Patents

Literature

58 results about "Thermal limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal limit. [′thər·məl ′lim·ət] (electricity) A limit on the power carried by an electric power system that results from the heating effects of the power carried by the devices.

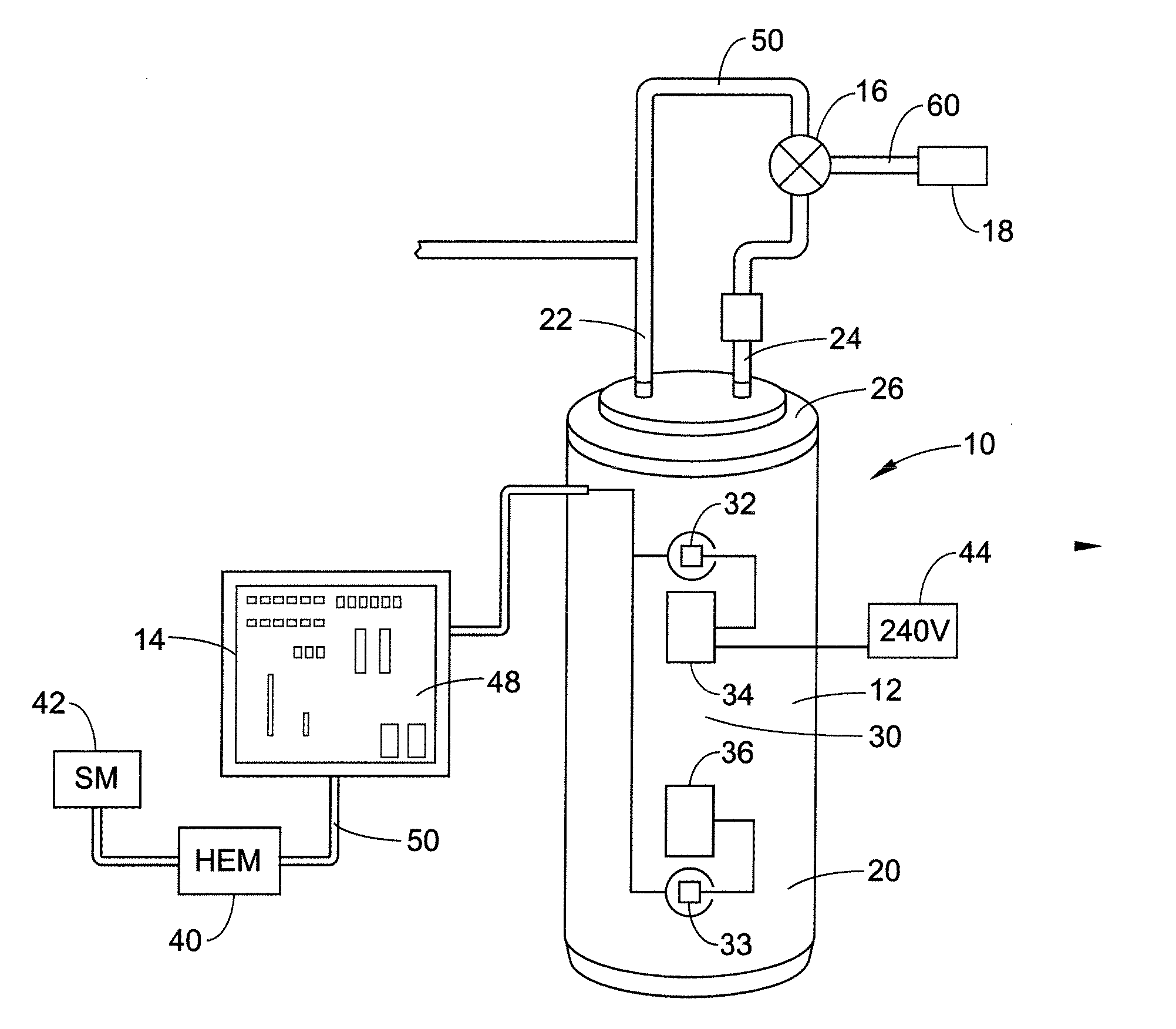

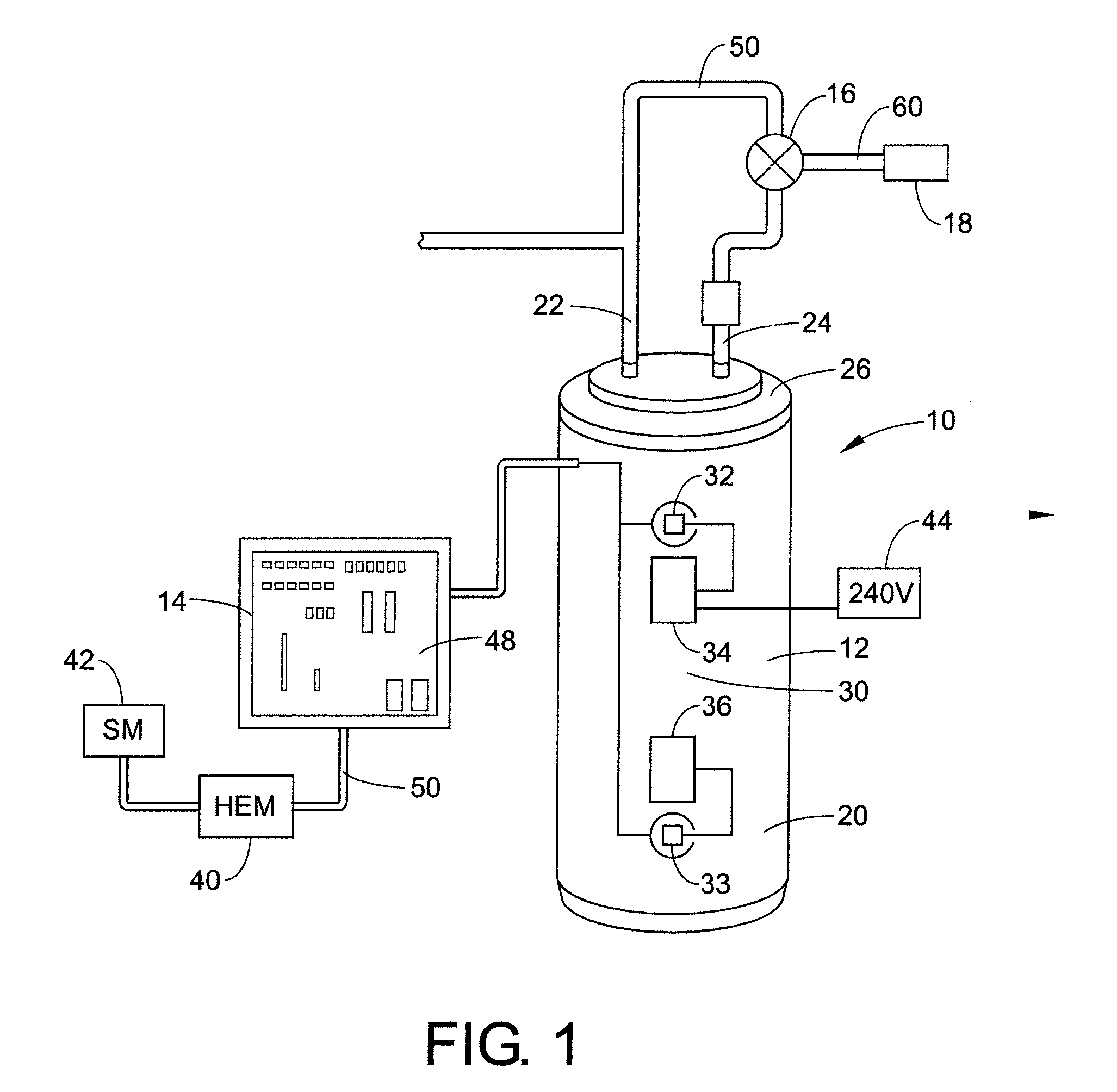

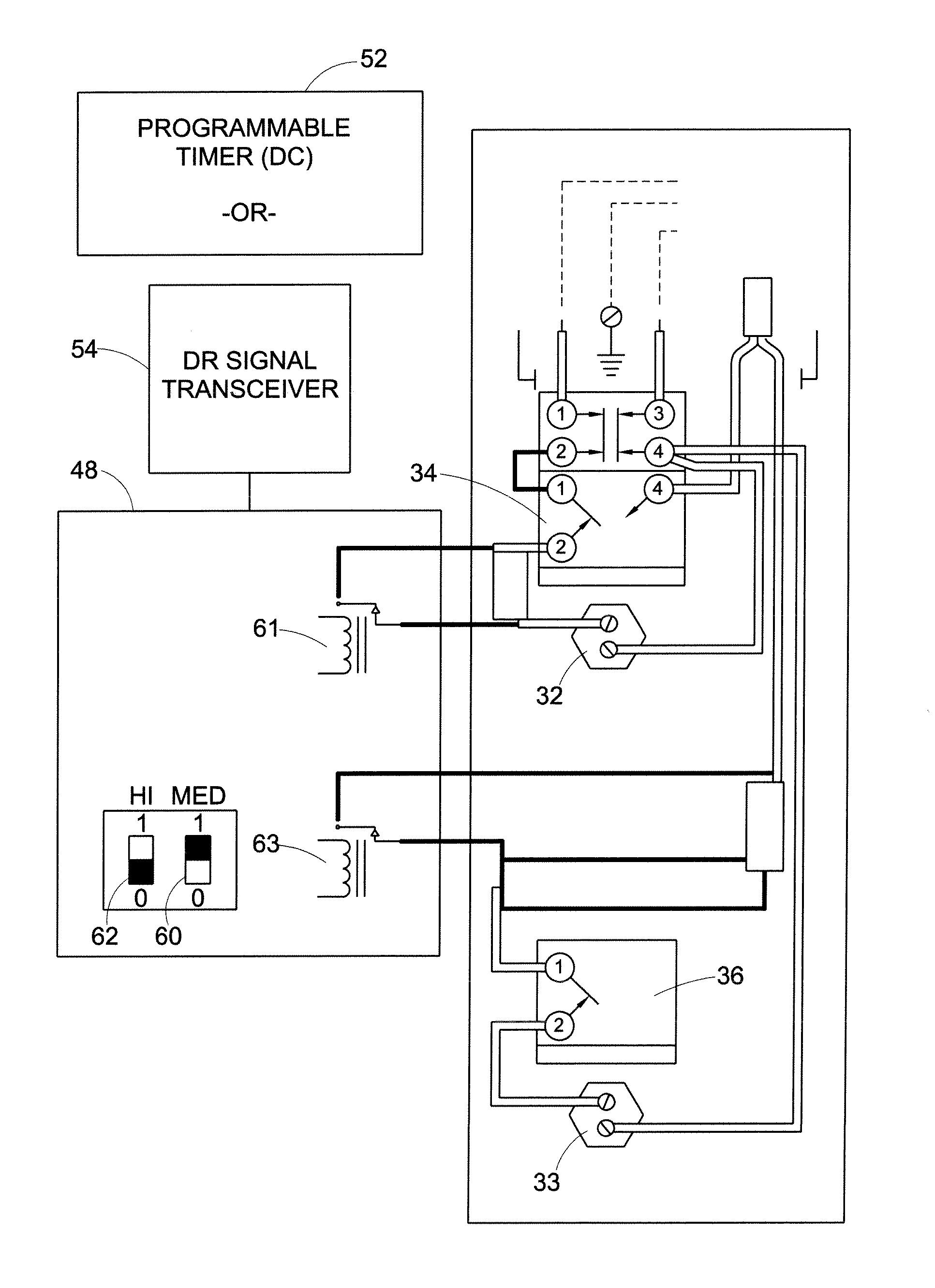

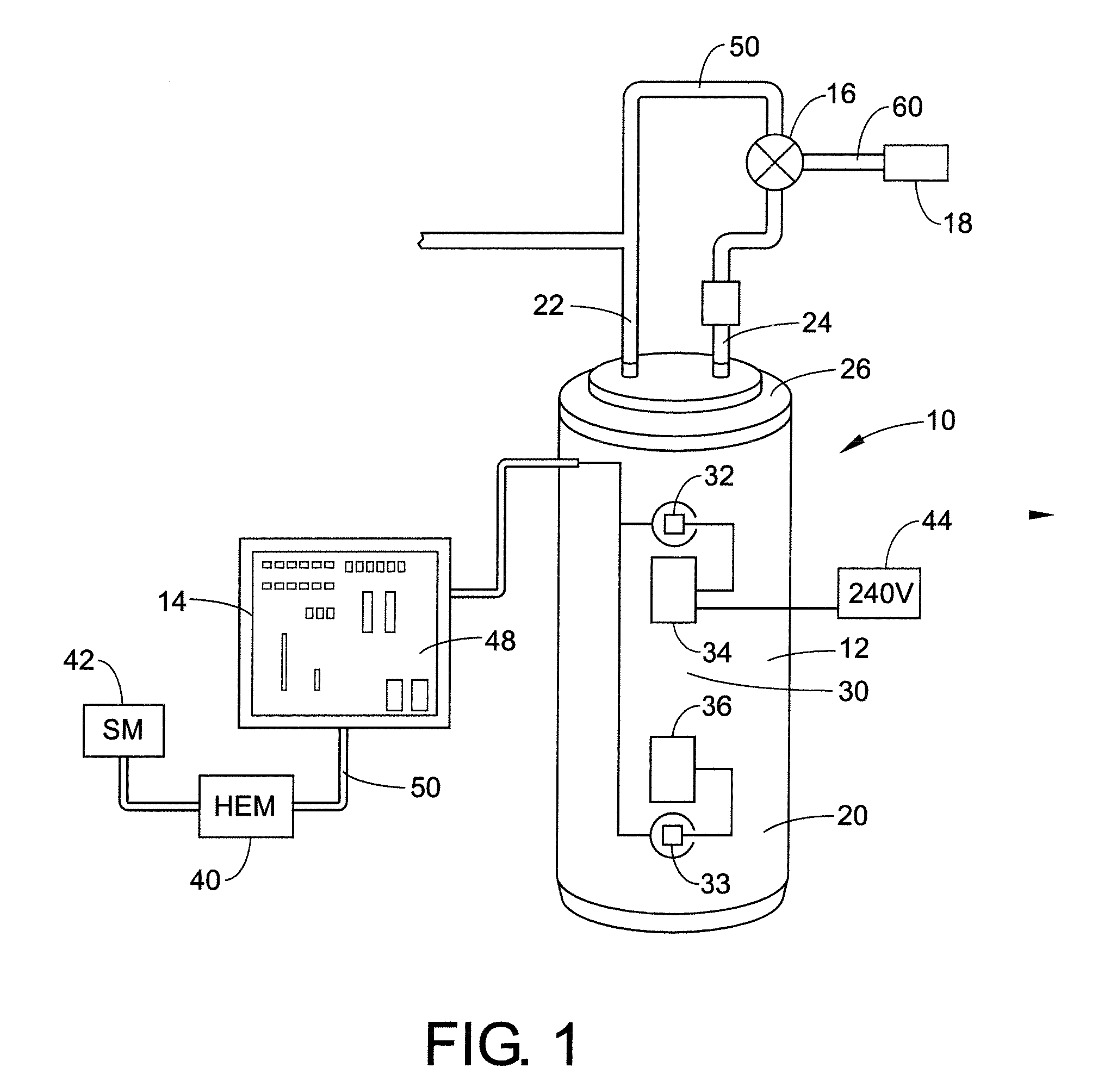

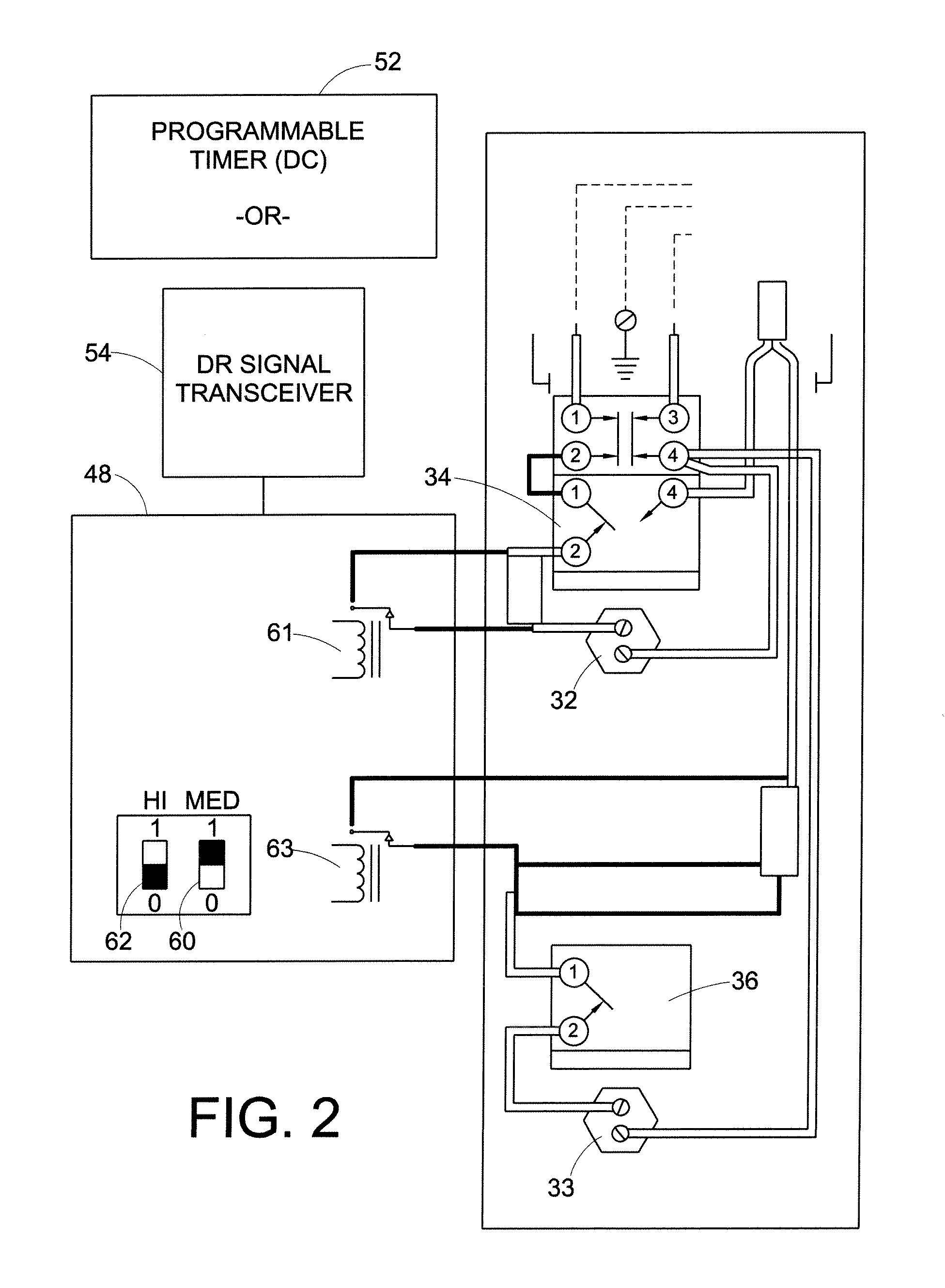

Water heating control and storage system

ActiveUS20110123179A1Reduce operating costsReduce the temperatureHeat storage plantsTemperatue controlThermal limitEngineering

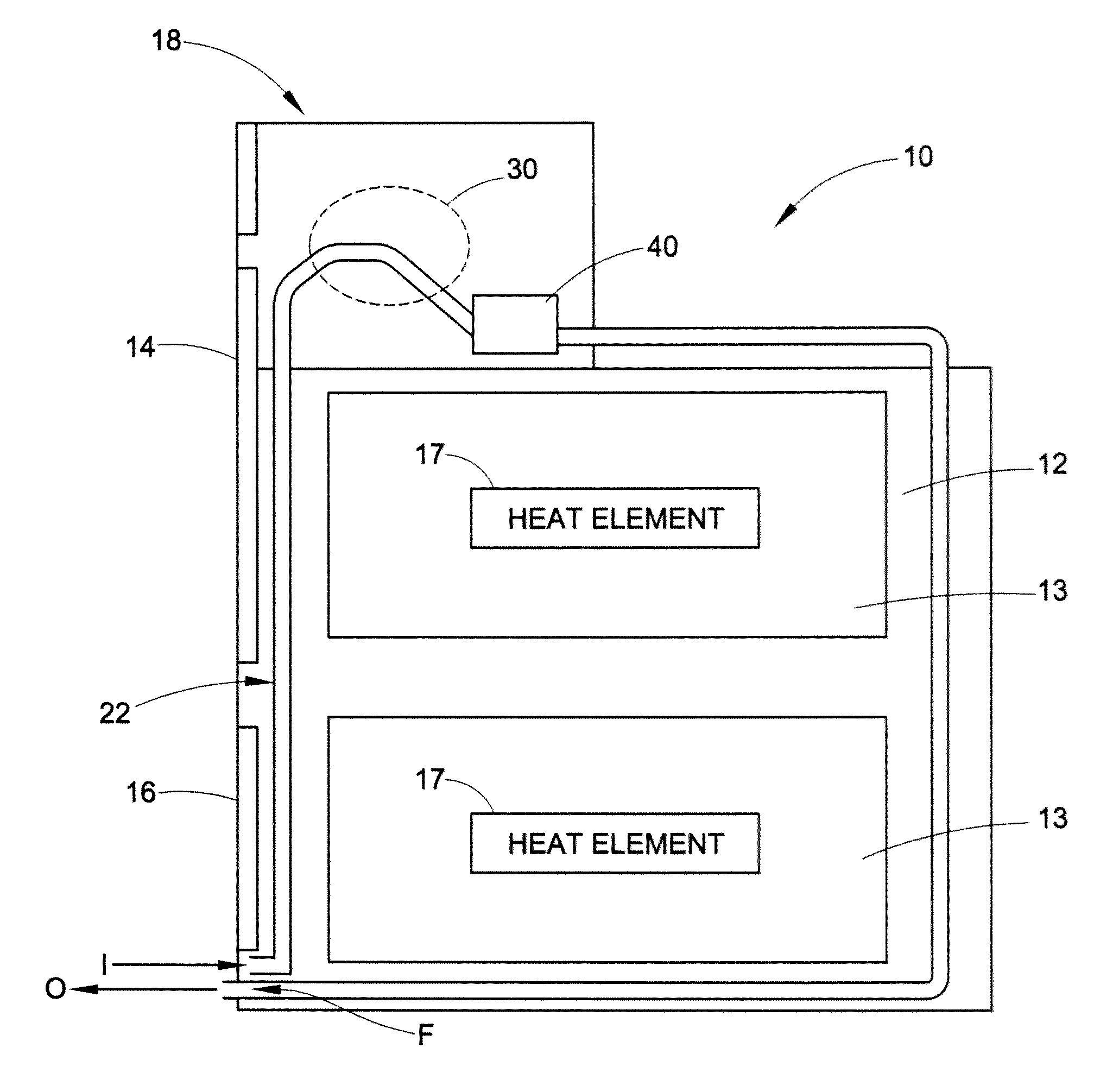

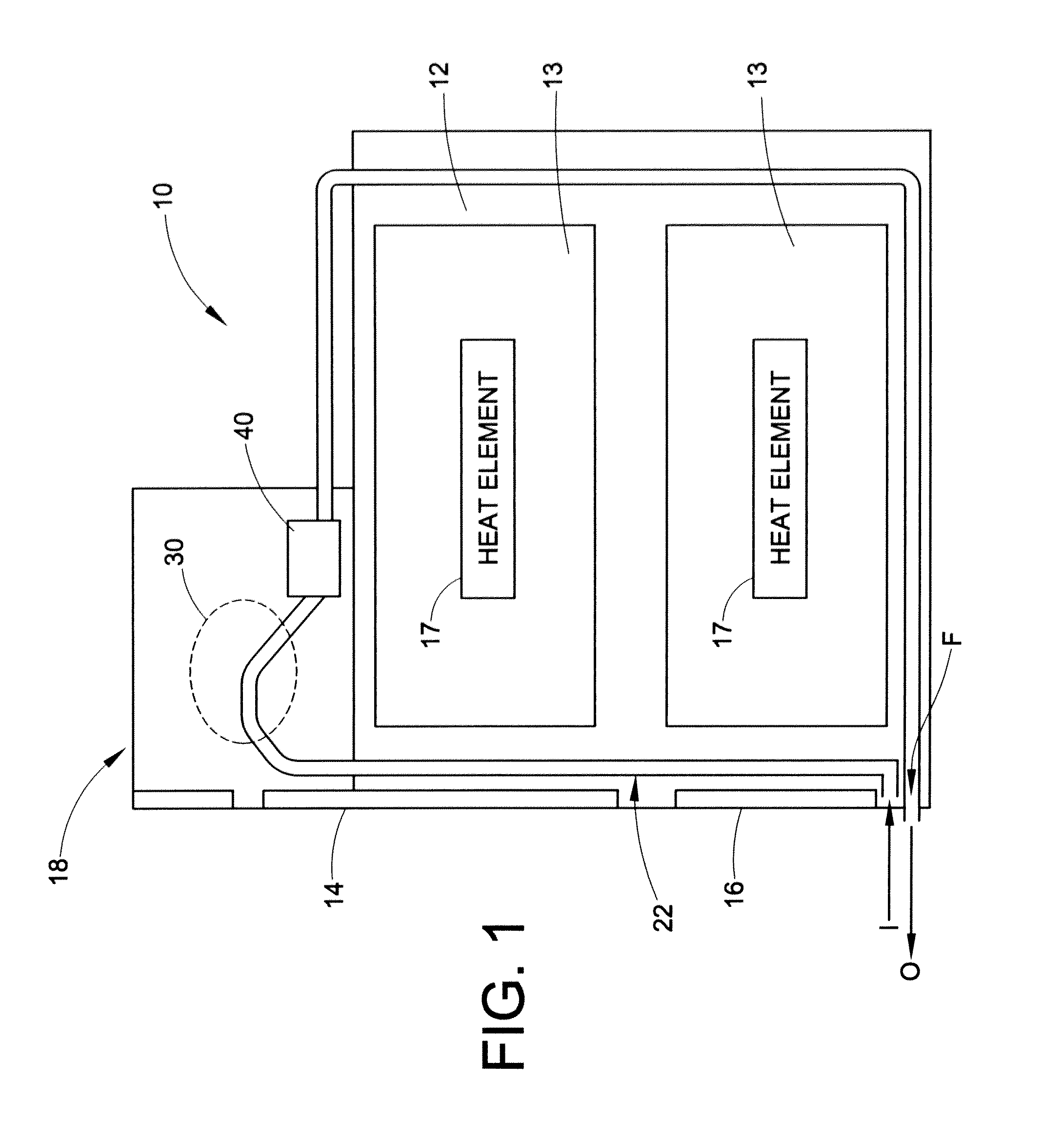

A water heating control and storage system, including an insulated tank for containing water to be heated. The tank has at least two heating elements, including an upper heating element and a lower heating element. An operation control device receives a demand response signal and enables each element to independently heat water for usage. A method for controlling a water heating storage system includes providing an insulated tank for containing water to be heated; providing an upper heating element with a thermostat and thermal limiting device and a lower heating element with a thermostat and thermal limiting device to heat upper and lower portions of water inside the tank; and providing a pair of switches for enabling each of the heating elements to independently heat upper and lower portions of the water for usage.

