Cross beam pipe punching equipment in automobile fitting

A technology for punching equipment and auto parts, which is applied in the direction of drilling/drilling equipment, metal processing equipment, boring/drilling, etc. It can solve the problem that the cooperation between beam pipe transportation and machine drilling cannot be well grasped, and small businesses Unable to afford, high cost and other problems, to achieve the effect of simple structure, avoid collision and wear, and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

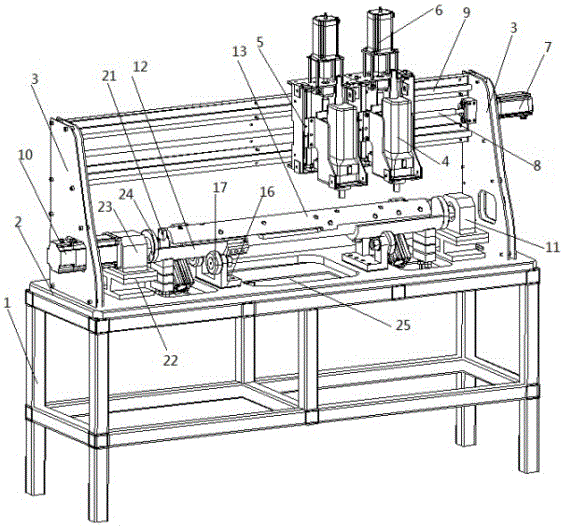

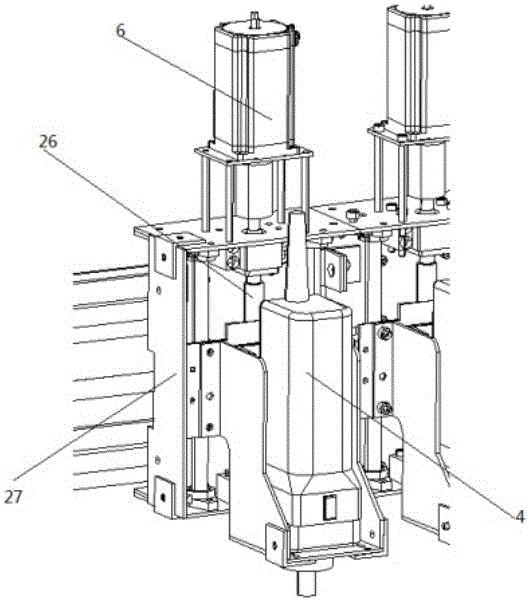

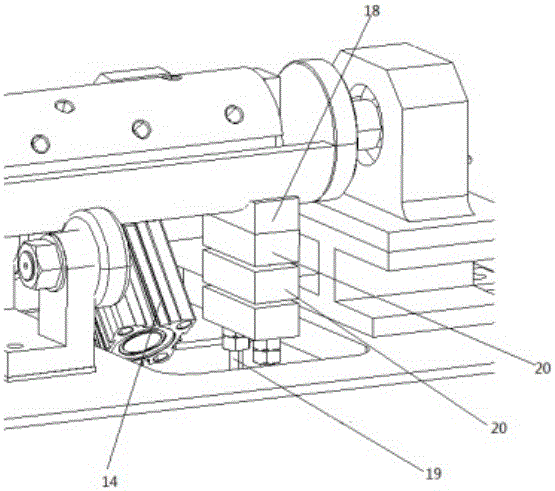

[0019] Refer to attached figure 1 , the present invention provides a beam tube punching equipment in auto parts, including a frame 1, a workbench 2 is arranged on the frame 1, a support plate 3 is arranged on the workbench 2, and two support plates 3 are arranged , respectively arranged on both sides of the workbench 2, a punching mechanism and a positioning mechanism are arranged between the two support plates 3, the punching mechanism includes a drilling device and a sliding device, and the drilling device and the sliding device Movably connected together, the drilling device includes a drilling machine 4, a connecting device 5 and a servo motor A6, the drilling machine 4 is connected with the servo motor A6 through a connecting device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com