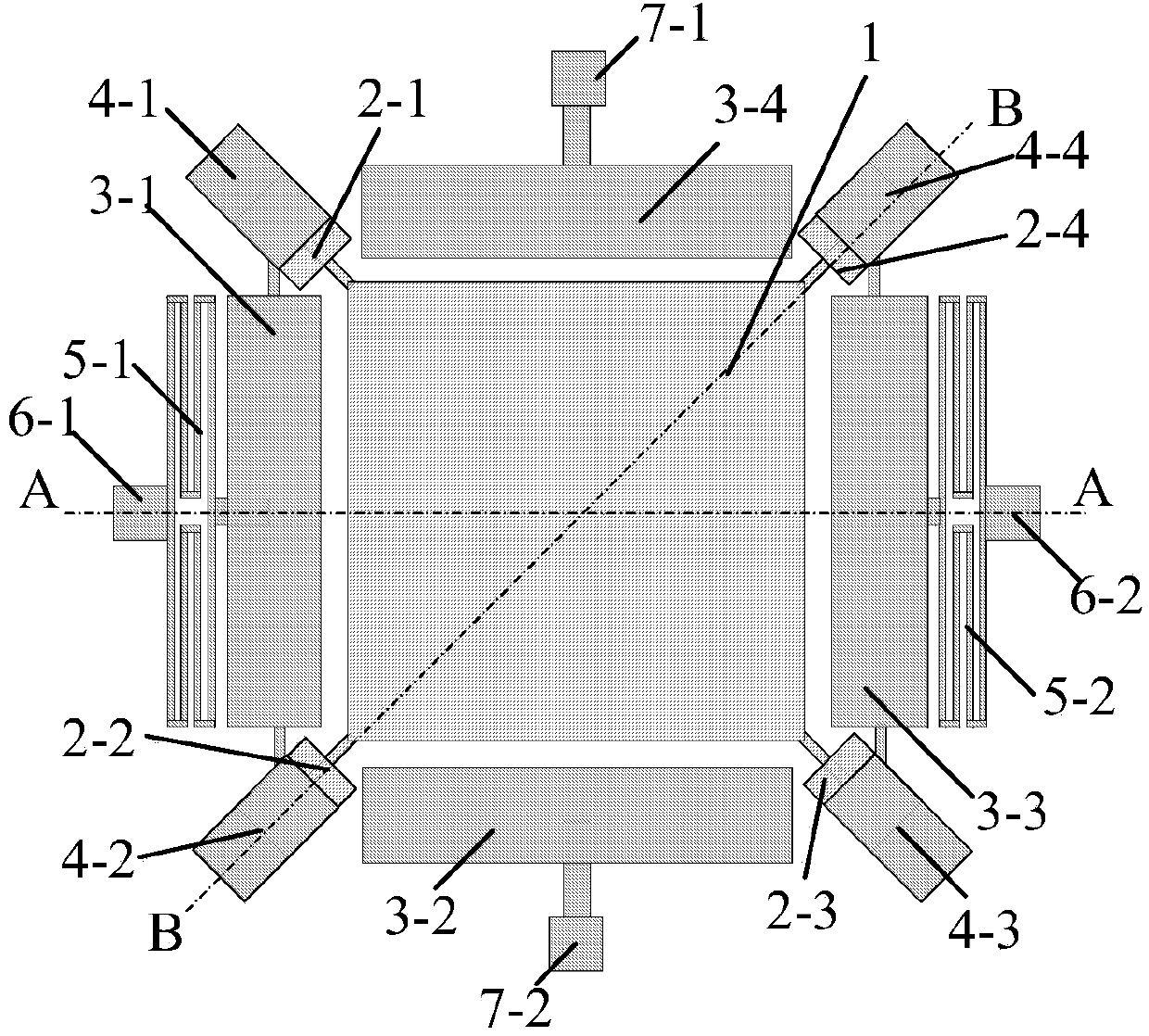

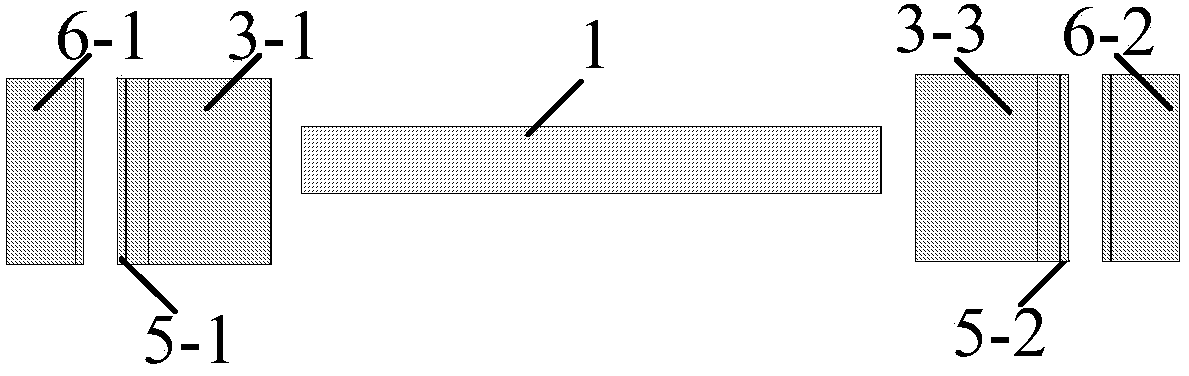

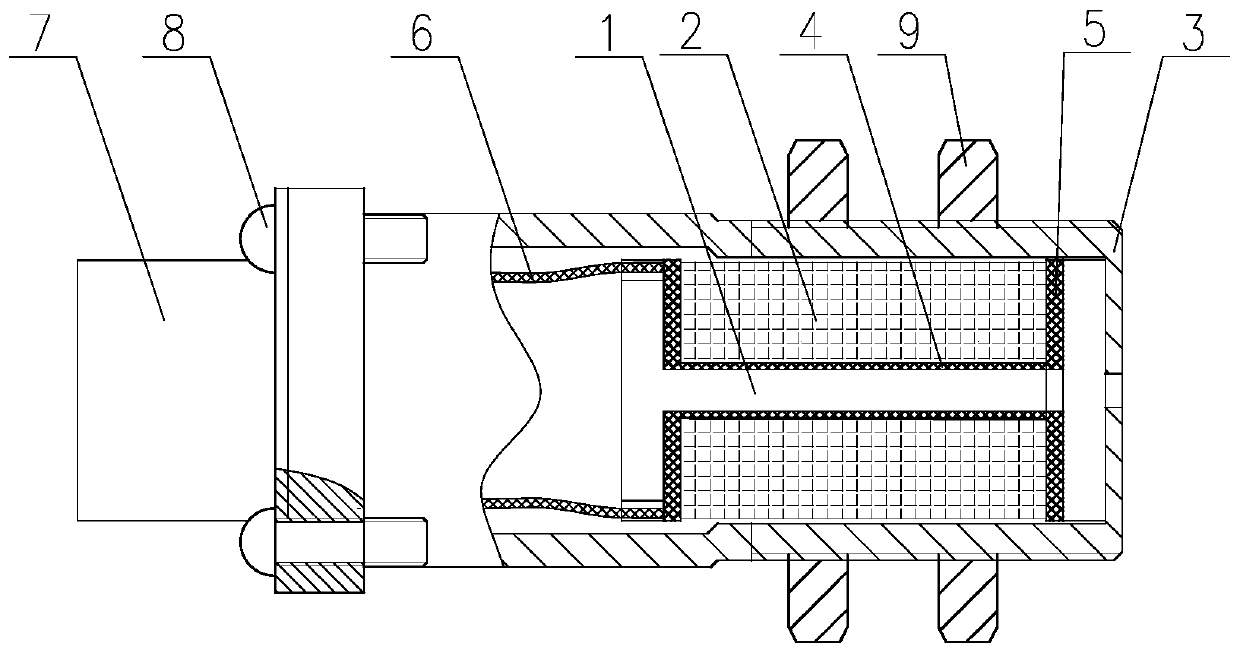

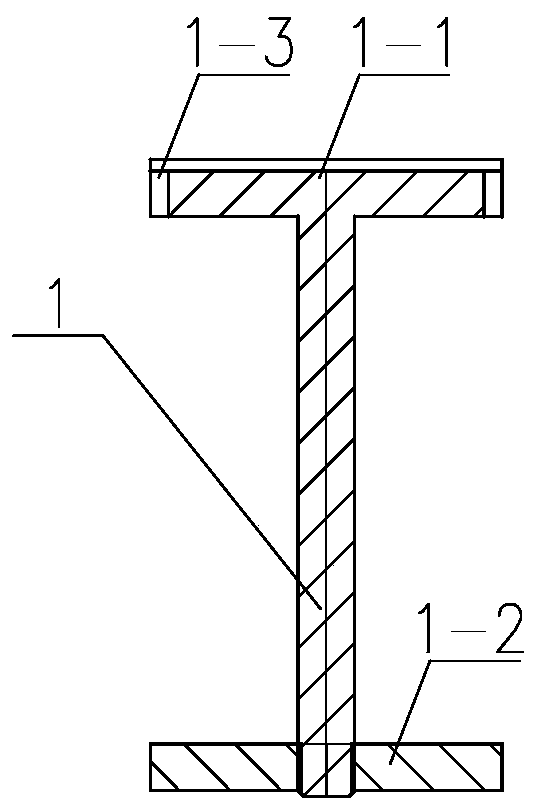

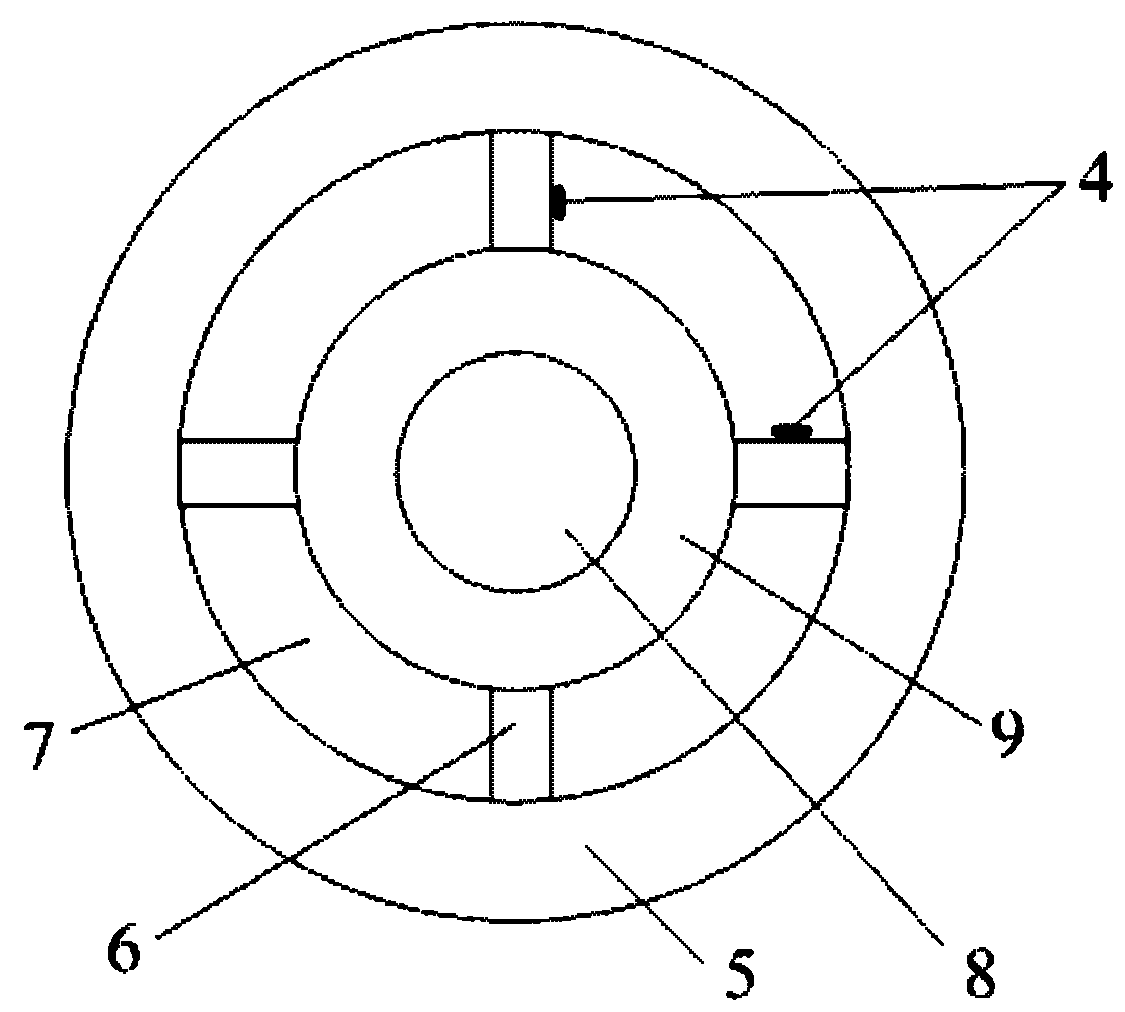

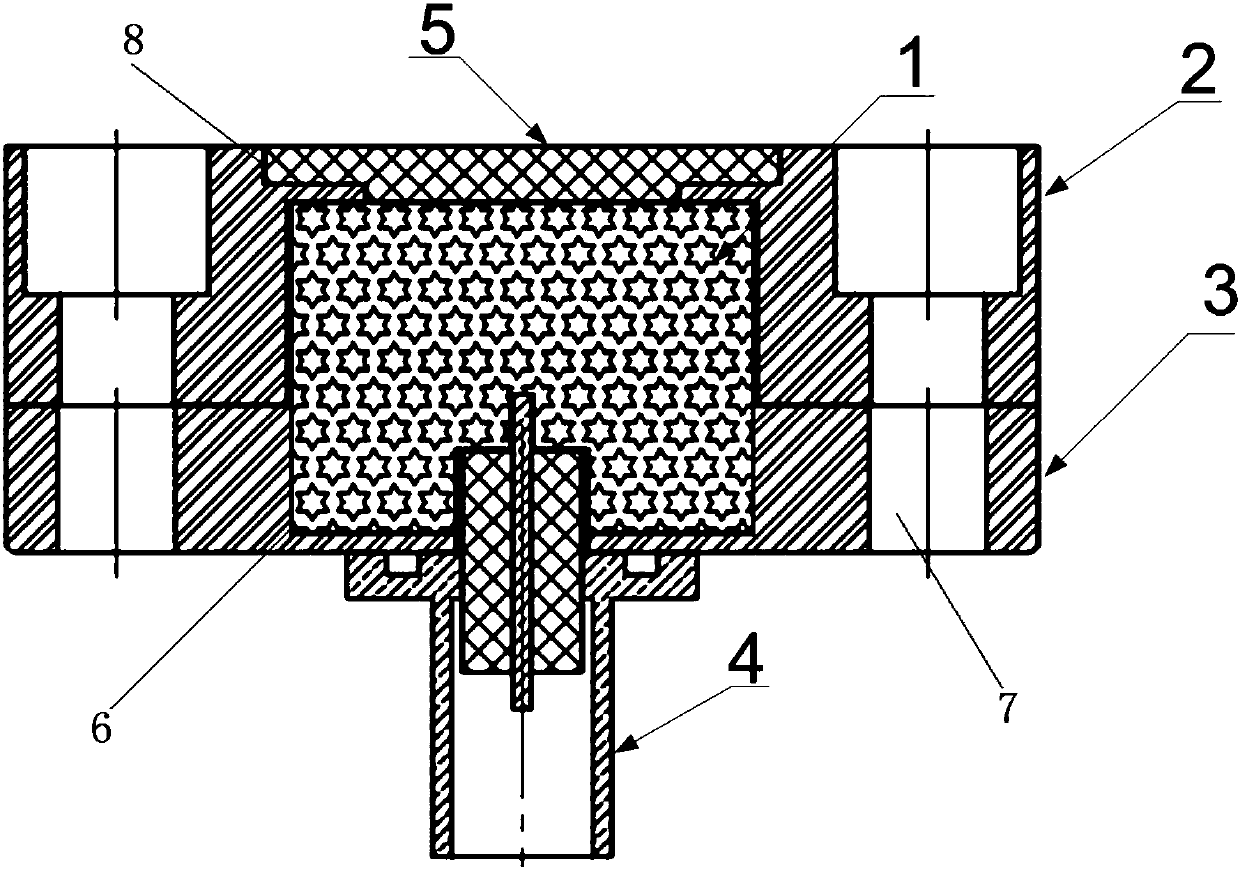

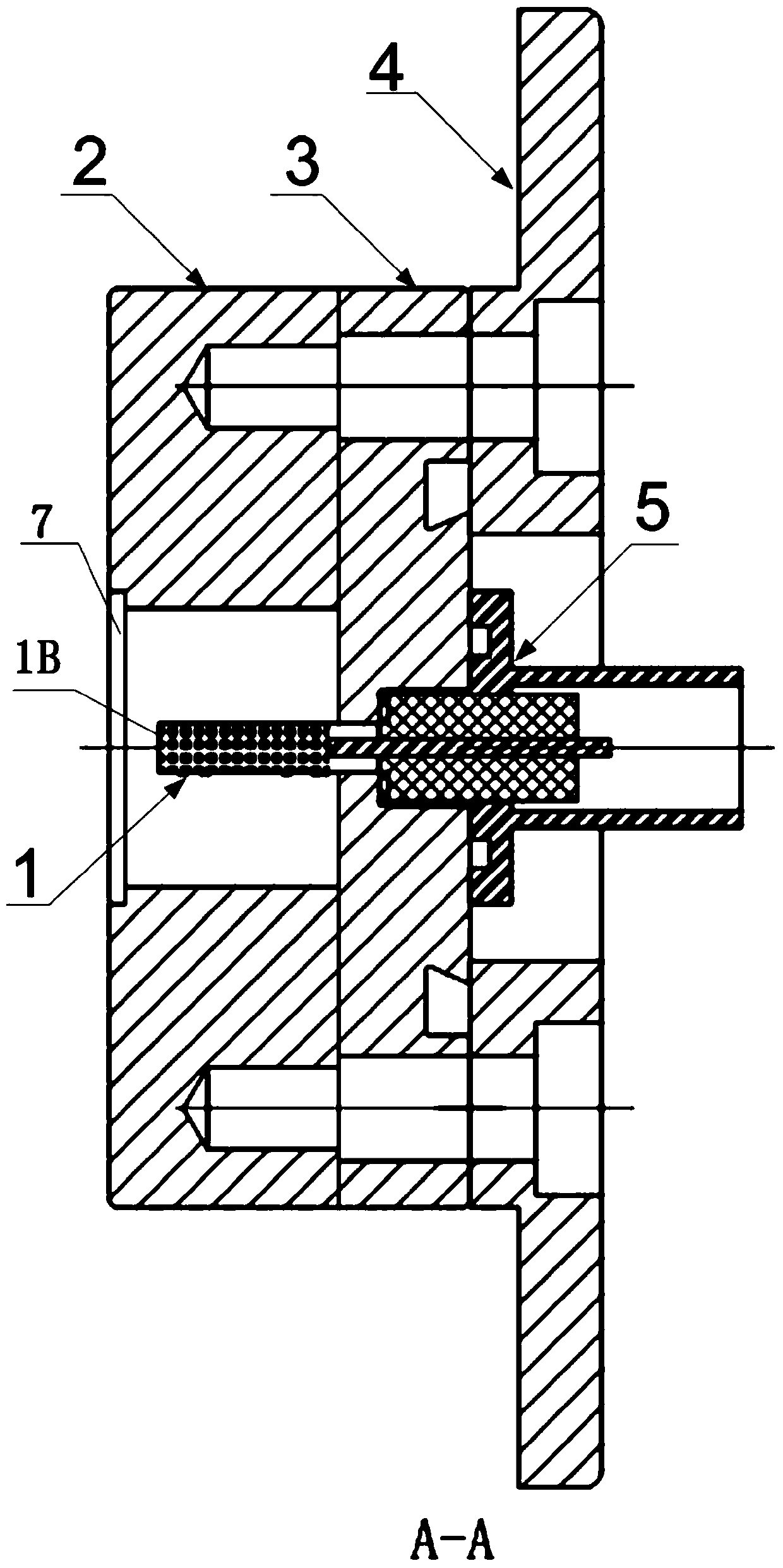

Control device for ultrasonic planar array probe

ActiveCN107198543AOvercome the problem of time out of syncEasy to controlUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsControl signalLow voltage

The invention discloses a control device for an ultrasonic planar array probe. The control device comprises an isolation unit (1), a high-voltage pulse unit (2), a high-voltage switch unit (3), a matching network, a receiving unit (5) and a control unit, wherein a first output end of the control unit is connected with the input end of the isolation unit (1); a second output end of the control unit is connected with a first input end of the high-voltage pulse unit (2); a third output end of the control unit is connected with a first input end of the high-voltage switch unit (3); the control unit is used for supplying low-voltage pulse signals with the amplitude range not larger than 5V to the isolation unit (1), sending a preset first control signal to the high-voltage pulse unit (2) and sending a preset second control signal to the high-voltage switch unit (3). According to the method, control over a whole row of or a whole column of or multiple rows and columns of array elements of the probe can be achieved at the same time, so that the complexity and instability of a traditional ultrasonic system circuit using discrete components are eliminated.