Owner:HAIER US APPLIANCE SOLUTIONS INC

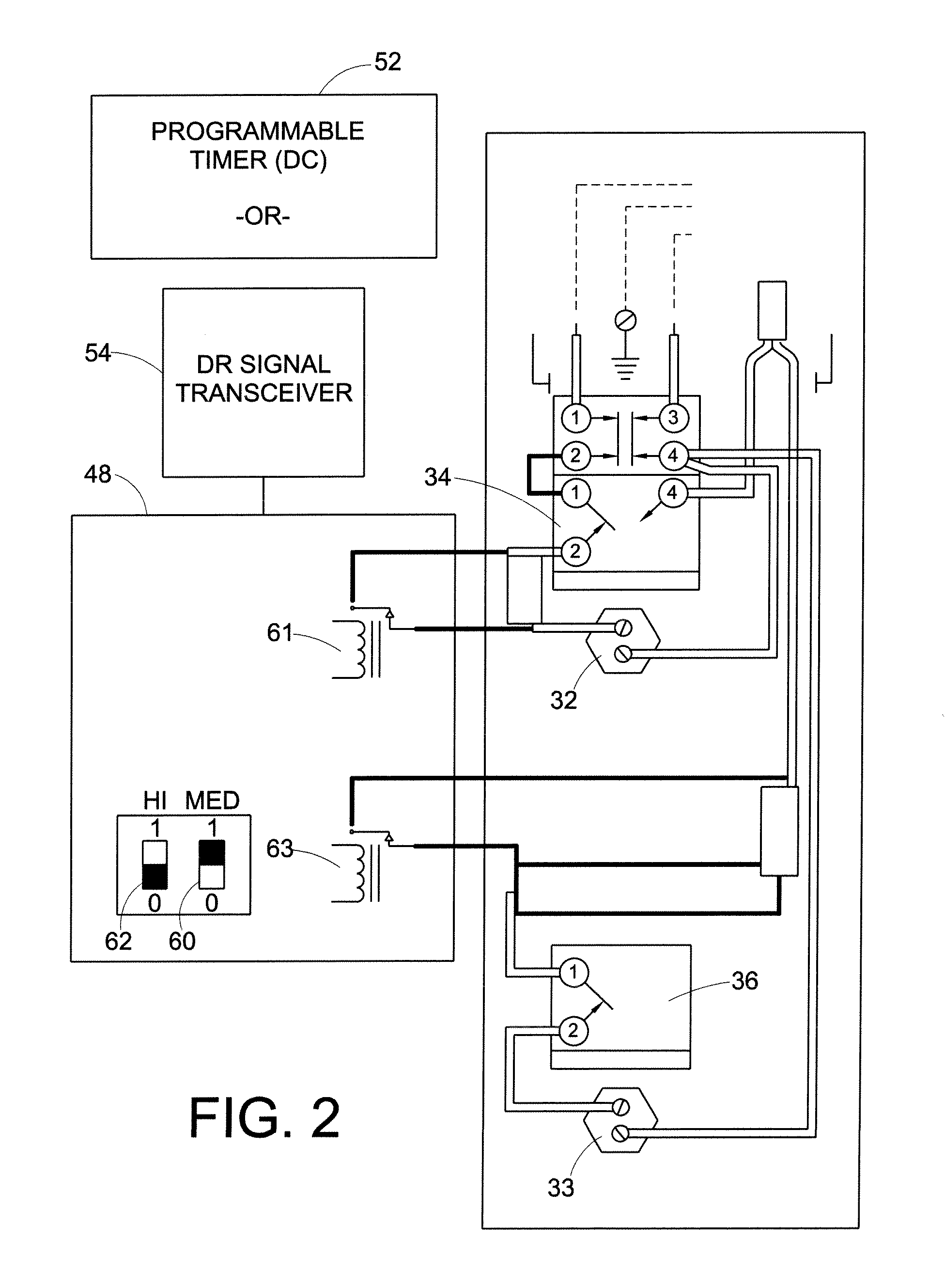

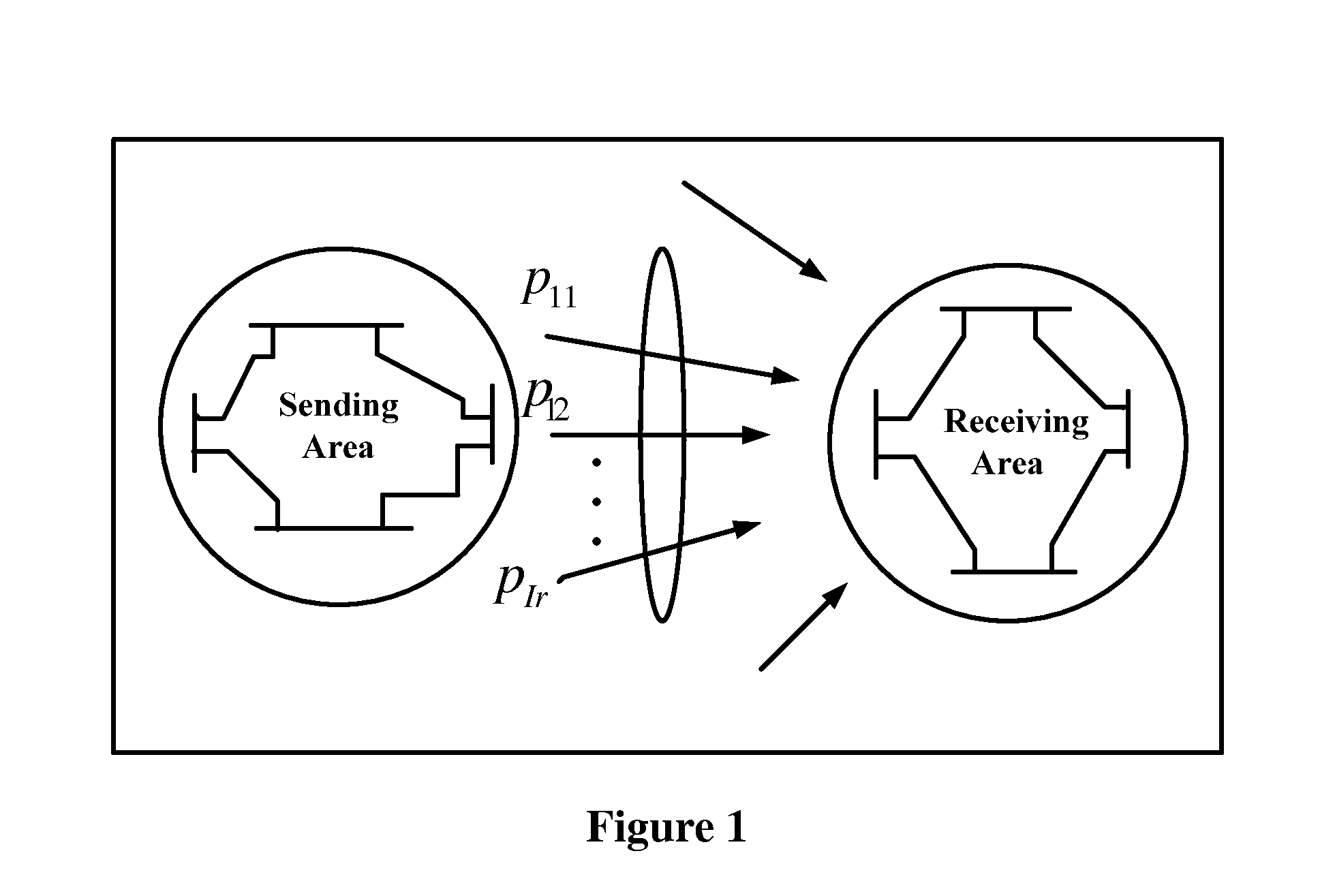

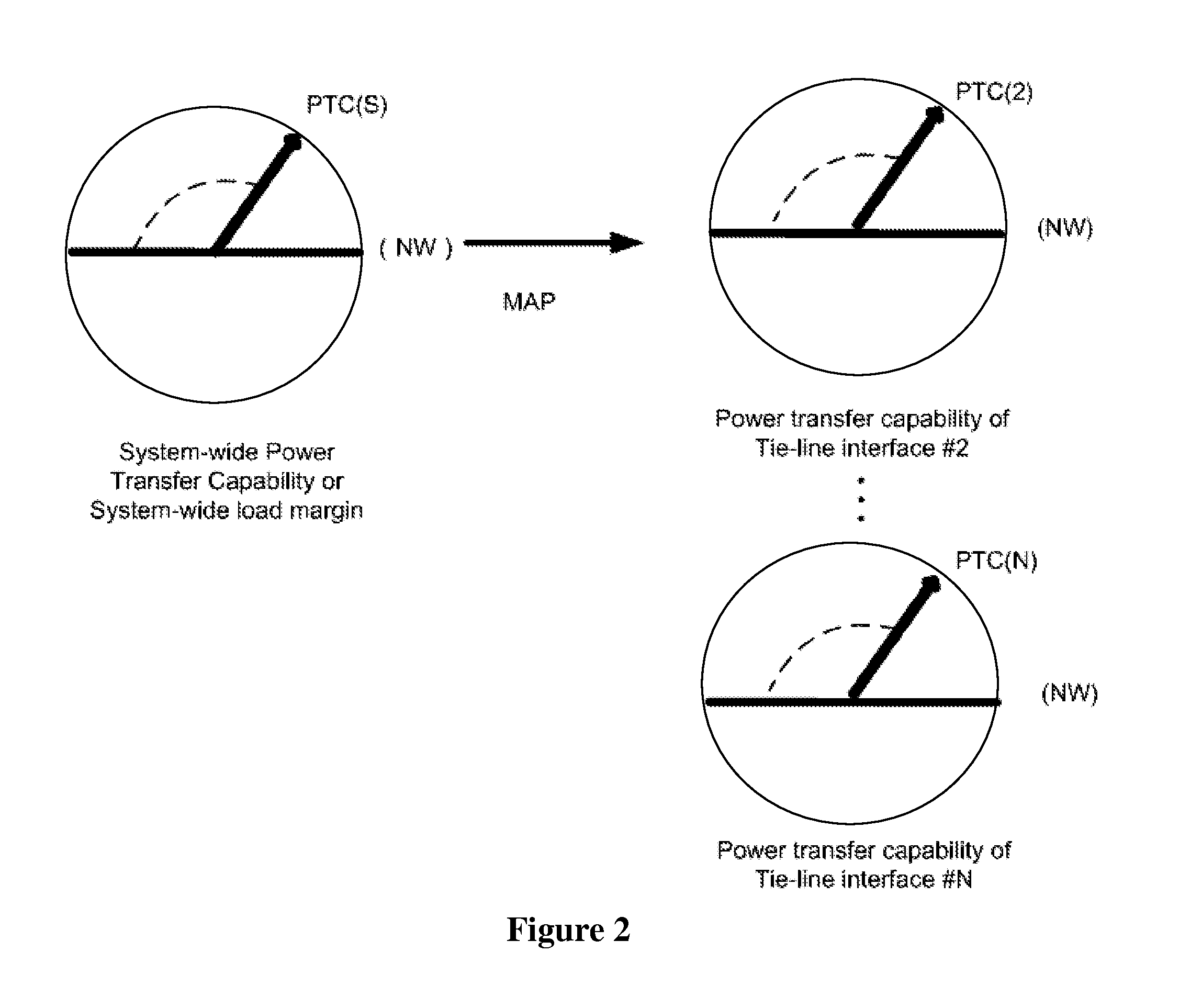

Systems for Real-Time Available Transfer Capability Determination of Large Scale Power Systems

InactiveUS20130218494A1Accurately Transfer CapabilityElectric devicesPower network operation systems integrationThermal limitSteady state stability

A system for accurately determining real-time Available Transfer Capability and the required ancillary service of large-scale interconnected power systems in an open-access transmission environment, subject to static and dynamic security constraints of a list of credible contingencies, including line thermal limits, bus voltage limits, voltage stability (steady-state stability) constraints, and transient stability constraints.

