High-power microwave power detector

A technology of microwave power and detector, which is applied in the direction of electric power measurement by applying digital technology, can solve the problems of weak detection output signal, complex measurement system, and increased measurement error, and achieve large output signal amplitude, adjustable sensitivity, Withstand high power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

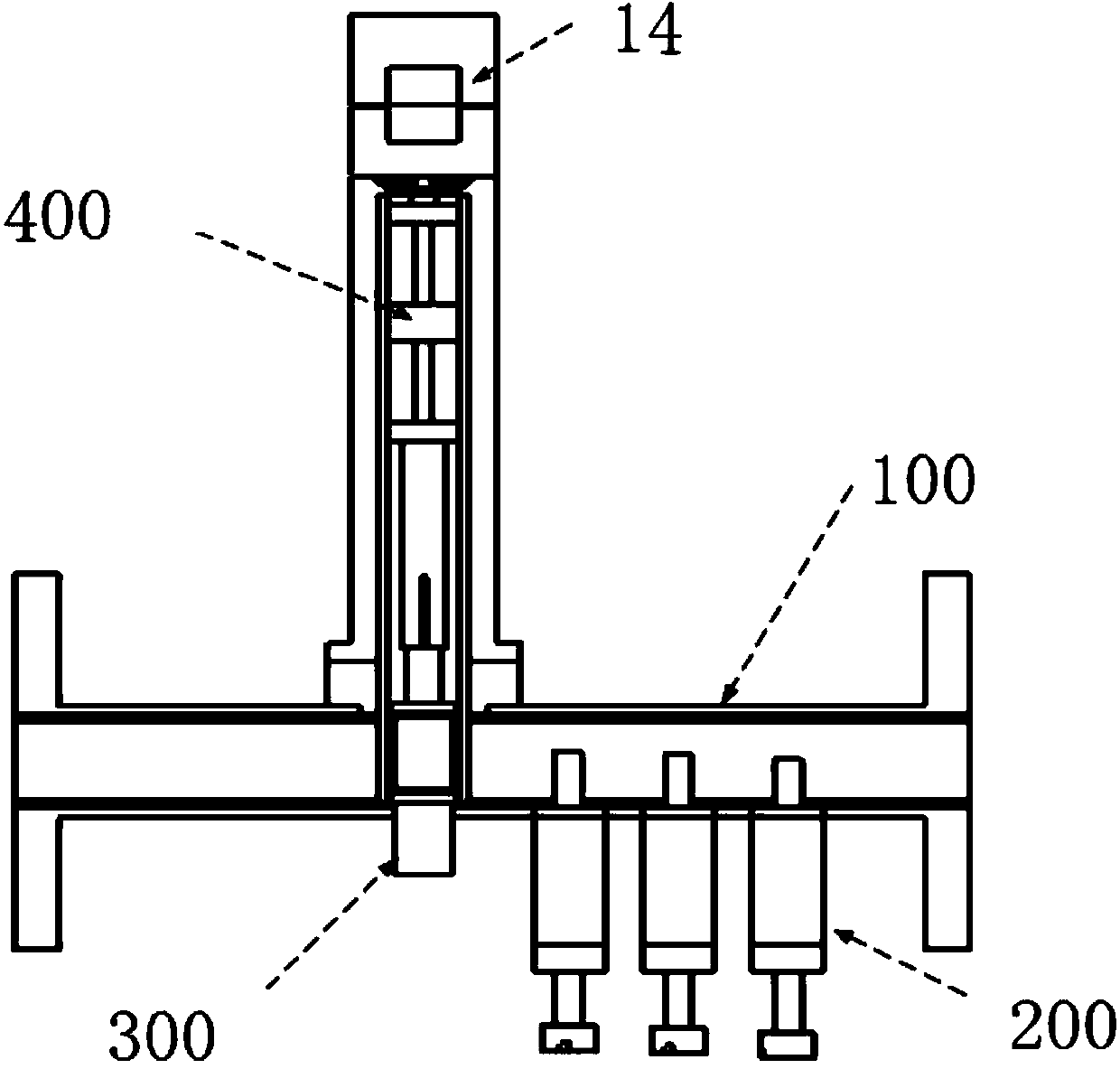

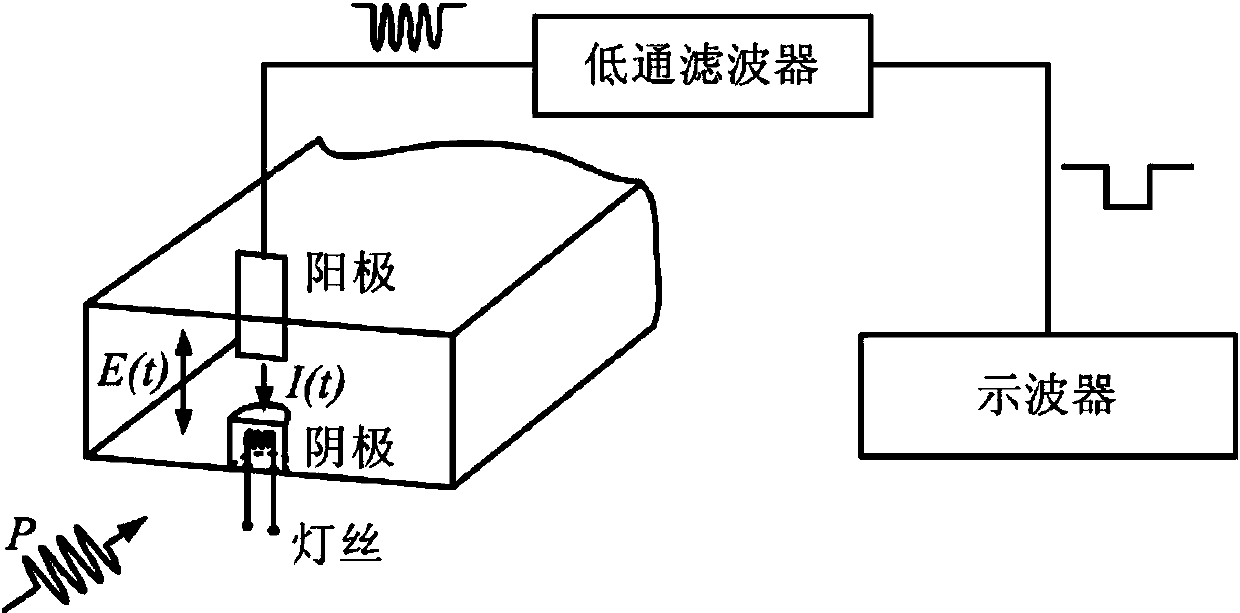

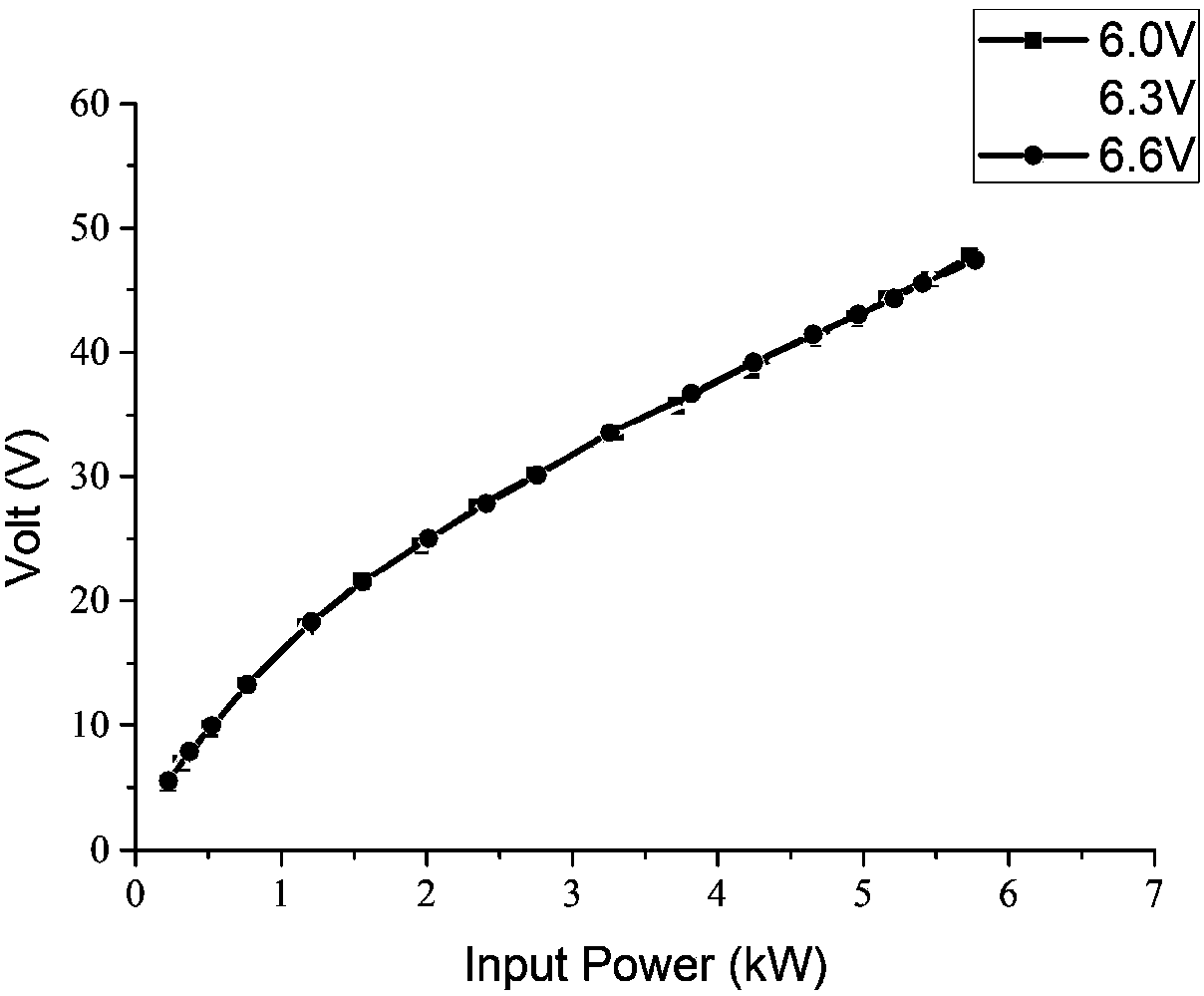

[0019] In order to improve the input power capacity and output voltage of the microwave power detector, the present invention provides a high-power microwave power detector based on vacuum diodes, including a waveguide 100 (BJ-100 waveguide is selected in the present invention), an input matching circuit 200, Detection diode 300, output filter circuit 400, DC power supply, etc., such as figure 1 As shown, the detection diode 300 adopts a vacuum diode and is placed in the center of the waveguide broadside; the input matching circuit 200 adopts a three-tuned screw assembly, which is placed in front of the detection diode 300, and the input impedance is realized by changing the depth of the screw inserted into the waveguide. match. The output filter circuit 400 adopts a coaxial low-pass filter, which is convenient to connect with a vacuum diode. The DC power supply is connected with the vacuum diode filament for heating the filament.

[0020] The working principle of the high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com