Multichannel mechanical acceleration switch

An acceleration switch, mechanical technology, applied in the direction of electrical switches, electrical components, circuits, etc., can solve the problems of lack of control technology, long time, influence, etc., to eliminate wasteful consumption of useless power, eliminate wasteful consumption, and ensure stable power supply. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

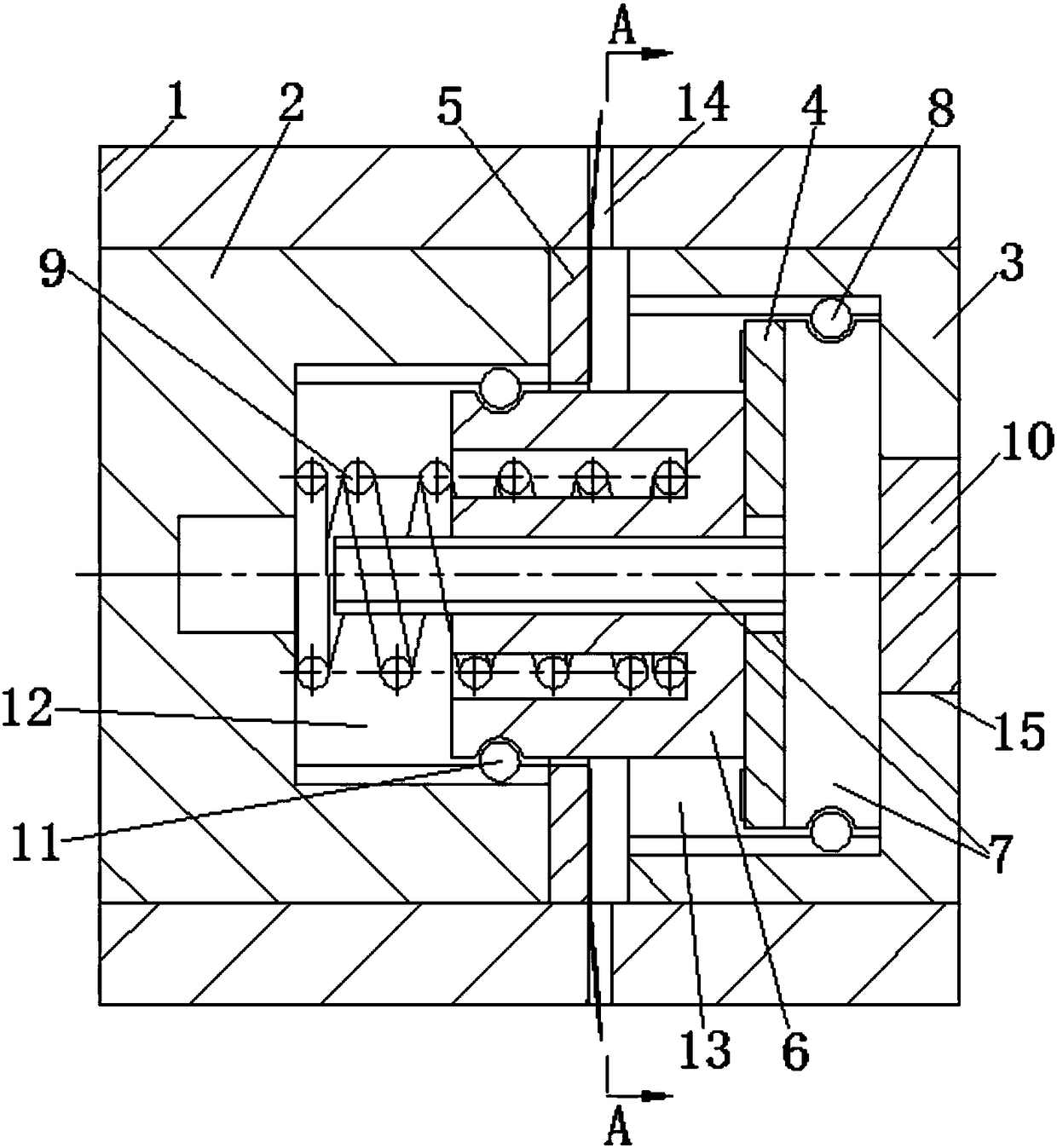

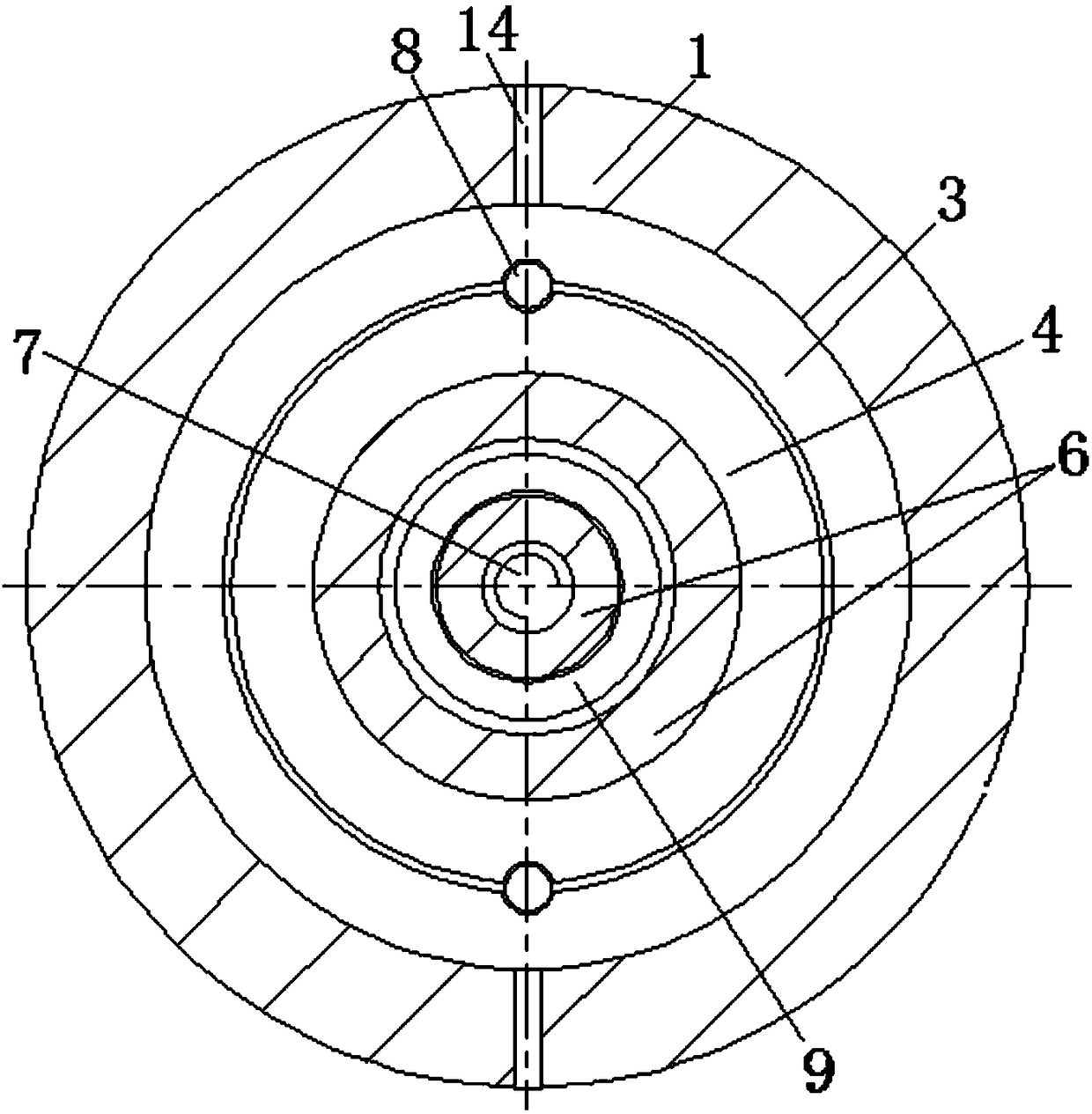