Owner:THE TOKYO ELECTRIC POWER CO INC +2

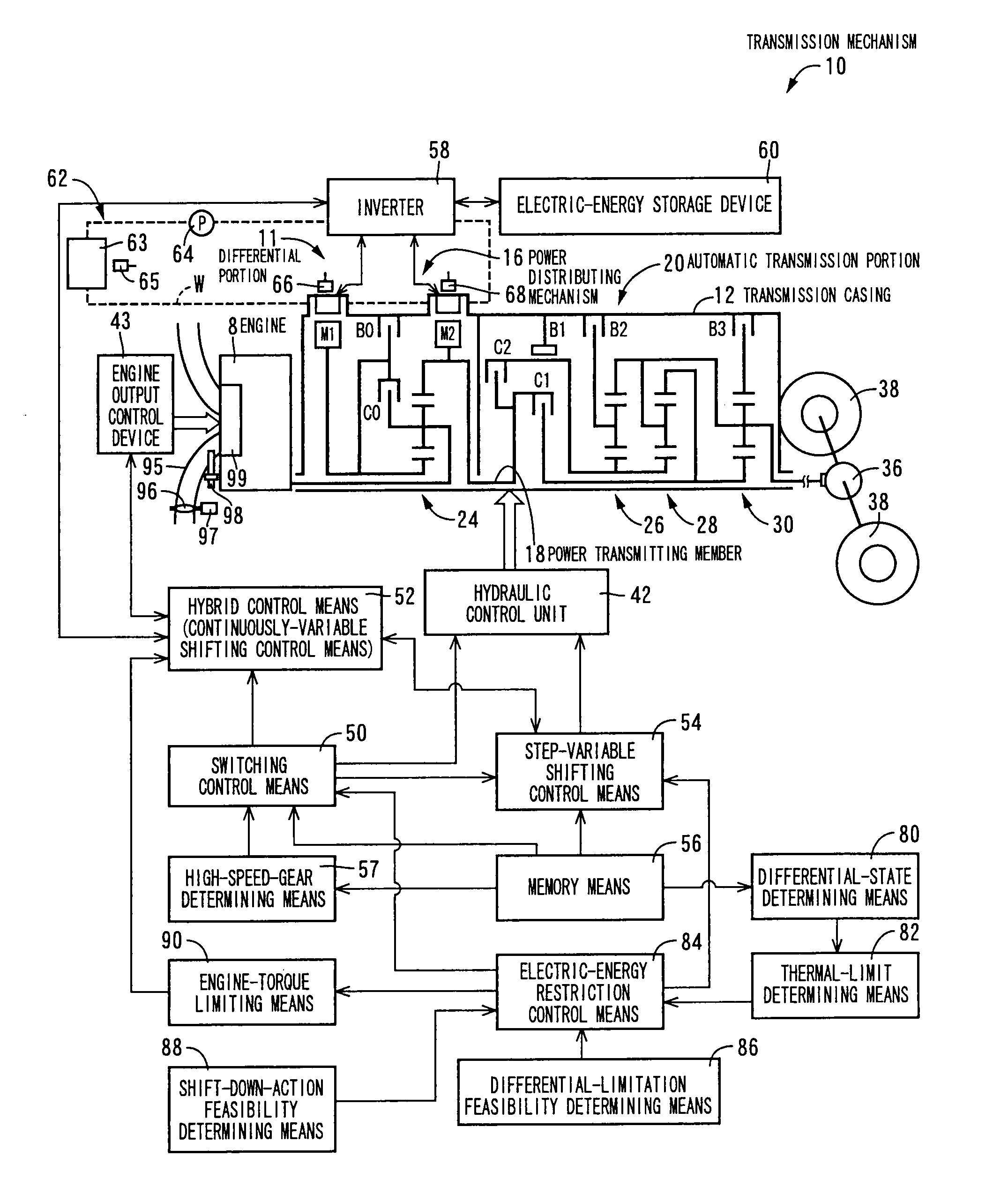

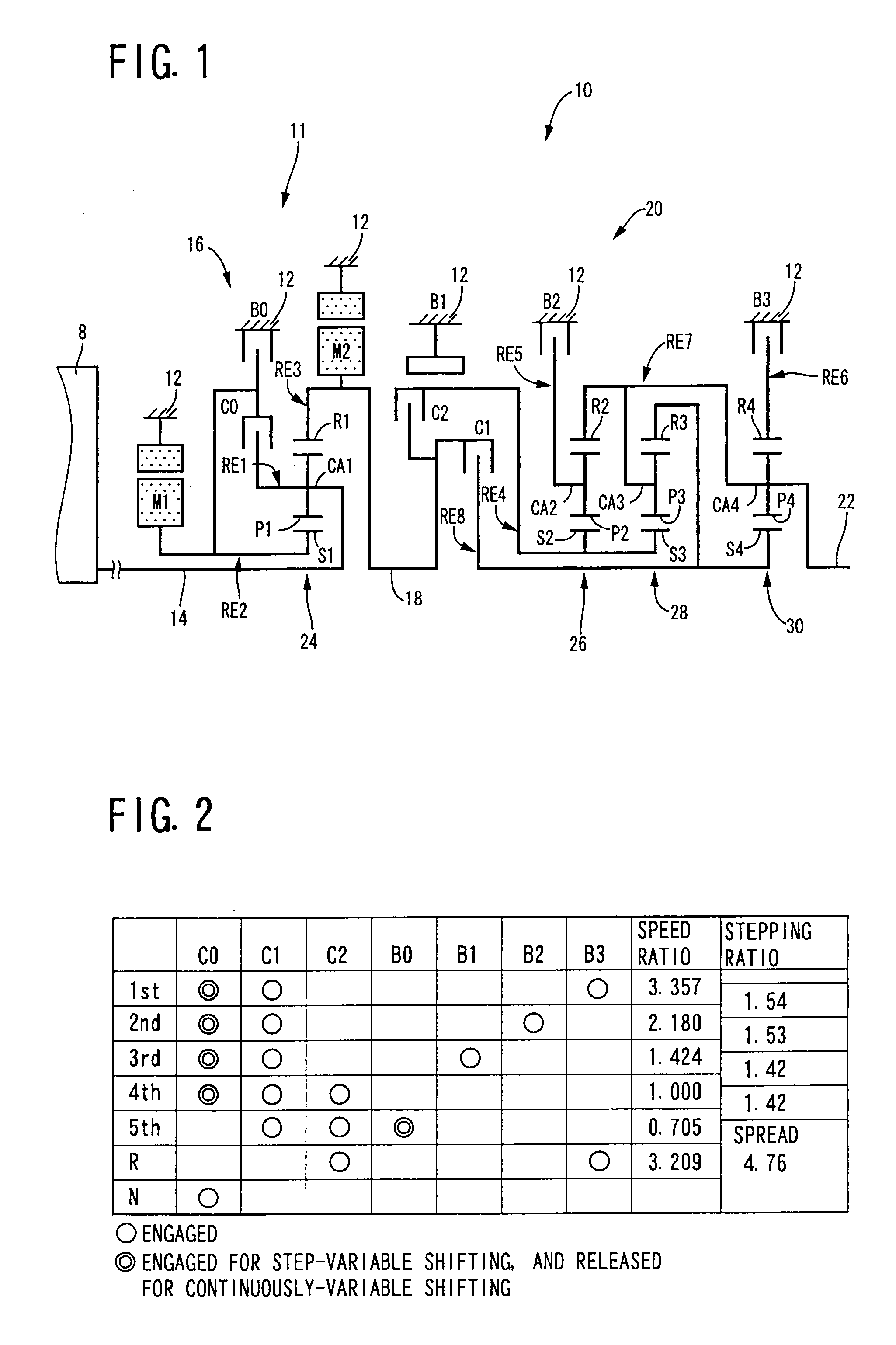

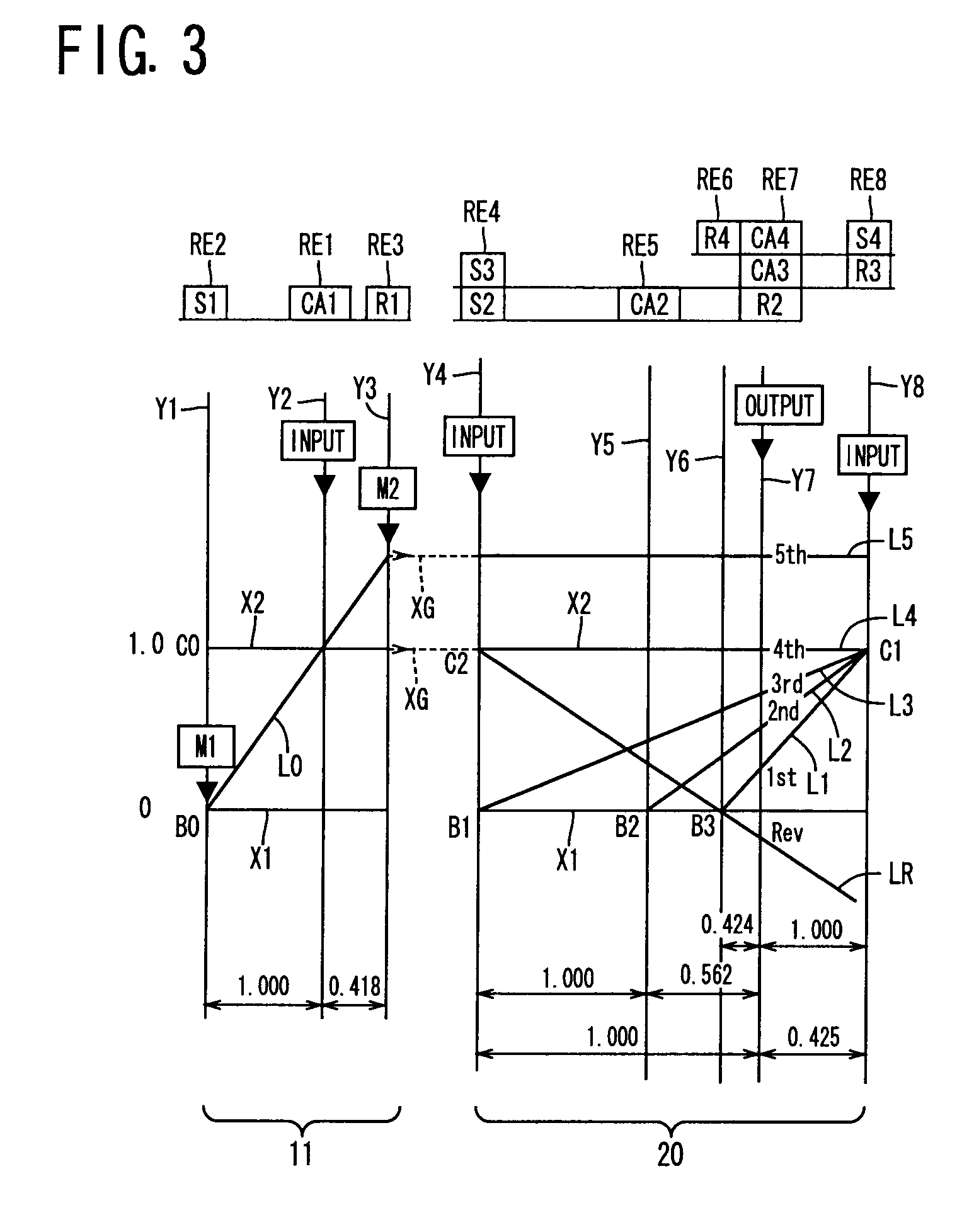

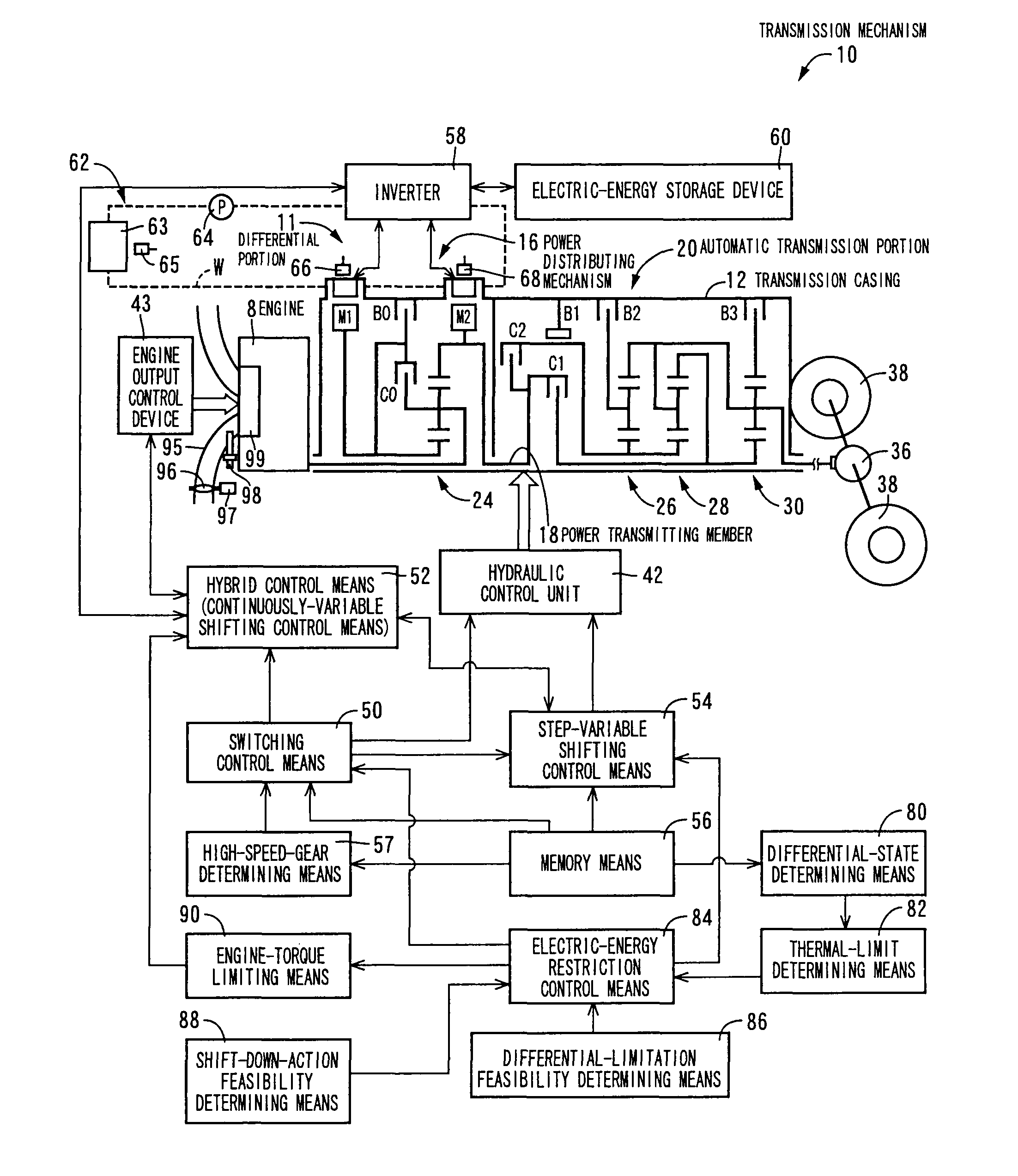

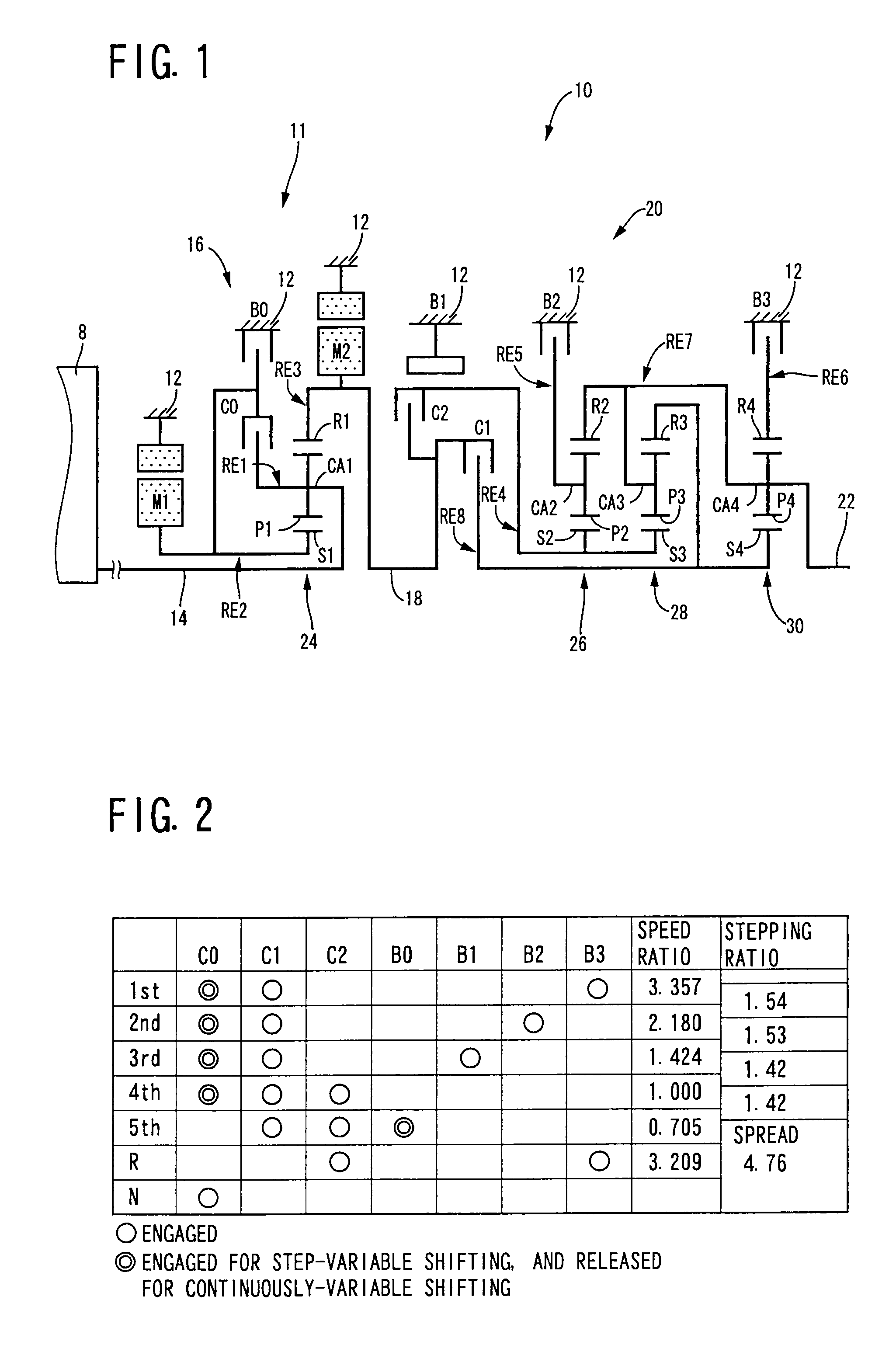

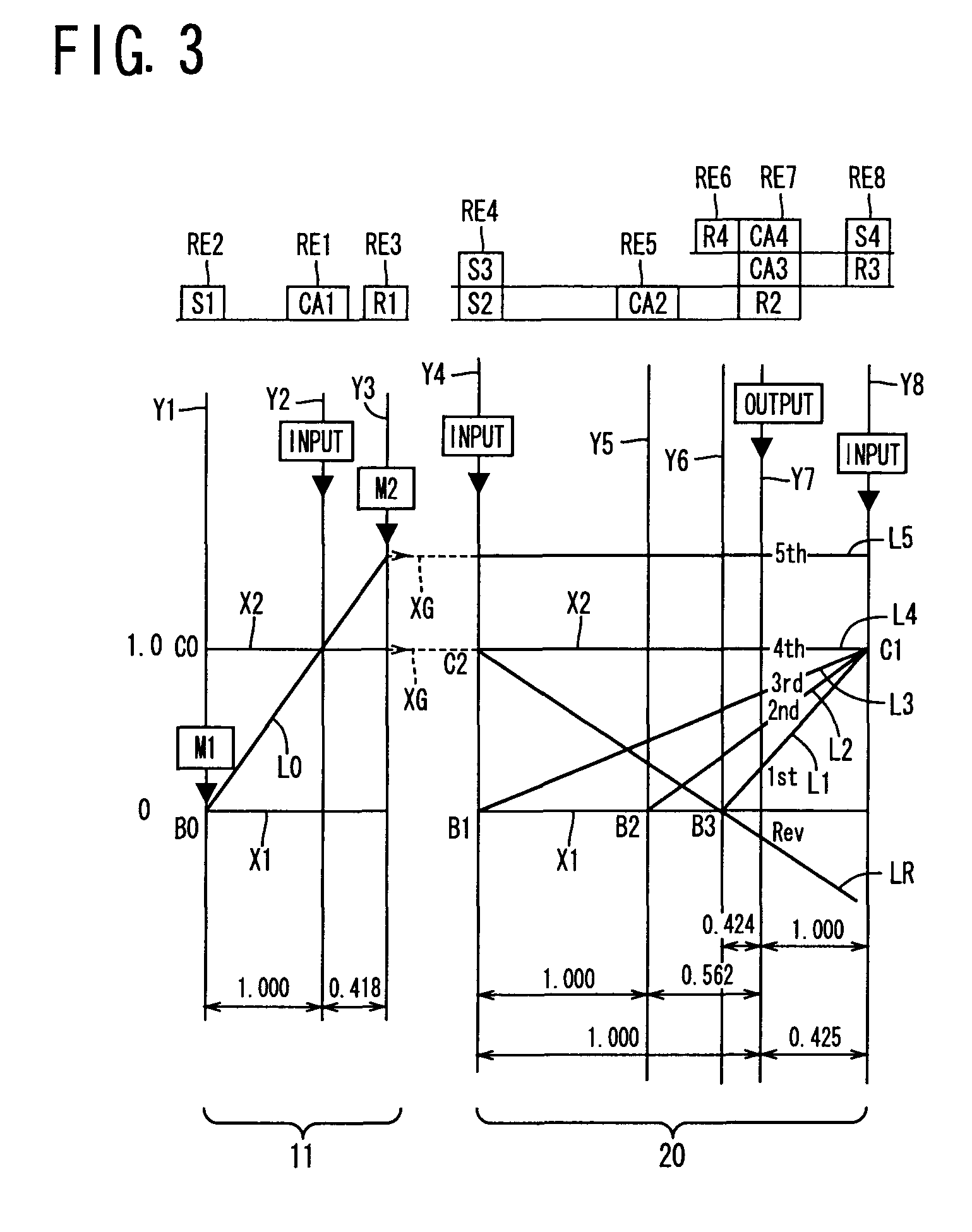

Controller of driver for vehicle

ActiveUS20090076694A1Easy constructionGuaranteed normal transmissionDigital data processing detailsGearing controlElectricityThermal limit

A control apparatus for a vehicular drive system arranged to electrically transmit a portion of an output force of an engine through an electric path, which control apparatus is configured to reduce loads of components associated with the electric path and to restrict a temperature rise of the components associated with the electric path, making it possible to reduce the required size of a cooling system.Electric-energy restriction control means 84 is provided to place differential portion 11 in a non-differential state or to place switching clutch C0 or switching brake B0 in a partially engaged state, when an amount of transmission of electric energy through the electric path has increased to a thermal limit, so that a reaction force which corresponds to engine torque TE and which must be received by first electric motor M1 is reduced, whereby an amount of generation of electricity by the first electric motor m1 is reduced, and the amount of the generated electric energy is reduced, making it possible to restrict the temperature rise of the components associated with the electric path and to reduce the required size of the cooling system for cooling those components and the loads of the components associated with the electric path.

Owner:TOYOTA JIDOSHA KK

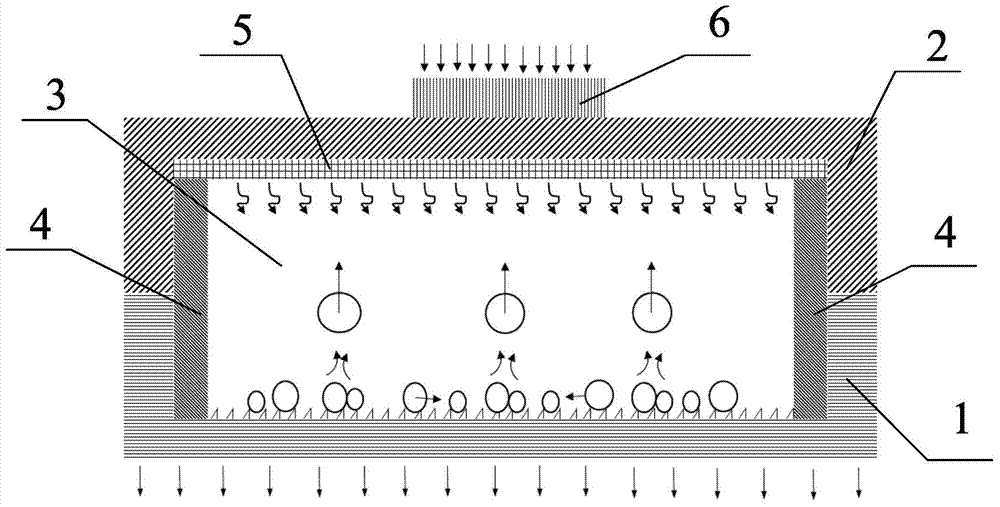

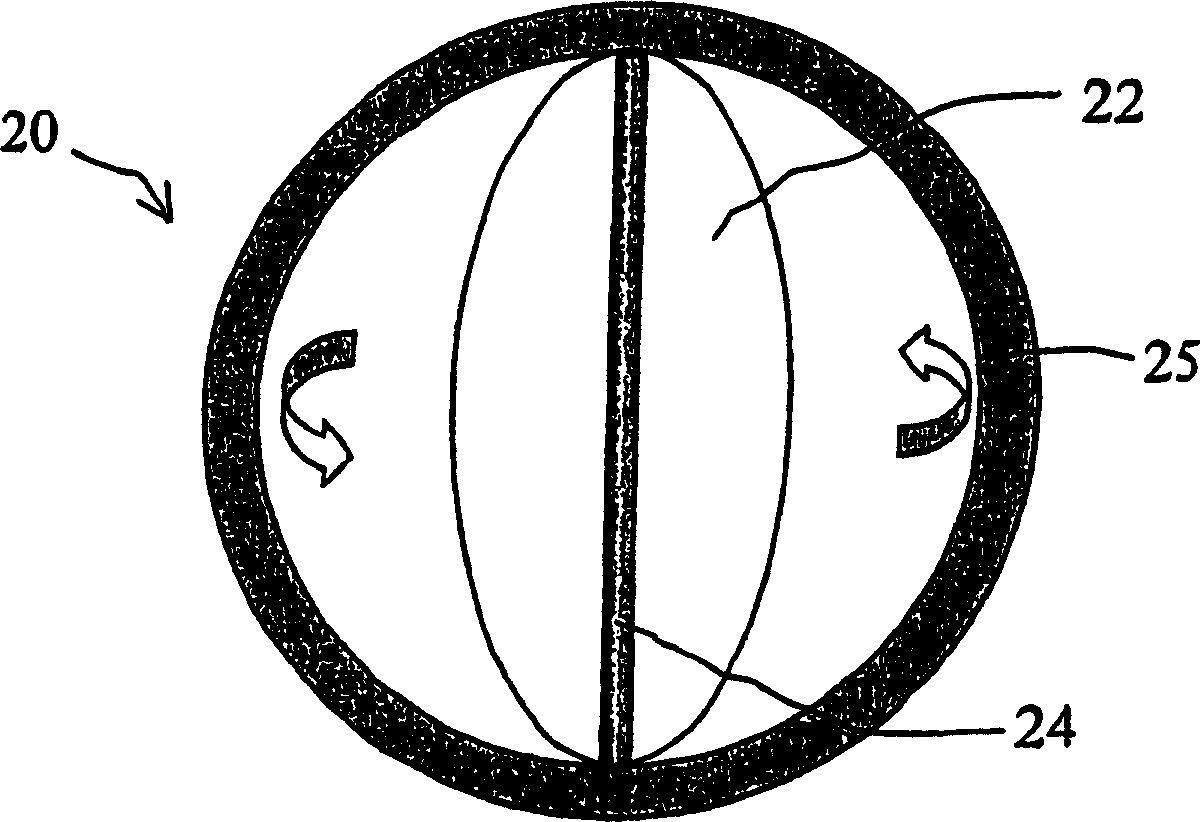

Vapor chamber

InactiveCN103687455ASpeed up circulationPromote circulationCooling/ventilation/heating modificationsEngineeringCopper

The invention discloses a vapor chamber, which comprises a bottom plate and a cover plate, wherein the bottom plate and the cover plate are hermetically connected to construct a hollow enclosed cavity; the bottom plate is provided with a super-hydrophobic surface which is taken as the condensing area of the vapor chamber; the cover plate is provided with a super-hydrophilic surface which is taken as the evaporating area of the vapor chamber; foam copper is buried in the enclosed cavity by pressing; one end of the foam copper is connected with the cover plate, and the other end of the foam copper is connected with the bottom plate, thereby facilitating return of a working medium from the condensing area to the evaporating area. According to the vapor chamber, the heat exchange performance of the evaporating area and the condensing area of the vapor chamber is enhanced, the heat exchange capability of the vapor chamber is enhanced by using circular flow of the working medium in the evaporating area and the condensing area, and the heat exchange limit of the vapor chamber is increased.