Owner:HUAZHONG UNIV OF SCI & TECH

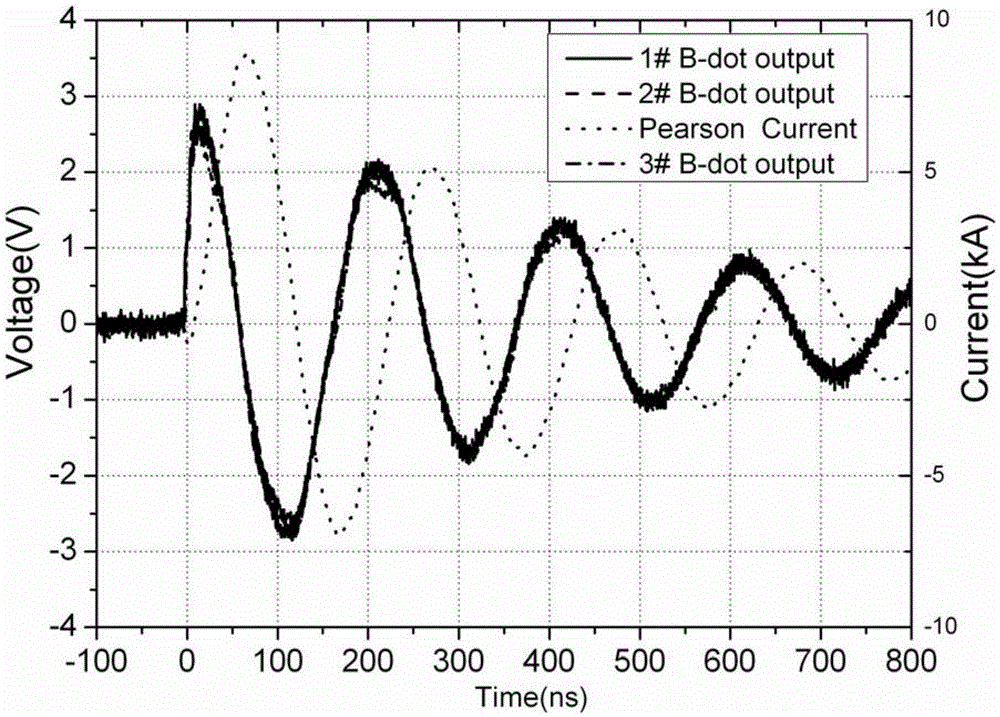

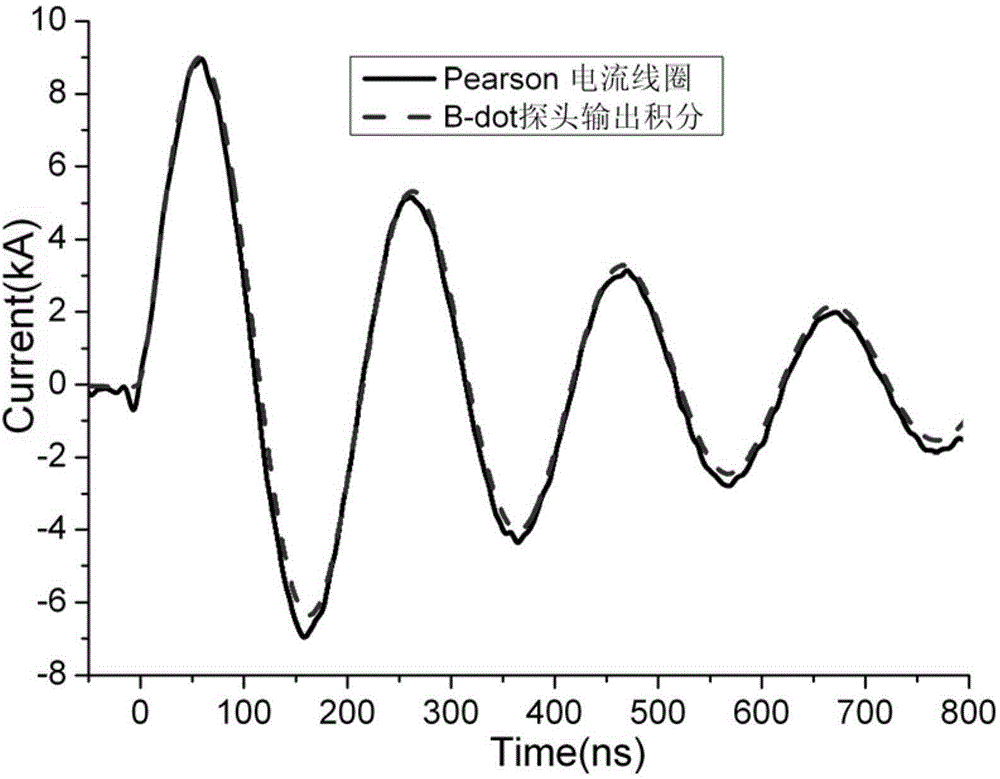

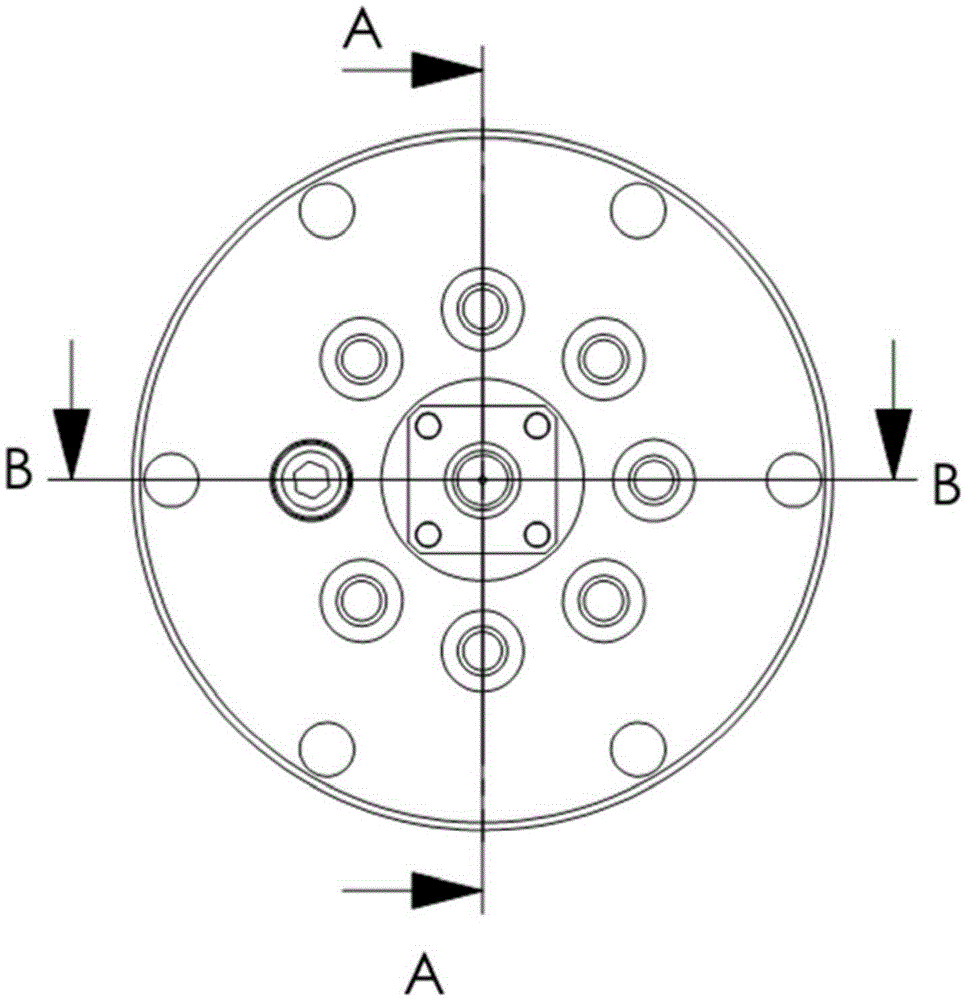

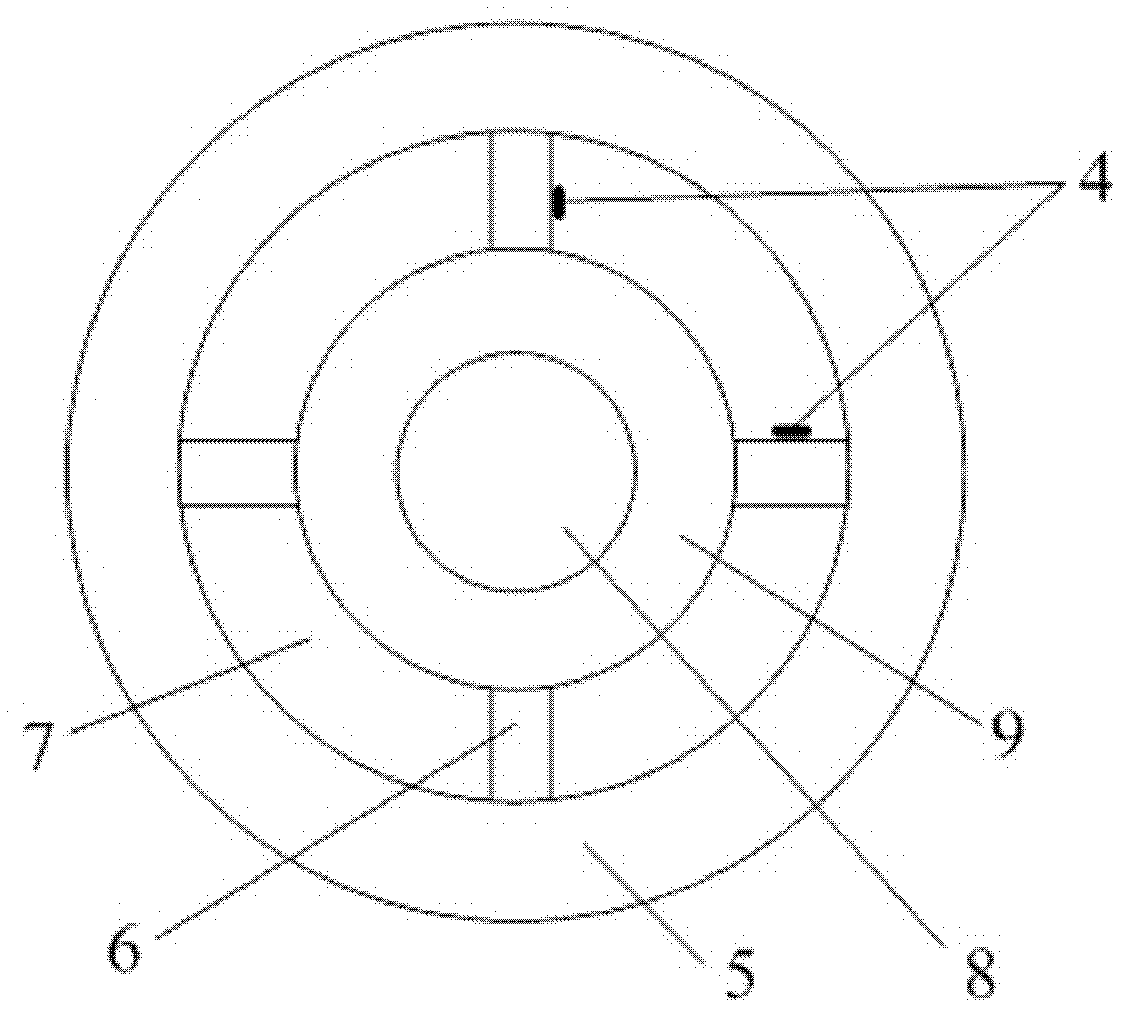

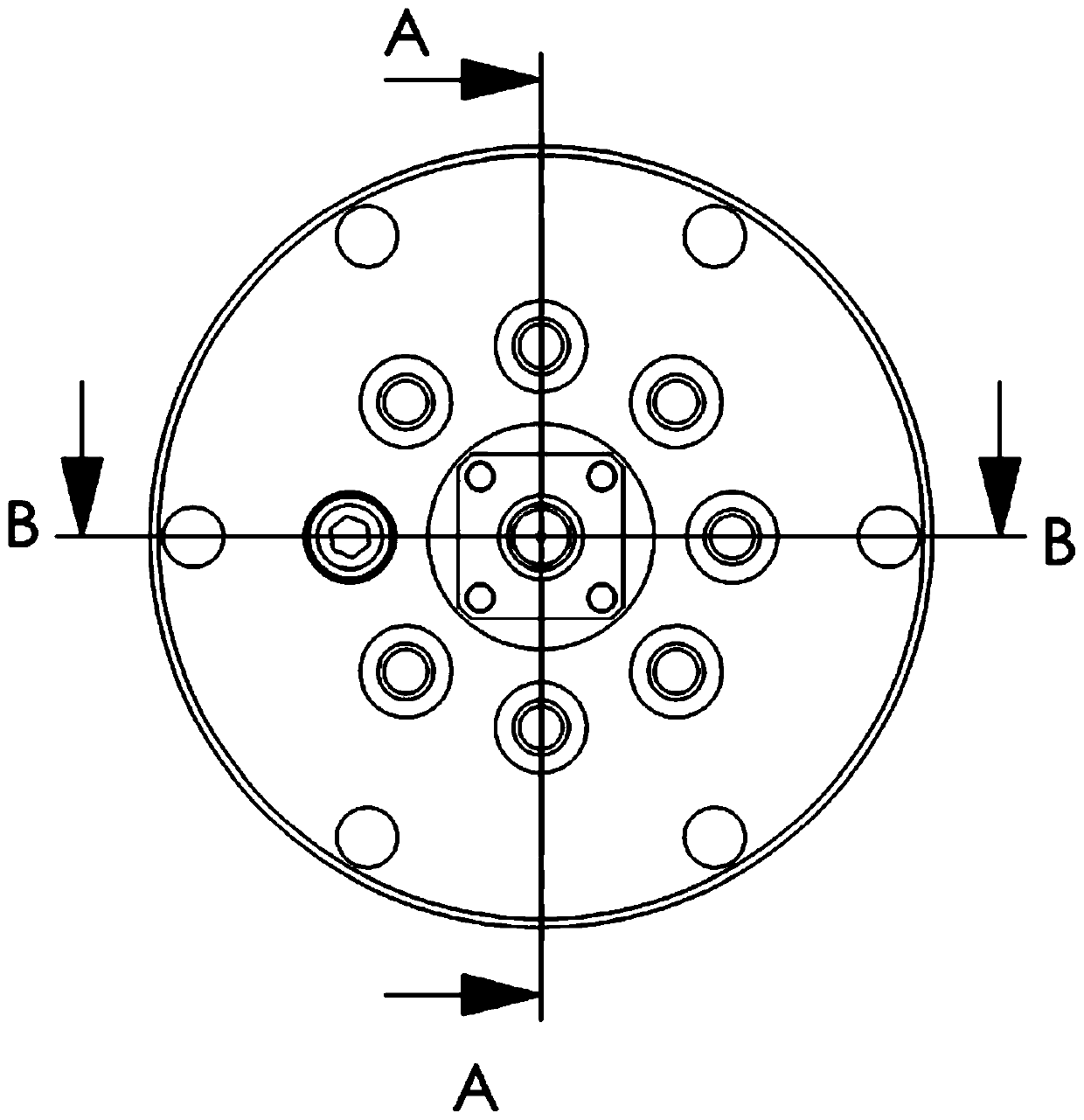

B-dot probe based on PCB type magnetic induction coil, and current spatial distribution measuring system

ActiveCN105388352AImprove consistencySmall difference in outputCurrent measurements onlyClockwiseElectrical current

The invention provides a B-dot probe based on a PCB type magnetic induction coil, and a current spatial distribution measuring system. A magnetic induction coil of the B-dot probe is clockwise or anticlockwise wired in the same direction on the circuit board, so that the PCB type magnetic induction coil is formed. Substantial advantages are achieved when an array formed by the plurality of B-dot probes is used to measure the current spatial distribution uniformity. A metal shielding cover is arranged on the top end, is buckled with a metal support ring and is fastened through fastening screws. A narrow gap is further formed in the metal shielding cover. The direction of long edges of the narrow gap is perpendicular to the plane of the magnetic induction coil. The metal shielding cover inhibits strong electromagnetic and strong radiation interference and also enables a magnetic field to be introduced to the magnetic induction coil through the narrow gap.

Owner:NORTHWEST INST OF NUCLEAR TECH

Measuring method of mid-infrared light signal intensity in wide temperature environment

InactiveCN103076088AMonitor operating temperatureImprove measurement uncertaintyPhotometry using electric radiation detectorsInstrumentation amplifierMeasurement device

The invention relates to a measuring method of the mid-infrared light signal intensity in wide temperature environment. According to the method, firstly, a measuring device is built, the measuring device comprises a mid-infrared light guide detector, a driving circuit and a signal collection recording instrument, wherein the driving circuit comprises an instrument amplifier unit and a constant flow source unit; secondly, the dark resistance value and the response rate value of the mid-infrared light guide detector at application environment temperature are obtained through measurement, and in addition, the balancing resistance and the magnification time parameter in the driving circuit are determined; and finally, the mid-infrared light signal intensity is obtained through calculation through the voltage signal and the monitored work temperature. The measuring method has the advantages that the optimal solution of the balancing resistance and the circuit magnification times is obtained according to the parameters of the dark resistance valve, the work voltage and the like of each detector at the wide temperature range end point, the output signal amplitude and the measurement dynamic range of a constant flow source type mid-infrared detection circuit are improved, the characteristics of concise step and convenience in realization are realized, and the measuring method can be used for the batch design of the mid-infrared detection circuit.