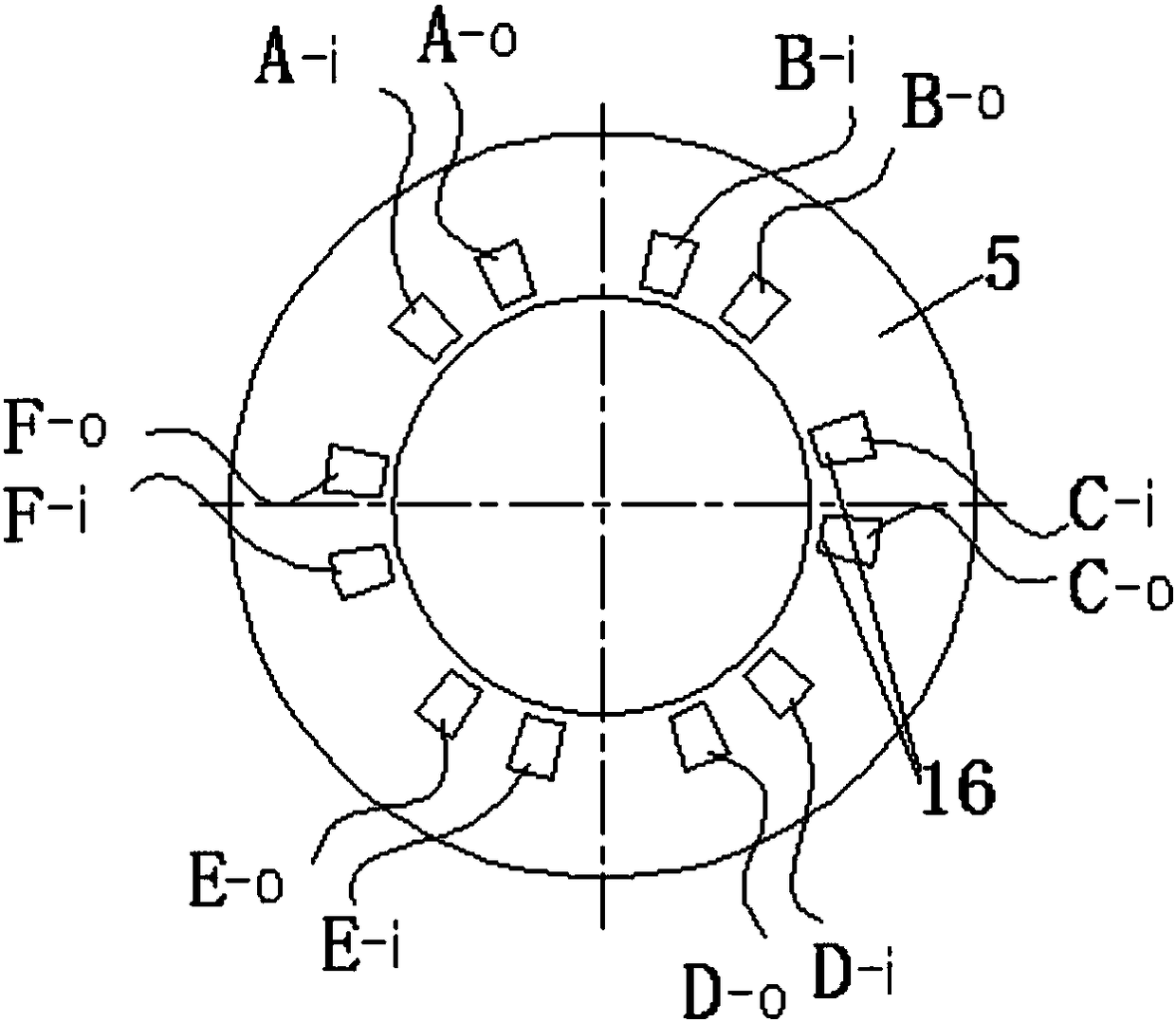

[0033] The invention relates to an acceleration switch, in particular to a multi-channel mechanical acceleration switch, which is especially suitable for power control of a telemetry transmitter in mechanical vibration testing. Below in conjunction with the accompanying drawings of the description - that is figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The technical content of the present invention is described in detail and clearly.

[0034] see Figure 1 to Figure 5As shown, the present invention is arranged on the centrifugal rotating part-for example, on the turbine shaft, and the radial radius from the center of the centrifugal rotating part to the outer edge is provided with a mounting hole (or groove), and the present invention is installed in the mounting hole (or groove) of the centrifugal rotating part or slot) in the testing device box, the axial direction of the acceleration switch of the present invention is required to be consistent with the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com