Owner:SHANGHAI JIAO TONG UNIV

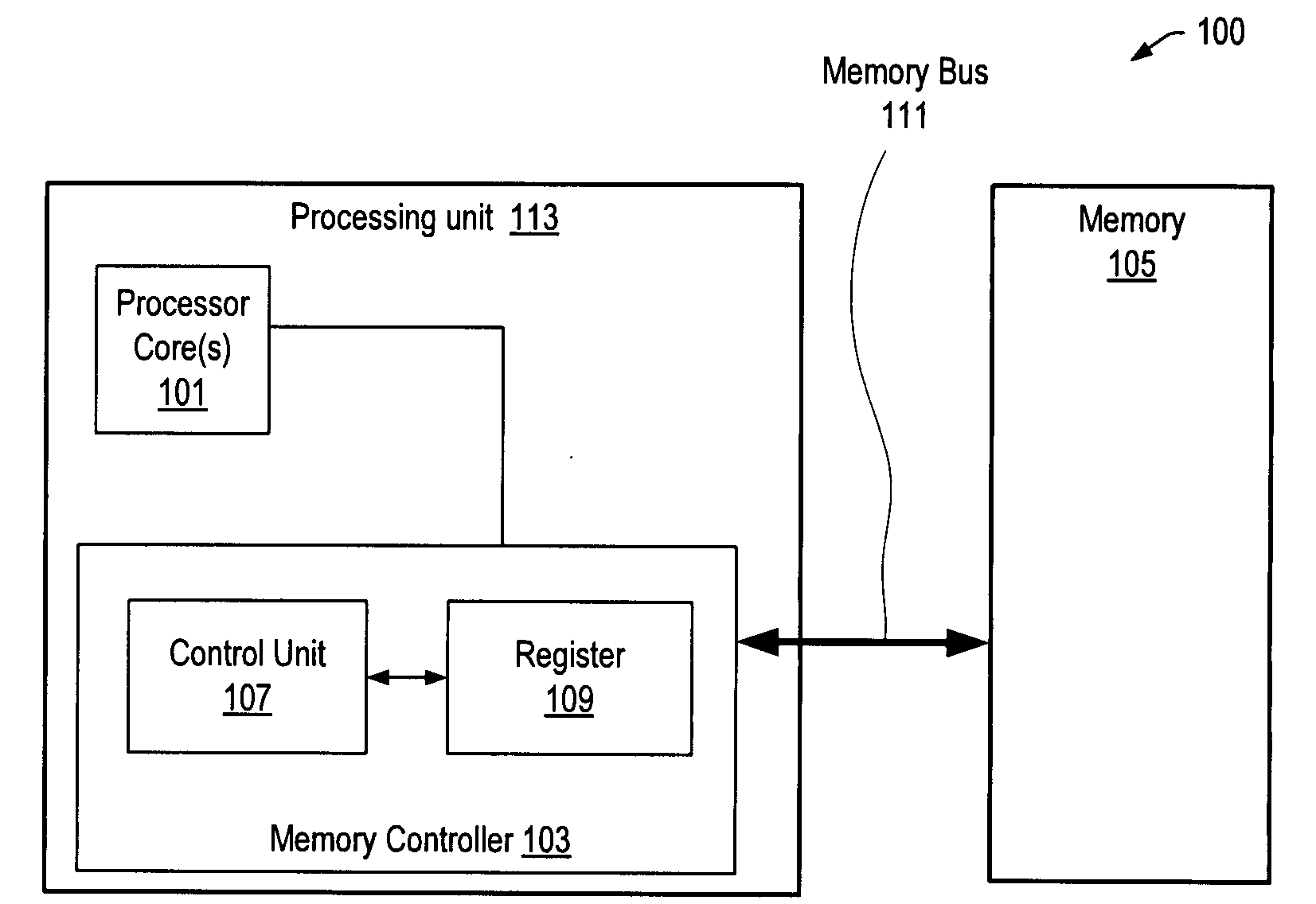

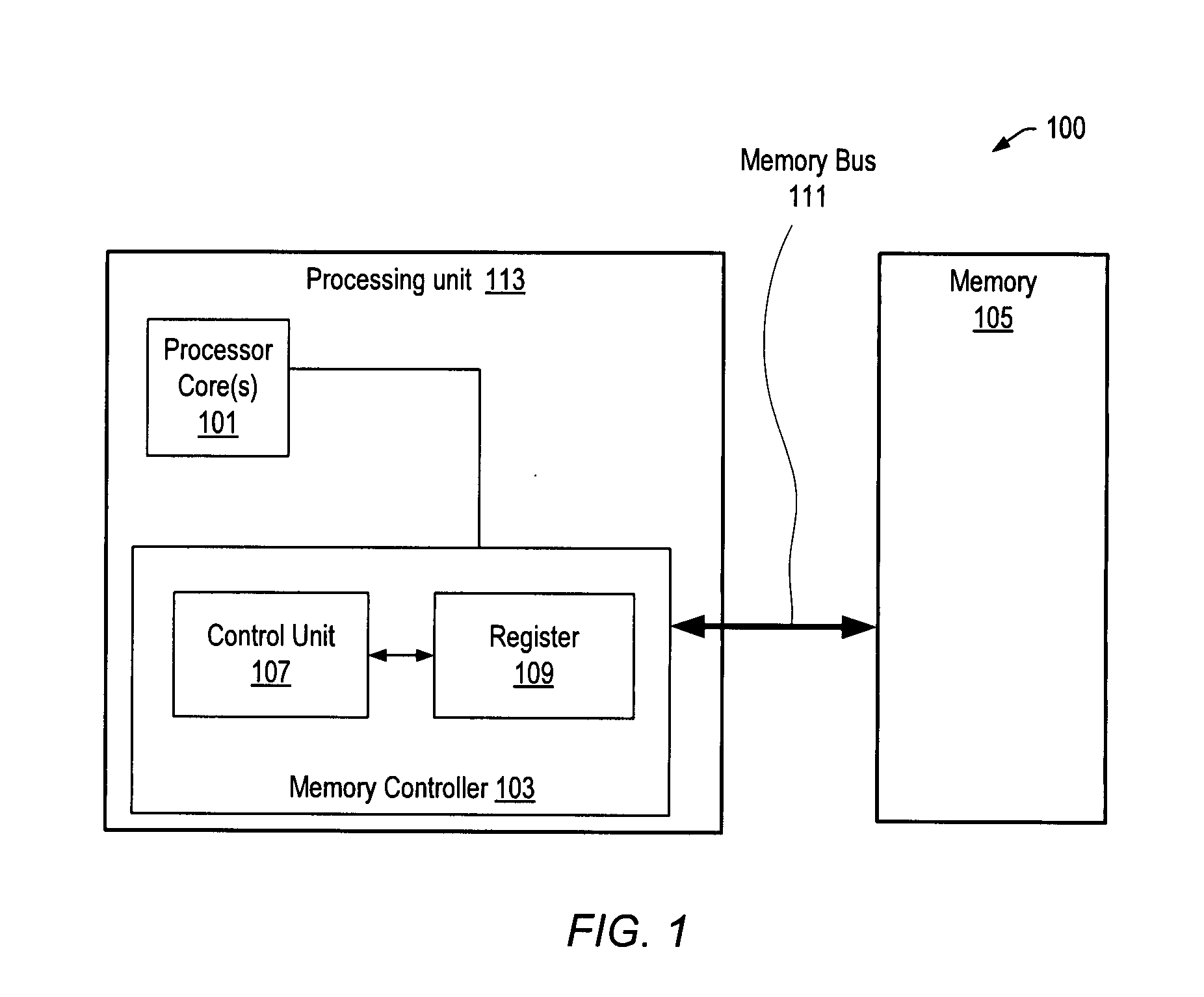

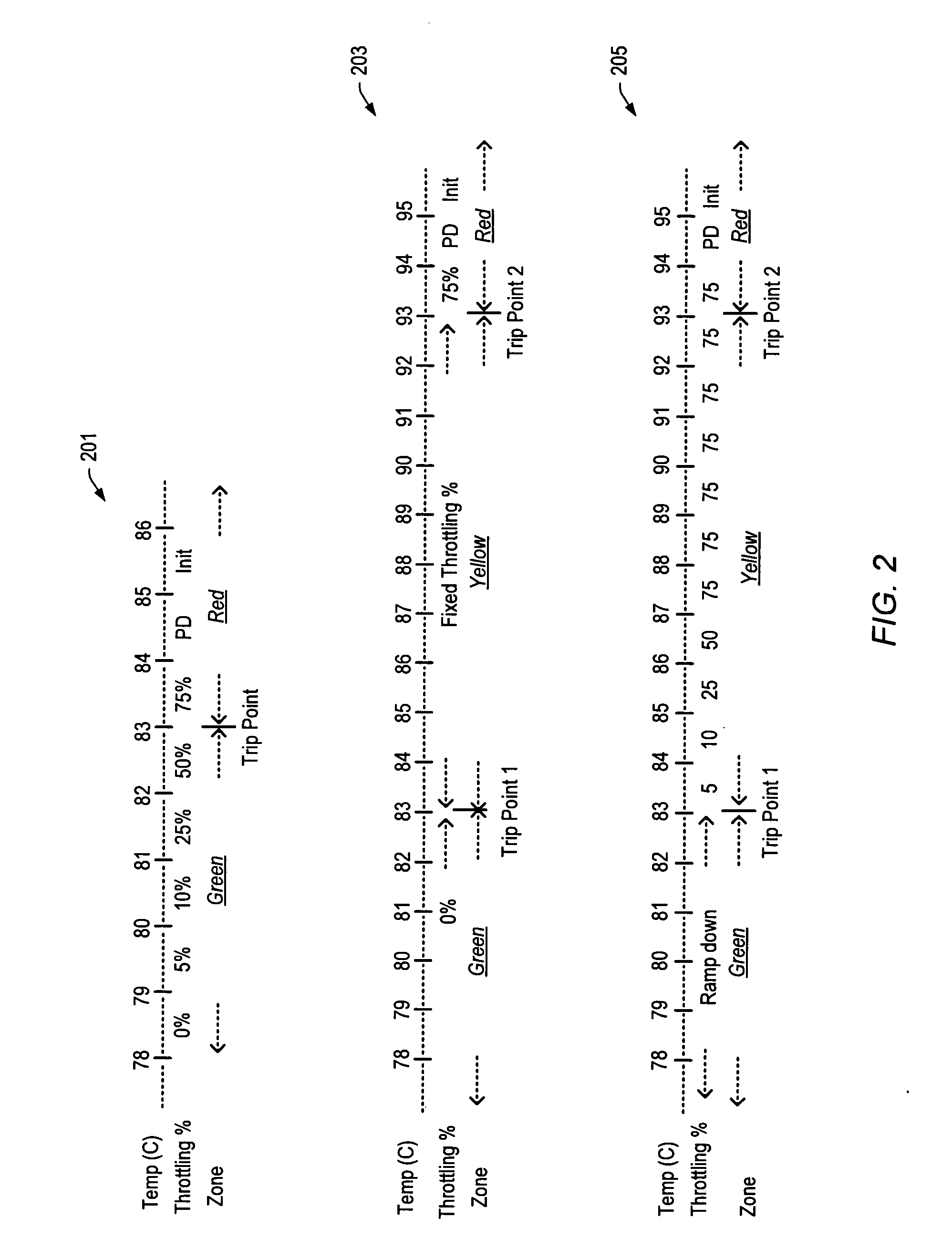

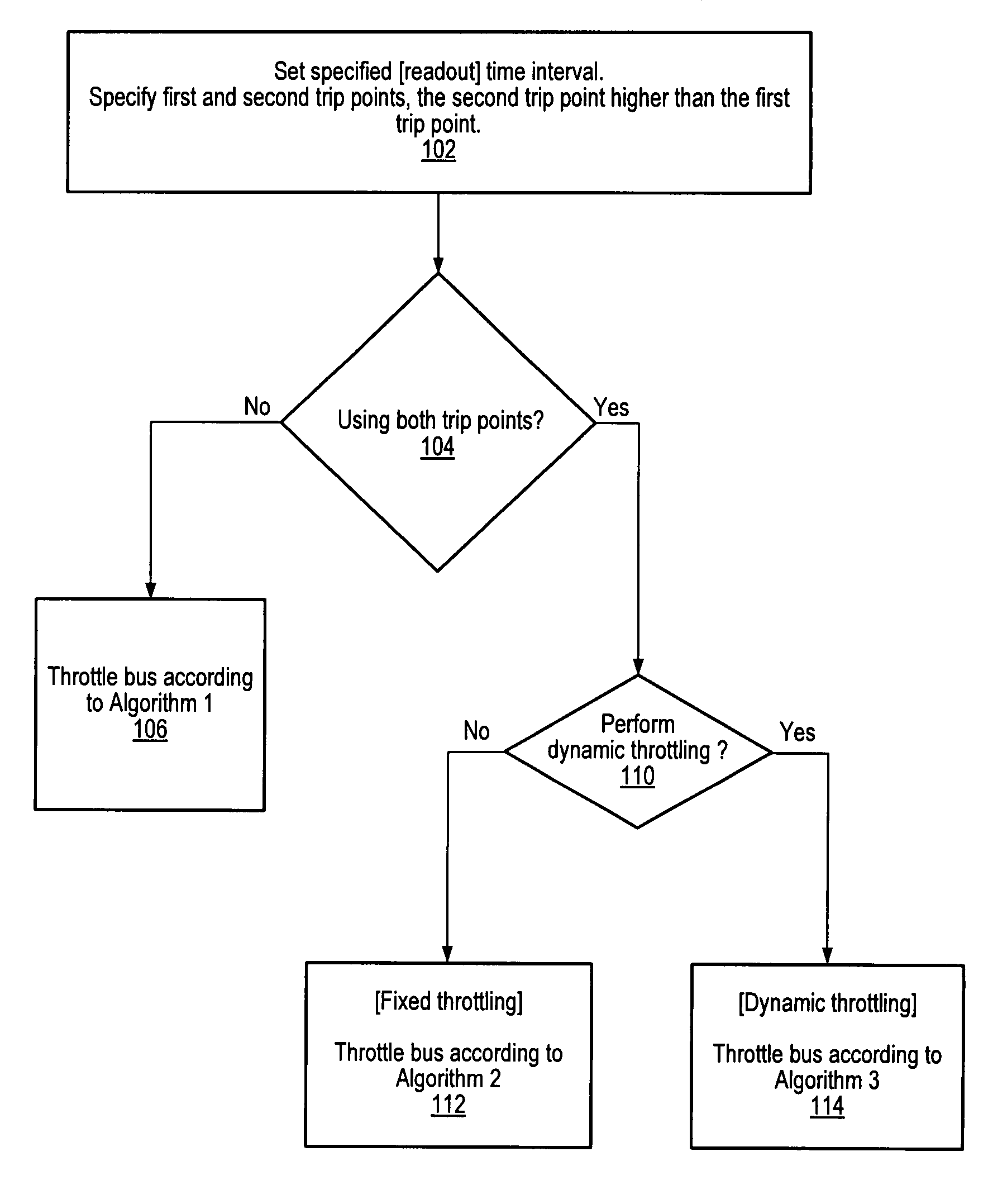

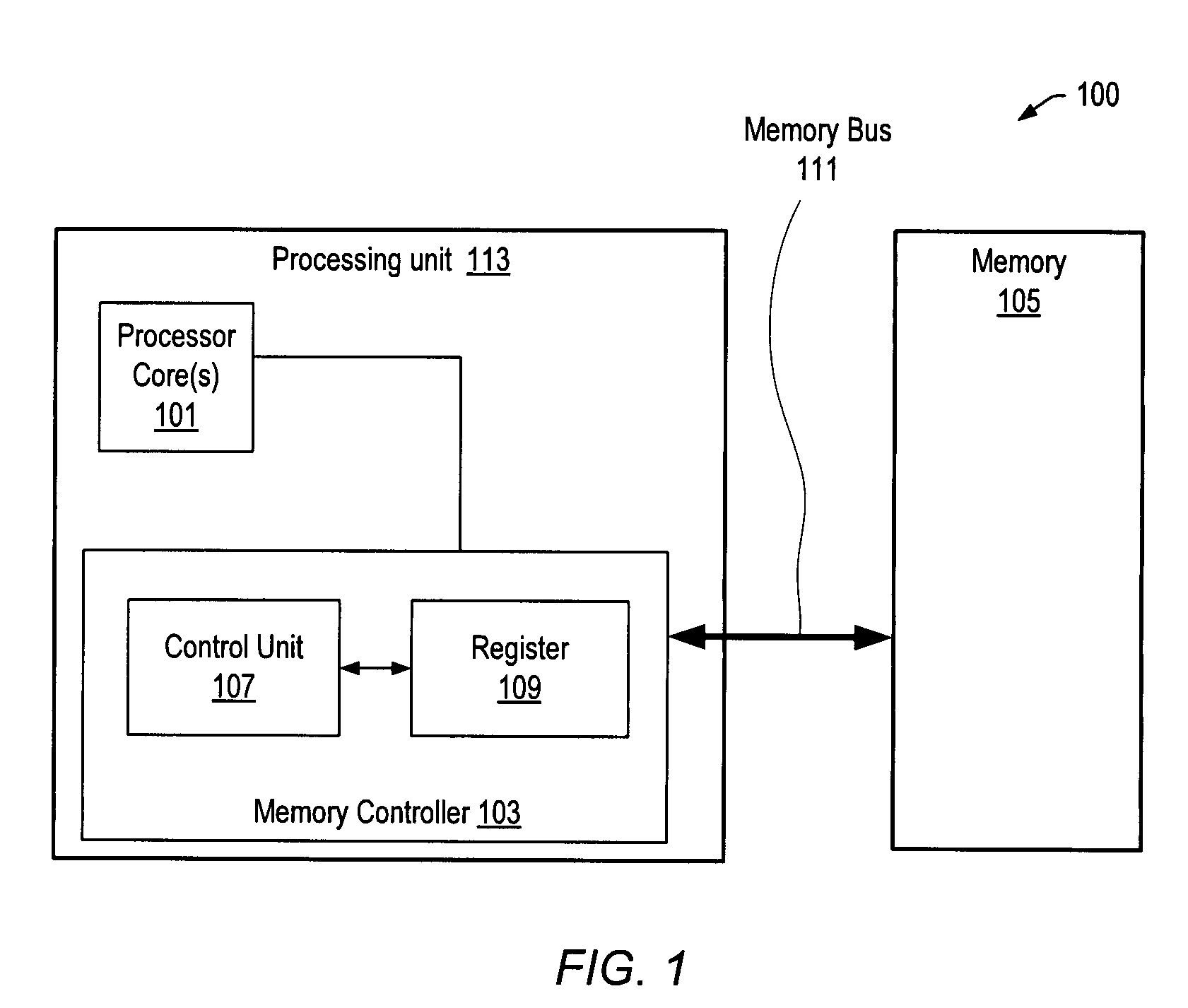

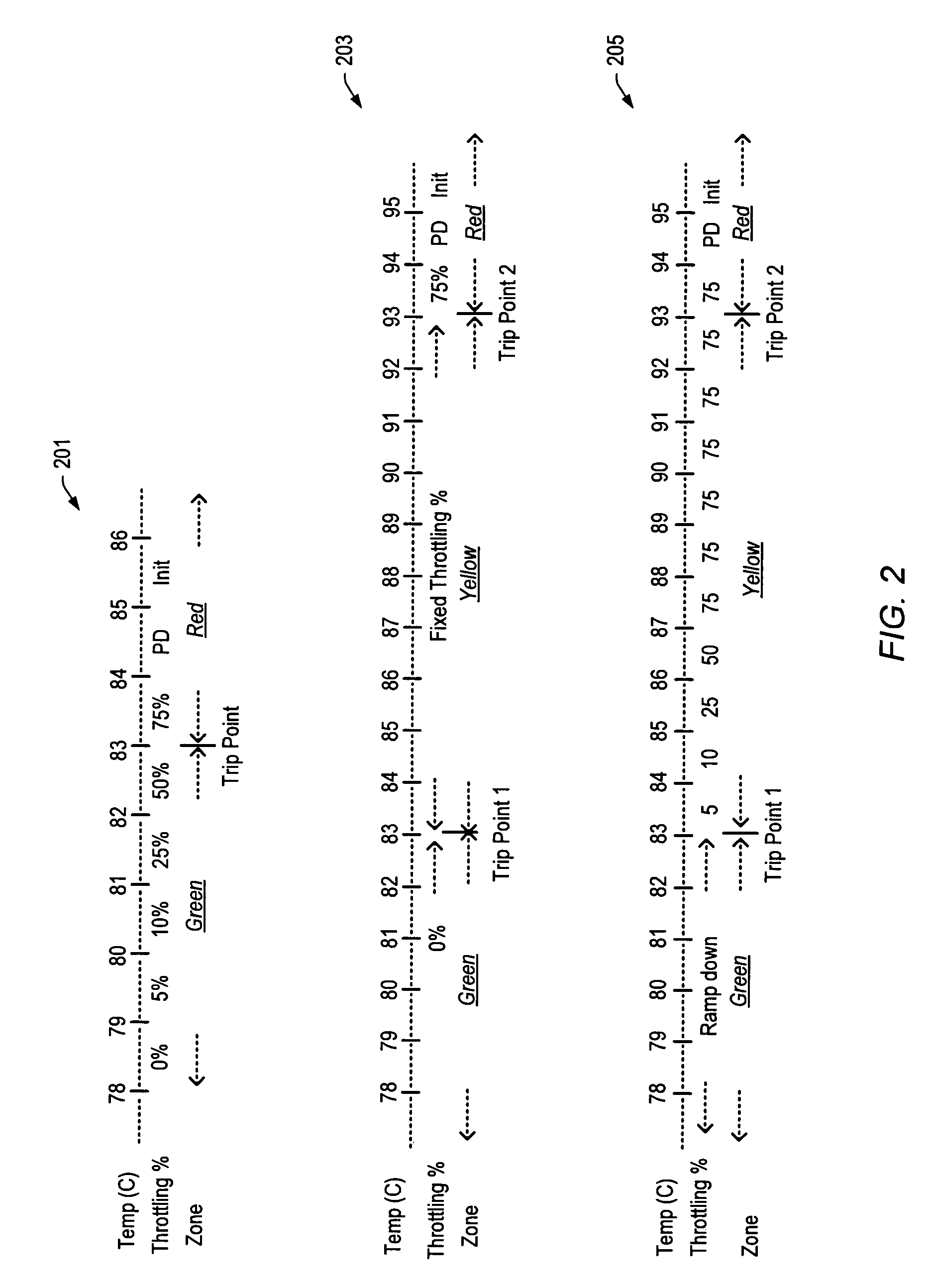

Temperature throttling mechanism for ddr3 memory

ActiveUS20090052266A1Optimal combination of performanceOptimal combination of safetyDigital storageElectric digital data processingThermal limitMemory bus

A method for throttling a bus, e.g. a memory bus, may be used to compensate for potential inaccuracy of feedback information received for monitored characteristics, e.g. temperature, reported by sensors configured in monitored devices, e.g. memory devices, accessed through the bus. For example, in case of a memory bus, a memory controller may be configured to throttle the memory bus in a way that maximizes system performance while ensuring that the memory devices keep operating within their thermal limits. Readings obtained from the memory, or from close proximity to the memory, may indicate whether the temperature of the memory has crossed over one or more designated trip points, and one or more algorithms may be executed to perform throttling according to the readings and based on fixed and dynamic throttling modes. The memory controller may infer temperature changes taking place in the memory devices when successive readings are indicating that the temperature of the memory device has remained over a given trip point. Based on these inferences, the memory controller may then change the manner in which the bus is throttled.

