Anti-corrosion tension transducer and its manufacturing method and tension measurement system

A transducer and anti-corrosion technology, applied in the direction of measuring force, measuring devices, instruments, etc., can solve problems such as transducer damage, achieve light weight, improve reliability and durability, and improve the quality of experimental teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The purpose of the first embodiment is to provide a double-hole cantilever beam type tension transducer.

[0053] In order to achieve the above objective, the present invention adopts the following technical solution:

[0054] Such as Figure 5 As shown,

[0055] A double-hole cantilever beam type tension transducer, including:

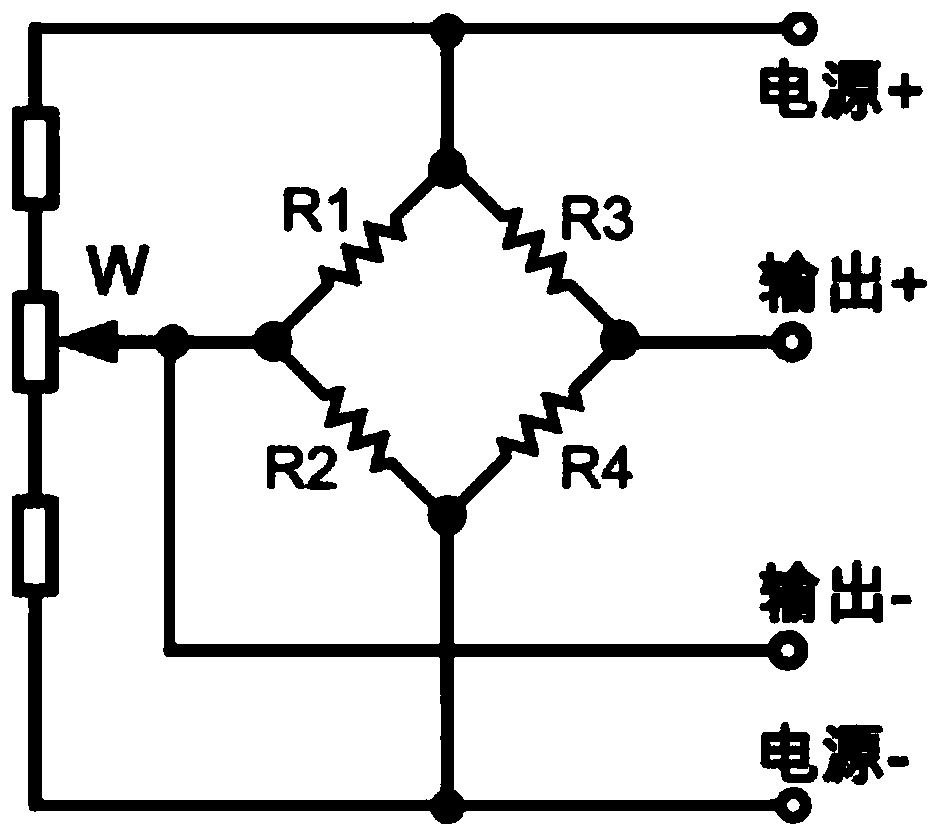

[0056] Two-hole cantilever beam, the two ends are measuring end and fixed end respectively, two sets of strain gauges are attached to both sides of the double-hole cantilever beam, the outer wall of the double-hole cantilever beam and the thinnest part of the two holes, the strain gauges are connected to each other to form a Wheatstone Bridge, such as Image 6 Shown is a schematic diagram of the principle of the Wheatstone bridge, which expands and contracts with the strain of the measured object, so that the metal foil inside the strain gauge is stretched or compressed. When the metal foil is stretched or contracted, its resistance will change accord...

Embodiment 2

[0059] The purpose of the second embodiment is to provide an anti-corrosion tension transducer.

[0060] In order to achieve the above objective, the present invention adopts the following technical solution:

[0061] Such as Figure 7 As shown,

[0062] An anti-corrosion tension transducer, including:

[0063] A closed shell with a containment space. A double-hole cantilever beam 3 is arranged inside the shell. The two ends are the measuring end and the fixed end, respectively connected to the detachable measuring rod 12 and the fixed rod 1, which extend out of the shell. Two sets of strain gauges are 4 points Attached to both sides of the double-hole cantilever beam 3, strain gauges 4 are connected to each other to form a Wheatstone bridge. The double-hole cantilever beam 3 is embedded and sealed with an amplifying device 6 which is connected to the output signal line 8.

[0064] In the preferred mode of Example 1 and Example 2, the two sets of strain gauges 4 adopt foil-type metal r...

Embodiment 3

[0081] The purpose of the third embodiment is to provide a method for manufacturing an anti-corrosion dual-hole cantilever beam tension transducer.

[0082] In order to achieve the above objective, the present invention adopts the following technical solution:

[0083] A method for manufacturing an anti-corrosion double-hole cantilever beam type tension transducer includes:

[0084] Step (1): Detect the performance quality of the two sets of strain gauges, select four foil-type metal resistance strain gauges with a resistance deviation of less than 1Ω; in this embodiment, the strain gauges act as sensing and conducting in the force measuring transducer The important role of equipment strain. The foil type BF1K-3AA high-precision resistance strain gauge (1000Ω) is selected, which has the characteristics of high accuracy, good linearity, good repeatability, and small temperature drift, which can greatly improve the detection accuracy of biological signals. The performance and quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com