Torsional vibration error monitoring method for shaft system of steam turbine generator unit, monitor and system

A technology for torsional vibration of turbogenerator sets and shafting, which is applied in the testing of machine gears/transmission mechanisms, etc., and can solve problems such as insufficient anti-noise ability and insufficient sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] The present invention will be further described below in conjunction with examples.

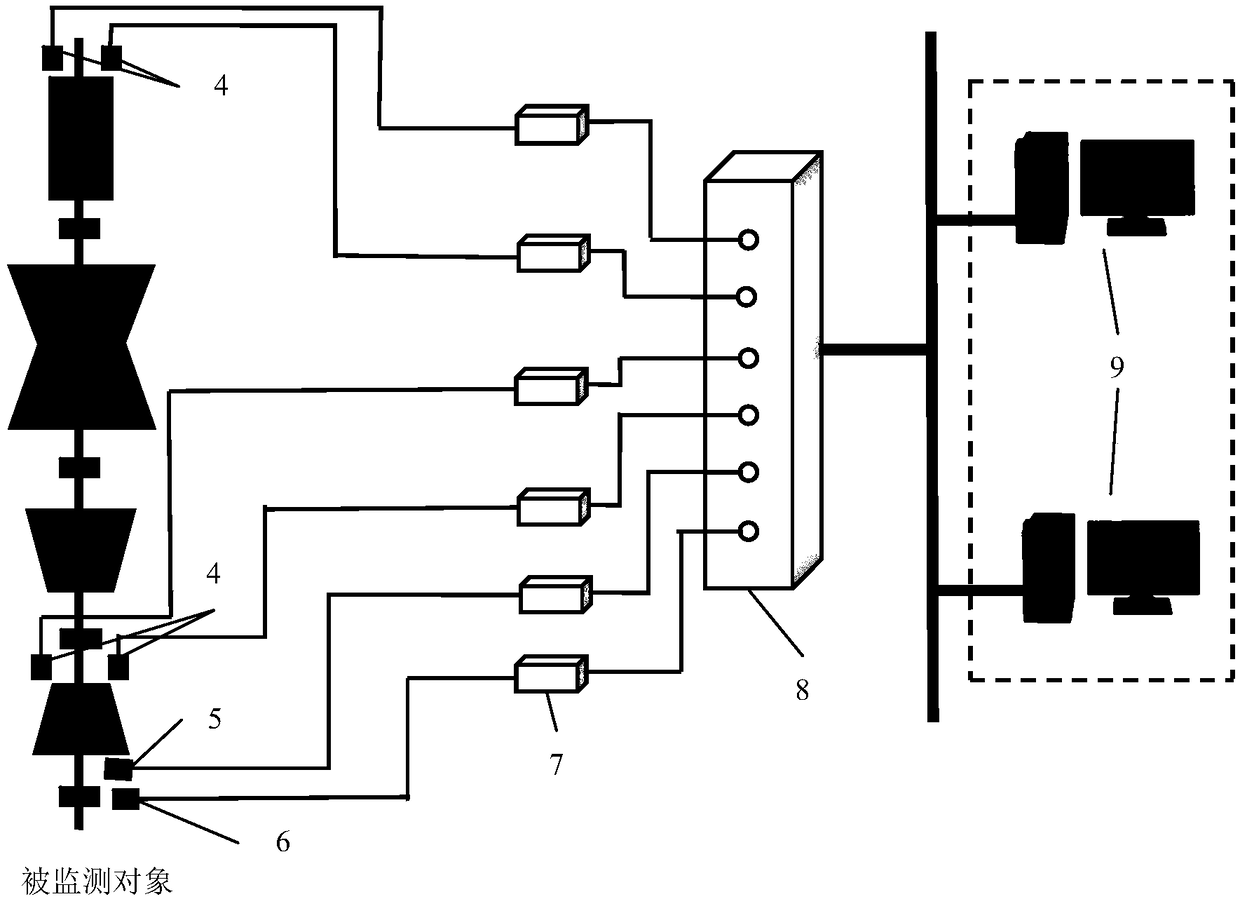