Owner:ADVANCED MICRO DEVICES INC

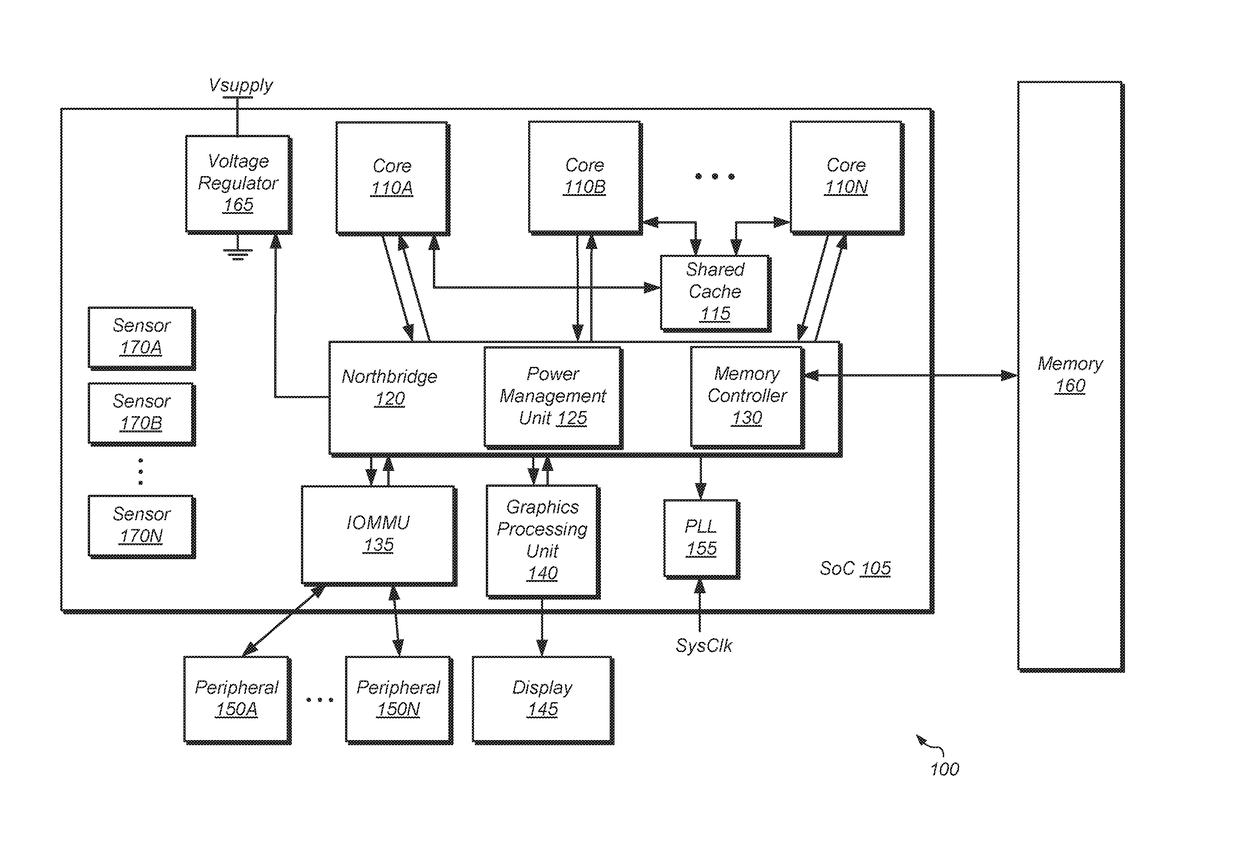

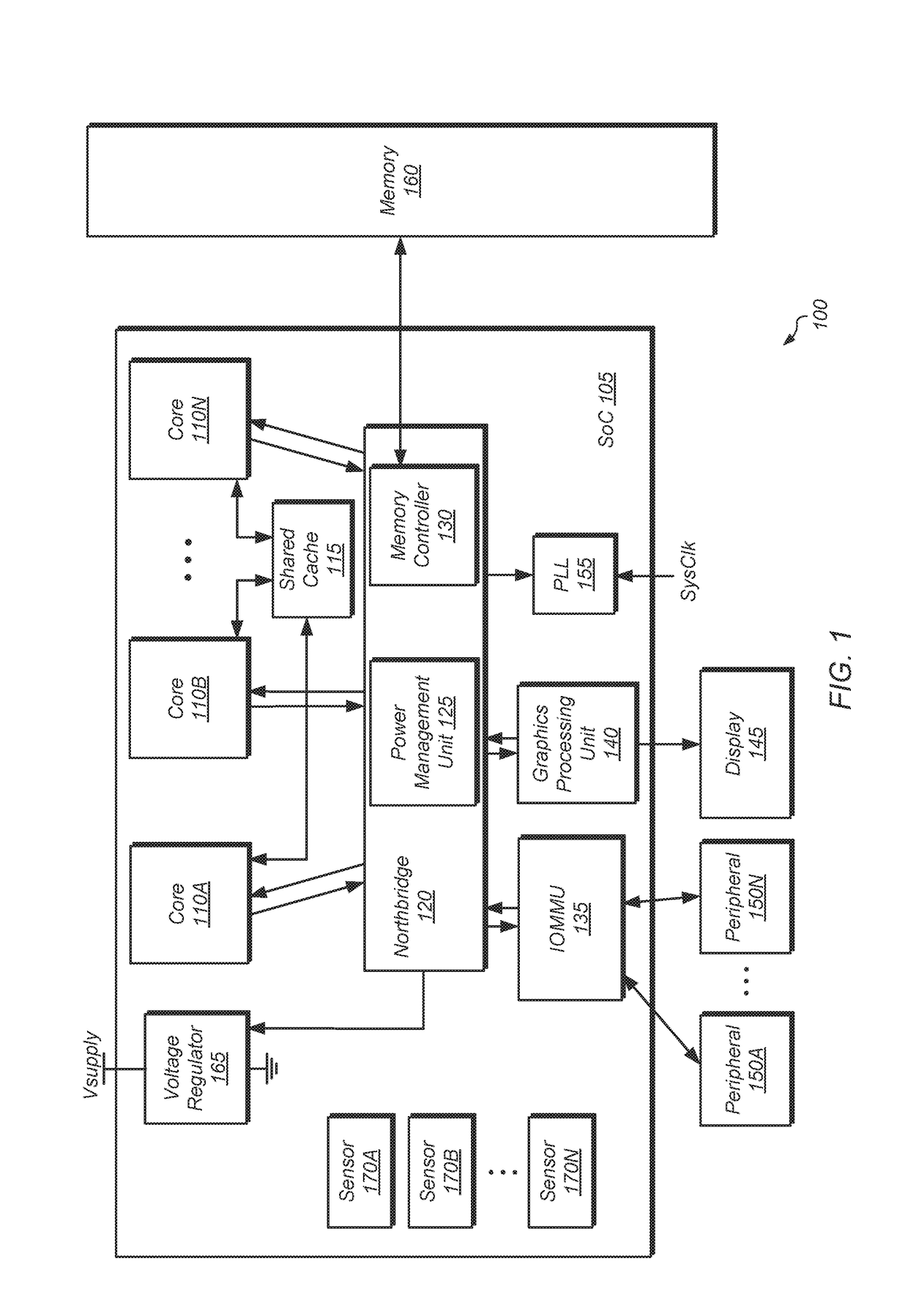

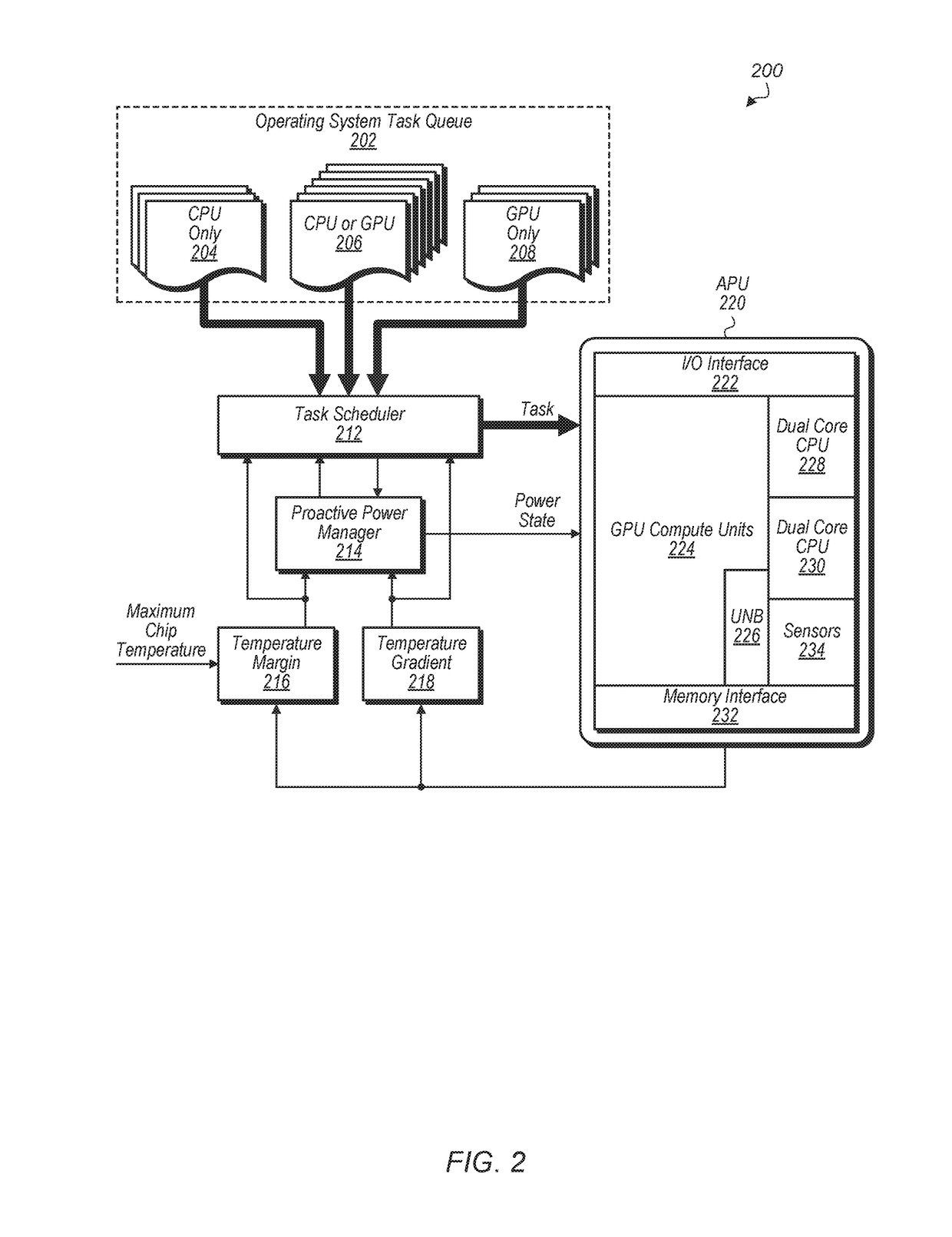

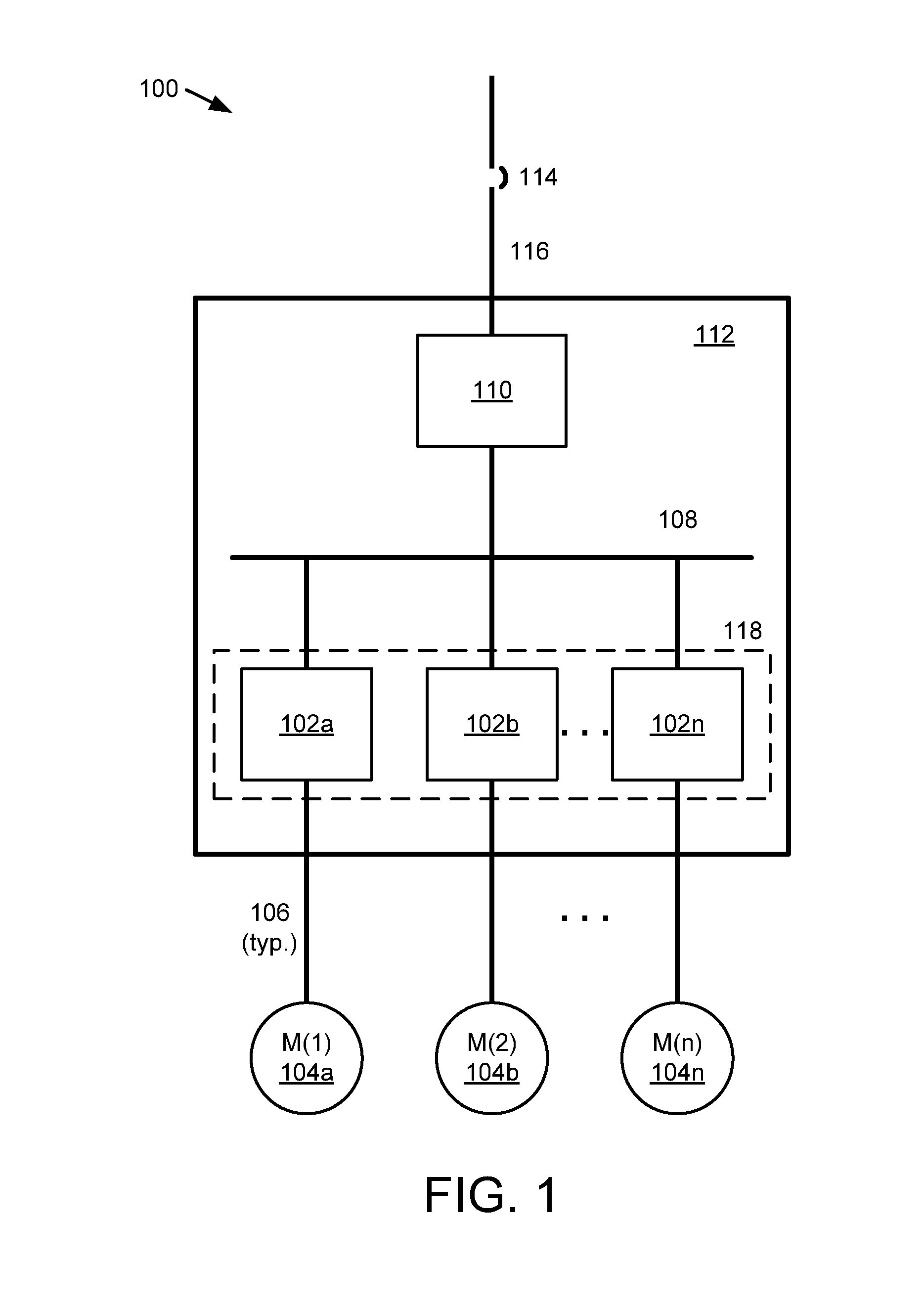

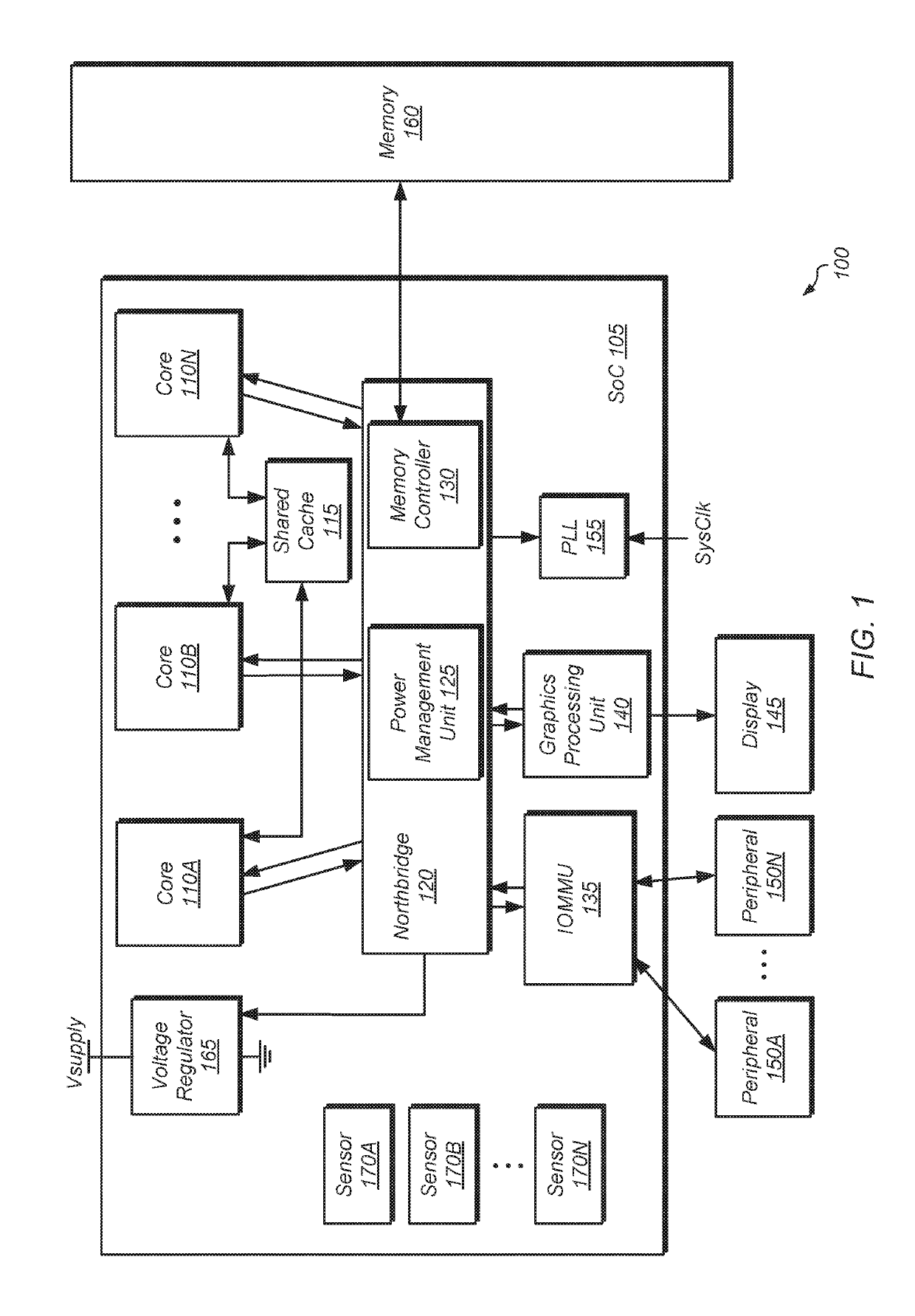

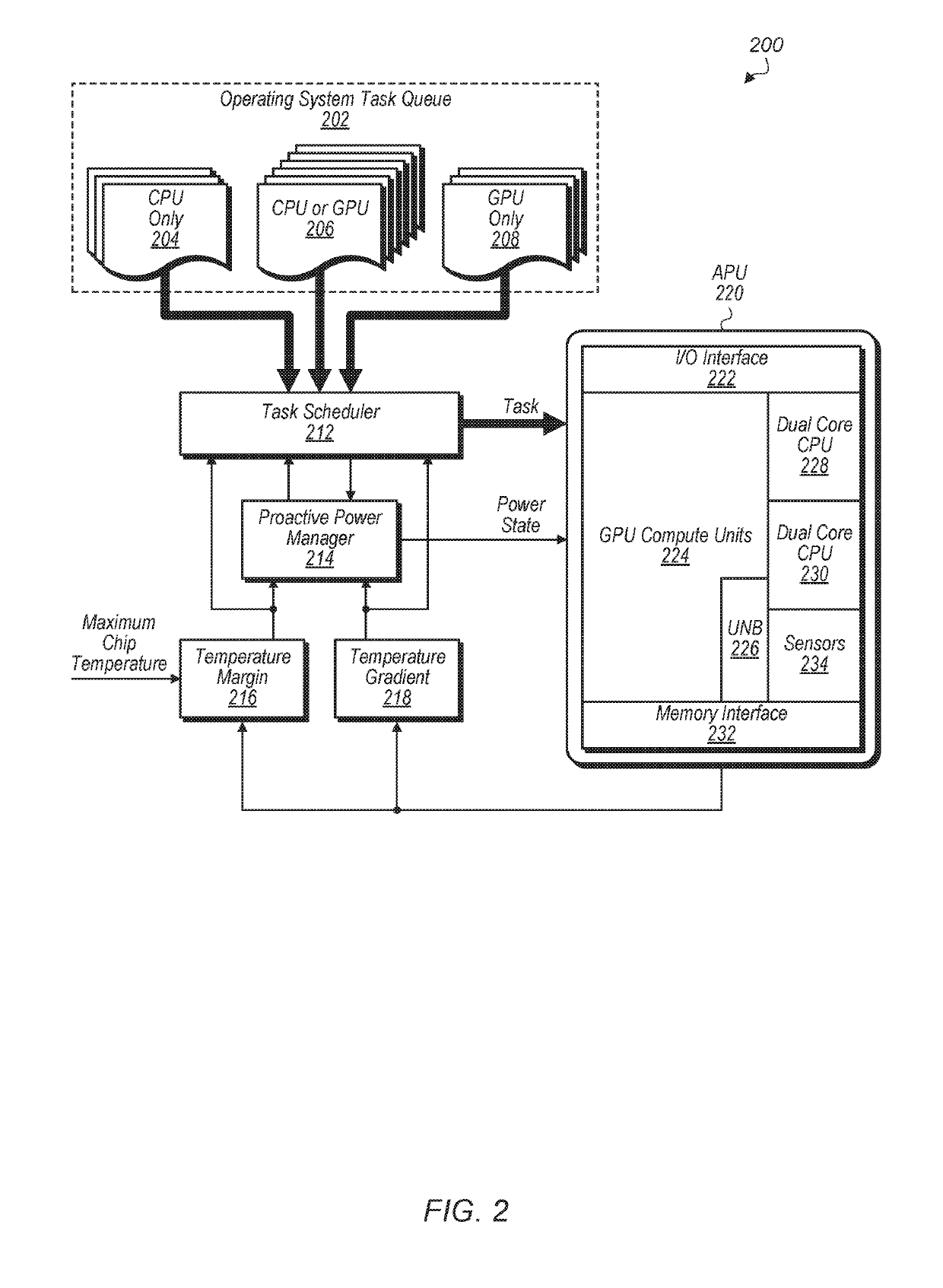

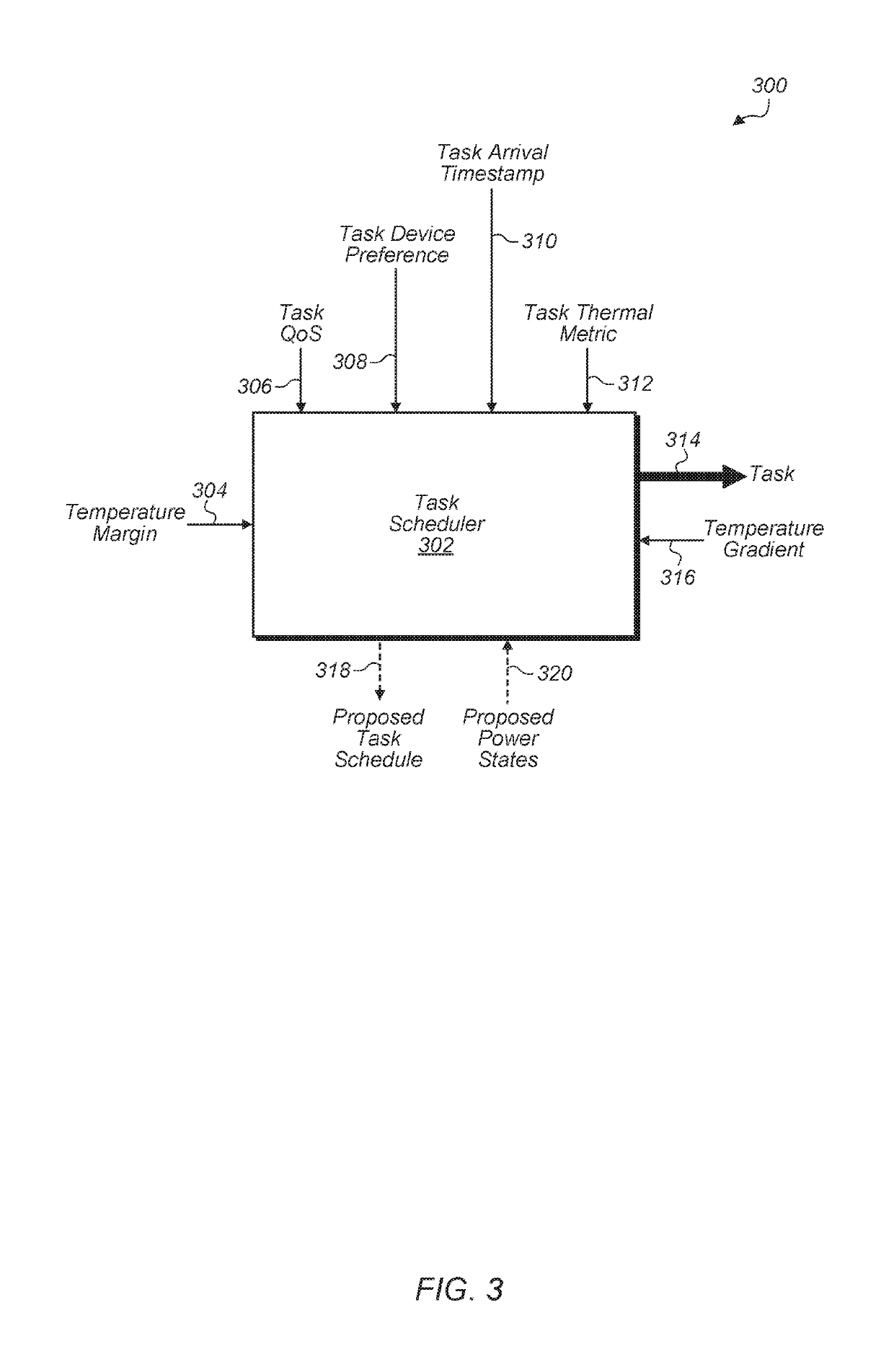

Temperature-aware task scheduling and proactive power management

ActiveUS20170371719A1Resource allocationPower supply for data processingThermal limitParallel computing

Systems, apparatuses, and methods for performing temperature-aware task scheduling and proactive power management. A SoC includes a plurality of processing units and a task queue storing pending tasks. The SoC calculates a thermal metric for each pending task to predict an amount of heat the pending task will generate. The SoC also determines a thermal gradient for each processing unit to predict a rate at which the processing unit's temperature will change when executing a task. The SoC also monitors a thermal margin of how far each processing unit is from reaching its thermal limit. The SoC minimizes non-uniform heat generation on the SoC by scheduling pending tasks from the task queue to the processing units based on the thermal metrics for the pending tasks, the thermal gradients of each processing unit, and the thermal margin available on each processing unit.

Owner:ADVANCED MICRO DEVICES INC

Water heating control and storage system

ActiveUS8498527B2Reduce operating costsReduce the temperatureTemperatue controlHeat storage plantsThermal limitThermostat

A water heating control and storage system, including an insulated tank for containing water to be heated. The tank has at least two heating elements, including an upper heating element and a lower heating element. An operation control device receives a demand response signal and enables each element to independently heat water for usage. A method for controlling a water heating storage system includes providing an insulated tank for containing water to be heated; providing an upper heating element with a thermostat and thermal limiting device and a lower heating element with a thermostat and thermal limiting device to heat upper and lower portions of water inside the tank; and providing a pair of switches for enabling each of the heating elements to independently heat upper and lower portions of the water for usage.

Owner:HAIER US APPLIANCE SOLUTIONS INC

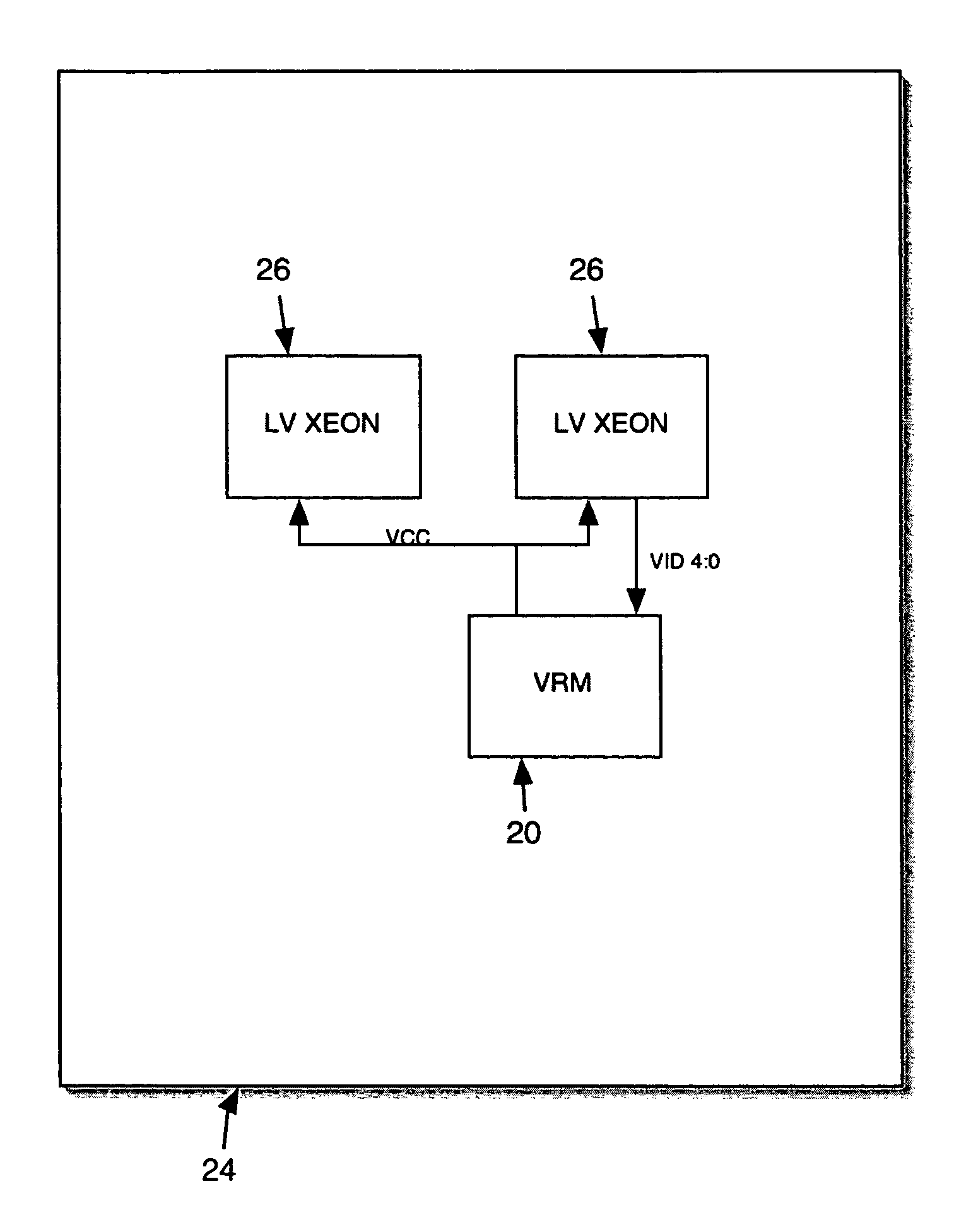

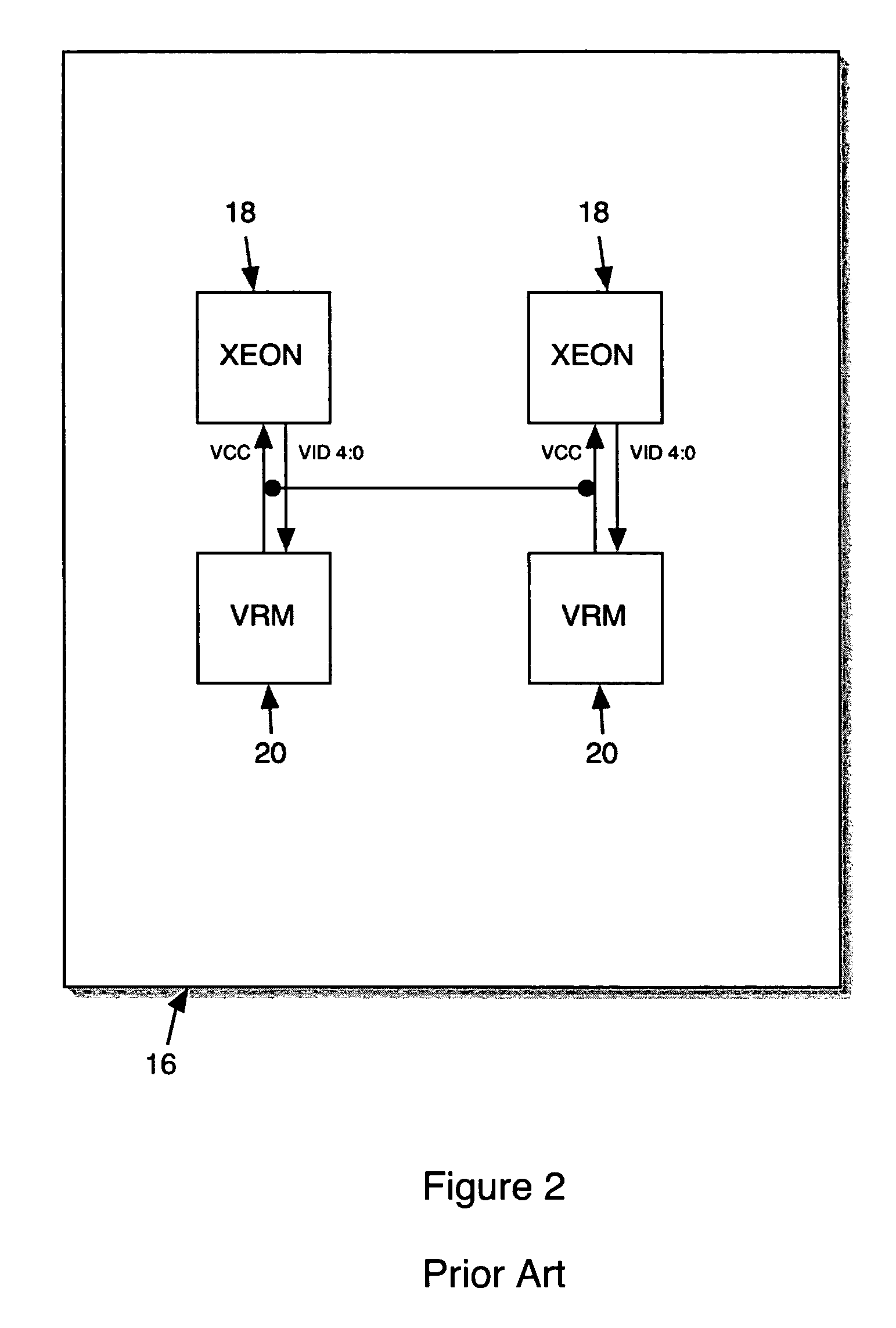

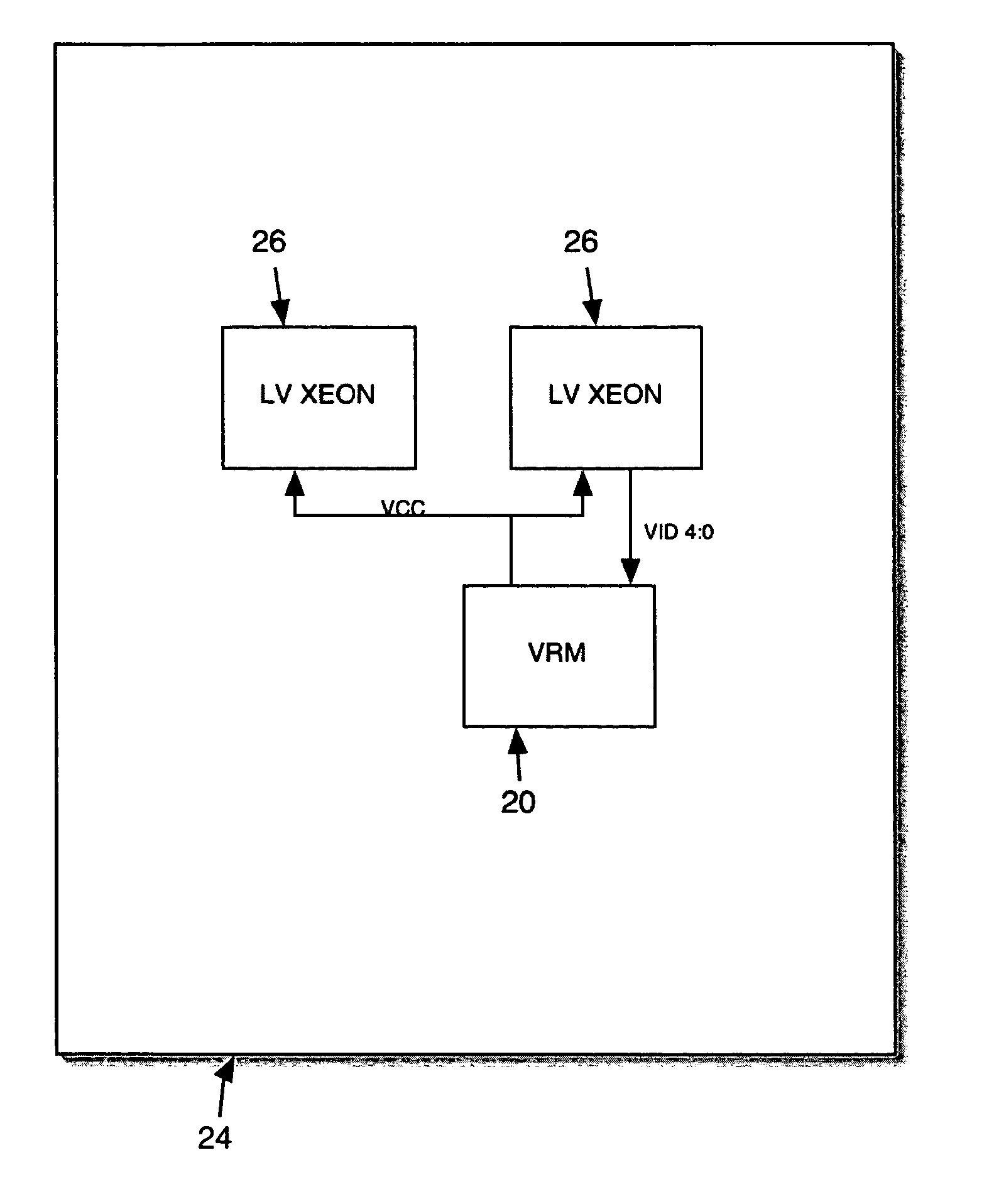

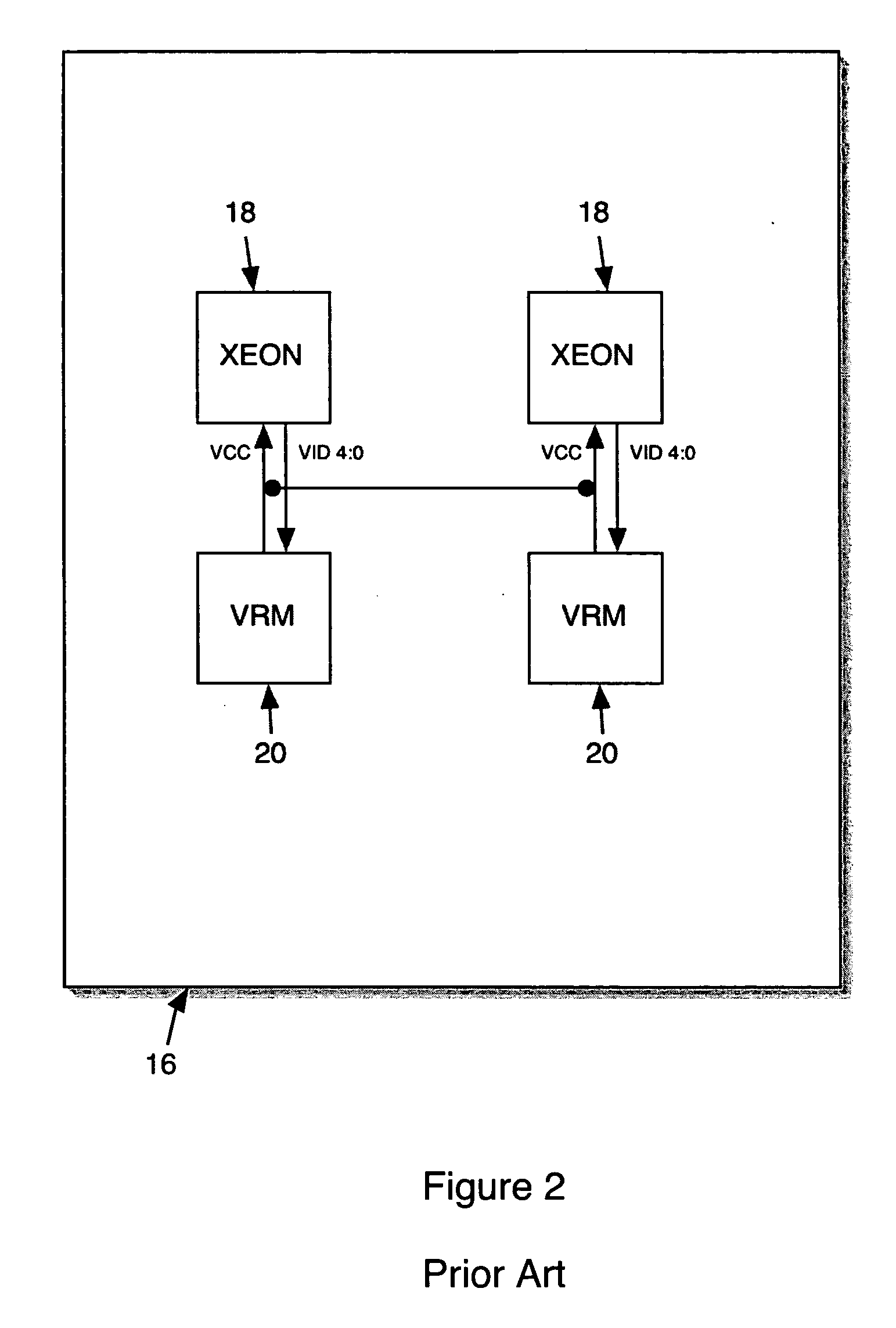

Use of one voltage regulator module to support two processors to improve power and thermal limitations

ActiveUS7293181B2Volume/mass flow measurementPower supply for data processingVoltage regulator moduleThermal limit

Several processors have specifications setting forth that each processor be coupled to a separate specified voltage regulator circuit. Instead, a number of specified voltage regulator circuit(s) is coupled to the several processors. The number of voltage regulator circuit(s) is less than the number of processors. The processors and voltage regulator circuit(s) are coupled to a module, and a thermal limit for the module is maintained because the several processors are coupled to the smaller number of voltage regulator circuits.