Owner:NORTHWEST INST OF NUCLEAR TECH

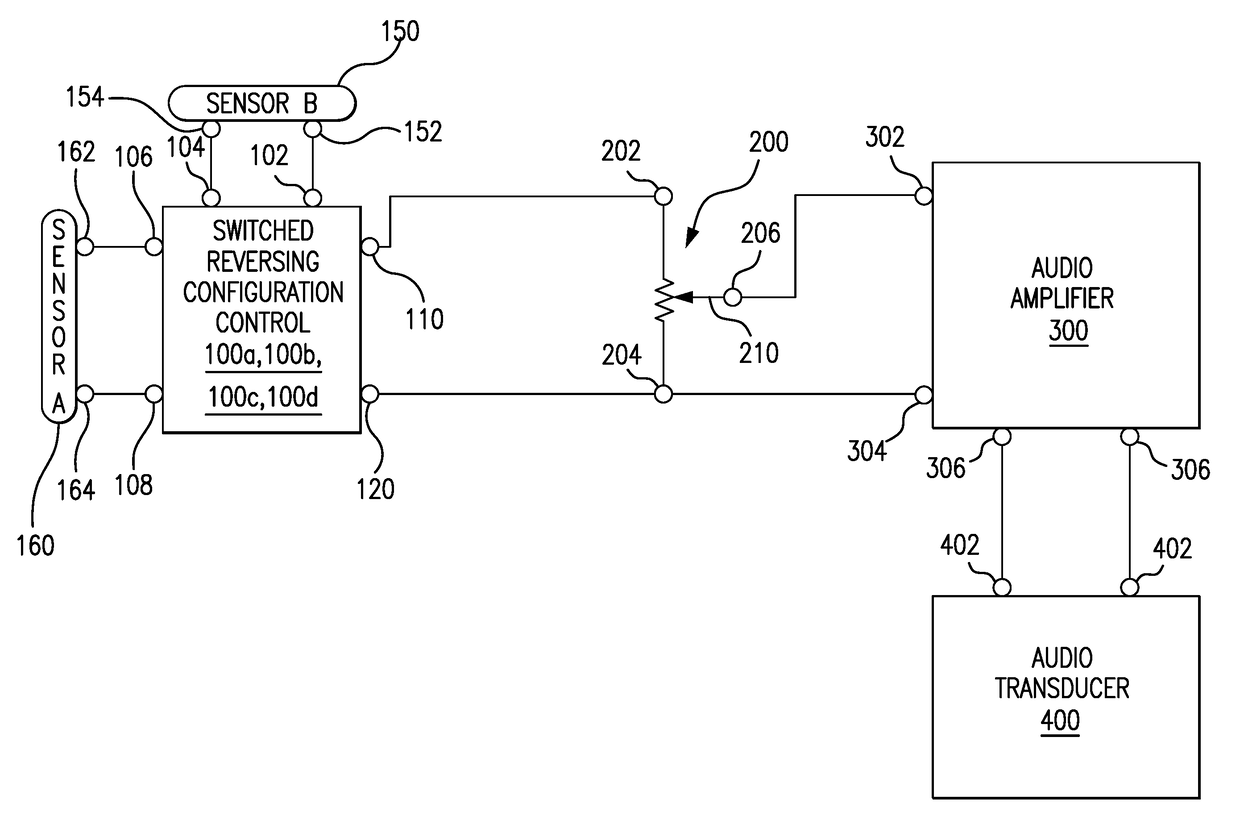

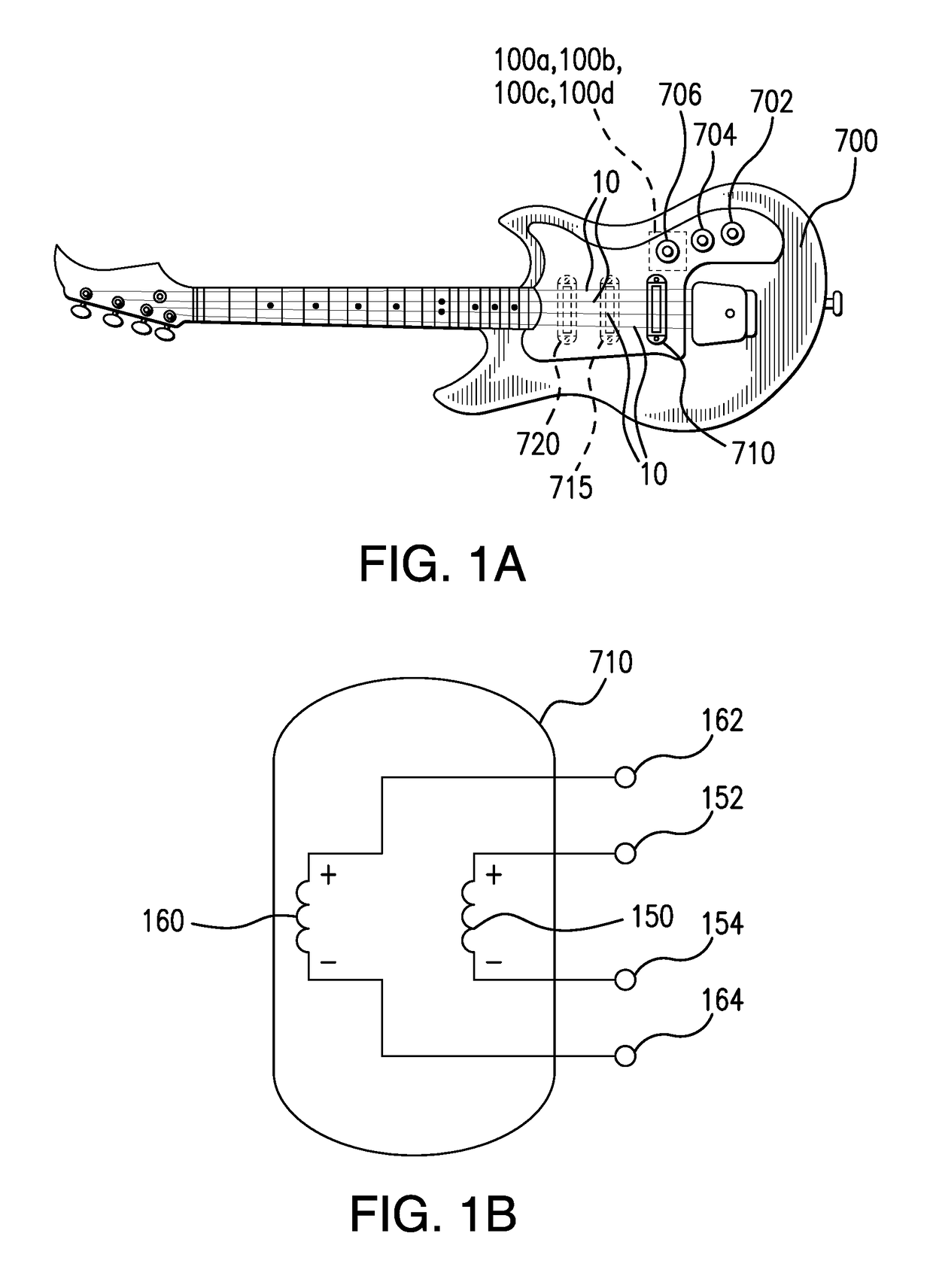

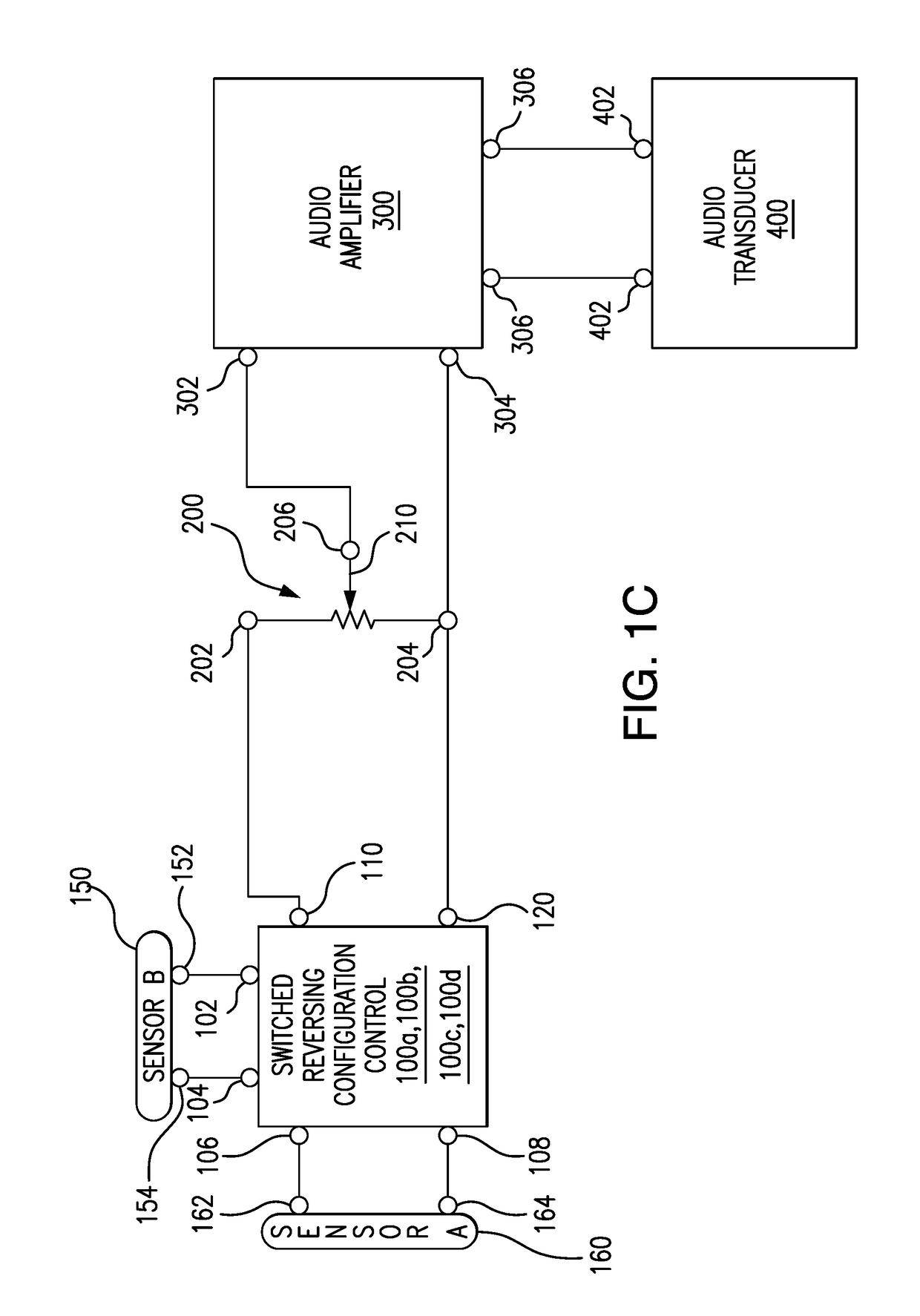

Switched reversing configuration control for string instruments and boost circuit therefor

ActiveUS9747882B1Increase signal amplitudeIncrease output signal amplitudeElectrophonic musical instrumentsElectricityEngineering

A switched reversing configuration control for string instruments connects to a pair of pickup sensors located on an electric string instrument for selectively electrically configuring the pickup sensors between (a) the pair of pickup sensors being coupled with like polarity in one of series or parallel with respect to a pair of output terminals, or (b) effectively coupling only one of the pair of pickup sensors to the output terminals, or (c) the pair of pickup sensors being coupled with opposing polarity in one of series or parallel with respect to the output terminals. An optional reverse polarity passive boost circuit is provided for increasing the output voltage coupled to the output terminals when the pickup sensors are coupled with opposing polarity as compared to the output voltage that would otherwise be provided absent the reverse polarity passive boost circuit.

