Magnetoelectric rotating speed sensor suitable for large-spacing measurement

A speed sensor, magnetoelectric technology, applied in measuring devices, devices using electric/magnetic methods, speed/acceleration/shock measurement, etc., can solve the problems of small output amplitude and prone to abnormalities, and achieve output signal Increased amplitude, improved output signal quality, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

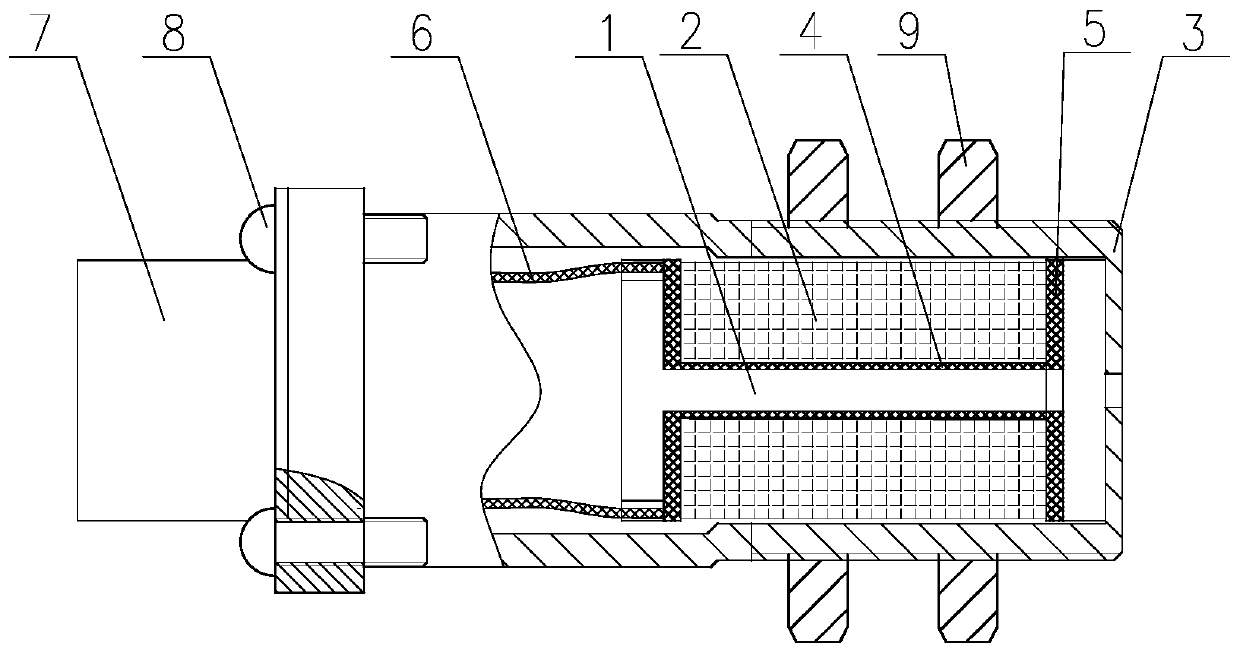

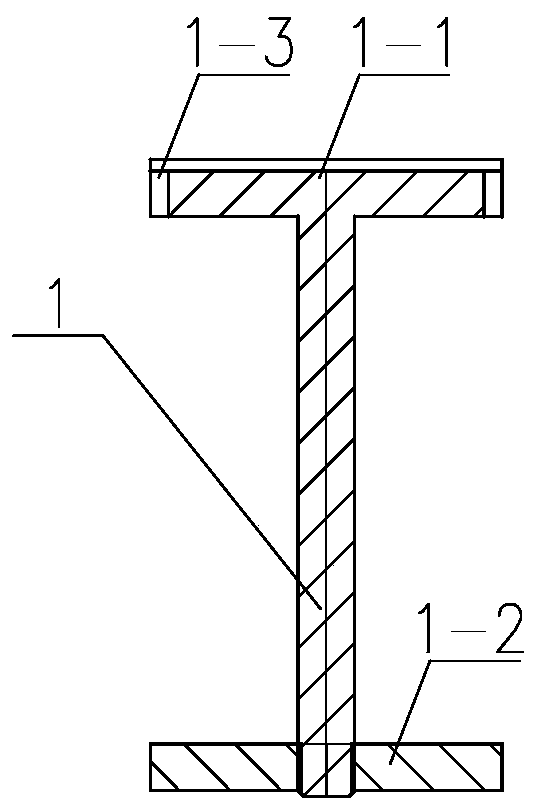

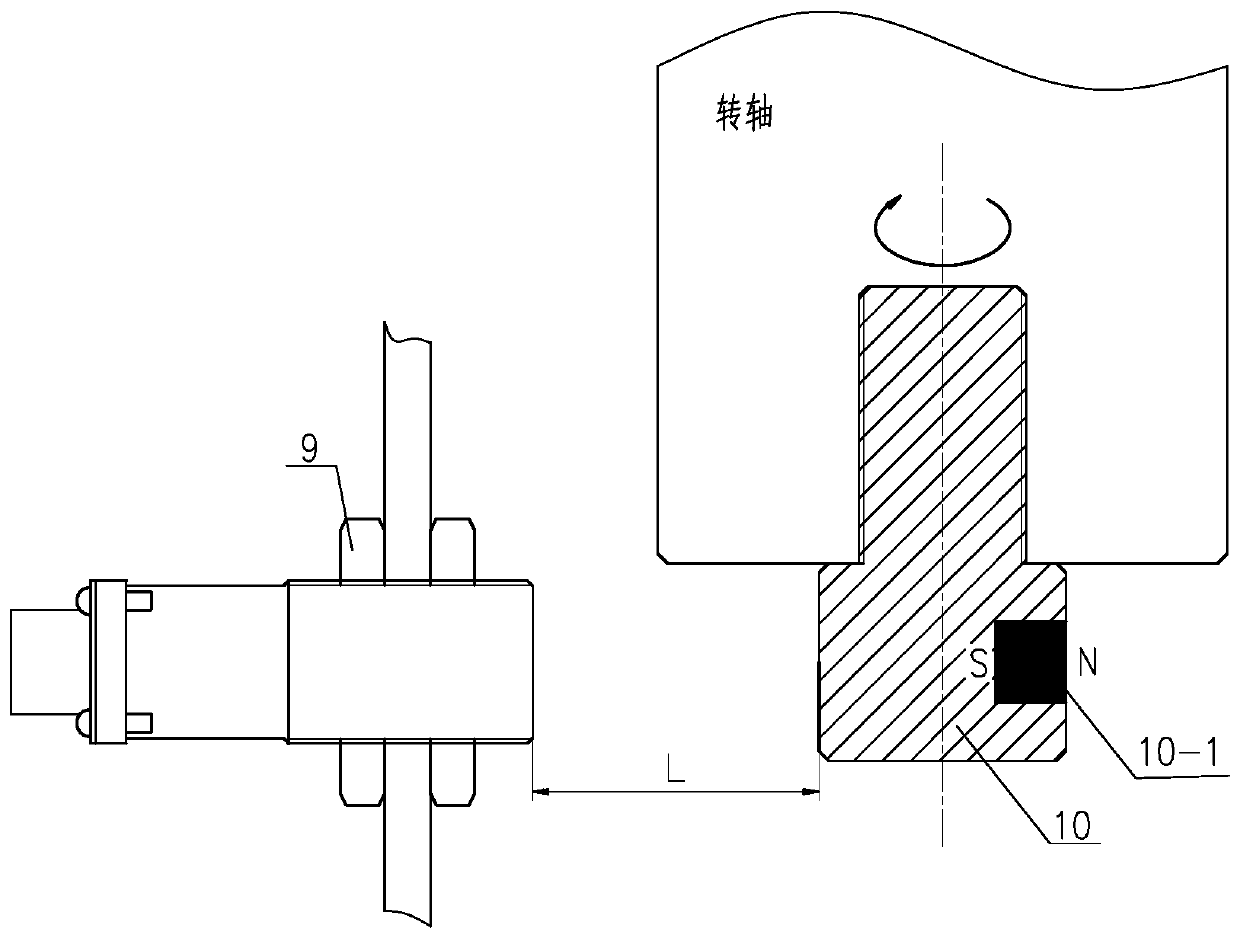

[0026] This example Figure 1 ~ Figure 3 As shown, a magnetoelectric speed sensor suitable for large distance measurement, including: armature skeleton 1, enameled wire coil 2, housing 3, insulating sleeve 4, insulating gasket 5, lead wire 6, connector 7, screw 8 And the shaft end bolt 10 embedded with the permanent magnet 10-1, the shaft end bolt 10 is installed on the end surface of the measured rotating shaft. The armature frame 1, the enameled wire coil 2, the insulating sleeve 4, and the insulating gasket 51 are assembled into an assembly, the lead wire 6 is used to connect the enameled wire coil 2 and the connector 7, and the armature frame 1, the enameled wire coil 2, The assembly assembled by the insulating sleeve 4 and the insulating gasket 5 is installed inside the housing 3, filled with silicone rubber and potted in the gap, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com