Owner:EMC IP HLDG CO LLC

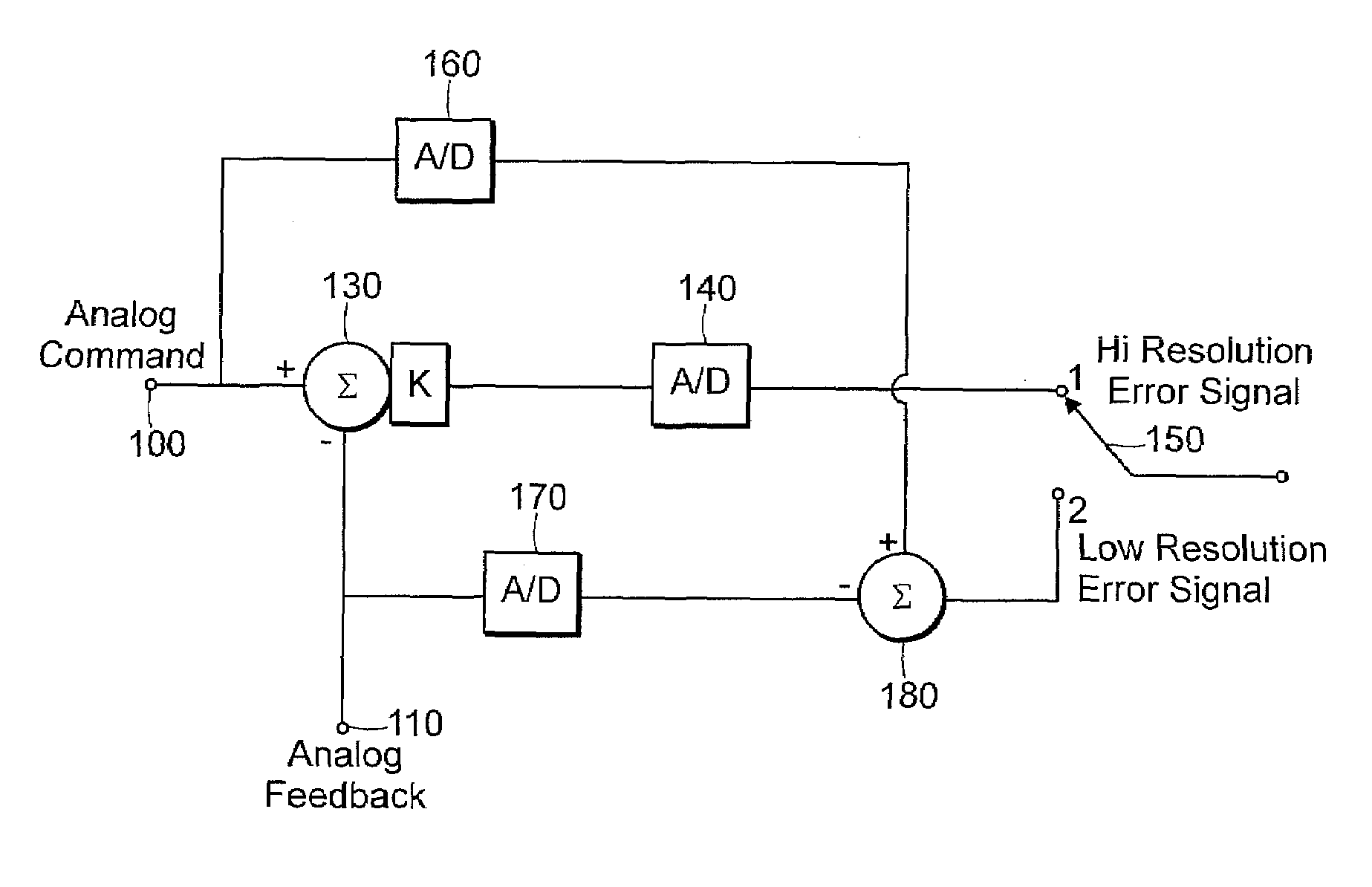

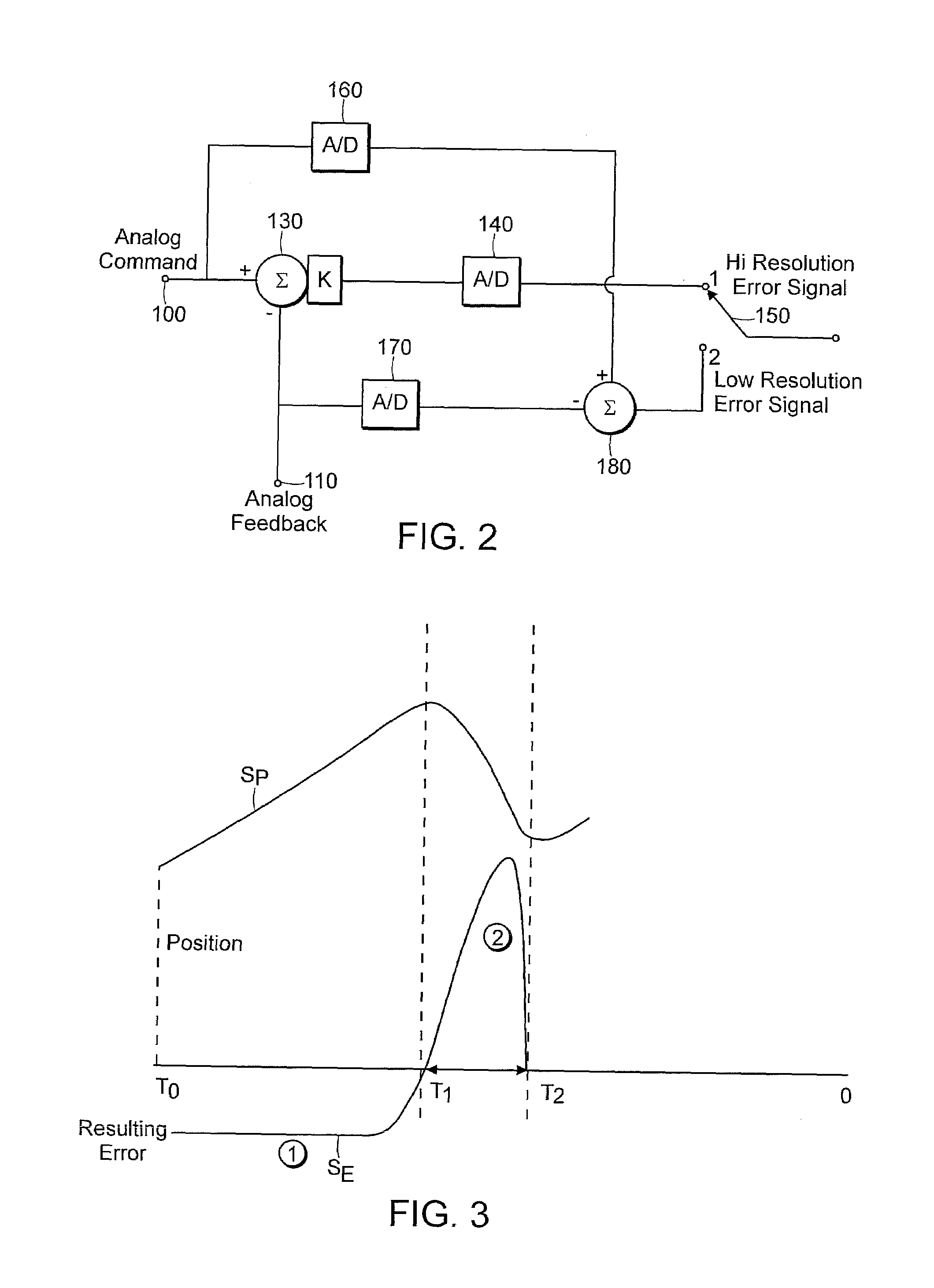

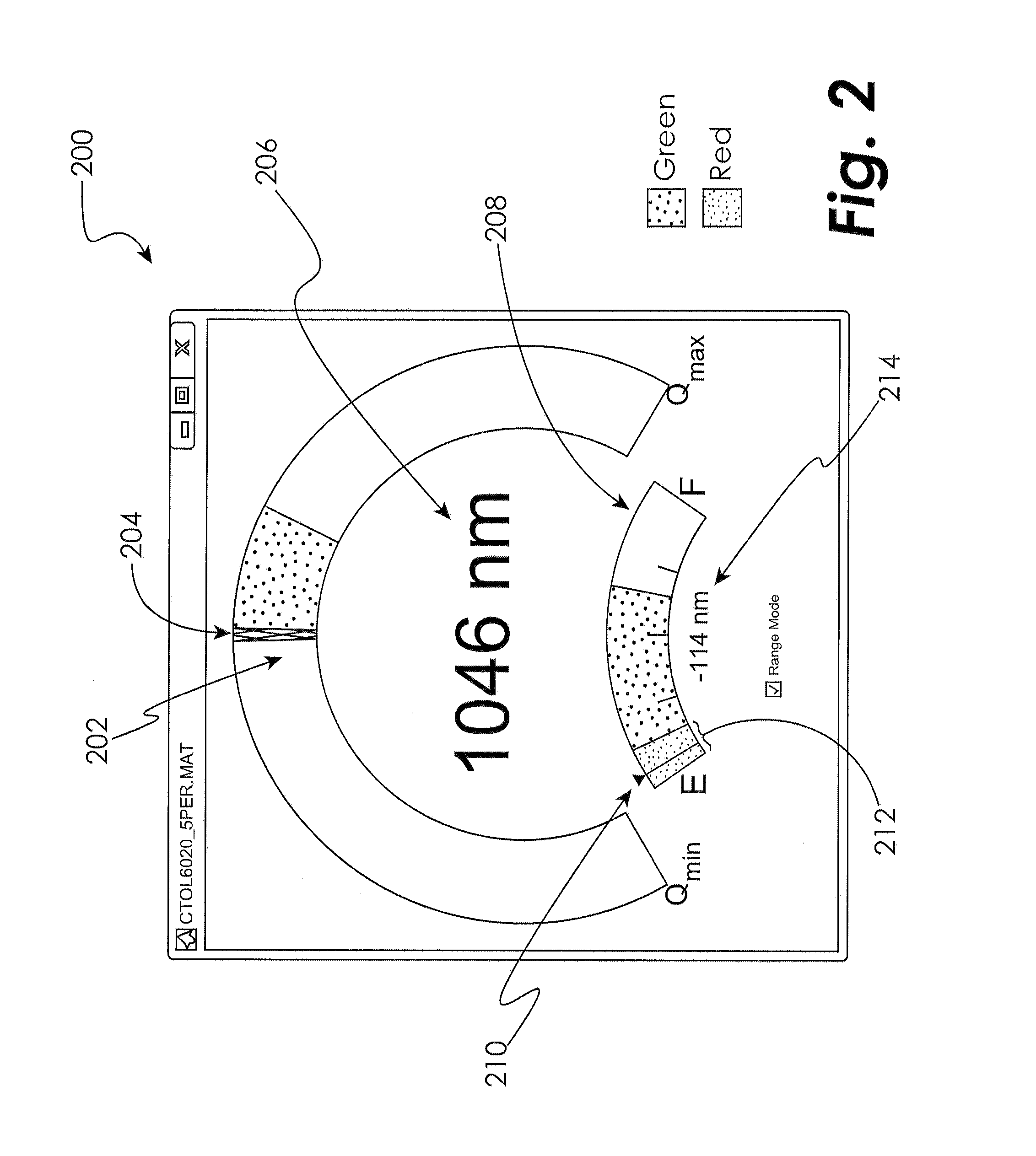

Digital control servo system

InactiveUS7200464B2Great effective resolution and dynamic rangeGreat effective rangeComputer controlSimulator controlDigital signal processingDirect effects

An improved servo system for galvanometers, scanners and similar devices which uses digital processing to increase the dynamic range and provide greater effective resolution. The system provides digital control of a reference point that directly influences the excitation, which in turn directly influences the gain of the circuit. A high and low resolution switching path is provided to optimize dynamic range. Wide angle torque compensation improves uniformity of response at large angular deflections from zero. Improved thermal protection allows safe operation near system thermal limits. A graphical user interface allows adjustments and changes response on the fly for tuning due to input conditions or user control.

Owner:GSI LUMONICS CORP +1

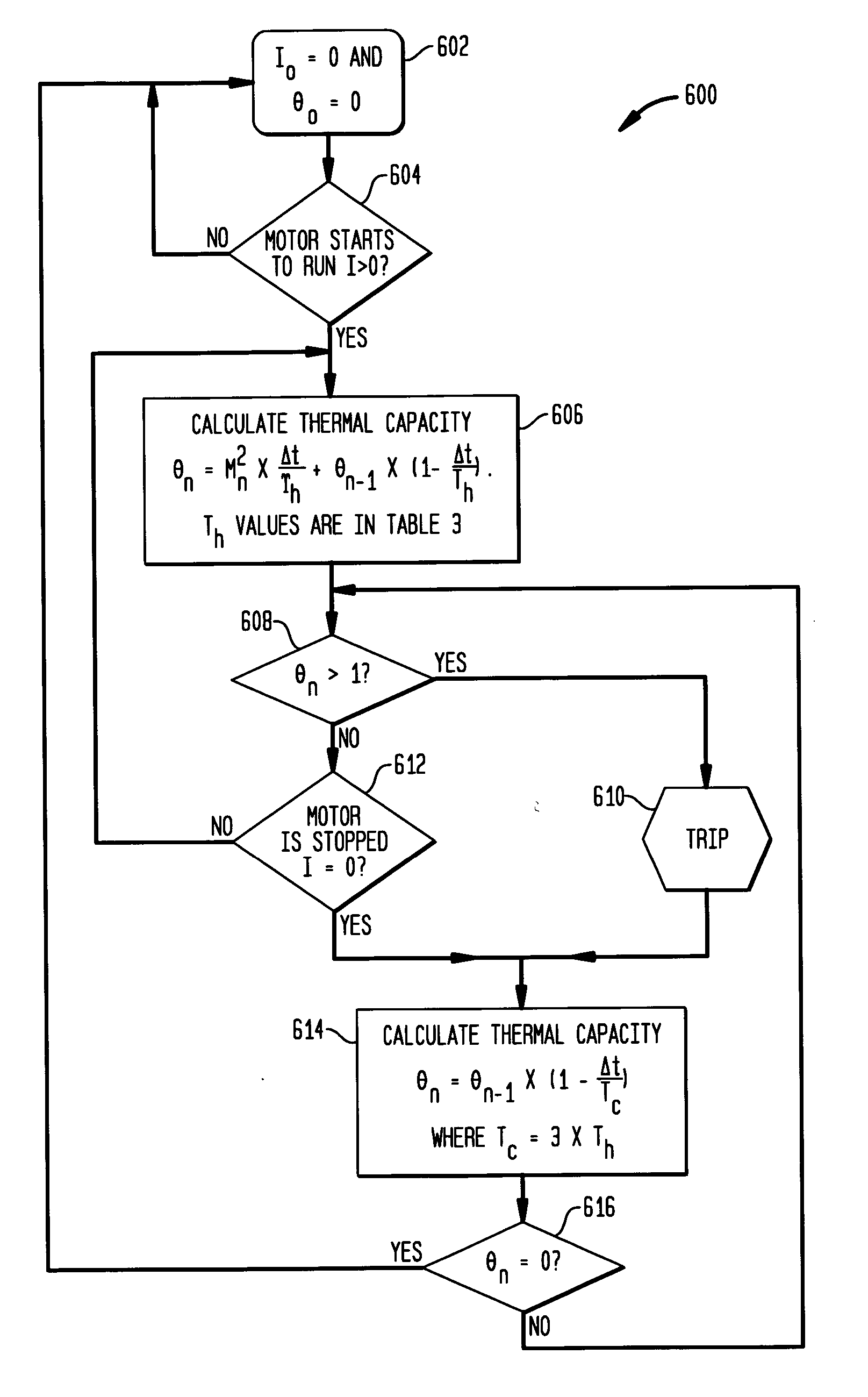

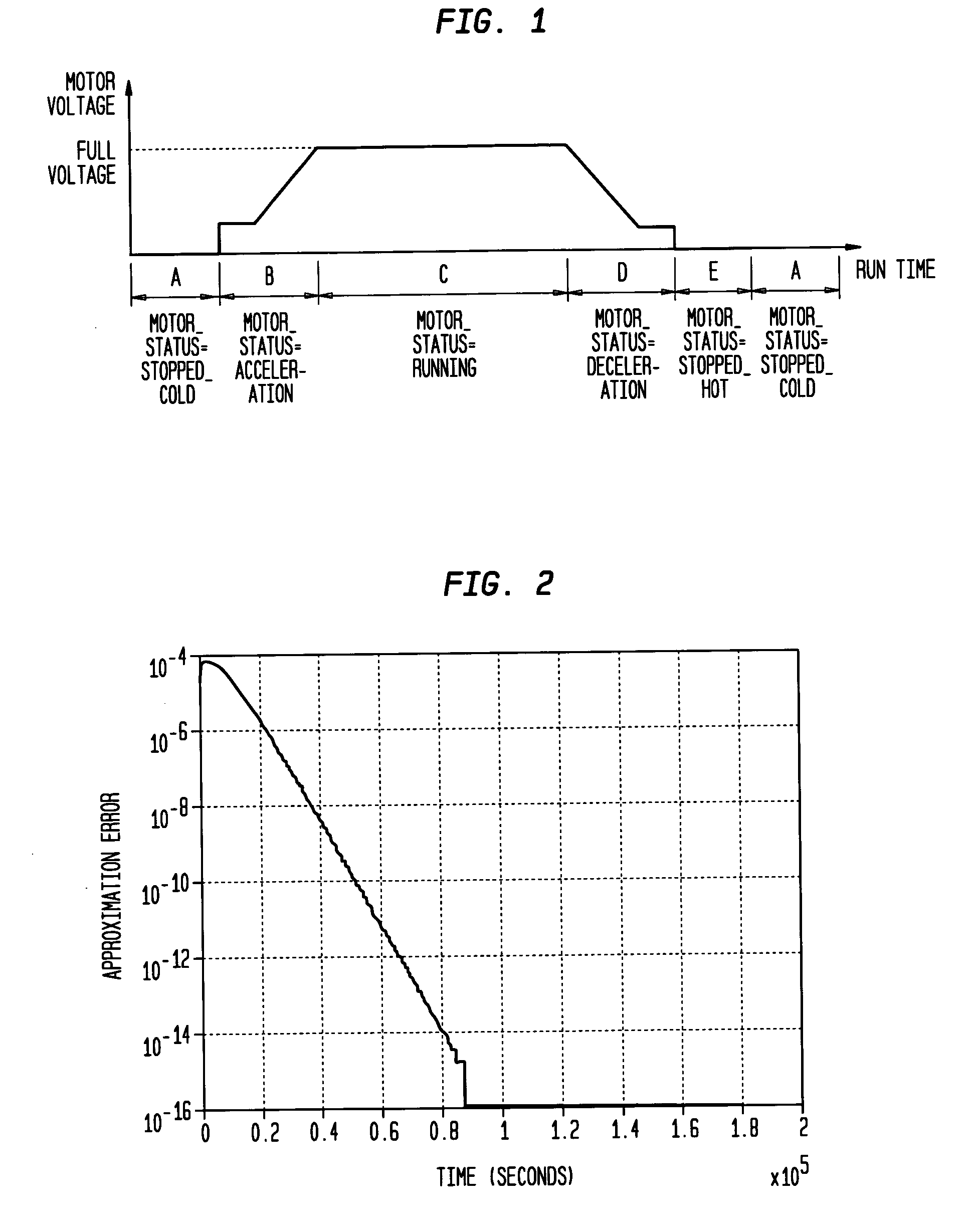

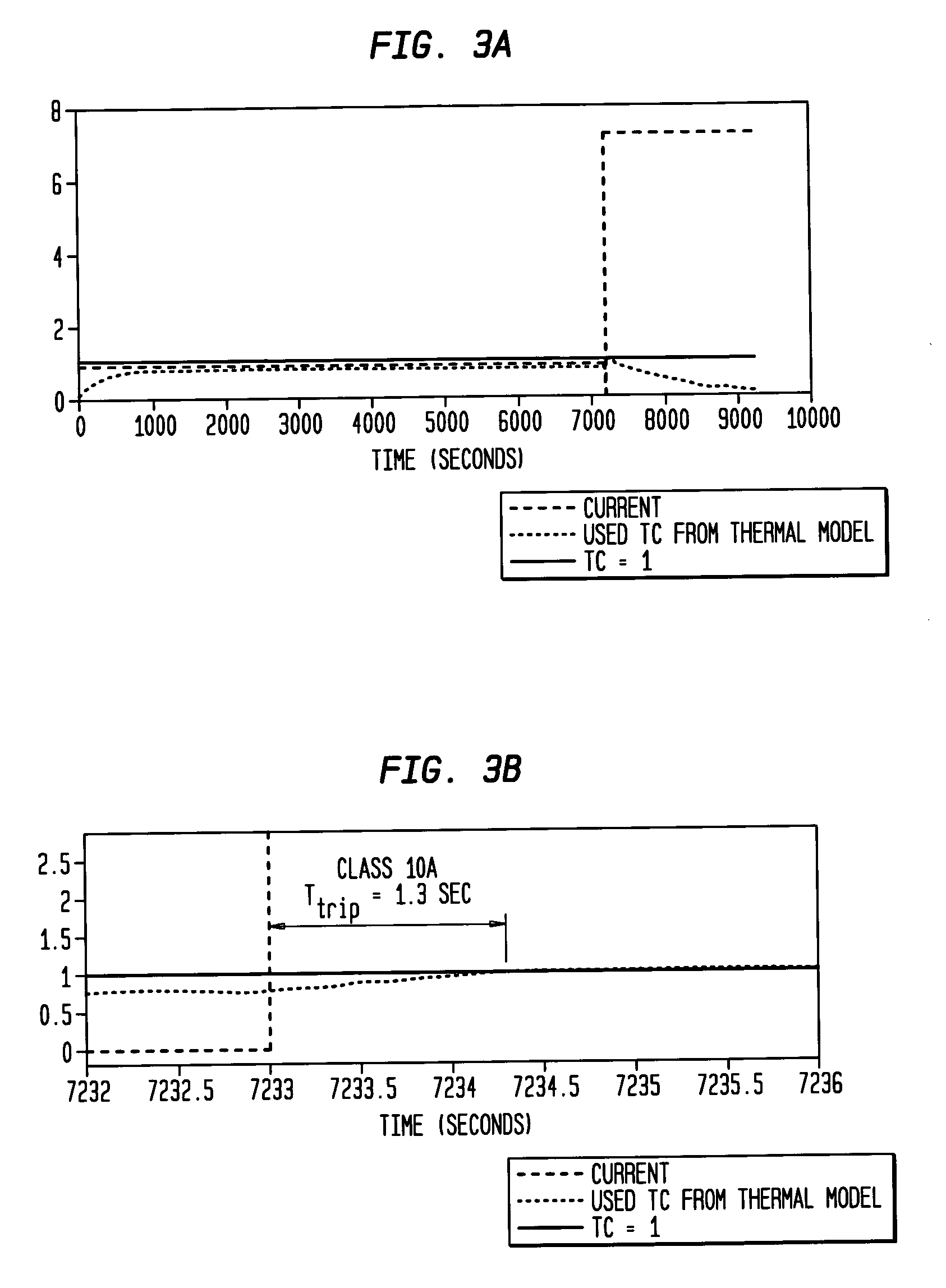

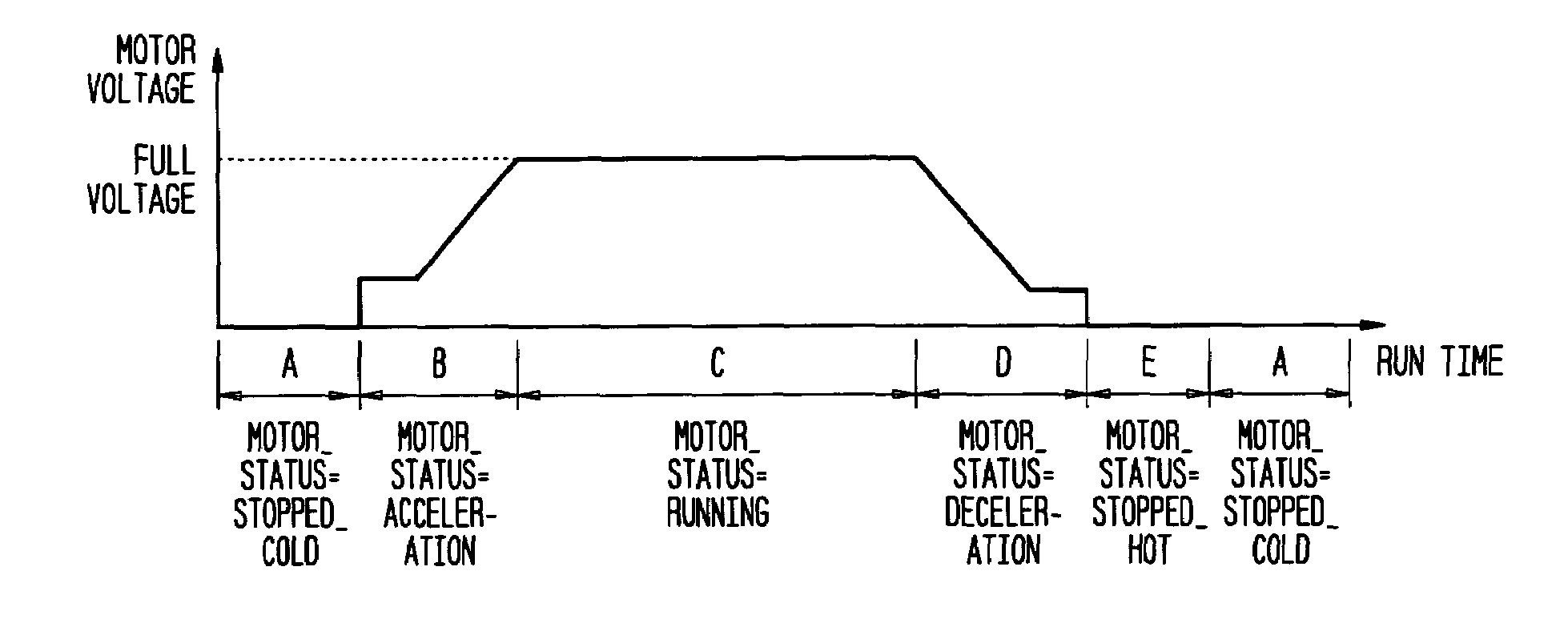

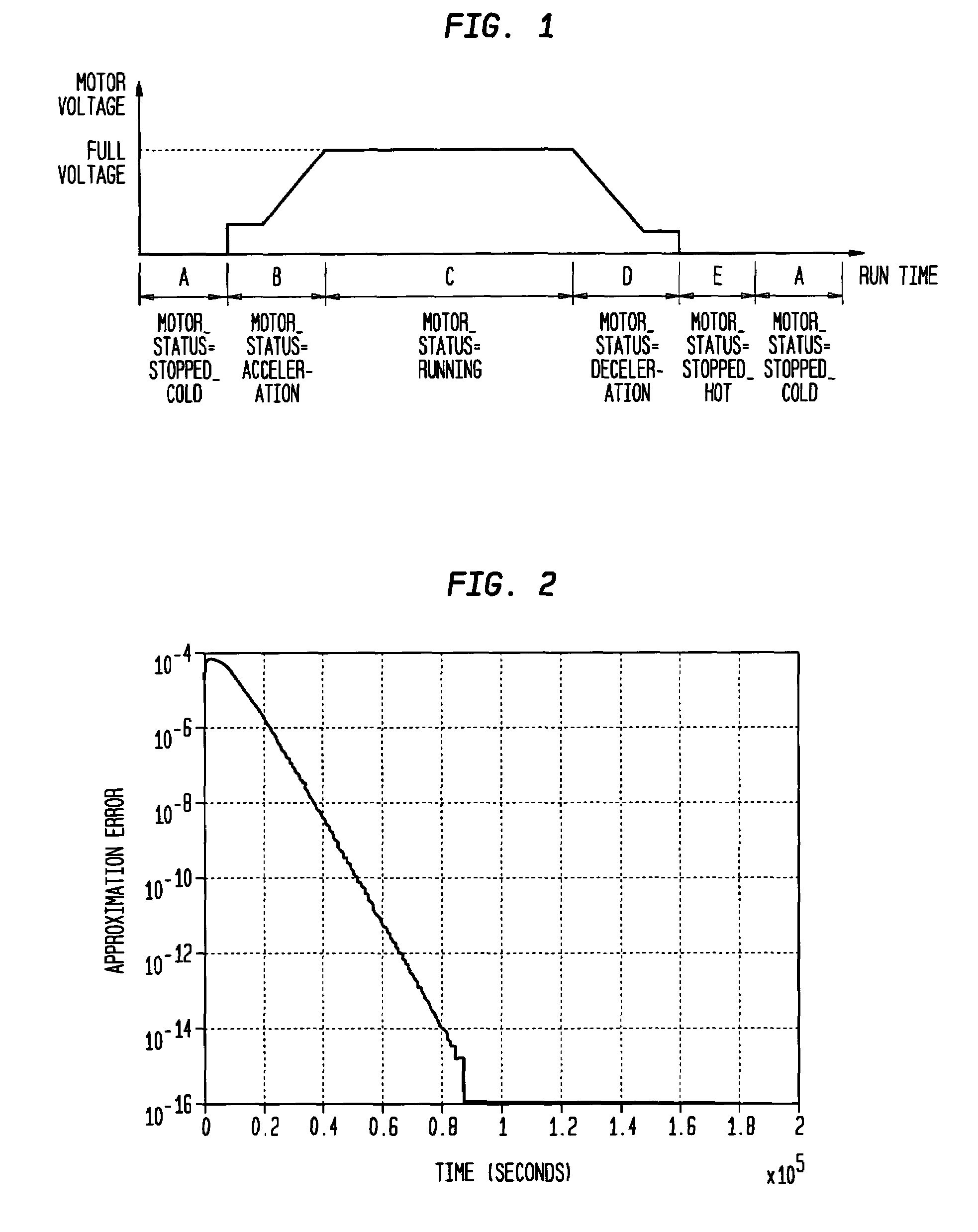

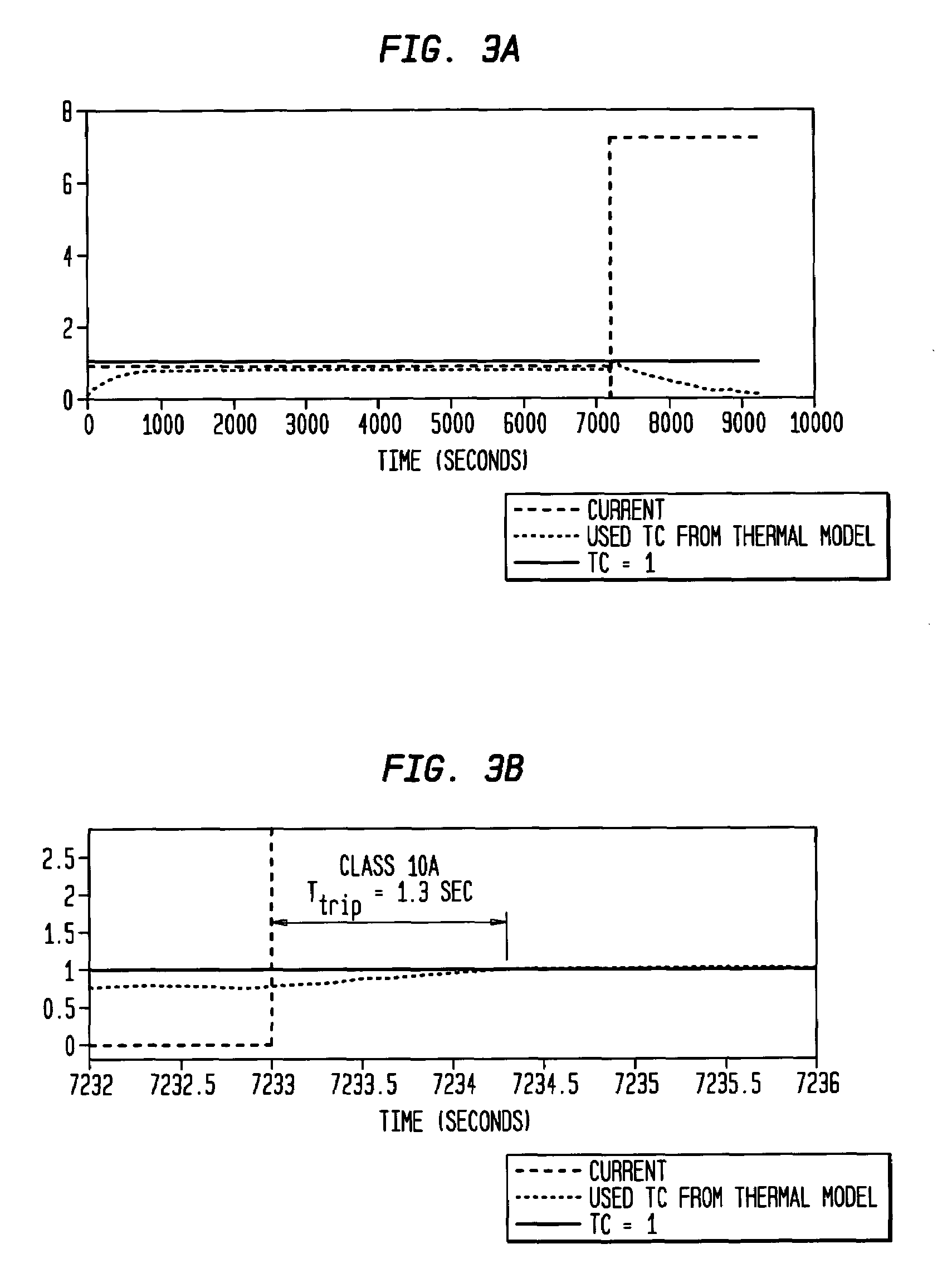

System, device, and method for over-current relays protecting motors

InactiveUS20070103822A1Prevent the motor from overheatingDC motor speed/torque controlAsynchronous induction motorsThermal limitInduction motor