Owner:MICEK PETR

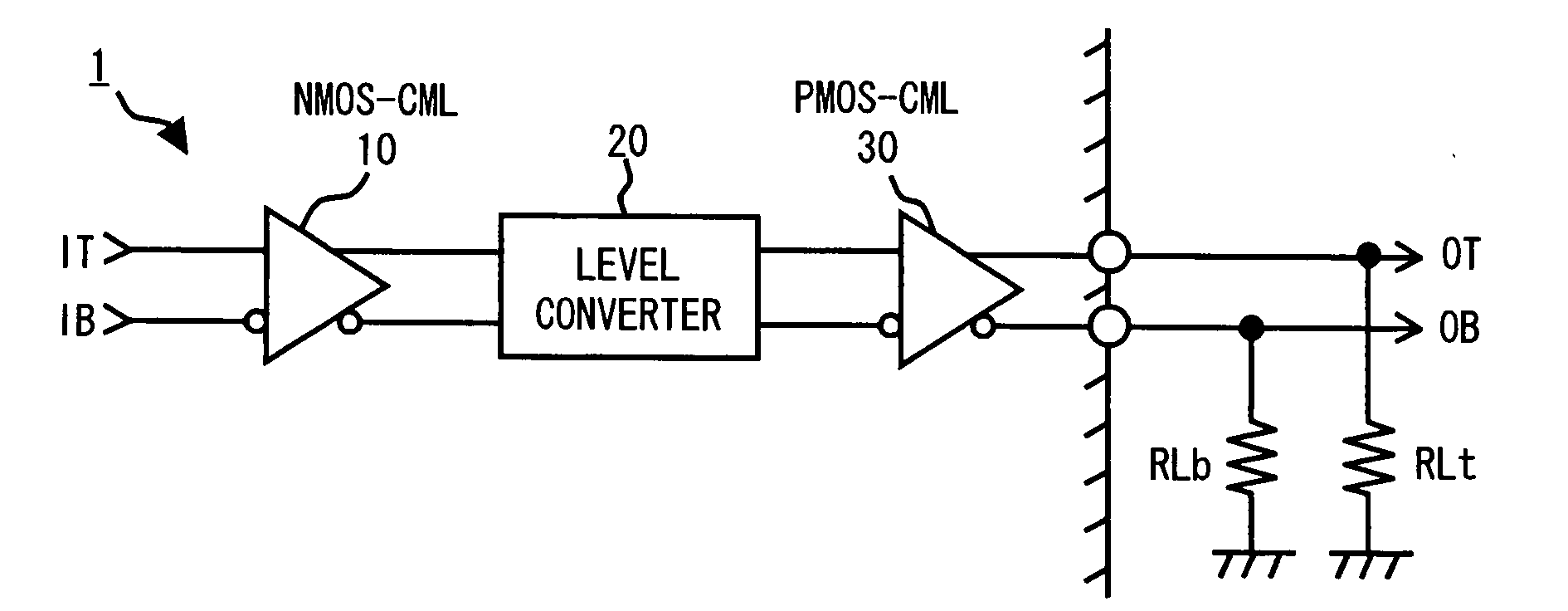

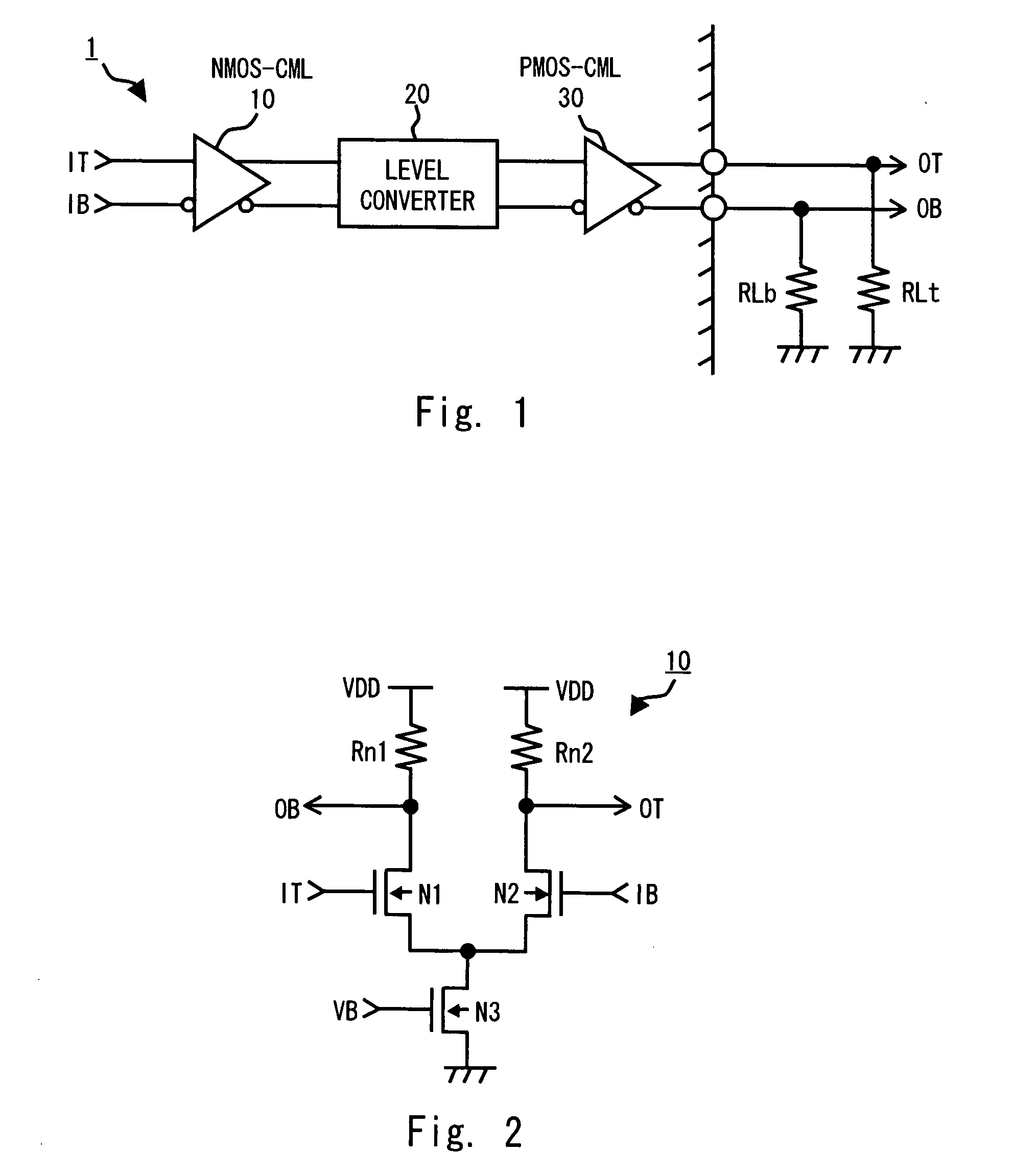

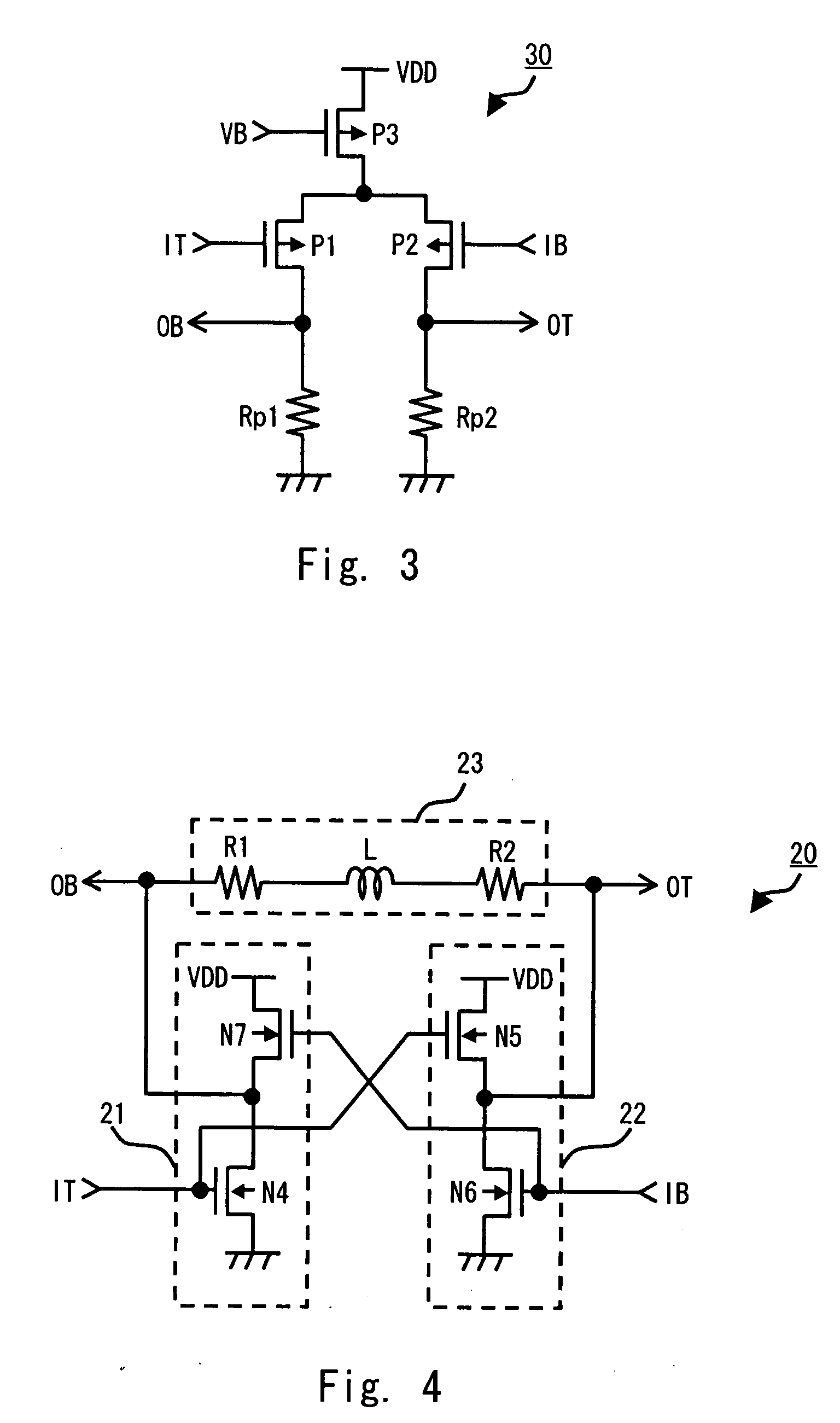

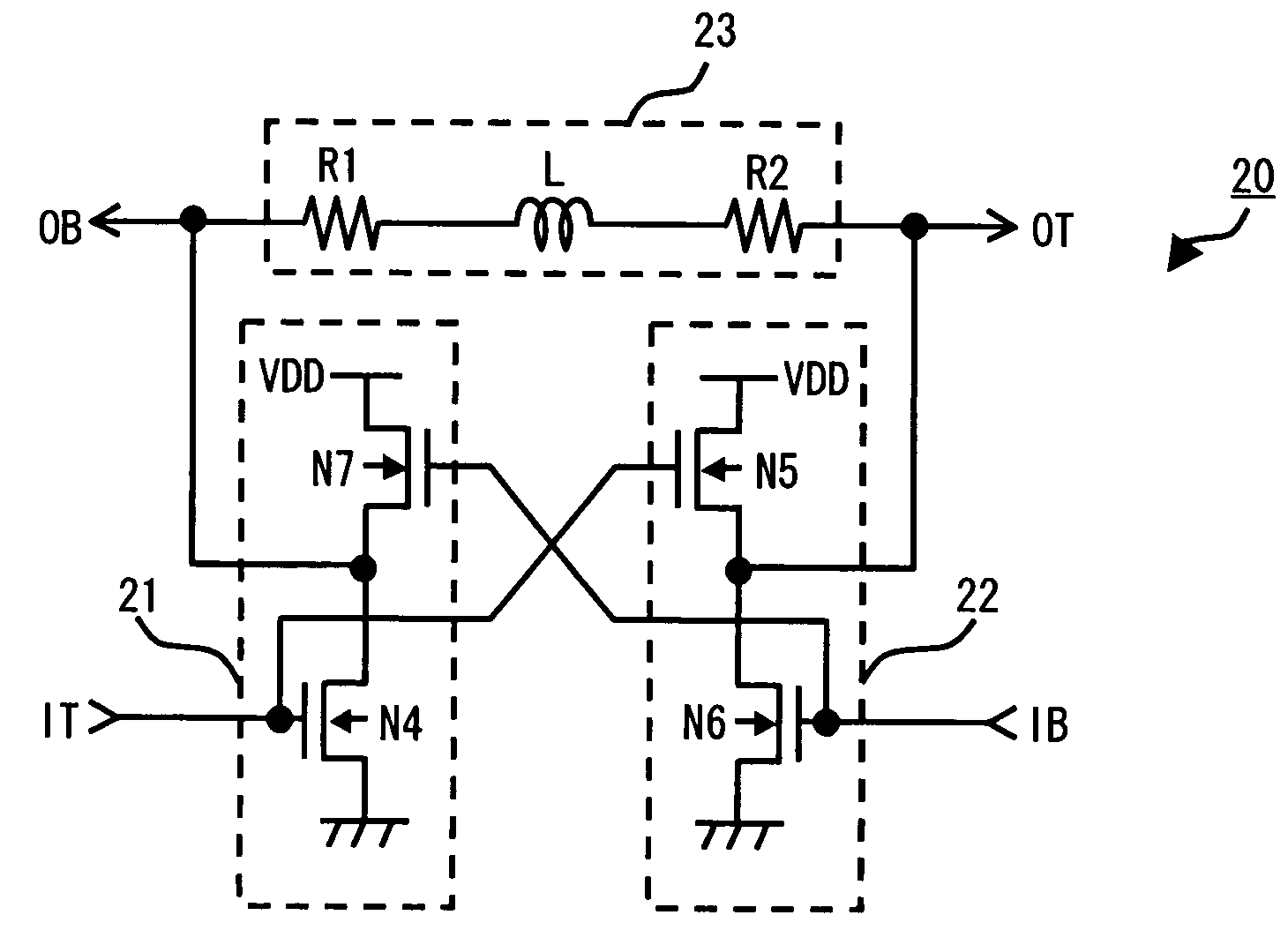

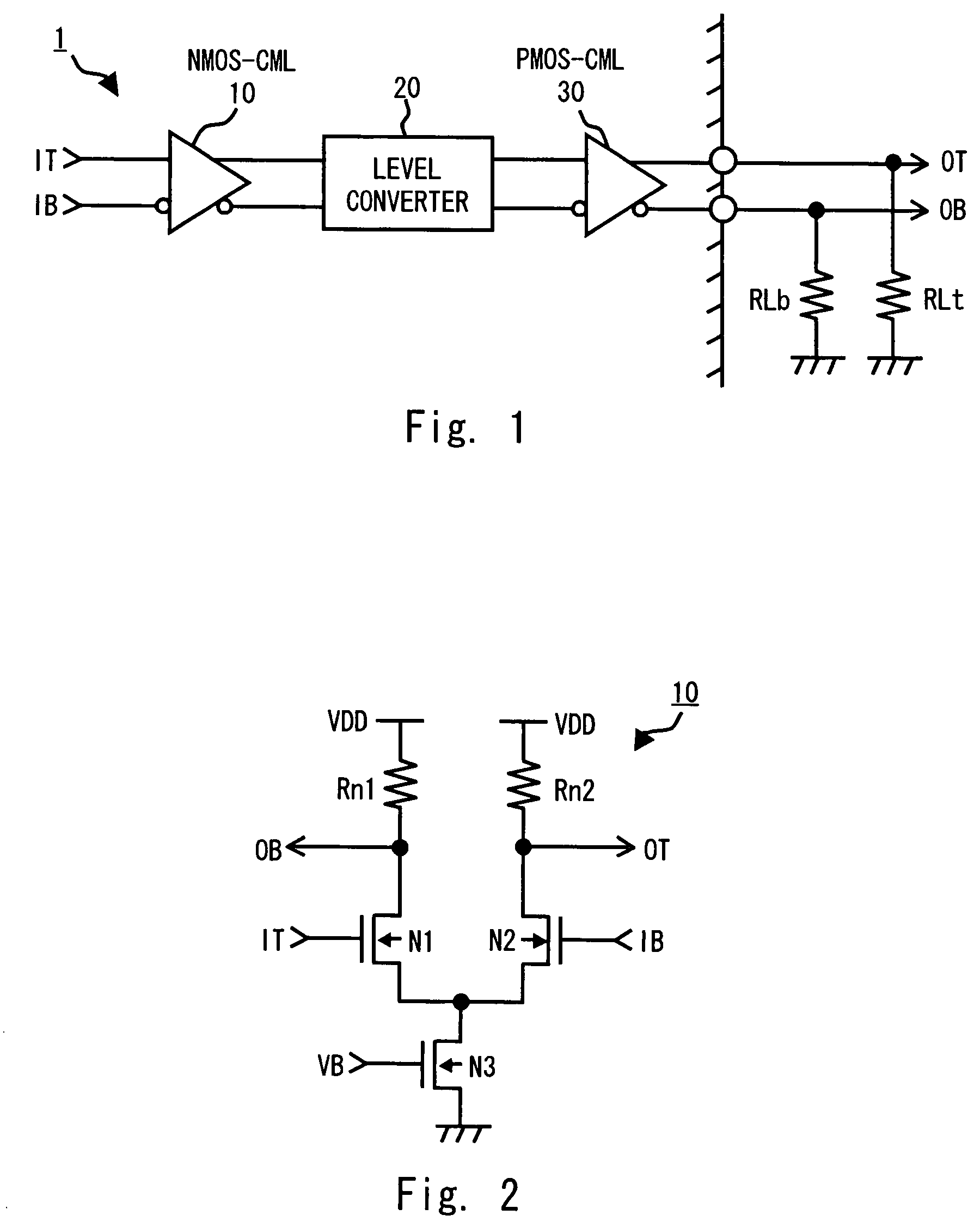

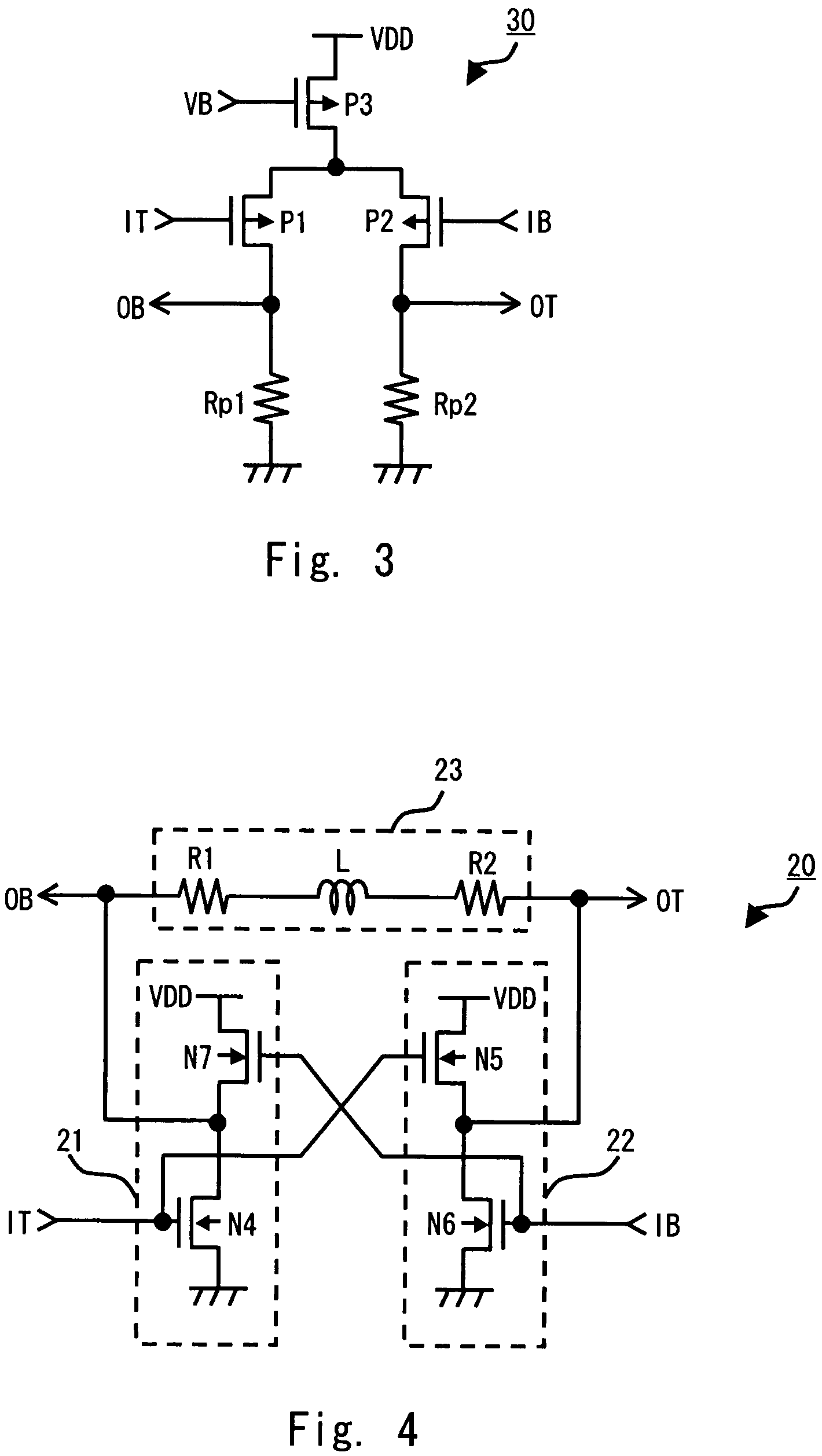

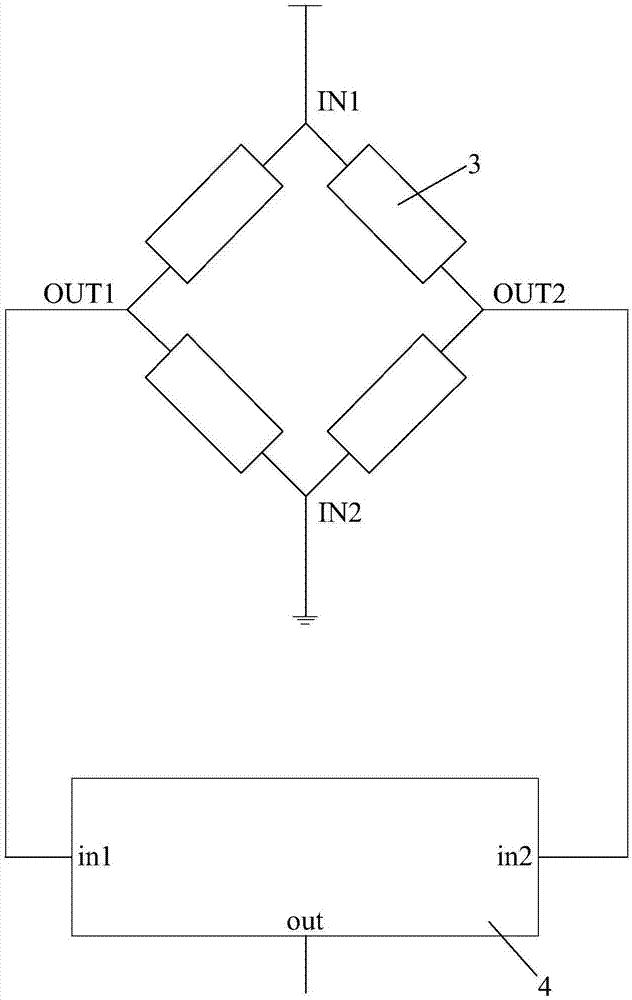

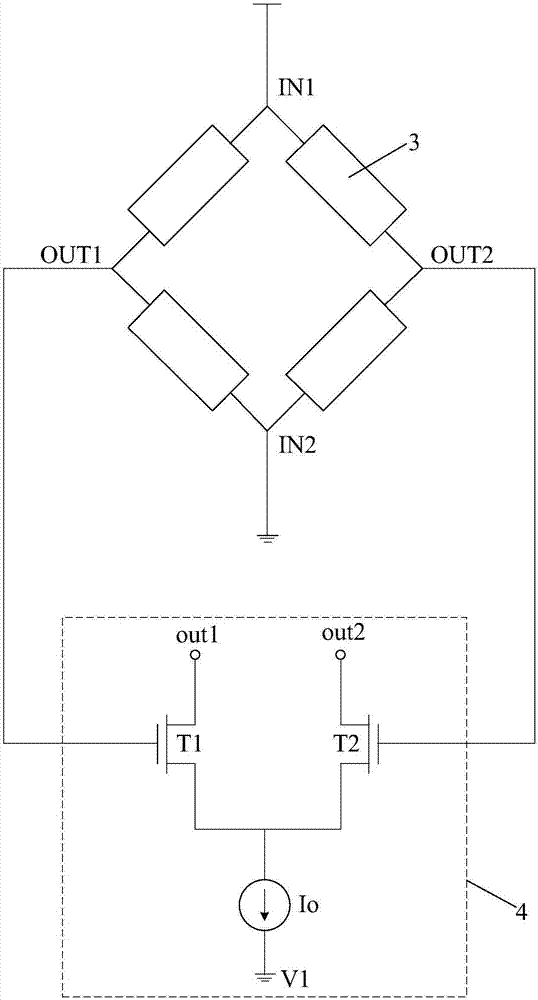

Level converter and semiconductor device

InactiveUS20080042725A1Lower resistance valueHigh carrier mobilityPulse automatic controlDigital storagePower semiconductor deviceLevel converter

A level converter includes a first to fourth transistors formed of a semiconductor having a same conductivity type. The first transistor is connected between a first power supply and a second output terminal, the second transistor is connected between a second power supply and a first output terminal, the third transistor is connected between the first power supply and the first output terminal, the fourth transistor is connected between the second power supply and the second output terminal, the first and the second transistors are input with one of first differential signals and the third and the fourth transistors are input with another of the first differential signals.

