Surface marking device for machining mechanical parts

A technology of mechanical parts and placement table, applied in the field of parts processing, can solve the problems of single structure, prone to dislocation, jitter, unclear marking, etc., and achieve the effect of ensuring stability and avoiding dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

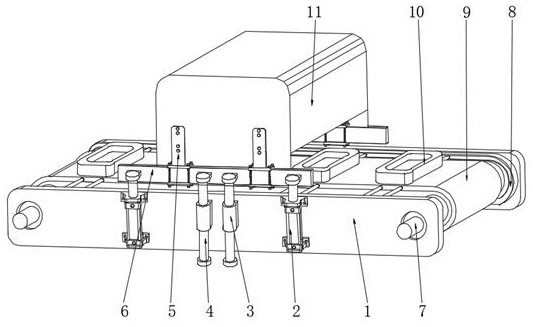

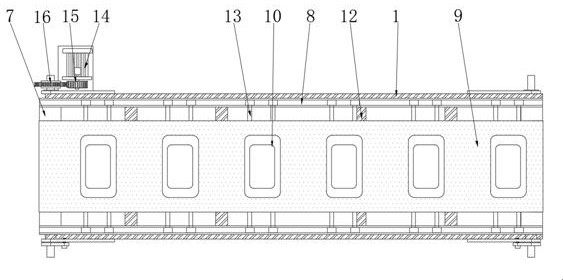

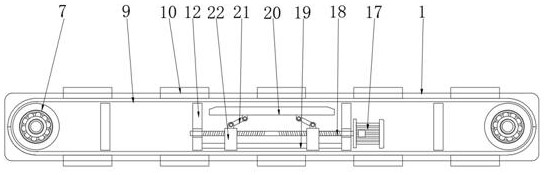

[0022] see Figure 1~5 , in an embodiment of the present invention, a surface marking device for processing mechanical parts includes a transport frame 1, hydraulic push rods 2 are symmetrically fixed on the front and rear sides of the transport frame 1, and the front and rear sides of the transport frame 1 are located at The middle position is symmetrically fixed with a positioning sliding sleeve 3, the inner side of the positioning sliding sleeve 3 penetrates and engages the limit sliding rod 4, the inner diameter of the positioning sliding sleeve 3 matches the outer diameter of the limiting sliding rod 4, and the limiting sliding rod 4 The length of the hydraulic push rod 2 is the same as the telescopic length of the hydraulic push rod 2. When marking the mechanical parts, the telescopic end of the hydraulic push rod 2 lifts up and down. The support plate 6 moves up and down smoothly to adjust the printing height and position of the printing needle 26 .

[0023] The telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com