Detection measure of leaf spring

A technology of leaf springs and measuring tools, which is applied in the direction of mechanical clearance measurement and plumb line, can solve the problems of inaccurate determination of the center hole position of the product and inaccurate detection results, and achieve a simple structure, improved detection efficiency, and easy storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

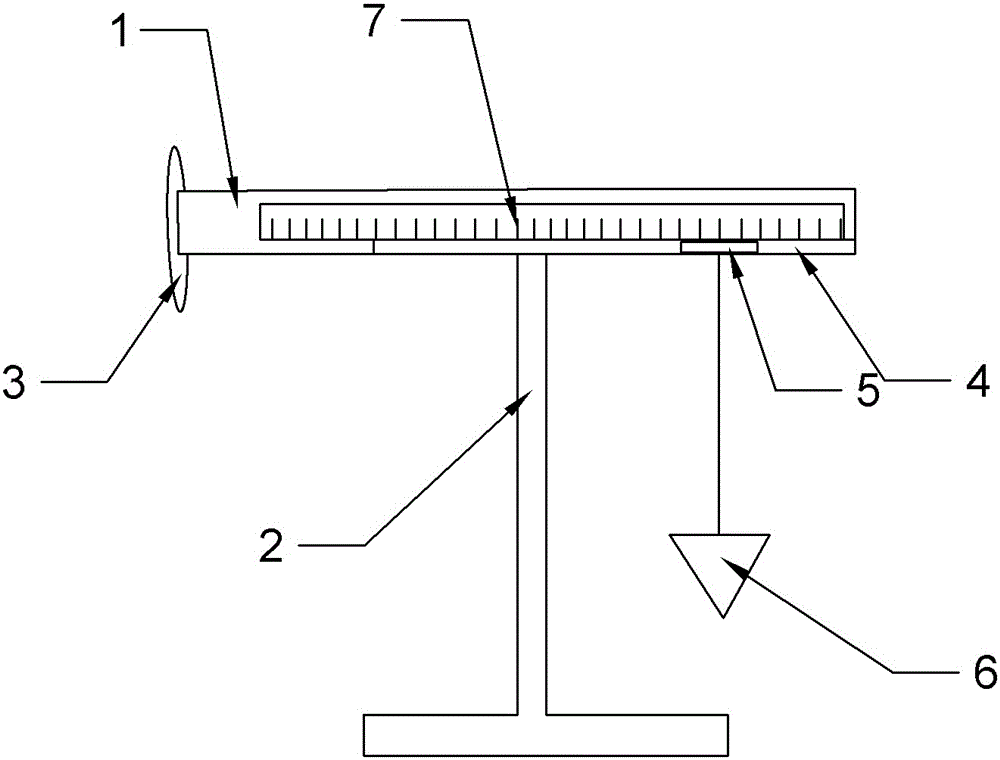

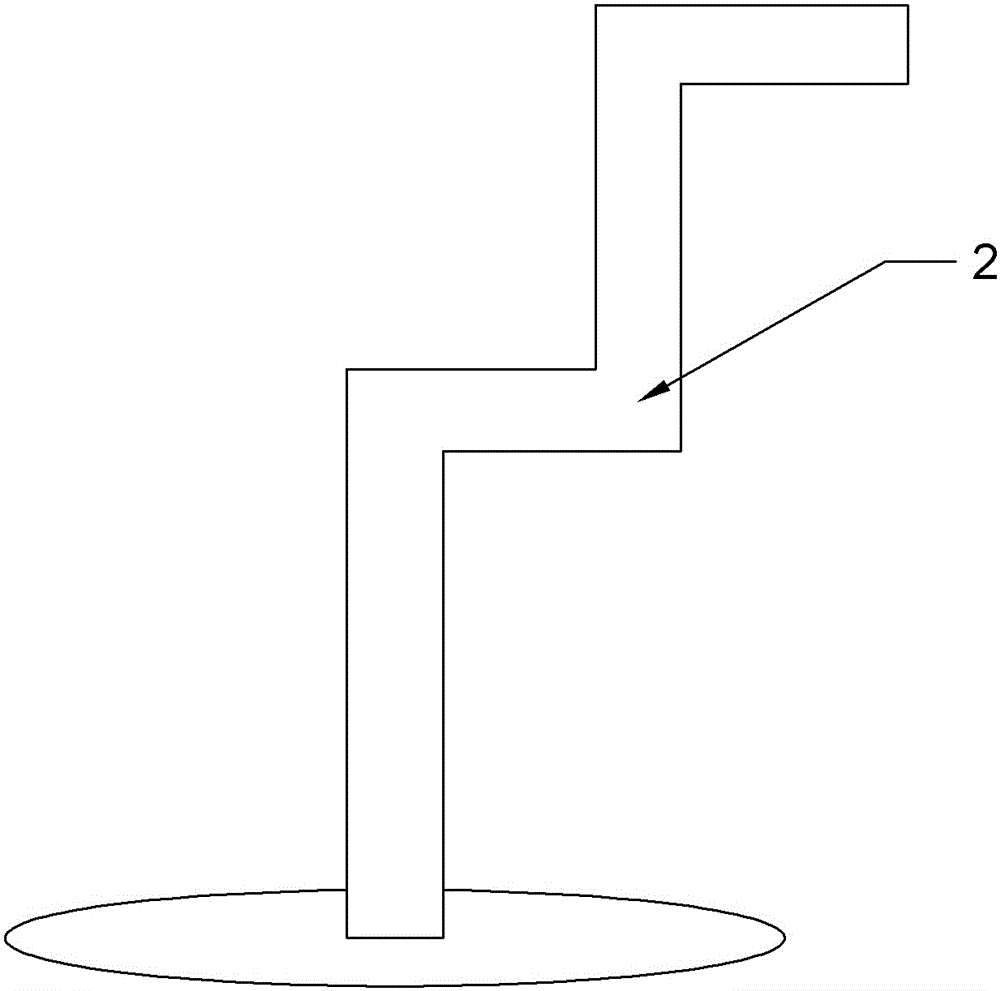

[0016] Example 1, such as figure 1 and figure 2 As shown, a leaf spring detection measuring tool includes a measuring tool body 1, the measuring tool body 1 is in a rectangular shape as a whole, the measuring tool body 1 is provided with a support frame 2, the measuring tool body 1 is provided with a mounting hole, and the measuring tool body 1 passes through the mounting hole with a screw It is detachably connected with the support frame 2. At the same time, the supporting frame 2 extends from one end of the measuring tool body 1, and a bent section bypasses the leaf spring, so that the supporting frame 2 supports the measuring tool body 1 in a horizontal state without touching the leaf spring. The length of the measuring tool body 1 is 900 mm, corresponding to the horizontal projection length of the leaf spring. At the same time, the end of the measuring tool body 1 is provided with a threaded hole, and the measuring tool body 1 is detachably connected to the fixed disk 3...

Embodiment 2

[0017] The difference between Embodiment 2 and Embodiment 1 is that the length of the measuring tool body 1 is 1000 mm.

Embodiment 3

[0018] The difference between Embodiment 3 and Embodiment 1 is that the length of the measuring tool body 1 is 1200 mm.

[0019] First, remove the fixed disk 3 from the measuring tool body 1, and then install the fixed disk 3 on the end of the measuring tool body 1 through the wrapping lug of the leaf spring, and the fixed disk 3 is stuck on the wrapping ear. Keep the measuring tool body 1 in a horizontal state, and then slide the plumb weight 6 near the center of the leaf spring. When the top of the plumb weight 6 touches the center of the leaf spring, stop the sliding of the plumb weight 6, thereby positioning the steel plate accurately. The center position of the spring. From this, the distance between the wrap lug and the center of the leaf spring can be read off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com