Owner:RENESAS ELECTRONICS CORP

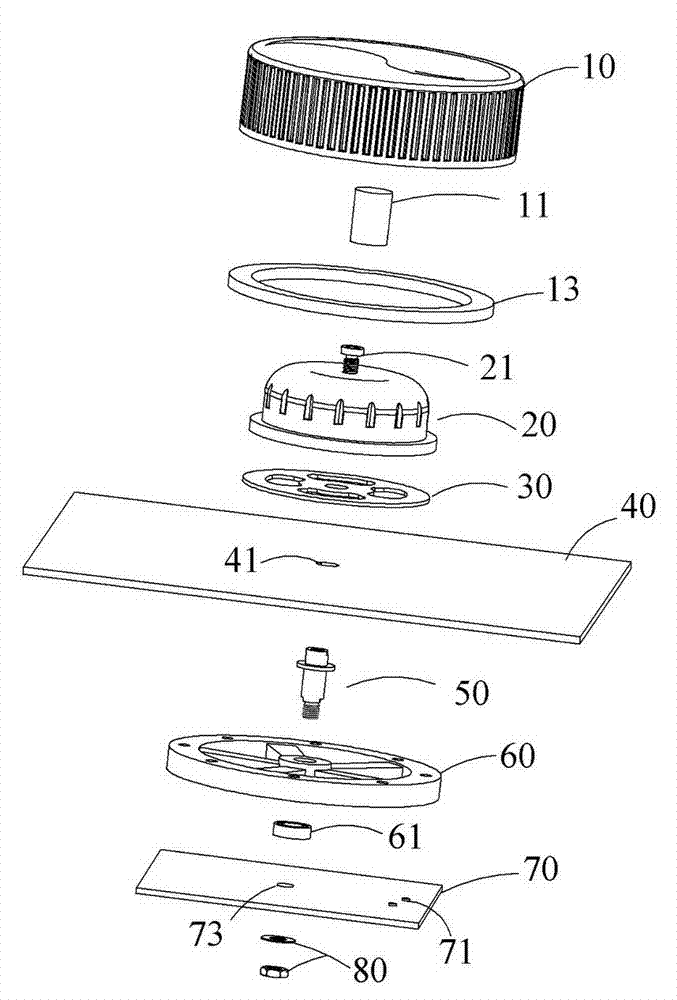

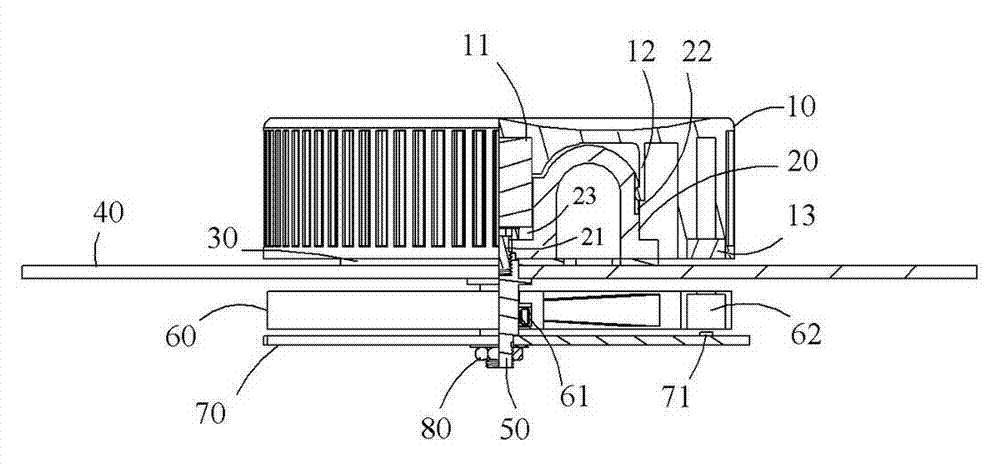

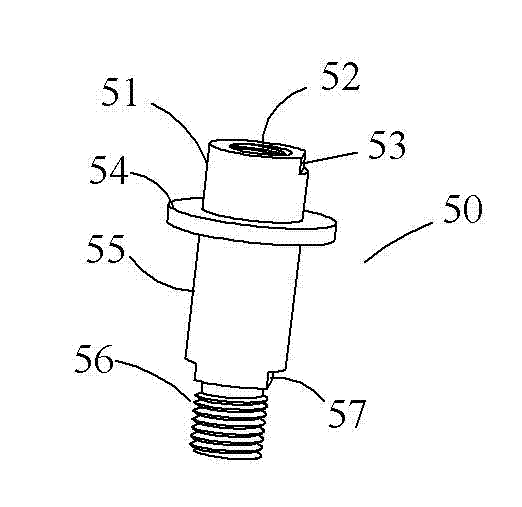

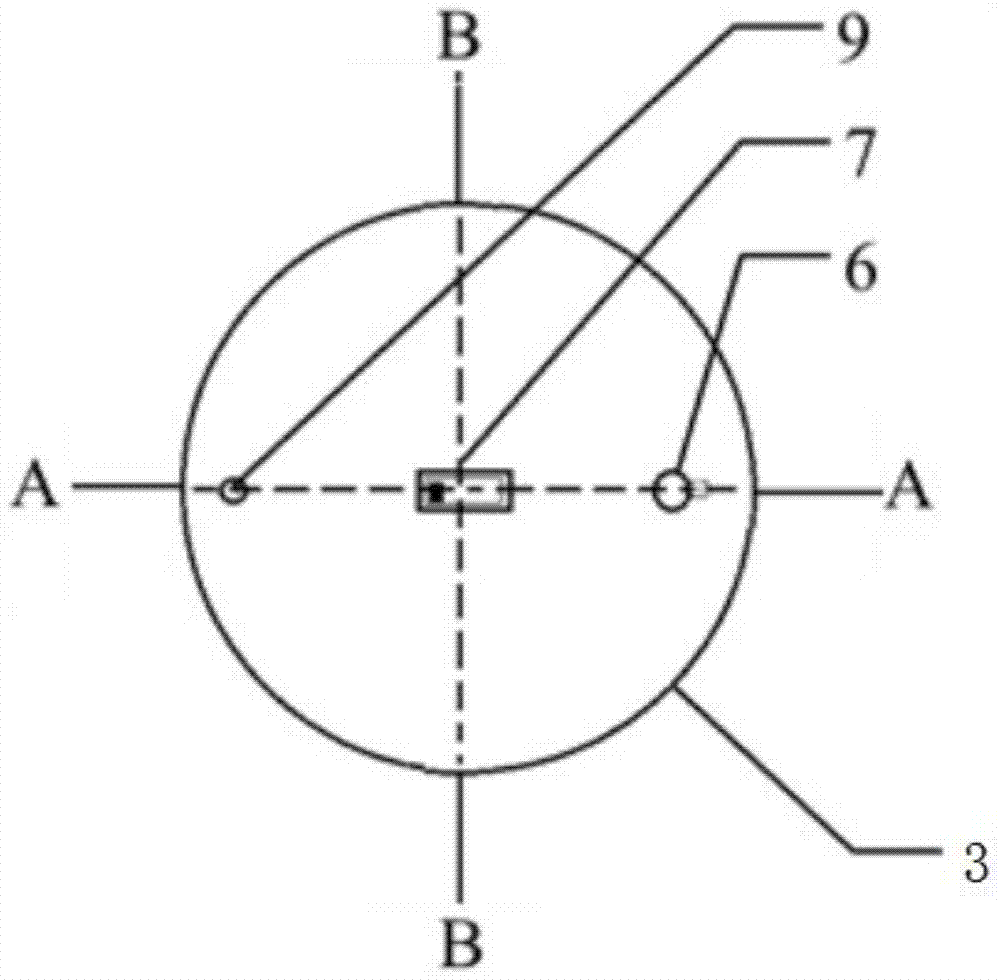

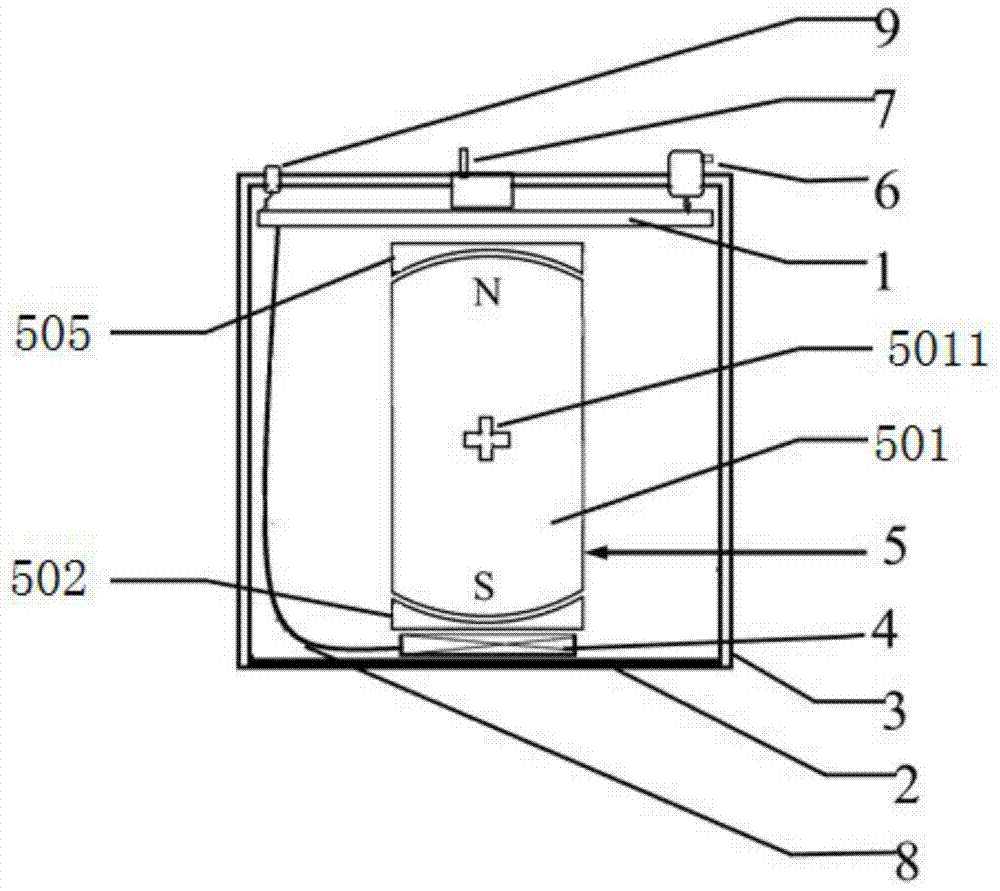

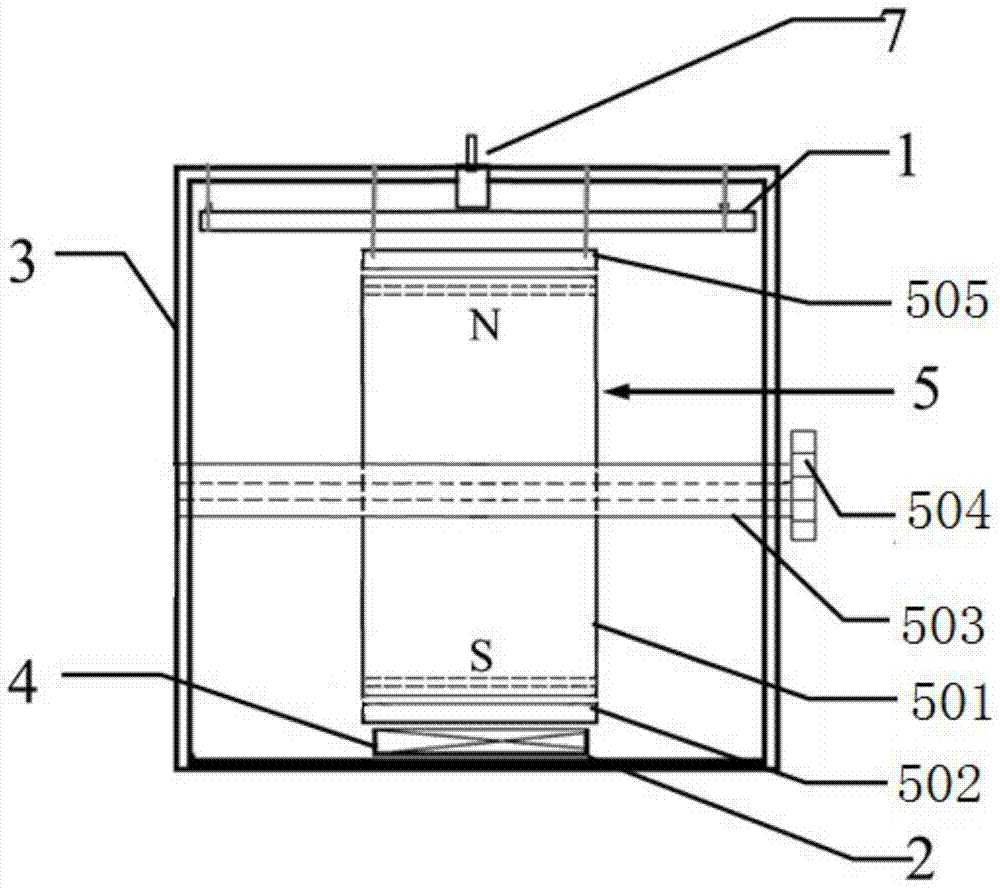

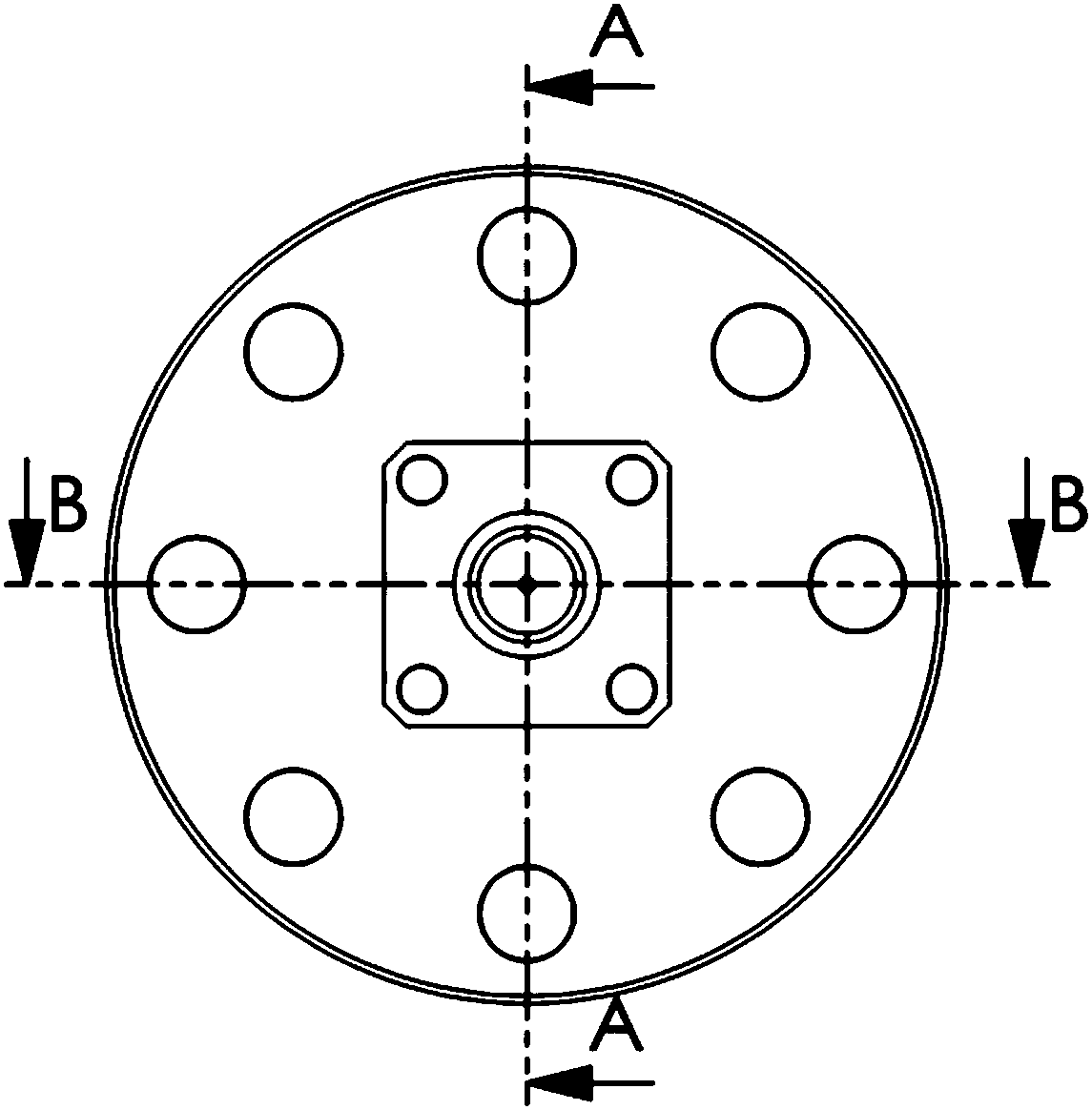

Waterproof coding device having built-in magnet disc

InactiveCN103591969ARotation doesn't happenIncrease the output signal amplitudeMeasurement apparatus componentsUsing electrical meansEngineeringMagnet

The invention relates to a waterproof coding device having a built-in magnet disc. The waterproof coding device having the built-in magnet disc comprises the magnet disc, a turn button with a shaft, an induction circuit board, a positioning shaft, and a circular support seat, wherein an inner top face of the turn button is provided with an elastic positioning sheet, a port portion of an annular chamber at an outer wall of the turn button is provided with a magnetic guide ring, the magnet disc is mounted at a central portion of the positioning shaft, the induction circuit board is fixed at a tail portion of the positioning shaft, an outer circumferential wall of the circular support seat is provided with a positioning groove, a central portion of the circular support seat is provided with a shaft sleeve, the circular support seat is on a panel, a head portion of the positioning shaft penetrates through a mounting hole of the panel, thread connection with the positioning shaft is realized through a screw, the turn button is mounted on the support seat, the shaft is in moving matching with the shaft sleeve in the support seat, and the magnetic guide ring is attracted by a magnet of the magnet disc to realize synchronous rotation of the magnet disc and the turn button. The magnet disc is arranged in the casing panel, axial positioning of the turn button is realized through magnetic force of the magnet disc, the waterproof coding device has advantages of compact structure, waterproof performance, anti-shock performance and low cost and is especially applicable to use in a high wet environment or an easy shocking occasion.

Owner:王嘉 +2

Level converter and semiconductor device

InactiveUS7504859B2Lower resistance valueHigh carrier mobilityPulse automatic controlDigital storageLevel converterSemiconductor

A level converter includes a first to fourth transistors formed of a semiconductor having a same conductivity type. The first transistor is connected between a first power supply and a second output terminal, the second transistor is connected between a second power supply and a first output terminal, the third transistor is connected between the first power supply and the first output terminal, the fourth transistor is connected between the second power supply and the second output terminal, the first and the second transistors are input with one of first differential signals and the third and the fourth transistors are input with another of the first differential signals.