A system, method, and device for protecting an induction motor are disclosed. The exemplary system may have a module for determining the current drawn by the motor and a module for determining the state of the motor. The system may calculate a used thermal capacity based on a first formula when the motor is in an active state. The system also calculates the used thermal capacity based on a second formula when the motor is in an inactive state. When the used thermal capacity attains a threshold, the relay is tripped thus removing current to the motor and preventing motor from overheating. A method to derive thermal time constants from desired trip time limits (such as those defined by IEC standards or the thermal limit curves provided by motor manufacturers) is also presented. For example, the thermal time constants can then be used in tacking motor used thermal capacity throughout various motor states.

Owner:SIEMENS ENERGY & AUTOMATION INC

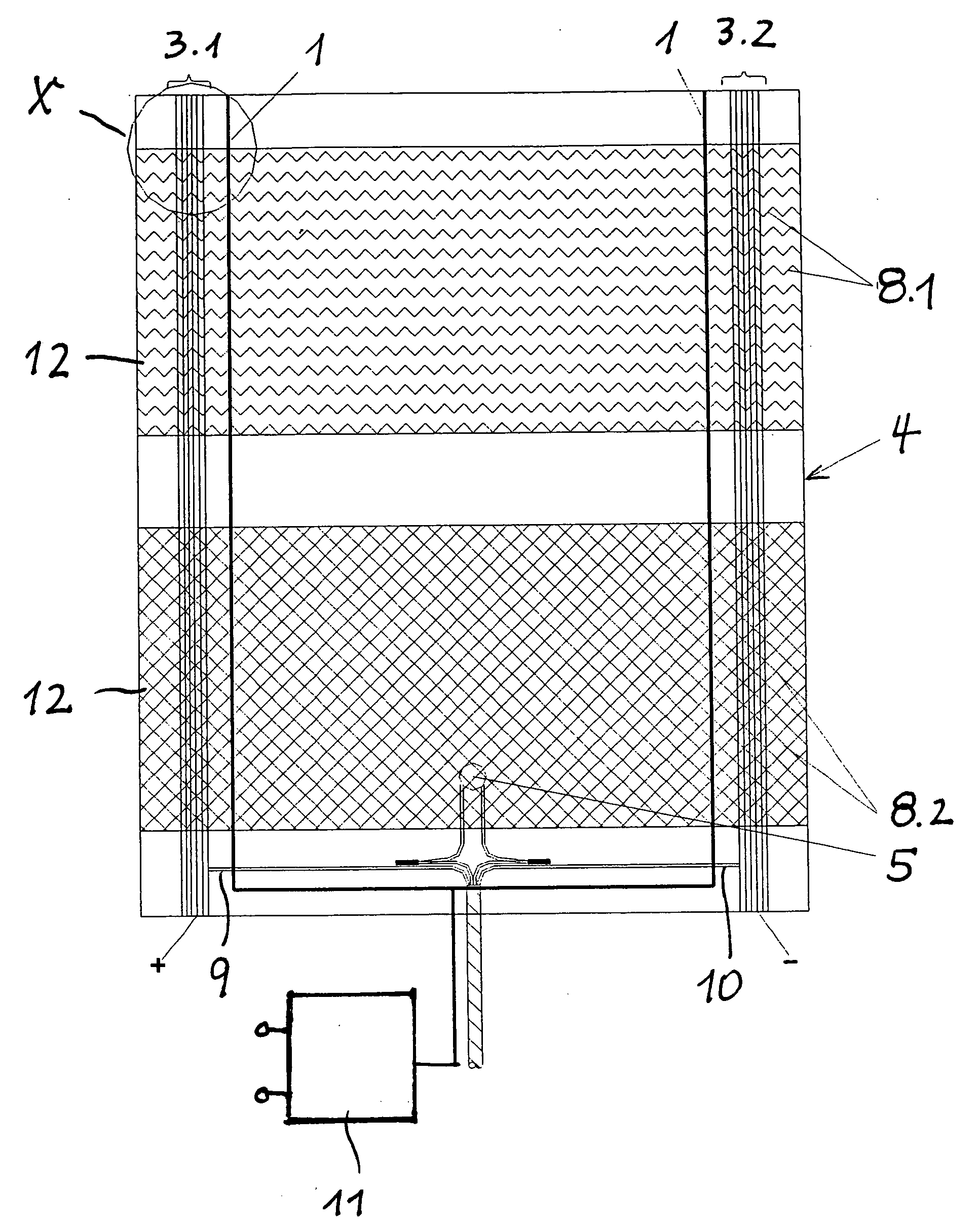

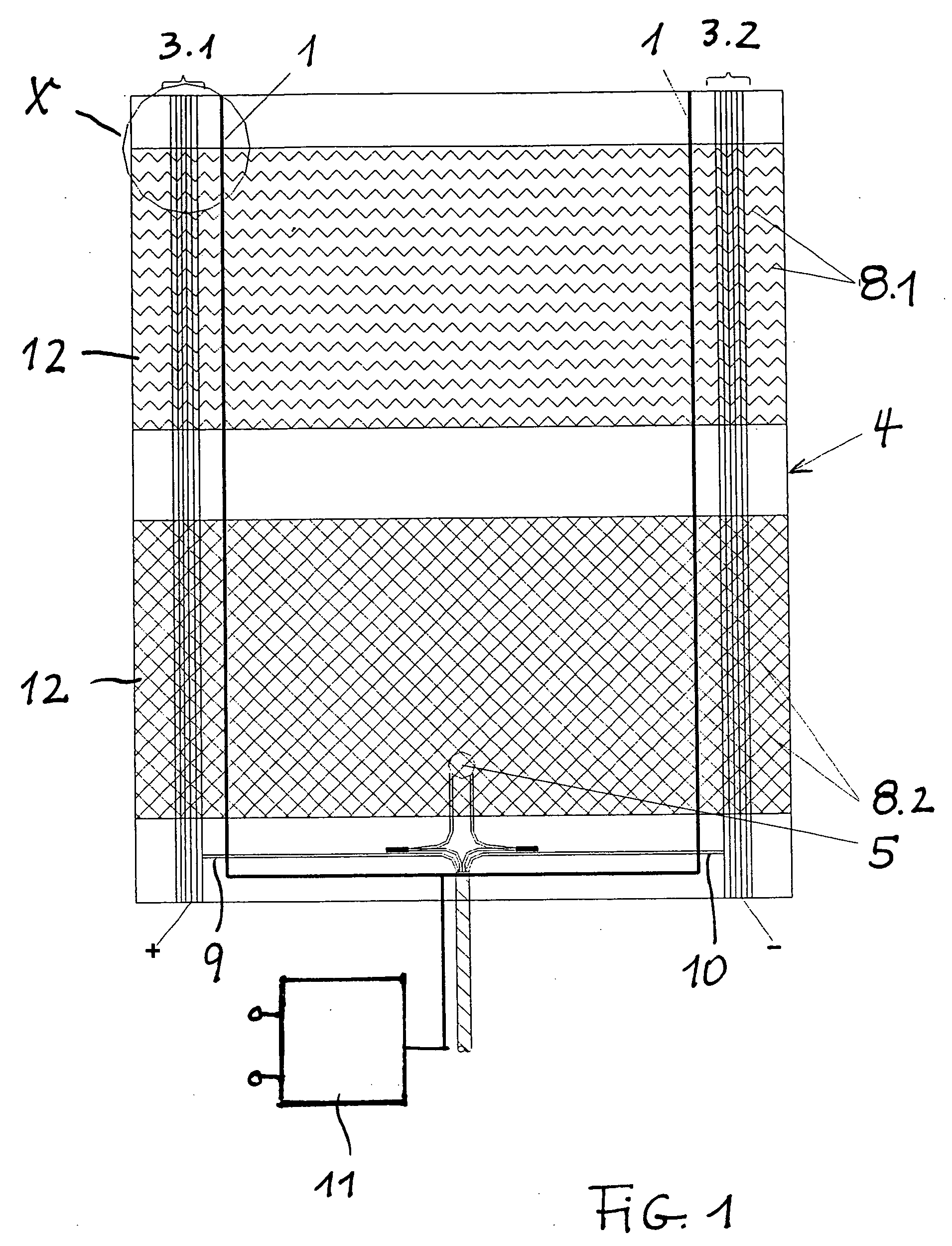

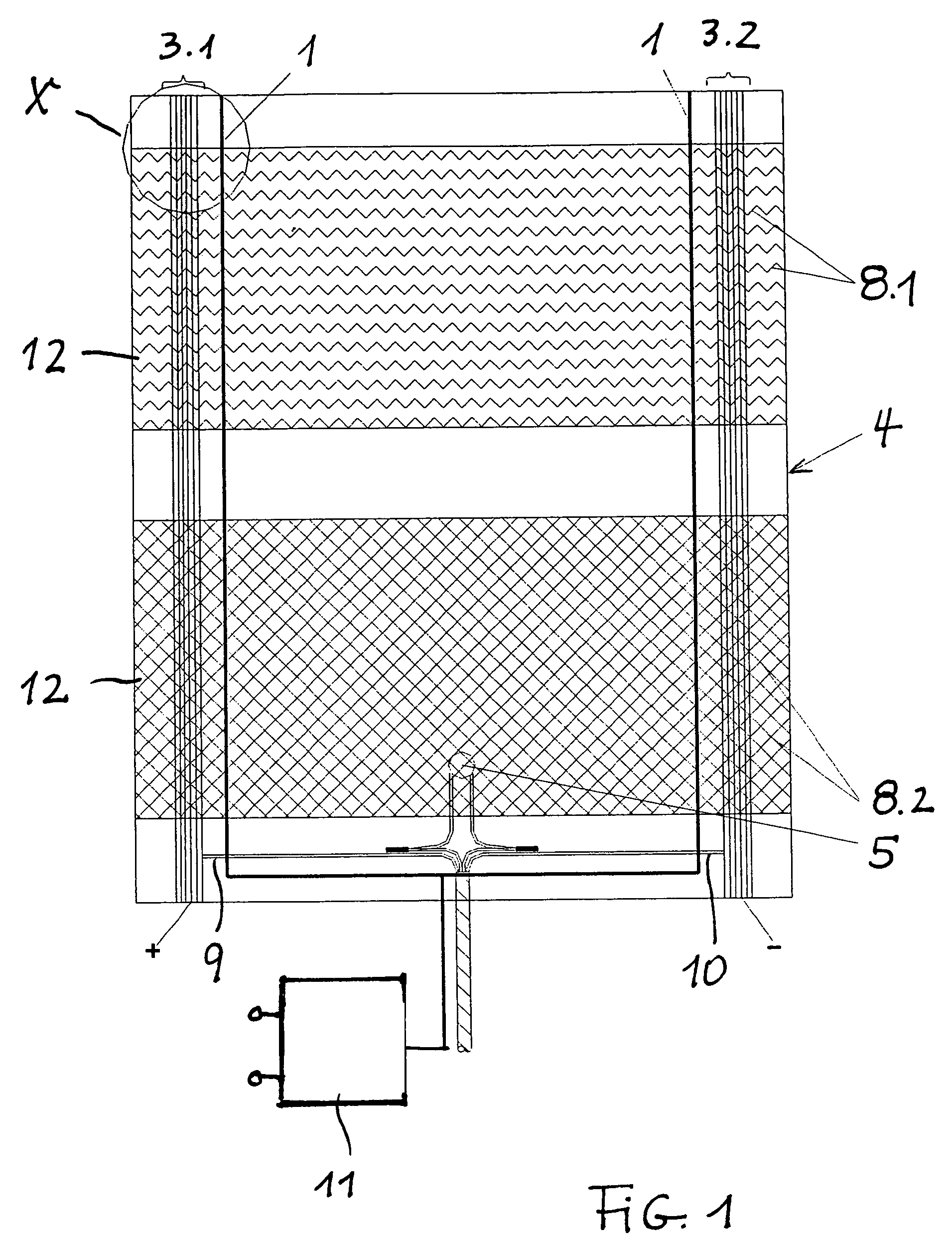

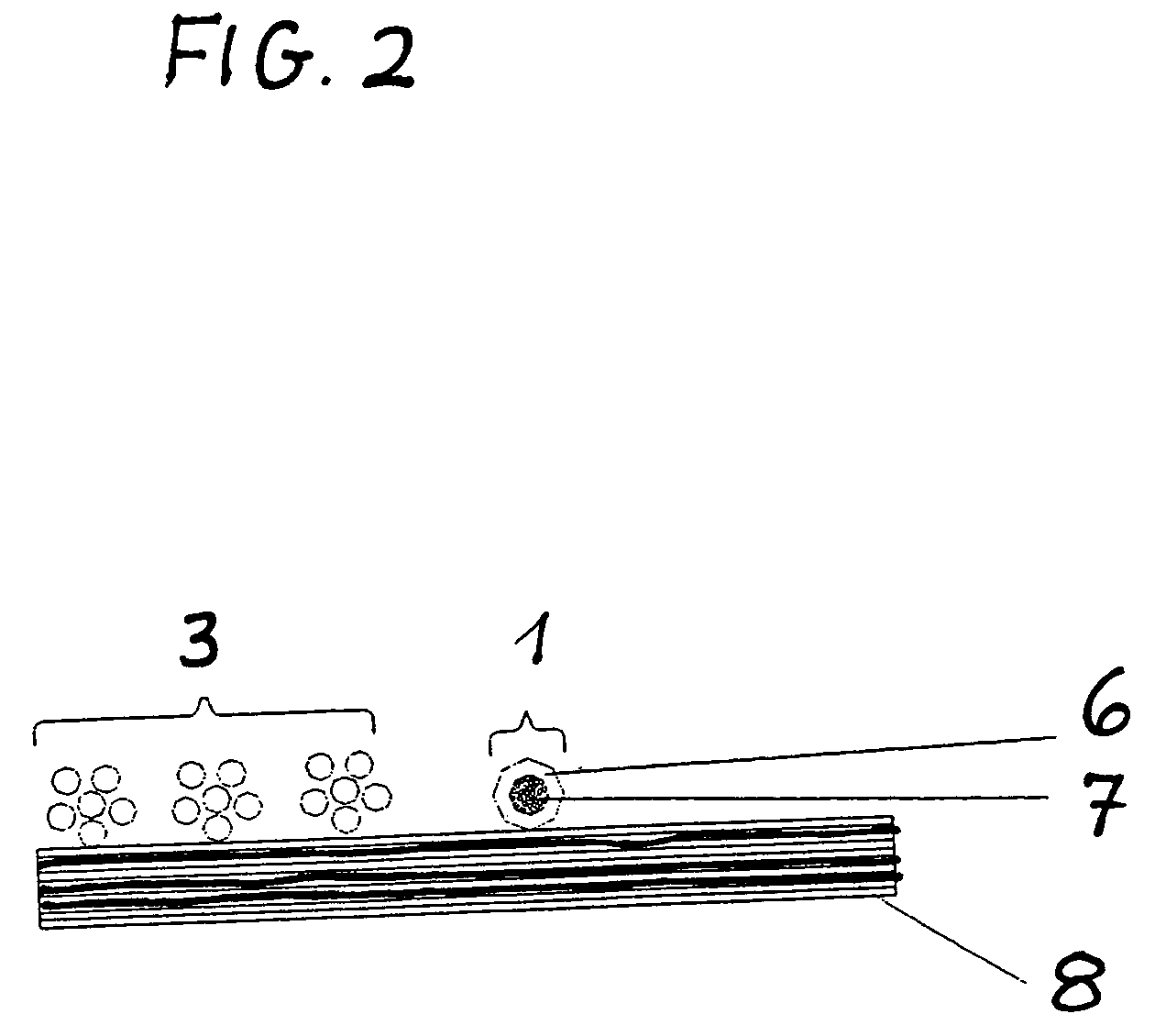

Monitoring device for flexible heating elements

Owner:I G BAUERHIN GMBH

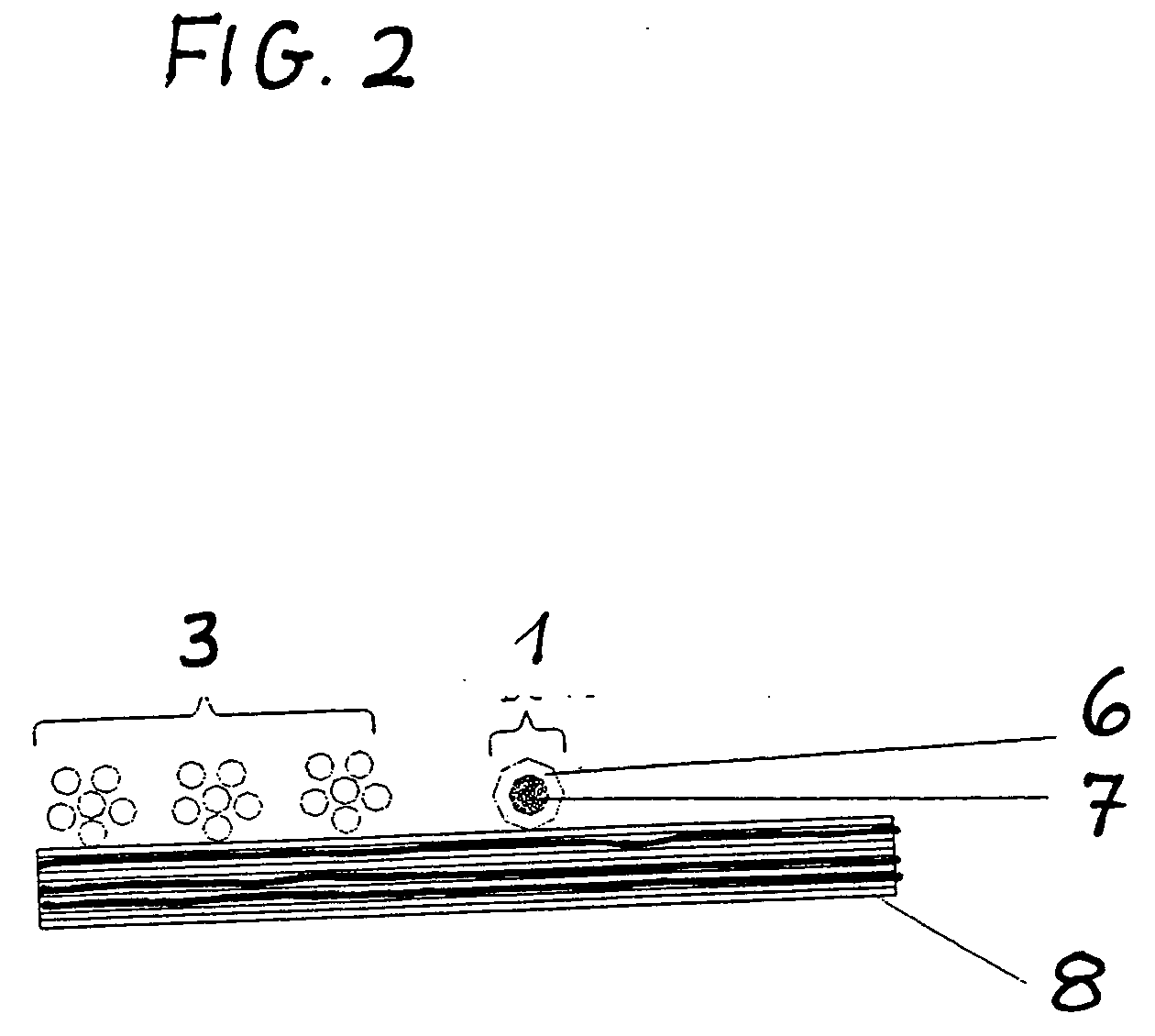

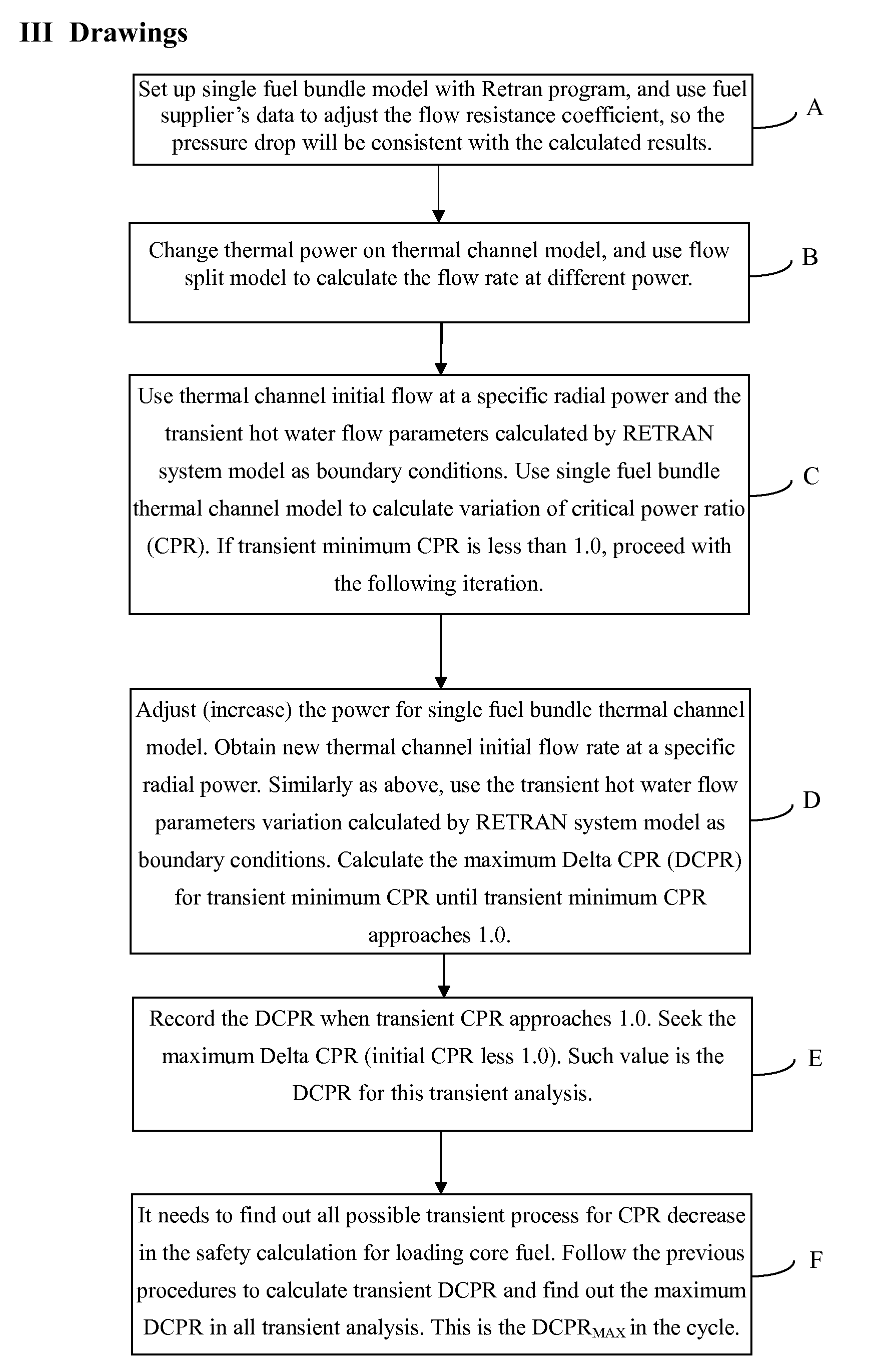

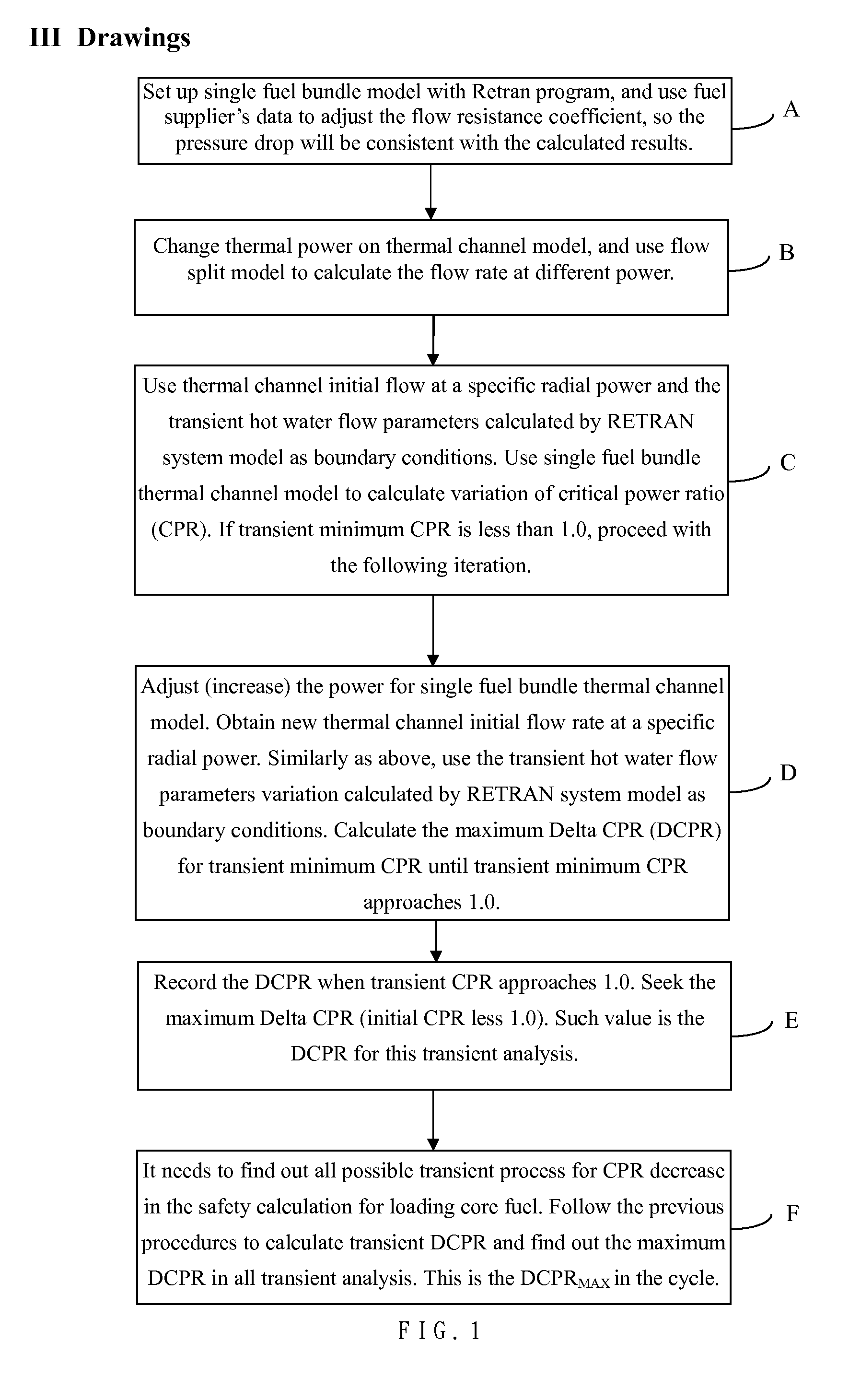

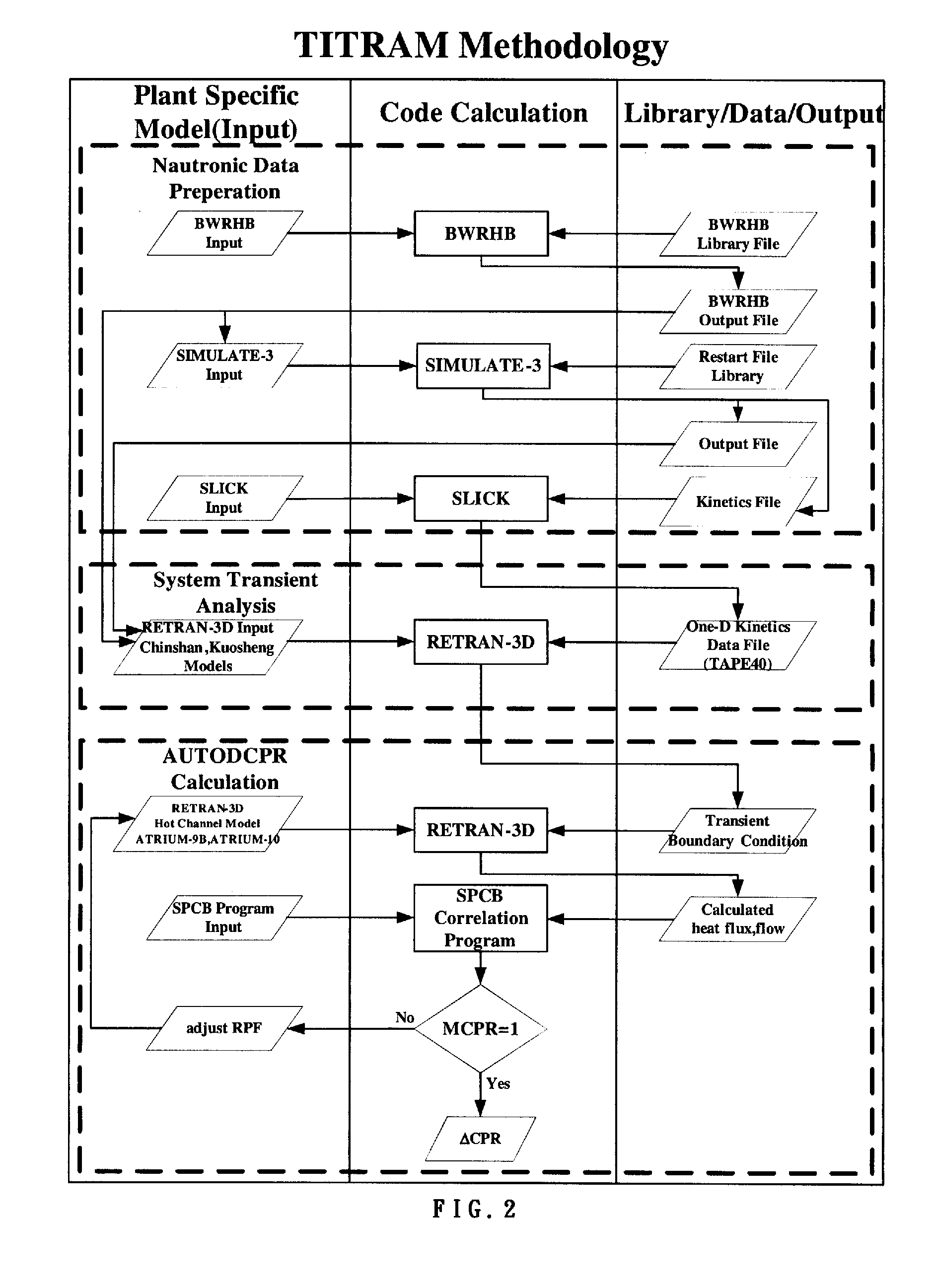

Thermal limit analysis with hot-channel model for boiling water reactors

InactiveUS20090168946A1Reduce computing timeNuclear energy generationNuclear monitoringThermal limitNuclear engineering

An analytical method for the initial flux and transient hot water flow parameters for a boiling water reactor with single fuel bundle. Firstly, the method is to calculate intial flux and transient hot water flow parameter based on single fuel bundle. Then, it uses supplier provided CPR (Critical Power Ratio) correlation to calculate transient CPR and calculate the whole reactor core for hot water parameters as boundary condition. Iteration is used to figure out DCPR (Delta Critical Power Ratio). The obtained limit transient is selected as the maximum from DCPR. The maximum transient DCPR combines Safety Limit Minimum Critical Power Ratio (SLMCPR) and safety margin to figure out the OLMCPR (Operating Limit Minimum Critical Power Ratio). Both the plant layout and operational thermal limit are based on OLMCPR to assure the safety of reactor core.

Owner:CHIU YANG KAI

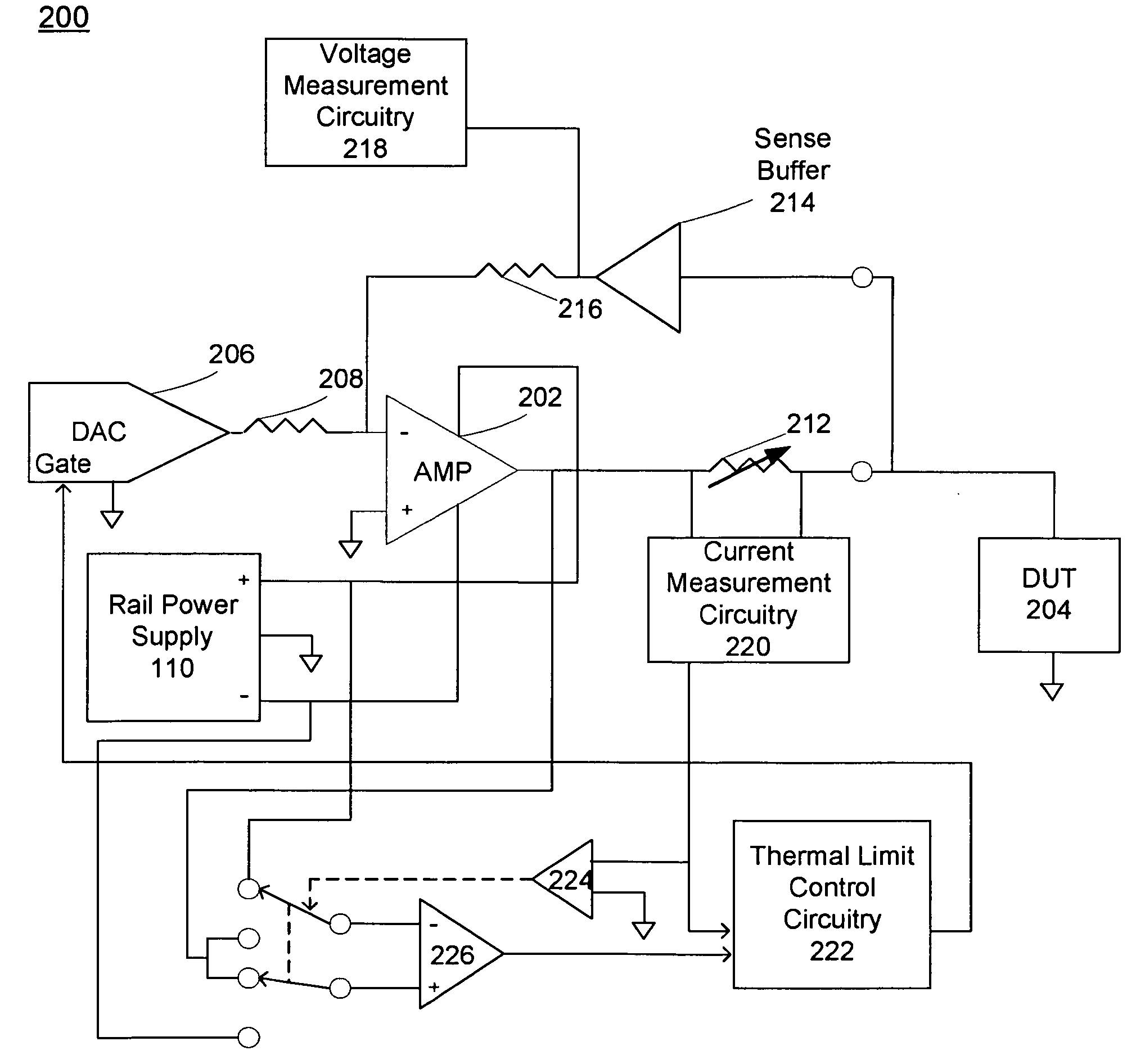

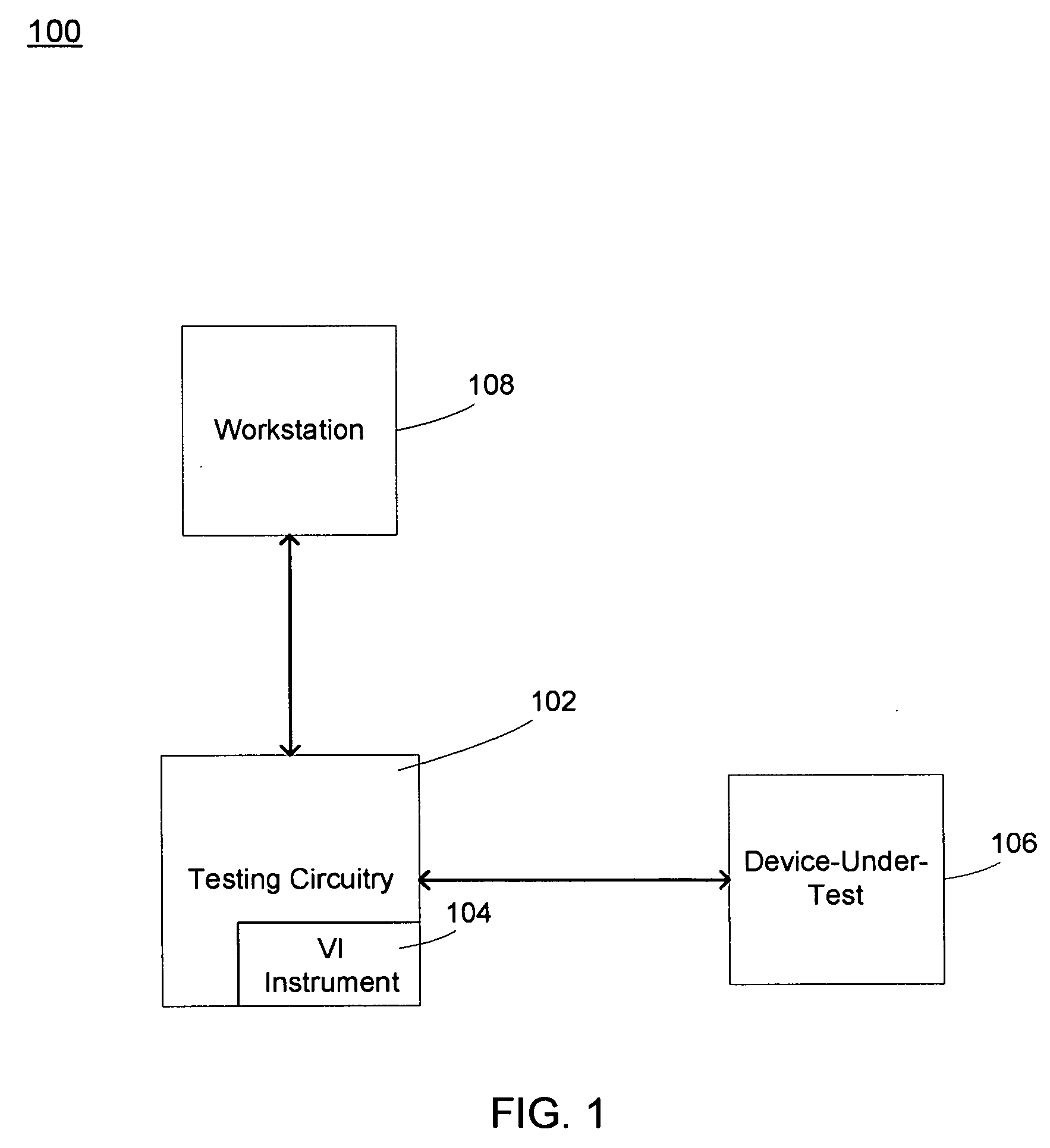

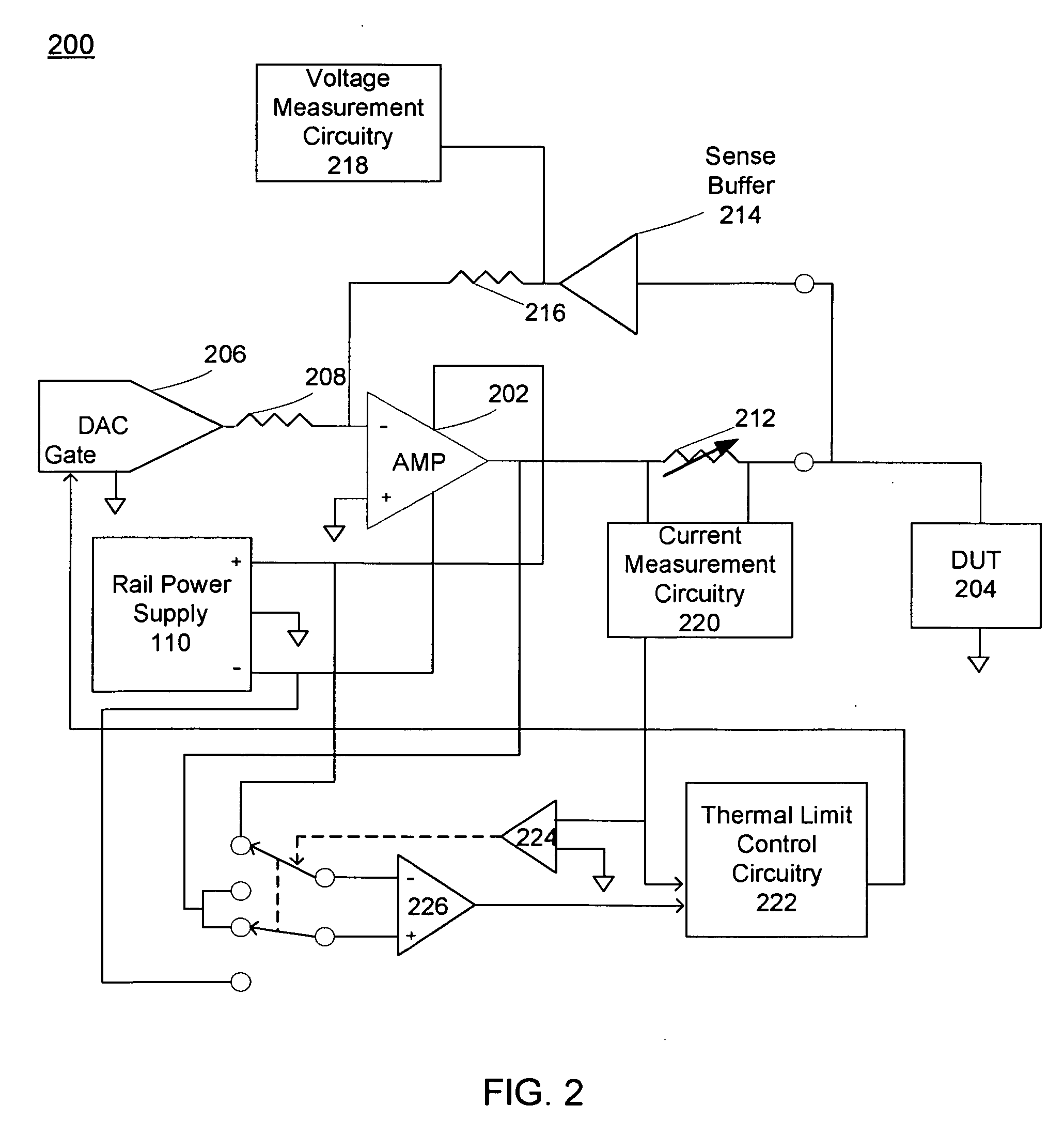

System and method for thermal limit control

