An electric vehicle rear axle assembly

A technology for electric vehicles and rear axles, applied in the field of electric vehicles, can solve the problems of poor oil injection effect, damaged screw teeth, inconvenient repeated repairs, etc., and achieve the effect of convenient oil injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

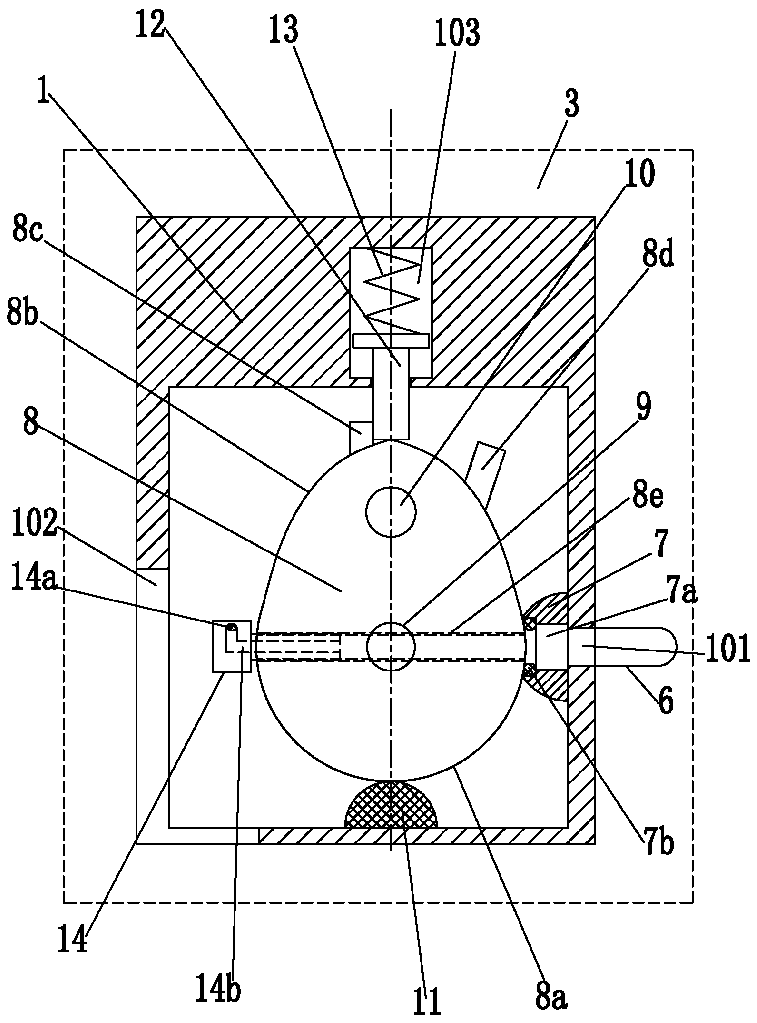

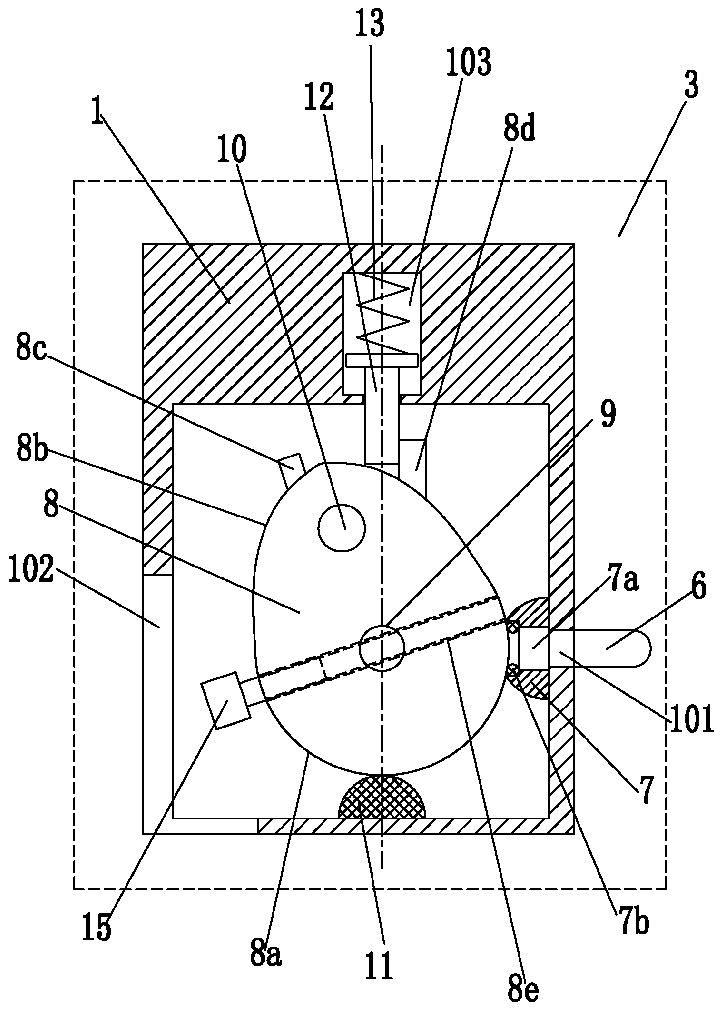

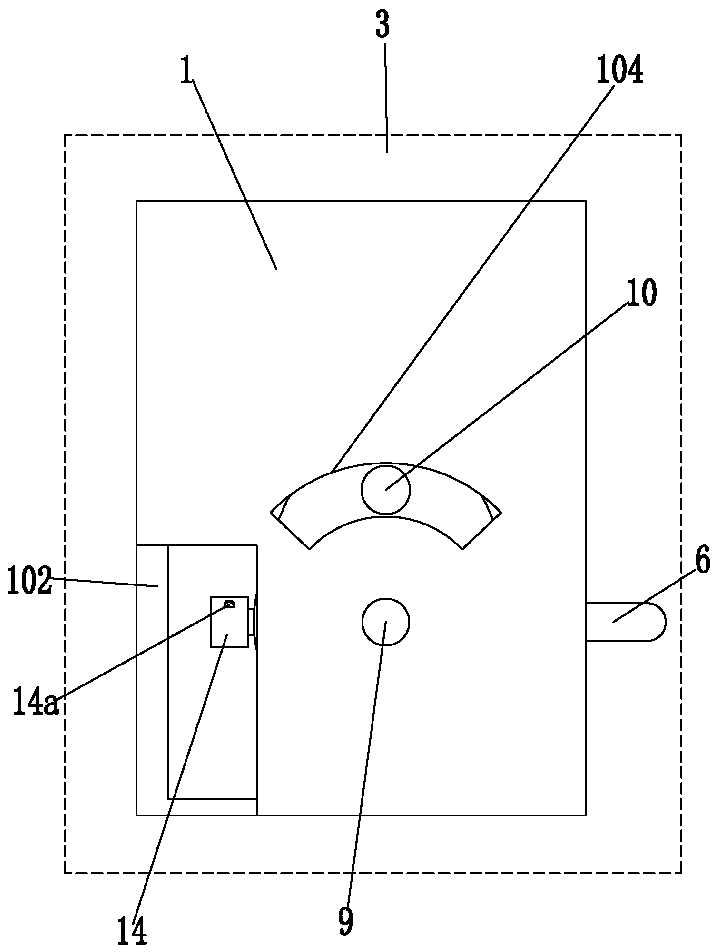

[0021] Such as Figure 1-7 As shown, an electric vehicle rear axle assembly includes a transmission differential 2, a drive motor 4 for providing power to the transmission differential 2, and a transmission differential housing with an oil supply hole 3a 3. It also includes a pair of half shafts 5 connected to the power output end of the transmission differential 2, and also includes a shaft that is installed in conjunction with the oil supply hole 3a and can deliver oil to the inner cavity of the transmission differential case 3 through the oil supply hole 3a. The oil delivery device, the oil delivery device includes a housing main box 1 fixed on the outer wall of the transmission differential case 3, made of a transparent material, and also includes an oil inlet pipe 6, a cam 8, a receiving block 7, and an adjustment rotating shaft 9.

[0022] The outer edge of the above-mentioned cam 8 includes an arc edge 8a, and the cam 8 is rotatably installed in the inner cavity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com