Owner:RENESAS ELECTRONICS CORP

Display panel and display device

InactiveCN107393497AIncrease the output signal amplitudeImprove touch functionalityStatic indicating devicesSolid-state devicesDisplay deviceEngineering

The embodiment of the invention provides a display panel and a display device and relates to the technical field of display. The adverse effects, caused when the heating value of a pressure induction sensor is high, on the touch control functions or display functions are improved. The display panel comprises the pressure induction sensor, an amplifying circuit and a drive chip, wherein the pressure induction sensor comprises a first input end, a second input end, a first output end and a second output end; the amplifying circuit corresponds to the pressure induction sensor and comprises a first amplifying input end, a second amplifying input end and at least one amplifying output end, the first amplifying input end of the amplifying circuit is connected with the first output end of the pressure induction sensor, and the second amplifying input end of the amplifying circuit is connected with the second output end of the pressure induction sensor; the drive chip is connected with the at least one amplifying output end of the amplifying circuit.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

MEMS (micro-electromechanical system) resonator with LC series resonance circuit

InactiveCN104218916AThe series resonant frequency is the sameConsistent frequencyImpedence networksCapacitanceMechanical resonance

The invention relates to an MEMS (micro-electromechanical system) resonator with an LC series resonance circuit and belongs to the technical field of electronic science. The resonator comprises a vibration block and supporting anchors thereof, input / output electrodes, an input-end LC series resonance structure and input / output ends. Each input end is connected with one input electrode through an inductor, and the supporting anchors of the resonance block form capacitor structures in the LC series resonance circuit. The MEMS resonator with the LC series resonance circuit has the advantages that the LC series resonance circuit composed of the inductors and capacitors is added in front of the input electrodes of a conventional electrostatic drive capacitive MEMS resonator, and the series resonance frequency is identical to mechanical resonance frequency of the vibration block; by introduction of the structure, actual input voltage and energy conversion efficiency of the resonator are improved, the resonator is enabled to excite larger displacement by vibration, further output amplitude is heightened, and output performance of is resonator is improved effectively.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

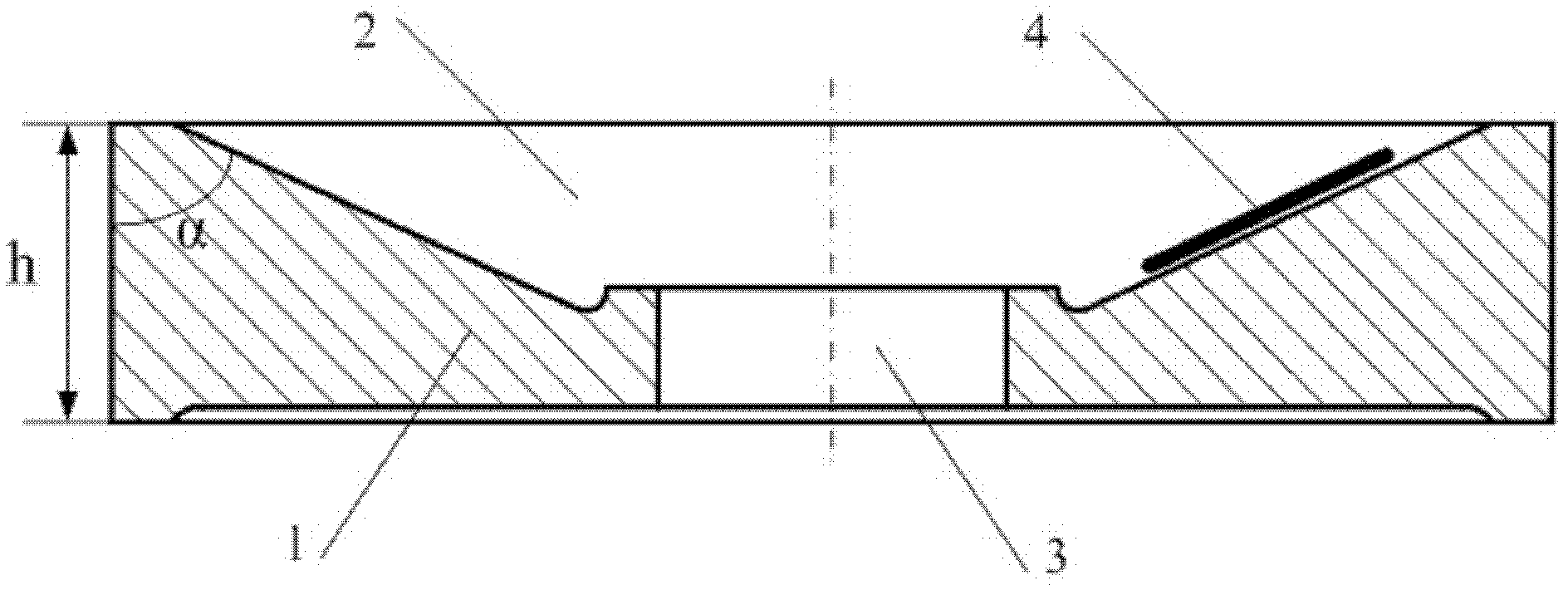

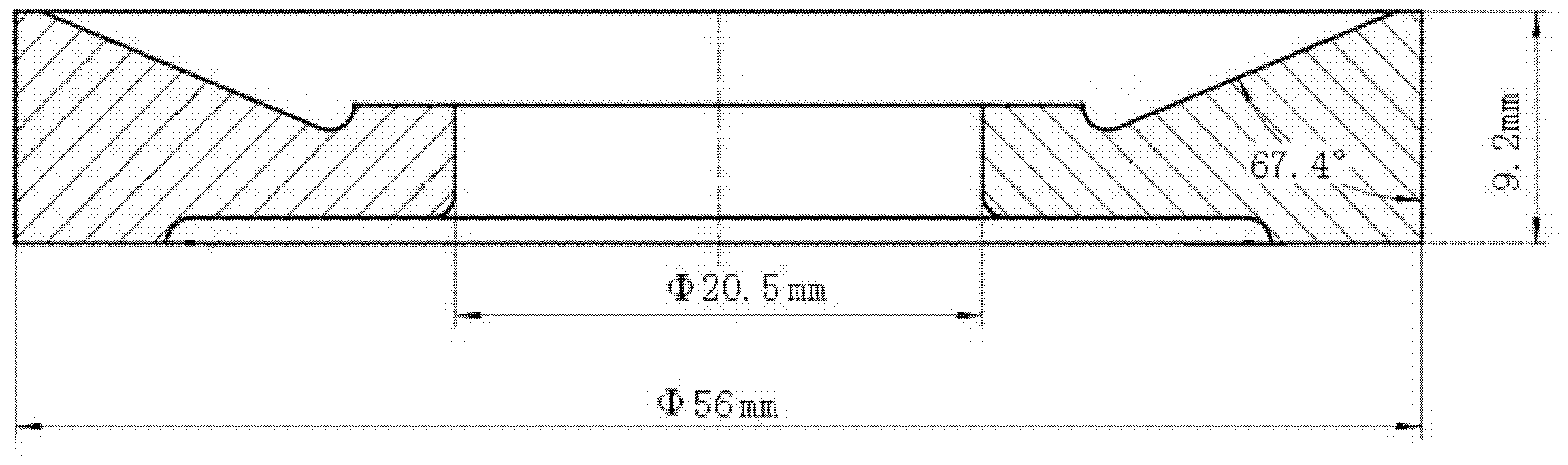

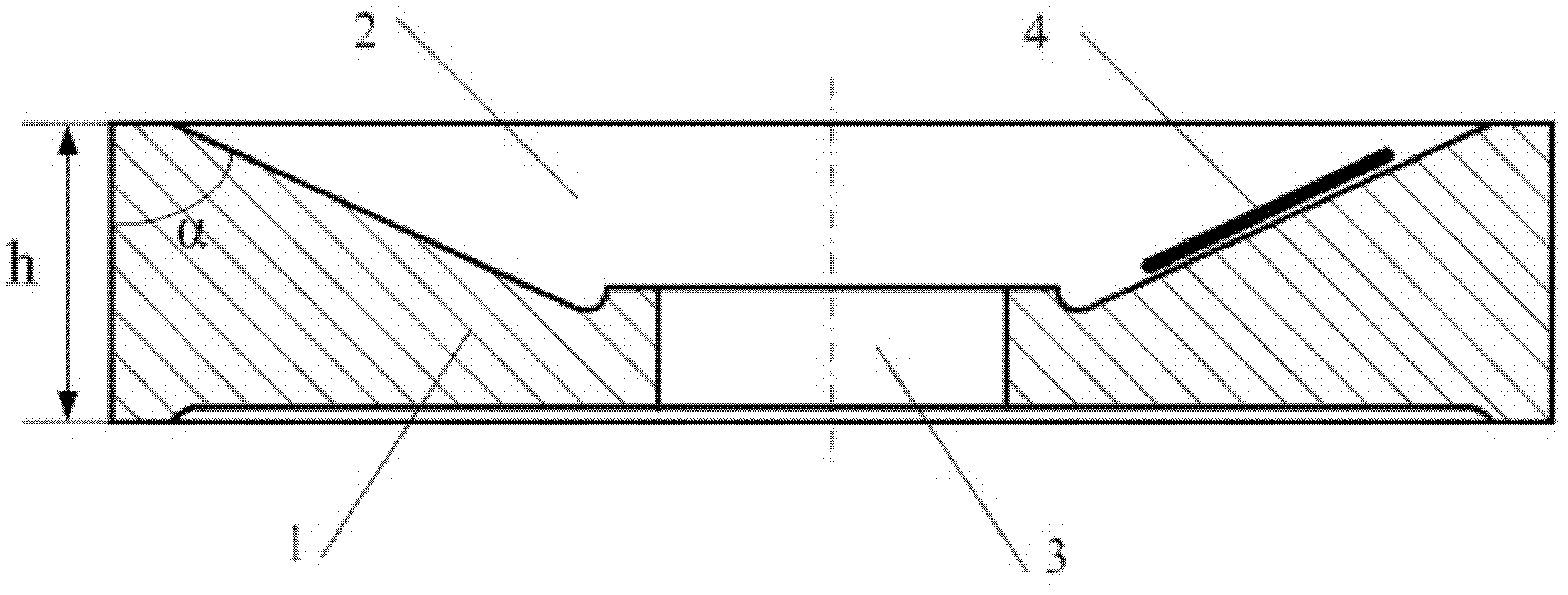

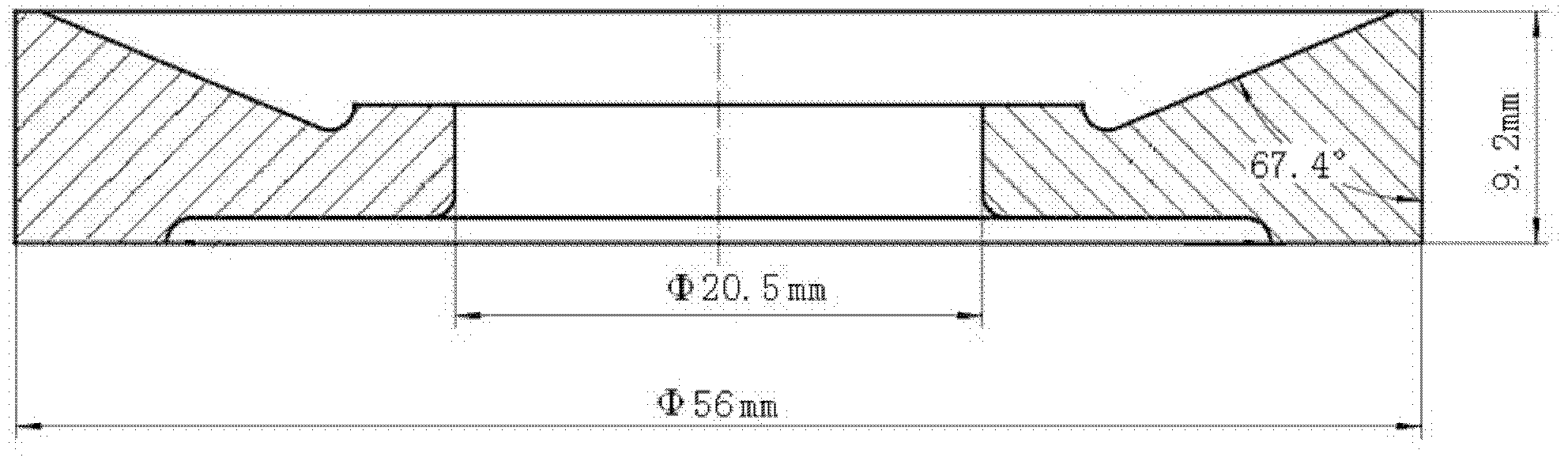

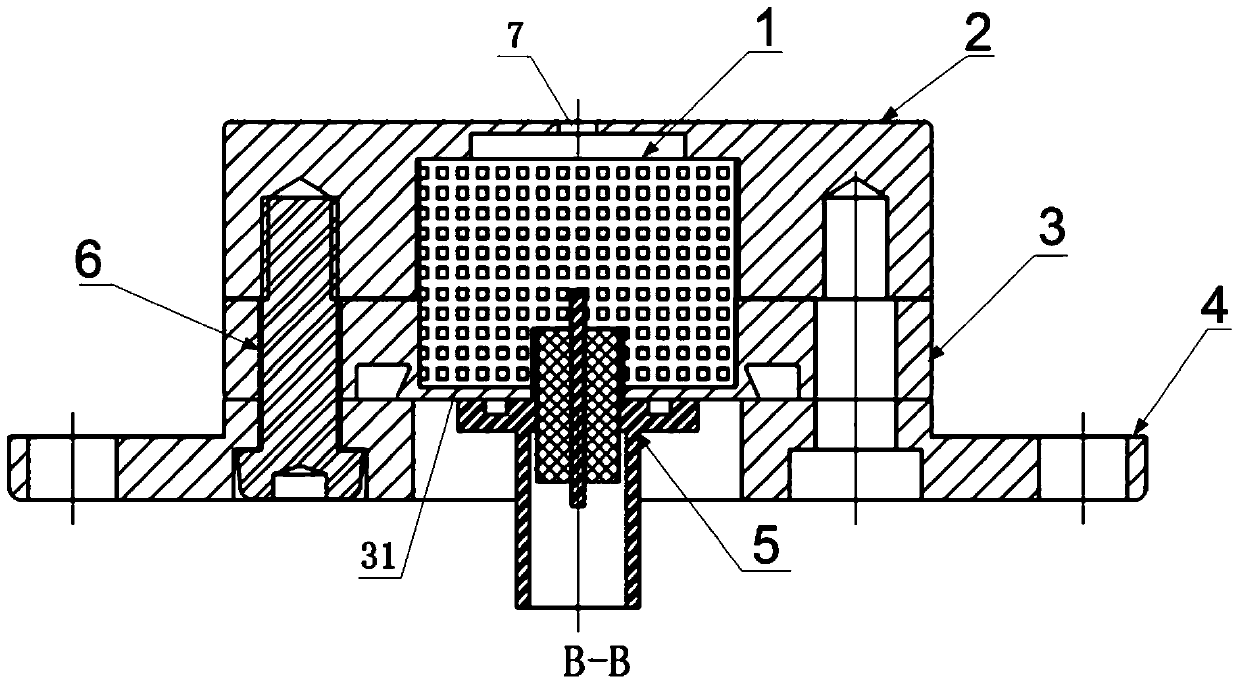

Inner conical elastomer for strain force transducer, and optimization method for inner conical elastomer

InactiveCN102539031AHigh sensitivitySimple shapeForce measurement using piezo-resistive materialsStress levelStrain gauge

The invention provides an inner conical elastomer for a strain force transducer. The inner conical elastomer comprises a cylindrical base body; the upper part of the base body is provided with a conical concave part; the bottom of the conical concave part is provided with a central hole; and the conical surface of the conical concave part is provided with a strain gauge. The optimization method for the elastomer comprises the following steps of: estimating an initial size; calculating stress of the elastomer under the action of the axial force of a bolt by a finite element method, and adjusting the cone angle of a model until stress on the inner conical surface is distributed uniformly; adjusting the thickness of the base body under the condition of not changing the cone angle to ensure that the stress level on the conical surface meets the requirement; and rounding the model size obtained through finite element calculation, wherein the rounded model size is used as the final size of the elastomer. The inner conical elastomer is a simple revolution solid, and is high in processing and heat treatment manufacturability; the stress of the adhesion part of the strain gauge is distributed uniformly; and the accuracy of the adhesion position of the strain gauge is not required. The axial size of the elastomer is smaller than that of a spoke elastomer, and the elastomer is more suitable for measuring the axial force of the bolt.

Owner:XIAN UNIV OF TECH

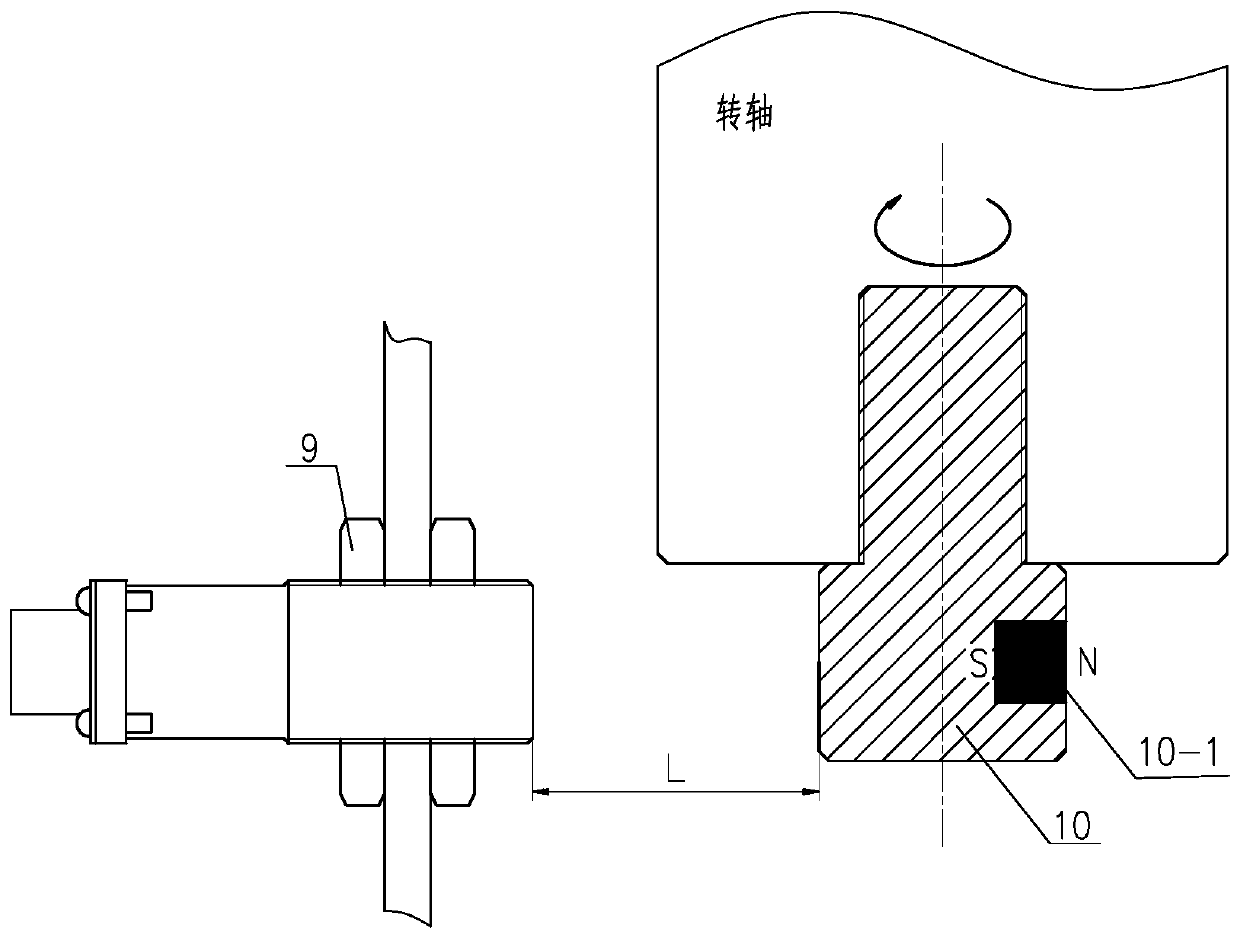

Magnetoelectric rotating speed sensor suitable for large-spacing measurement

ActiveCN110940827AIncrease the output signal amplitudeFacilitate subsequent signal processingSpeed/acceleration/shock instrument detailsDevices using electric/magnetic meansMagnetoEngineering

The invention relates to a magnetoelectric rotating speed sensor suitable for large-spacing measurement. The magnetoelectric rotating speed sensor comprises an armature framework, an enameled wire coil, a shell, an insulating sleeve, an insulating spacer, a lead, a connector and a shaft end bolt embedded with a permanent magnet, wherein the armature framework, the enameled wire coil, the insulating sleeve and the insulating gasket are assembled into an assembly, the assembly is installed inside the shell, the enameled wire coil and the connector are connected through a lead, and after connection is completed, potting is performed and the connector is fixed to the shell to form a magneto-electric rotating speed sensor sensitive assembly, the shaft end bolt is installed on a rotating shaft to be measured, periodic magnetic field changes are formed through the permanent magnet, and the assembly is installed in the magnetic field change range, so that the enameled wire coil generates sinusoidal alternating current signals, and then the alternating current is periodically converted into revolutions. The magnetoelectric rotating speed sensor has the advantages that large-spacing non-contact measurement between the sensor and the rotating shaft can be realized, the output amplitude is large, and the vibration resistance is strong.

