Cam follower roller device

一种滚柱、凸轮的技术,应用在阀装置、传动装置、燃料喷射装置等方向,能够解决妨碍套管滑动、强度不足支撑体、套管变型等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

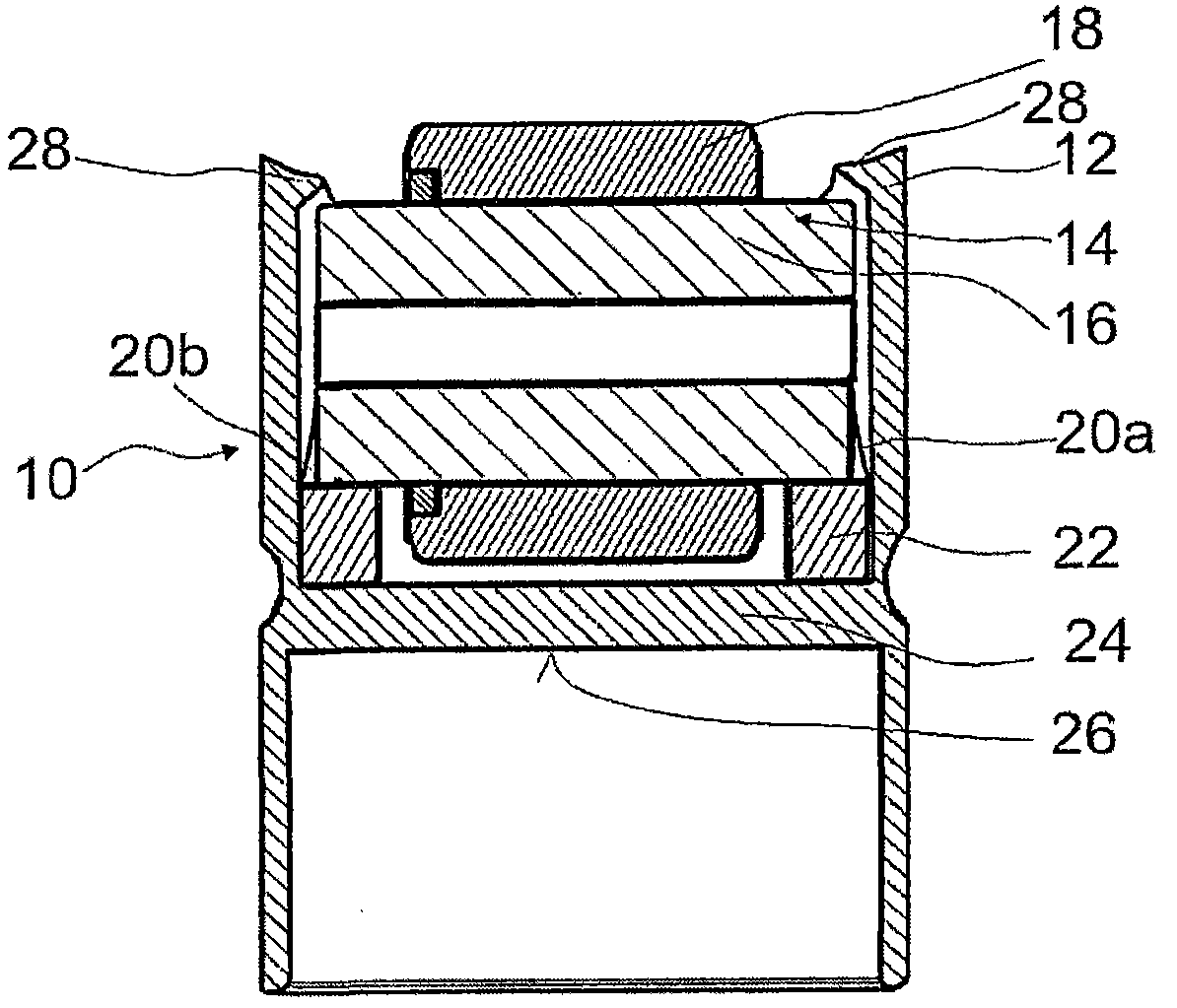

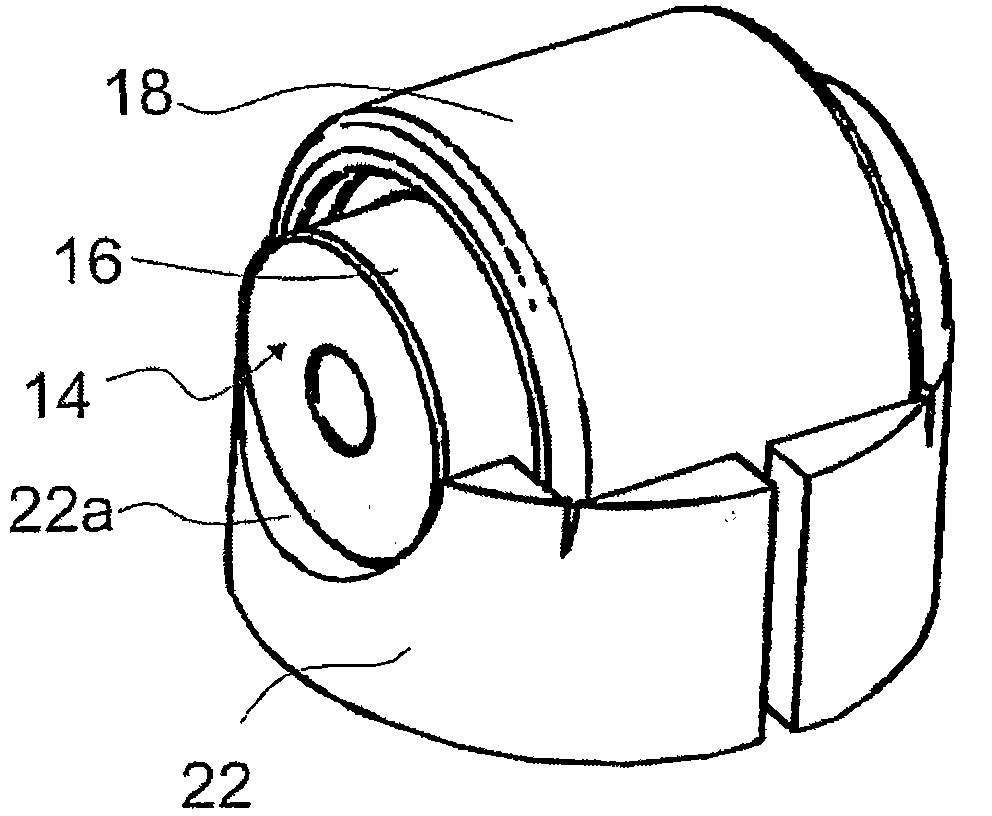

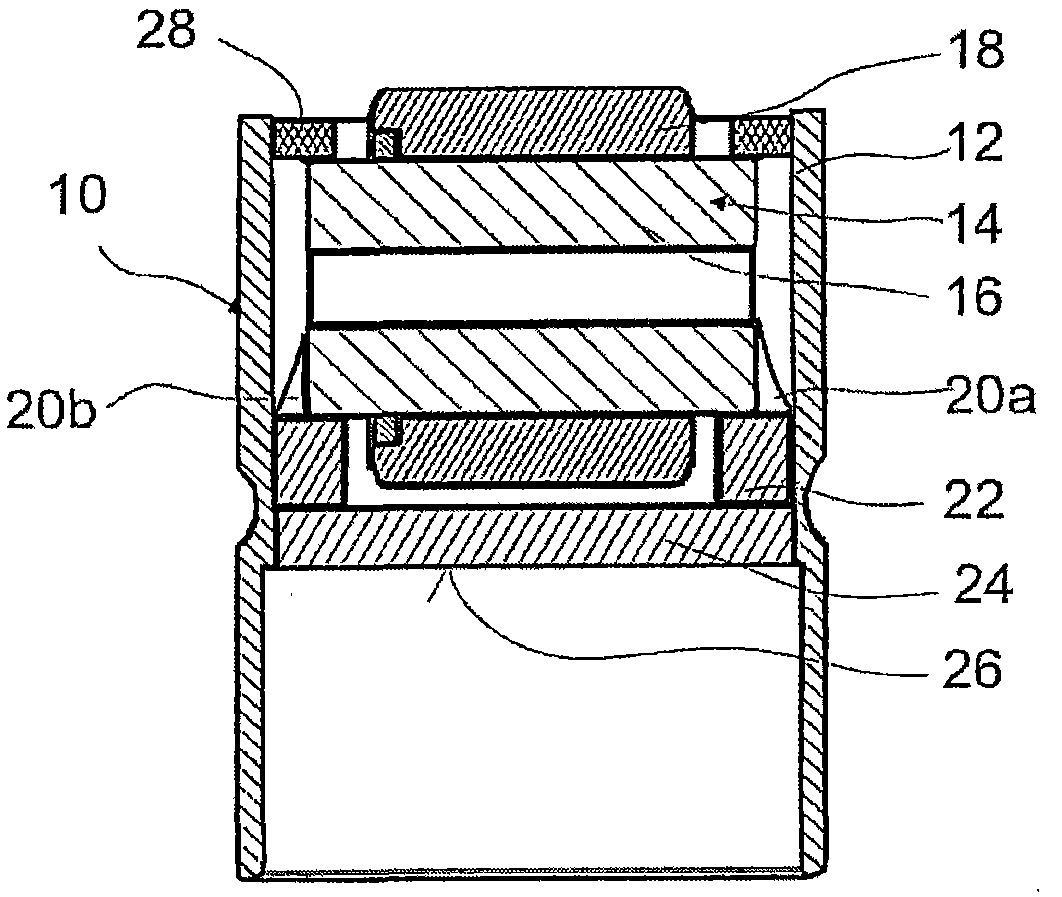

[0035] figure 1 is an axial sectional view of the cam traveling roller device according to the first embodiment of the present invention. The device comprises a tappet 10 having a sleeve 12 with a circular opening receiving the main part of a roller 14 . Roller 14 is rotatably mounted within bushing 12 and includes a portion axially projecting from an opening of bushing 12 . The portion is arranged to cooperate with a cam (not shown). The device can be used in a fuel injection pump of an internal combustion engine.

[0036] Roller 14 includes a spindle 16 and a cylinder 18 . The ends of the spindle 16 protrude from the lateral surface of the cylinder 18 of the roller 14 . The cylinder 18 may be rotatably mounted on the mandrel 16 by a bearing or needle bearing arrangement, or may be mounted in a fixed manner by upsetting or rolling. Alternatively, the spindle 16 and cylinder 18 of the rollers may be made in one piece.

[0037] The roller 14 support 22 is arranged on a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com