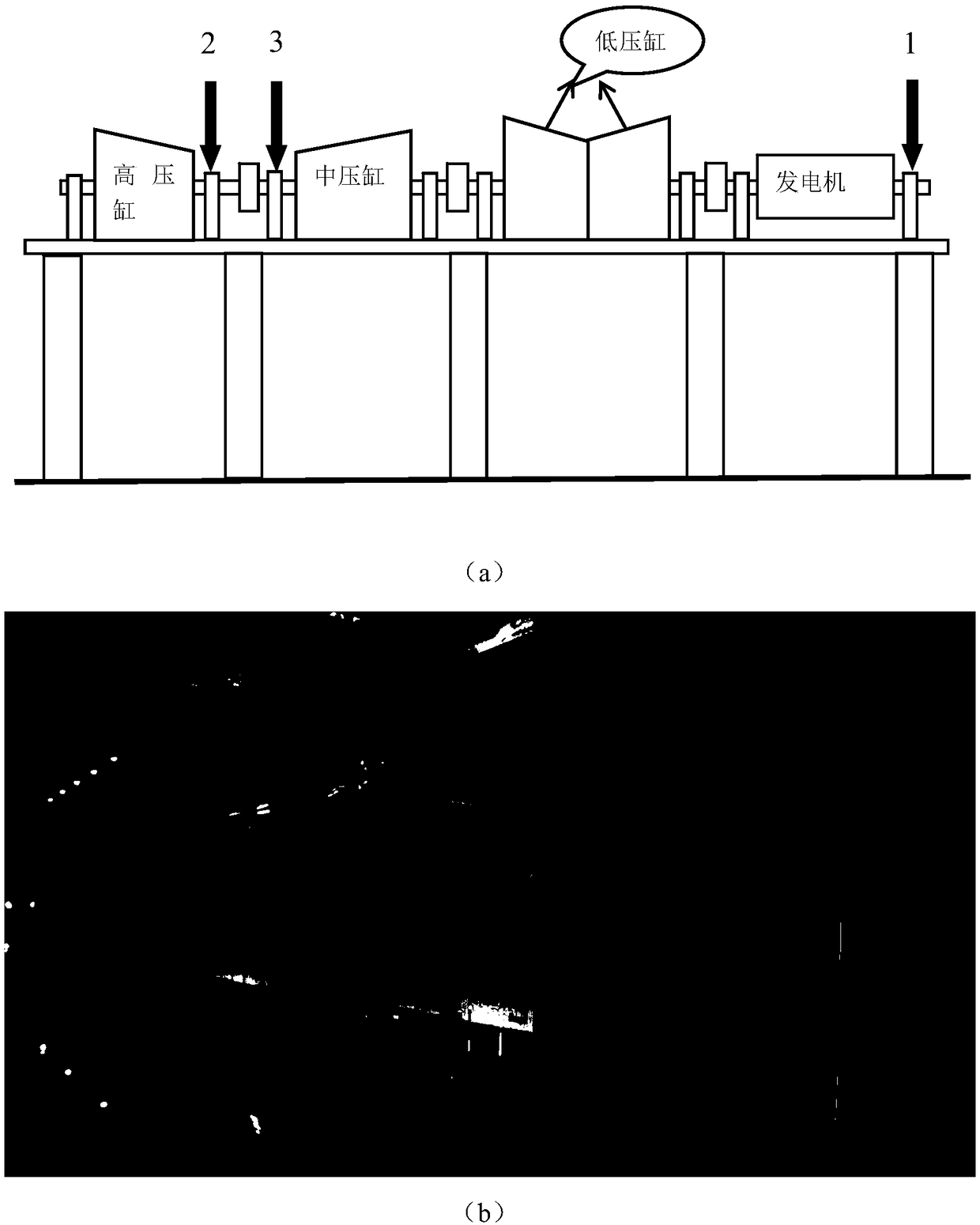

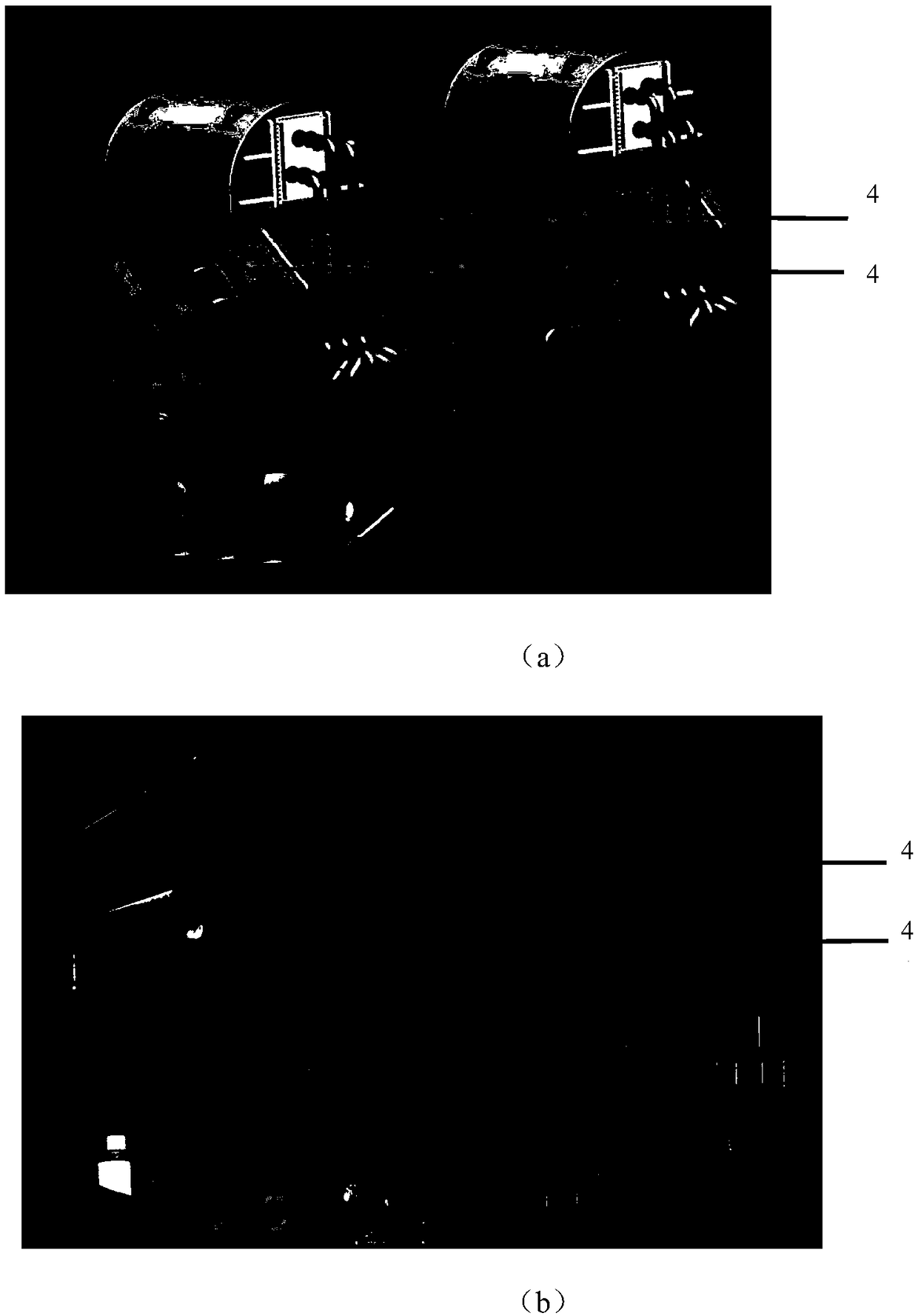

[0110] The present invention is based on the torsional vibration of the shaft system will inevitably cause the change of the bending vibration of the shaft system and the basic theory of the coupling vibration of the shaft system of the turbogenerator set, taking into account the modal frequency and mode shape of the shafting system of the large turbogenerator set According to the distribution law, it is proposed to detect the torsional vibration of the turbogenerator shaft system based on the "vibration acceleration sensor pair", so as to realize non-destructive and real-time monitoring. For example, the mechanisms of two common faults are as follows:

[0111] Subsynchronous resonance: The natural low-order torsional vibration frequency of modern large-capacity turbogenerator shafting is often lower than the power frequency. The power grid is an electrical circuit composed of resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com