Owner:BEIJING RES INST OF TELEMETRY +1

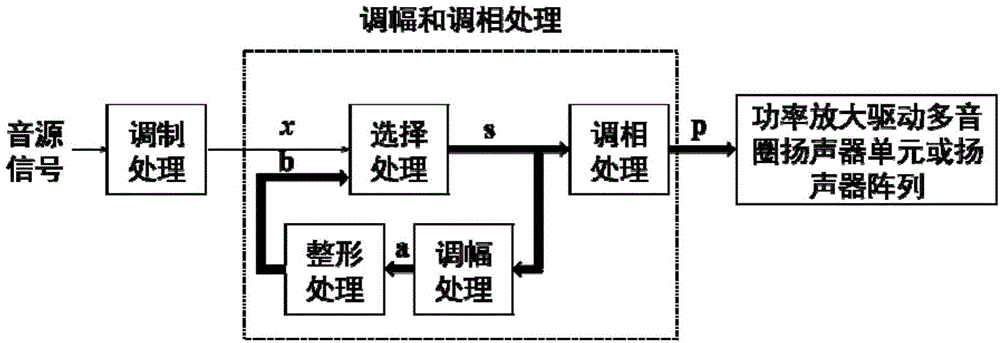

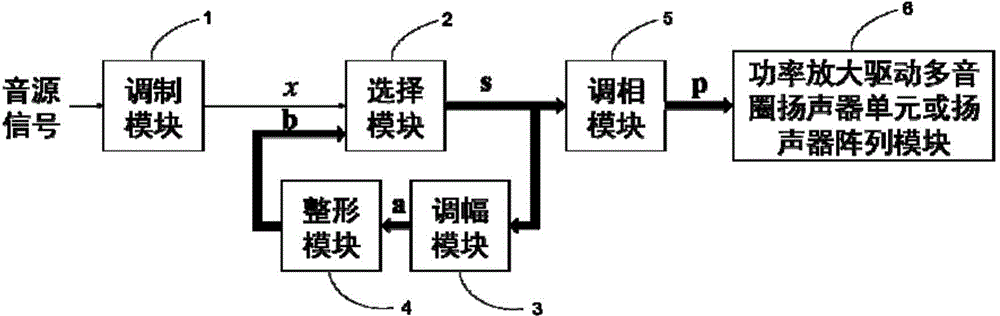

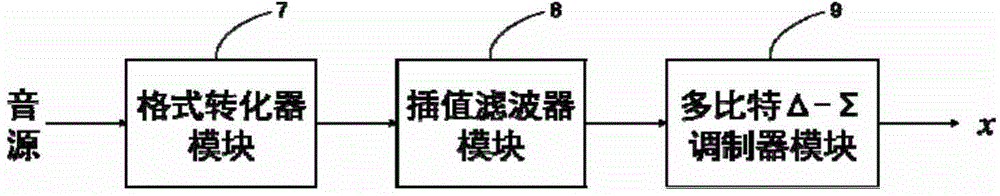

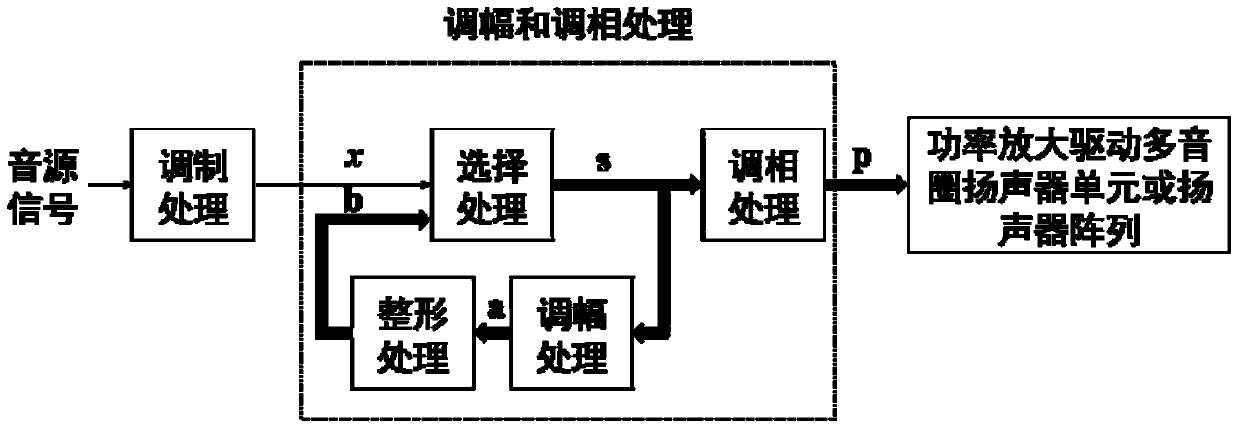

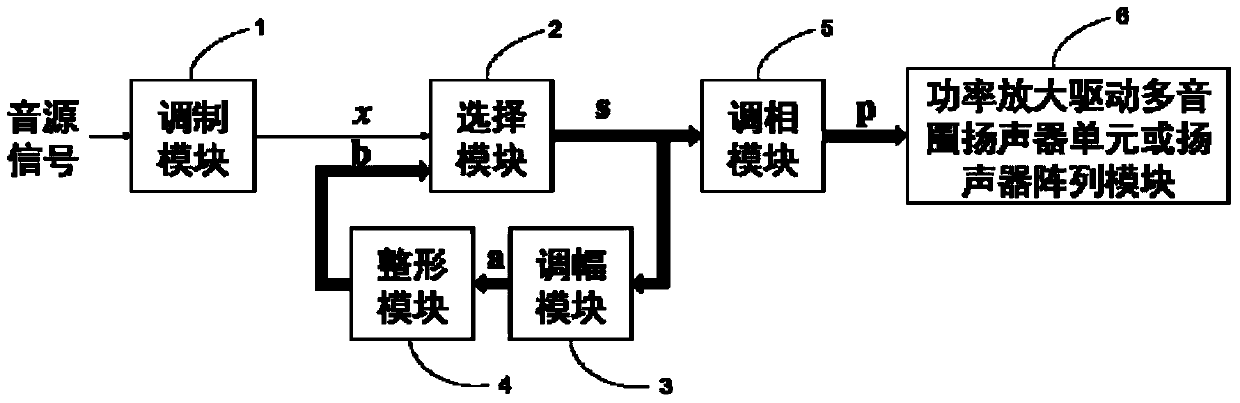

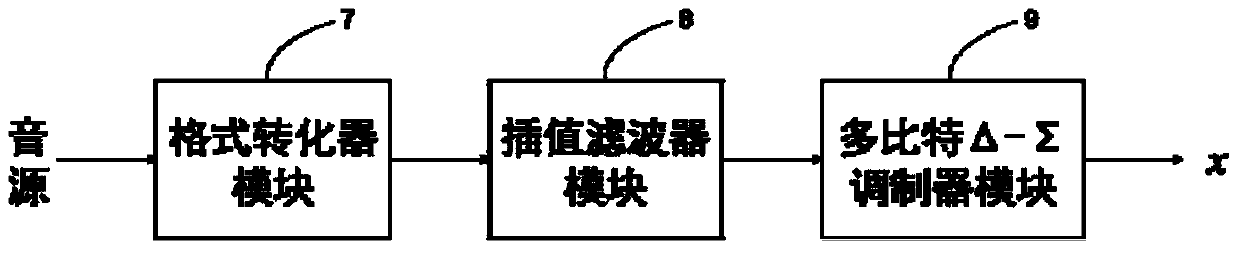

Method and apparatus for driving digital loudspeaker based on amplitude modulation and phase modulation

ActiveCN104967948AImprove signal-to-noise ratioReduce power consumptionTransducer circuitsSound sourcesTransducer

The present invention discloses a method and an apparatus for driving a digital loudspeaker based on amplitude modulation and phase modulation. The method comprises the steps of: performing modulation processing for a sound source signal to generate (2L+1) coded signals x at a level grade; performing selection processing for the coded signals x and a feedback vector signal b of M channels to generate a state vector signal s of the M channels, and then performing amplitude modulation processing for the state vector signal s to generate an amplitude modulation vector signal a of the M channels; performing shaping processing for the amplitude modulation vector signal a to generate a next feedback vector signal b of the M channels; performing phase modulation processing for the state vector signal s to generate a driving vector signal p of the M channels; and achieving electro-acoustic conversion of the driving vector signal p through a power amplification driving multichannel power amplifier and energy transducer unit. The method and the apparatus of the present invention can simultaneously adjust amplitudes and phases of various channels, thereby achieving better spatial domain directivity.

Owner:SUZHOU RUSHENG ELECTRONICS CO LTD

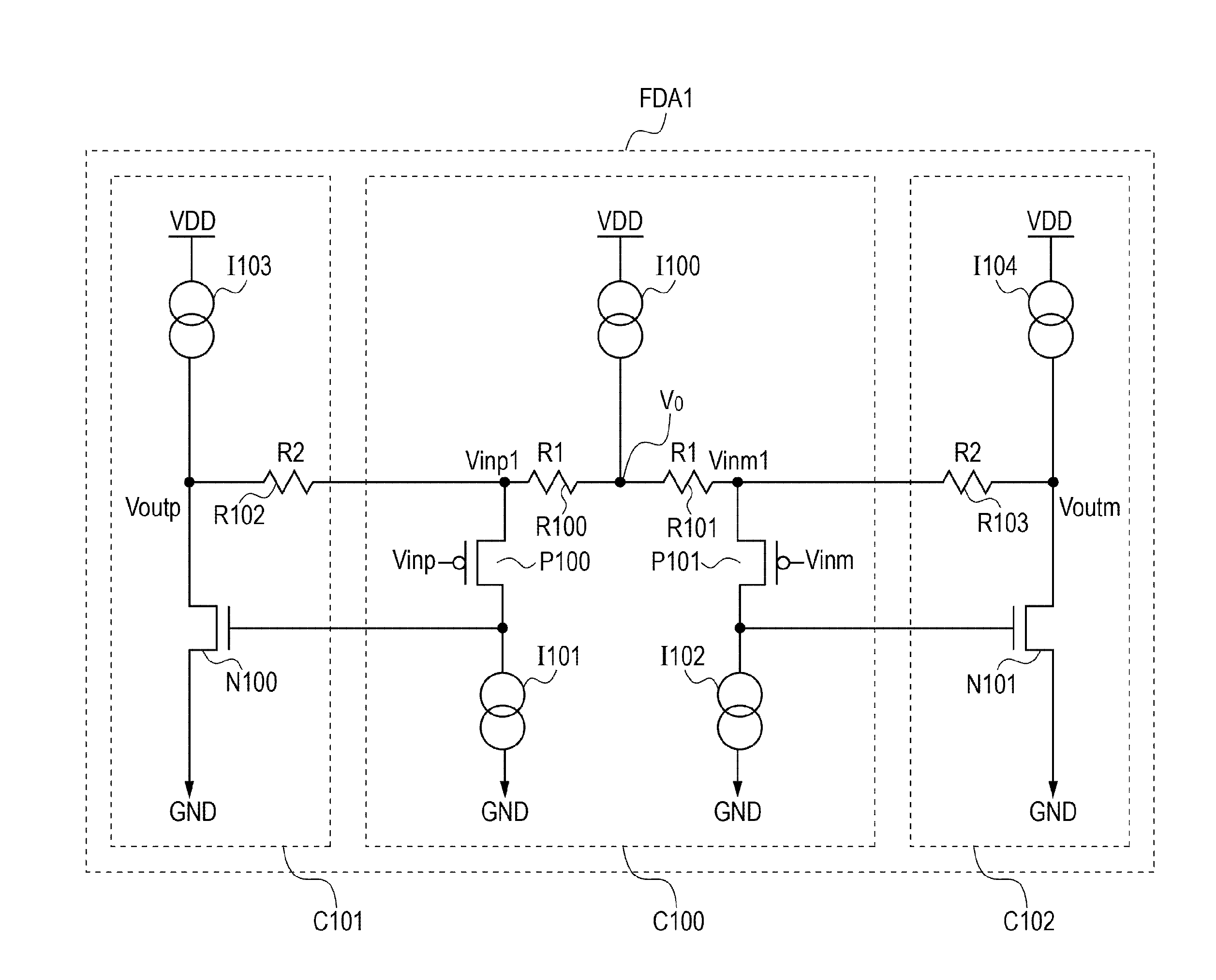

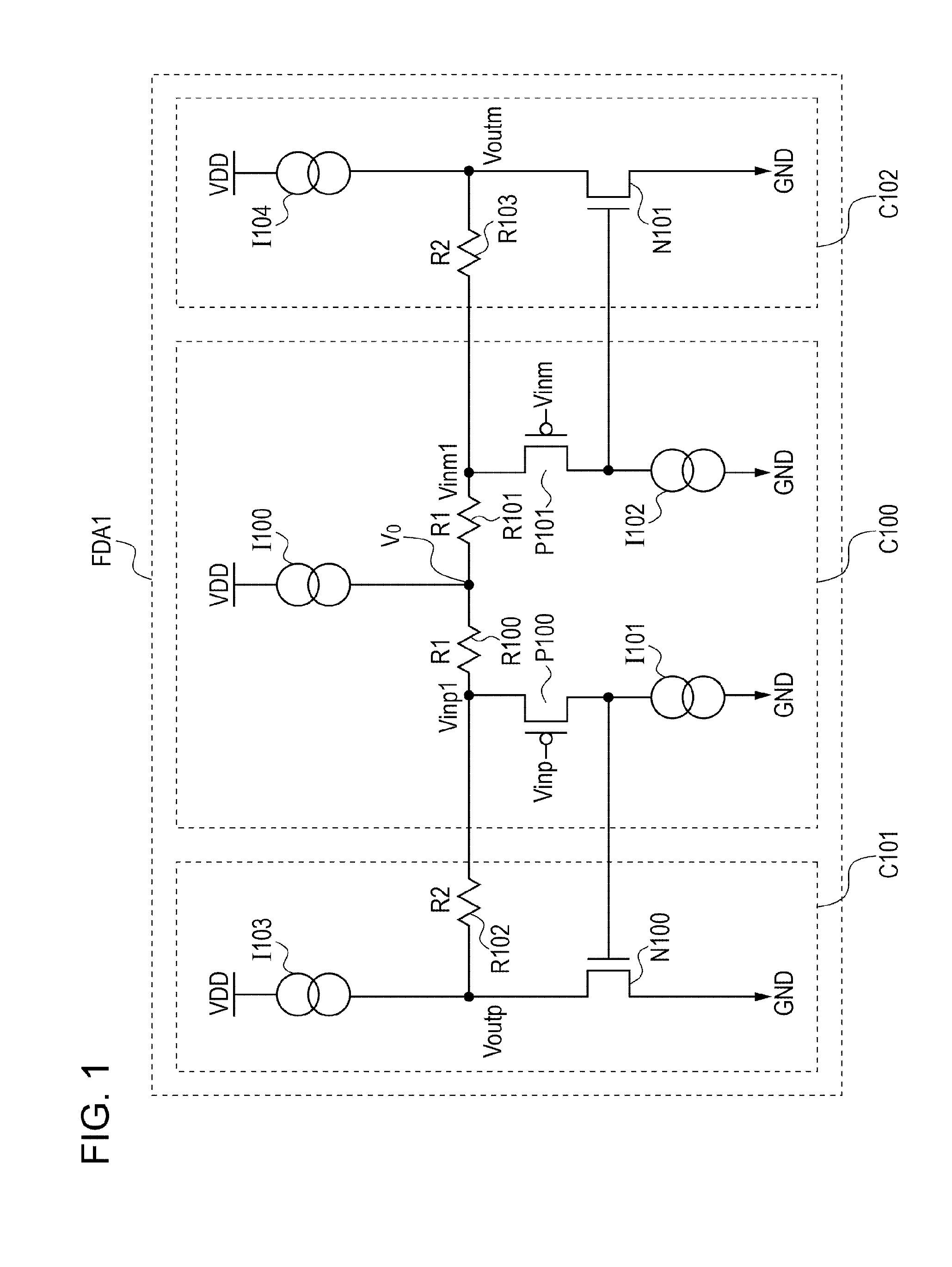

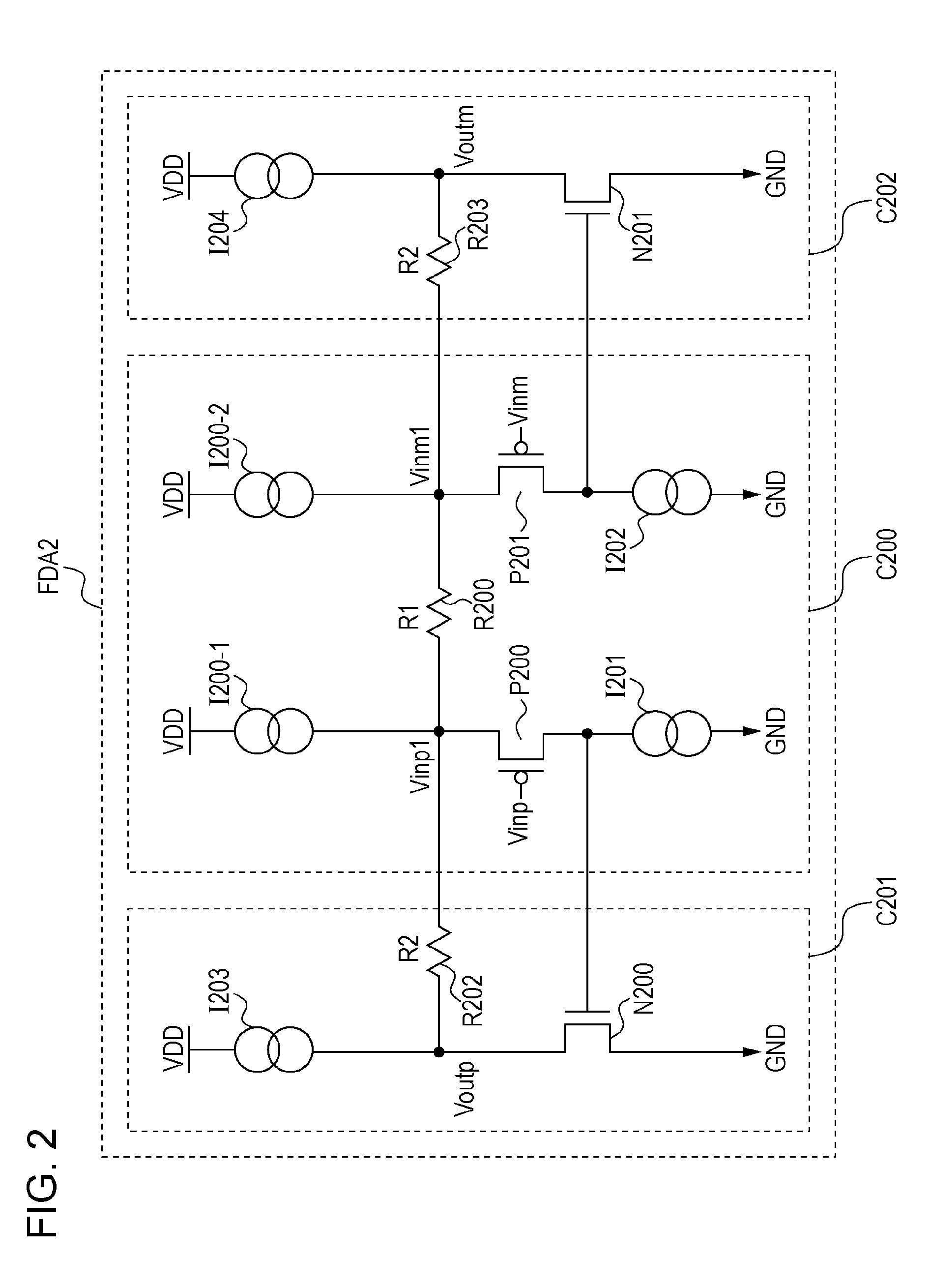

Fully-differential amplifier, photoelectric conversion apparatus including fully-differential amplifier, and image-pickup system

ActiveUS8547446B2Increase the output signal amplitudeTelevision system detailsTelevision system scanning detailsElectrical resistance and conductanceCurrent voltage

In a known fully-differential amplifier, it has been difficult to set a power voltage VDD to a low level while maintaining the signal amplitude and increase the amplitude of an output signal without increasing the power voltage VDD. The present invention provides a fully-differential amplifier including a voltage-current conversion unit, a first current-voltage conversion unit, and a second current-voltage conversion unit, where a resistance element included in the voltage-current conversion unit, a resistance element included in the first current-voltage conversion unit, and a resistance element included in the second current-voltage conversion unit are connected in parallel with one another.

Owner:CANON KK

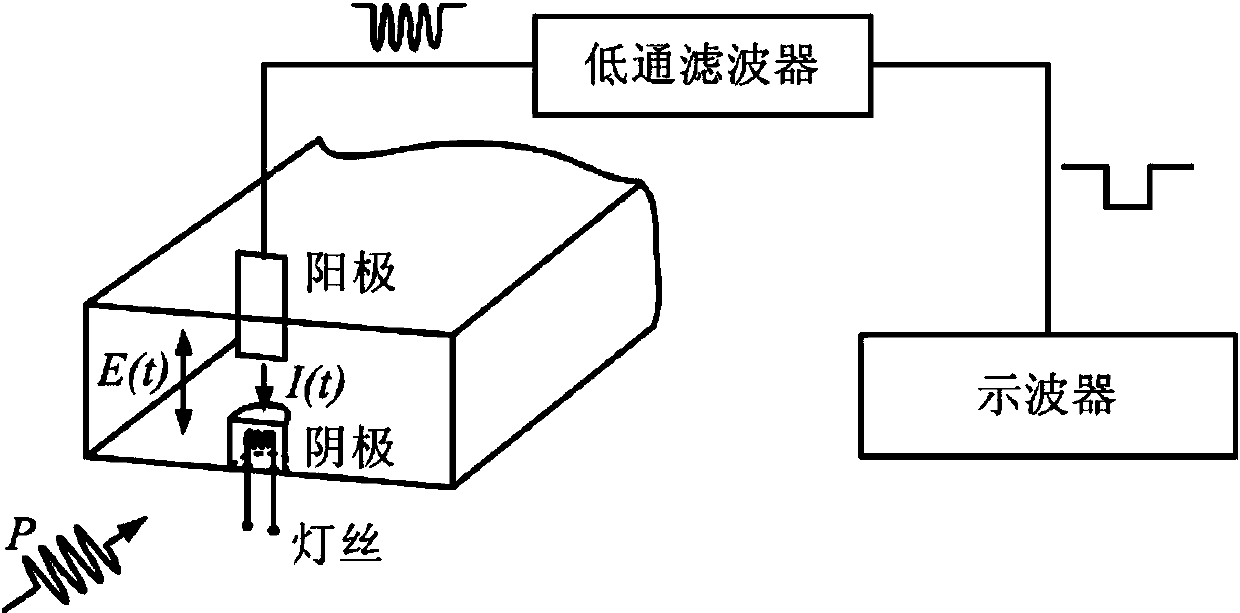

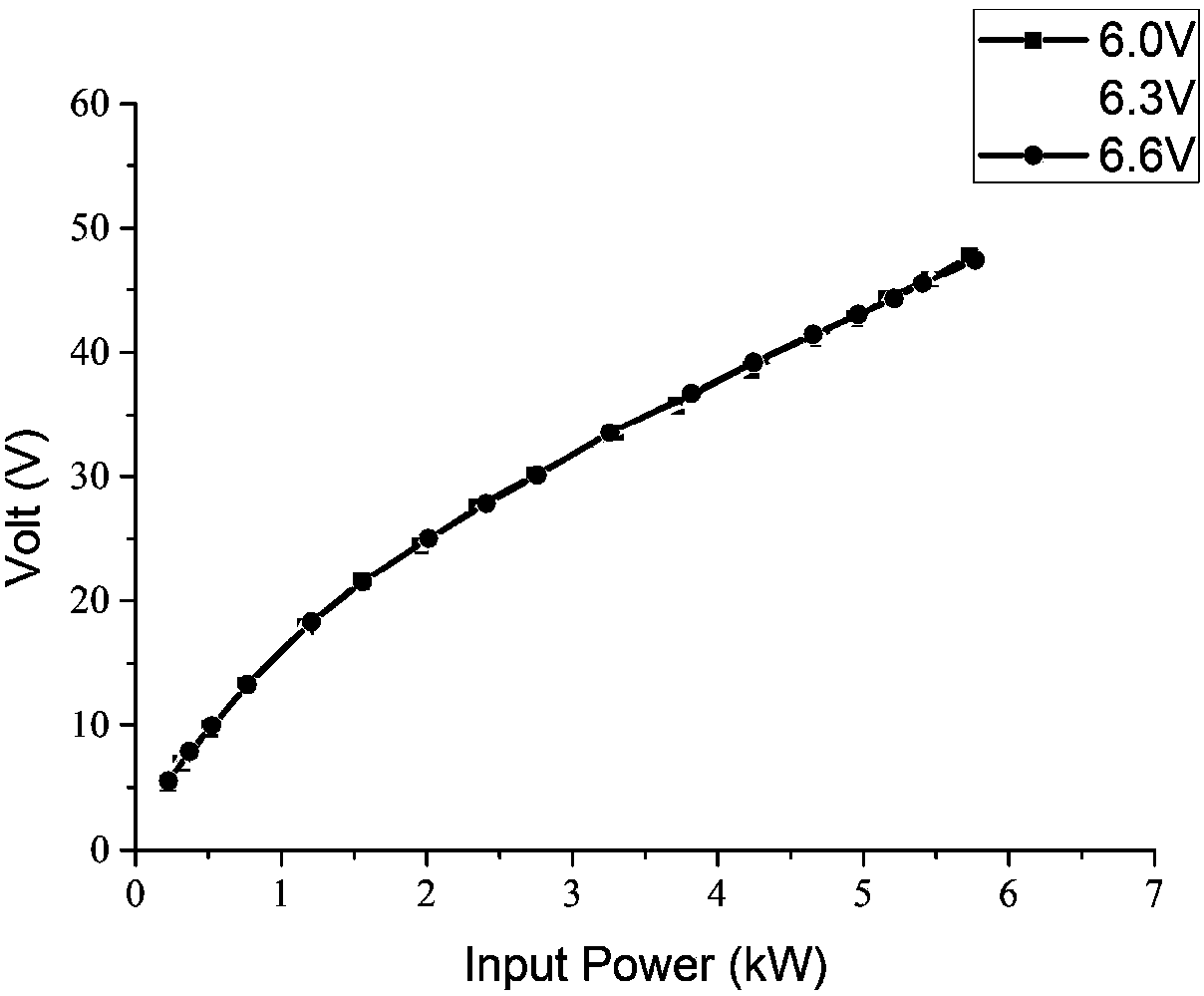

High-power microwave power detector

ActiveCN103698597AIncrease the output signal amplitudeEnhance the ability to resist strong electromagnetic radiation interferencePower measurement by digital techniqueLow-pass filterEngineering

The invention discloses a high-power microwave power detector, which comprises a waveguide, an input matching circuit, a detection diode, an output filtering circuit, and a direct current power supply, wherein the input matching circuit is a three-screw rod assembly, the output filtering circuit is a coaxial low-pass filter, the detection diode is a vacuum diode, the three-screw rod assembly and the coaxial low-pass filter are fixedly arranged on a cavity of the waveguide, one end of the coaxial low-pass filter is connected with the cavity of the waveguide through the vacuum diode, the other end of the coaxial low-pass filter is connected with a standard N-shaped joint, and the direct current power supply is connected with a lamp filament of the vacuum diode. After the lamp filament of the vacuum diode is preheated, a microwave signal is sent to the vacuum diode through the three-screw rod assembly, an alternating current electric field is generated between a cathode and an anode of the vacuum diode, and then the current is formed; after the current is filtered by the coaxial low-pass filter, a current path is formed by an oscilloscope detector sampling resistor, and then the size of the power of the detected microwave signal is obtained.

Owner:中国人民解放军63660部队

Inner conical elastomer for strain force transducer, and optimization method for inner conical elastomer

InactiveCN102539031BIncrease the output signal amplitudeReduce distortionForce measurement using piezo-resistive materialsStress distributionElastomer

The invention provides an inner conical elastomer for a strain force transducer. The inner conical elastomer comprises a cylindrical base body; the upper part of the base body is provided with a conical concave part; the bottom of the conical concave part is provided with a central hole; and the conical surface of the conical concave part is provided with a strain gauge. The optimization method for the elastomer comprises the following steps of: estimating an initial size; calculating stress of the elastomer under the action of the axial force of a bolt by a finite element method, and adjusting the cone angle of a model until stress on the inner conical surface is distributed uniformly; adjusting the thickness of the base body under the condition of not changing the cone angle to ensure that the stress level on the conical surface meets the requirement; and rounding the model size obtained through finite element calculation, wherein the rounded model size is used as the final size of the elastomer. The inner conical elastomer is a simple revolution solid, and is high in processing and heat treatment manufacturability; the stress of the adhesion part of the strain gauge is distributed uniformly; and the accuracy of the adhesion position of the strain gauge is not required. The axial size of the elastomer is smaller than that of a spoke elastomer, and the elastomer is more suitable for measuring the axial force of the bolt.

Owner:XIAN UNIV OF TECH

Digital loudspeaker driving method and device based on amplitude modulation and phase modulation

ActiveCN104967948BReduce power consumptionReduce overheadTransducer circuitsSound sourcesLoudspeaker

The present invention discloses a method and an apparatus for driving a digital loudspeaker based on amplitude modulation and phase modulation. The method comprises the steps of: performing modulation processing for a sound source signal to generate (2L+1) coded signals x at a level grade; performing selection processing for the coded signals x and a feedback vector signal b of M channels to generate a state vector signal s of the M channels, and then performing amplitude modulation processing for the state vector signal s to generate an amplitude modulation vector signal a of the M channels; performing shaping processing for the amplitude modulation vector signal a to generate a next feedback vector signal b of the M channels; performing phase modulation processing for the state vector signal s to generate a driving vector signal p of the M channels; and achieving electro-acoustic conversion of the driving vector signal p through a power amplification driving multichannel power amplifier and energy transducer unit. The method and the apparatus of the present invention can simultaneously adjust amplitudes and phases of various channels, thereby achieving better spatial domain directivity.

Owner:SUZHOU RUSHENG ELECTRONICS CO LTD

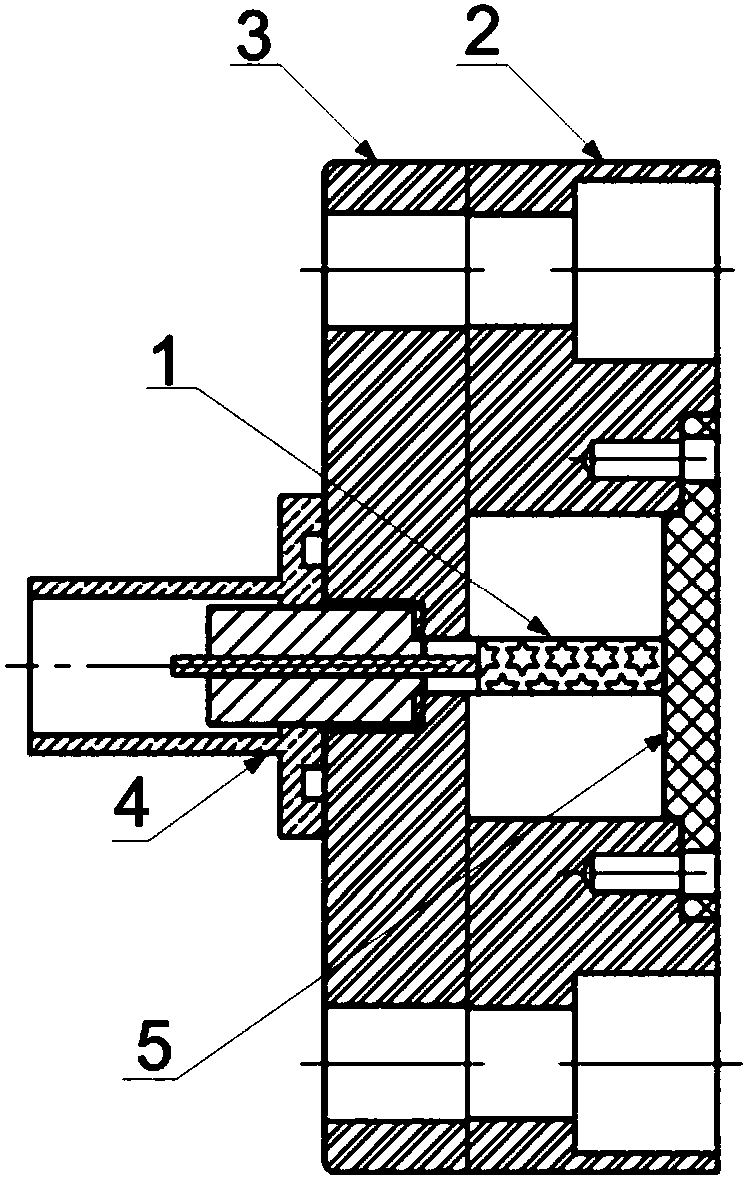

An electromagnetic ultrasonic probe

ActiveCN105372335BImprove energy conversion efficiencyTroubleshooting mobilityMaterial analysis using sonic/ultrasonic/infrasonic wavesCouplingIsolation layer

The invention relates to an electromagnetic ultrasonic probe which is characterized by comprising a preposition amplifying module, an isolating layer, a shell, a receiving coil and a permanent magnetic device; the top face of the shell is provided with a poking switch, a power line interface and a BNC connector, the inner side of the bottom face of the shell is provided with the isolating layer, the centers of the two side faces of the shell are provided with holes respectively, the preposition amplifying module is located in the shell and fixed to the inner side of the top face of the shell through a screw, and the receiving coil is pasted to the isolation layer; the receiving coil is connected with the input end of the preposition amplifying module through a signal line, the output end of the preposition amplifying module is connected with the BNC connector fixed to the shell, the poking switch controls the gear position of the preposition amplifying module, and the power line connector is connected with an external power source; the permanent magnetic device comprises a permanent magnetic body, a first curved magnetic boot, a second curved magnetic boot, a cross coupling and a mechanical knob, a permanent magnetic device is located between the two curved magnetic boots, and the middle of the permanent magnetic body is provided with a cross hole groove.

Owner:HEBEI UNIV OF TECH

b-dot probe and current spatial distribution measurement system for blocking magnetically insulating sheath electrons

ActiveCN105486908BImprove consistencySmall difference in outputCurrent measurements onlyMolecular materialsEngineering

The invention relates to a B-dot probe blocking electrons of a magnetically insulated sheath and a current space distribution measuring system. The B-dot probe comprises a magnetic induction coil, a cable connector and a supporting and fixing device, wherein the magnetic induction coil is wired on a circuit board clockwise or anticlockwise in the same direction to form a PCB type magnetic induction coil; and the supporting and fixing device comprises a metal clasp and a metal support ring, and a stepped hole is formed at the position, just facing the top of the PCB type magnetic induction coil, at the top of the metal clasp. An insulated slice of high-molecular material is arranged in the stepped hole and fixedly connected with the metal clasp, when the B-dot probe is bombarded by electrons of the sheath of a magnetically insulated transmission line, the electrons are blocked by the insulated slice, and energy of the electrons is accumulated in the insulated slice.

Owner:NORTHWEST INST OF NUCLEAR TECH

Pulse wave detector, pulsation detector and pressure detector

InactiveCN1268282CIncrease the output signal amplitudeSensorsMeasuring/recording heart/pulse ratePhase detectorMicrometer

A pulse wave measuring device is provided with a plurality of pulse wave measuring units. Each pulse wave measuring unit has a supporting member to which a beam of a pressure measuring device is attached. Contact portions at the distal end of the beam is in contact with the patient's arm, so that piezoelectric elements mounted on the beam measures the stress variation according to pulsation of the patient's radial artery. The supporting meter has two pressing legs between which the contact portions of the beam are situated. The distal ends of the pressing legs are also pressed against the patient's arm. The pressing legs are harder than the radial artery. The interval between the pressing legs can be altered by handling a micrometer head. The contact portions are situated back from the distal ends of the pressing legs.

Owner:SEIKO EPSON CORP

b-dot probe and current spatial distribution measurement system based on pcb magnetic induction coil

ActiveCN105388352BImprove consistencySmall difference in outputCurrent measurements onlyClockwiseElectrical current

The invention provides a B-dot probe based on a PCB type magnetic induction coil, and a current spatial distribution measuring system. A magnetic induction coil of the B-dot probe is clockwise or anticlockwise wired in the same direction on the circuit board, so that the PCB type magnetic induction coil is formed. Substantial advantages are achieved when an array formed by the plurality of B-dot probes is used to measure the current spatial distribution uniformity. A metal shielding cover is arranged on the top end, is buckled with a metal support ring and is fastened through fastening screws. A narrow gap is further formed in the metal shielding cover. The direction of long edges of the narrow gap is perpendicular to the plane of the magnetic induction coil. The metal shielding cover inhibits strong electromagnetic and strong radiation interference and also enables a magnetic field to be introduced to the magnetic induction coil through the narrow gap.

Owner:NORTHWEST INST OF NUCLEAR TECH

Anti-corrosion tension transducer and its manufacturing method and tension measurement system

ActiveCN108362411BAvoid damageAvoid enteringForce measurementElectrical resistance and conductanceCantilevered beam

The invention provides an anti-corrosion tonotransducer and a manufacture method thereof and a tension measuring system. The tension measuring system comprises a closed shell with containing space, the inner portion of the shell is provided with a two-hole cantilever beam, the two ends of the shell are respectively connected with a dismountable measuring rod and fixing rod extending out of the shell, two sets of strain gages respectively sticks to the two sides of the two-hole cantilever beam, and the two-hole cantilever beam is embedded in an amplifying device and sealed. A technology of 'active amplification, two-hole cantilever beam and high-precision strain gage' is adopted, the dismountable measuring rod with an anti-infiltration silicone rubber ring is designed, thereby the sensitivity, long-term stability, linearity, repeatability and other properties of the tonotransducer are greatly improved, the detection precision of biological signals is significantly improved, so that experimental data is more accurate and reliable, and the experimental success rate and teaching effect are further improved.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com