This disclosure relates to a system and method for pulse generation. A system in accordance with the present disclosure may include a power dissipating element configured to receive power from a power source. At least one of the power source and the power dissipating element may be configured to generate a first signal. The system may further include a measuring instrument in communication with the power source. The measuring instrument may be configured to measure the first signal and to provide an input corresponding to a measured signal to a duty cycle limiter. The system may also include a pulse controller operatively connected to the power source. The pulse controller may be configured to control a duty cycle of the first signal and to receive a second signal from the duty cycle limiter. The pulse controller may be configured to disable at least one of the power source and the power dissipating element if the duty cycle limiter has determined that a maximum condition has been exceeded. Other embodiments are also within the scope of the present disclosure.

Owner:LTX CORP

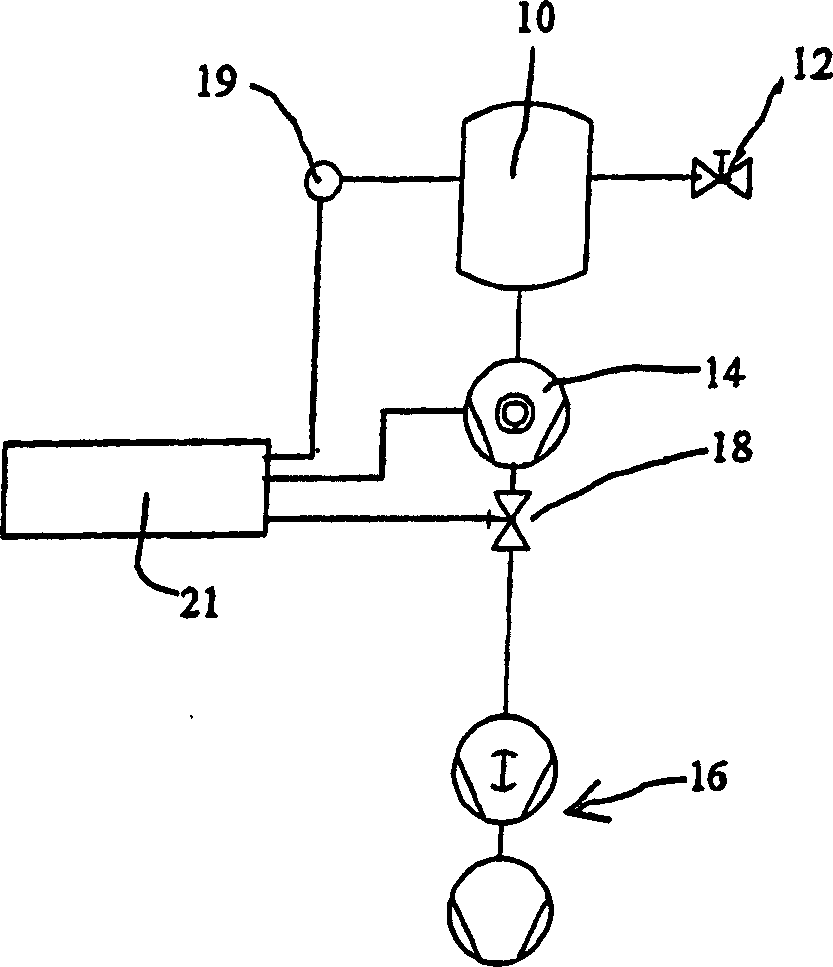

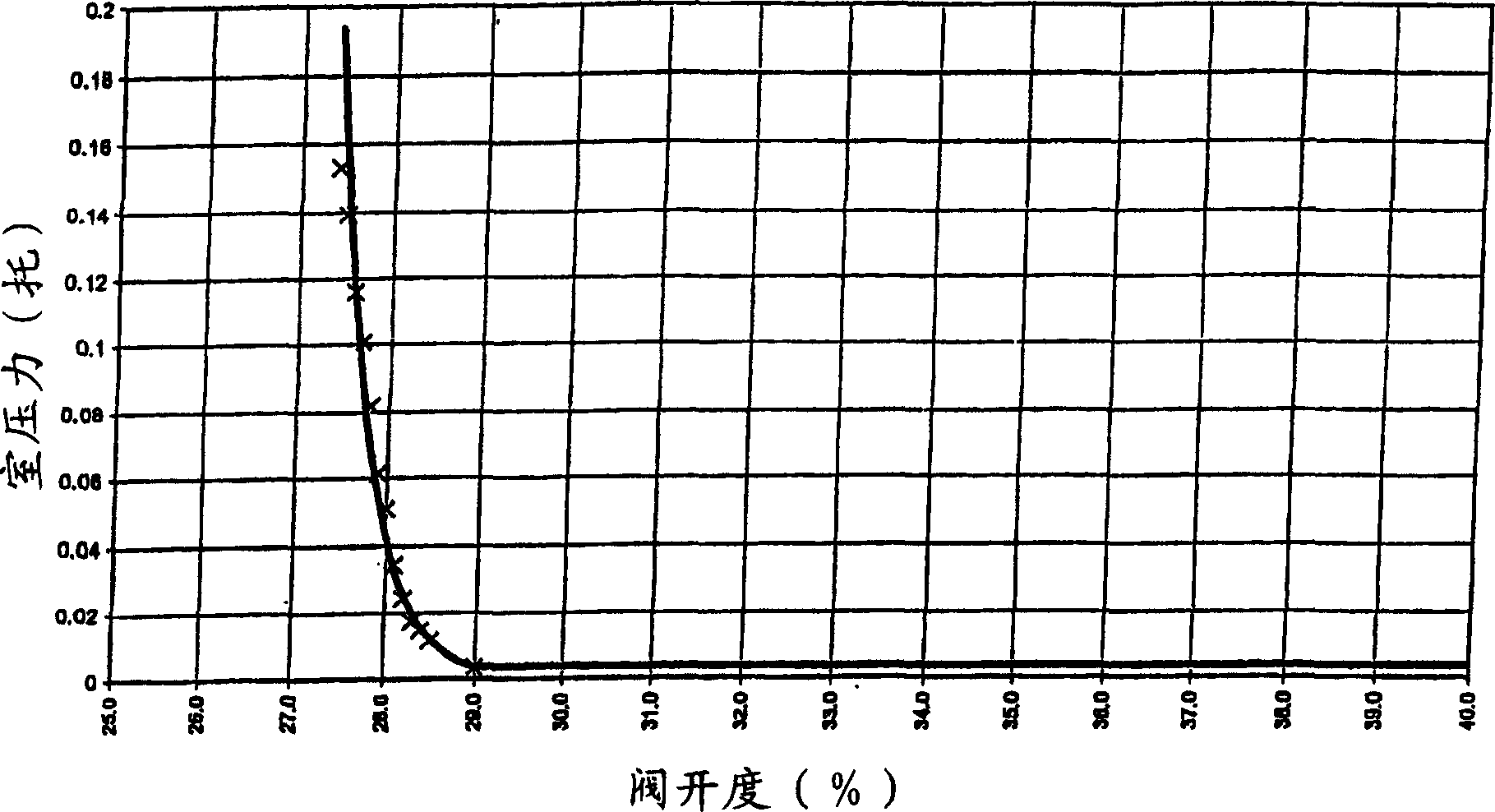

Apparatus for controlling the pressure in a process chamber and method of operating same

InactiveCN1662746ARotary/oscillating piston combinations for elastic fluidsSemiconductor/solid-state device manufacturingChamber pressureControl unit

A method of operating apparatus for controlling the pressure in a process chamber (10), the apparatus comprising a first pump unit (14) having an inlet in fluid connection with an outlet of said process chamber, and a second pump unit (16) having an inlet in fluid connection with an outlet of the first pump unit via a flow control unit (18) comprising a variable flow control device (20; 28) having variable conductance for controlling outlet fluid pressure at the outlet of the first pump unit, the method comprises controlling speed of the first pump unit to increase the range of chamber pressures over which control of the outlet fluid pressure produces changes in said chamber pressure without exceeding the thermal limit and / or motor stall limit of the first pump unit.

Owner:EDWARDS LTD

Use of one voltage regulator module to support two processors to improve power and thermal limitations

ActiveUS20060069927A1Volume/mass flow measurementPower supply for data processingVoltage regulator moduleThermal limit

Several processors have specifications setting forth that each processor be coupled to a separate specified voltage regulator circuit. Instead, a number of specified voltage regulator circuit(s) is coupled to the several processors. The number of voltage regulator circuit(s) is less than the number of processors. The processors and voltage regulator circuit(s) are coupled to a module, and a thermal limit for the module is maintained because the several processors are coupled to the smaller number of voltage regulator circuits.

Owner:EMC IP HLDG CO LLC

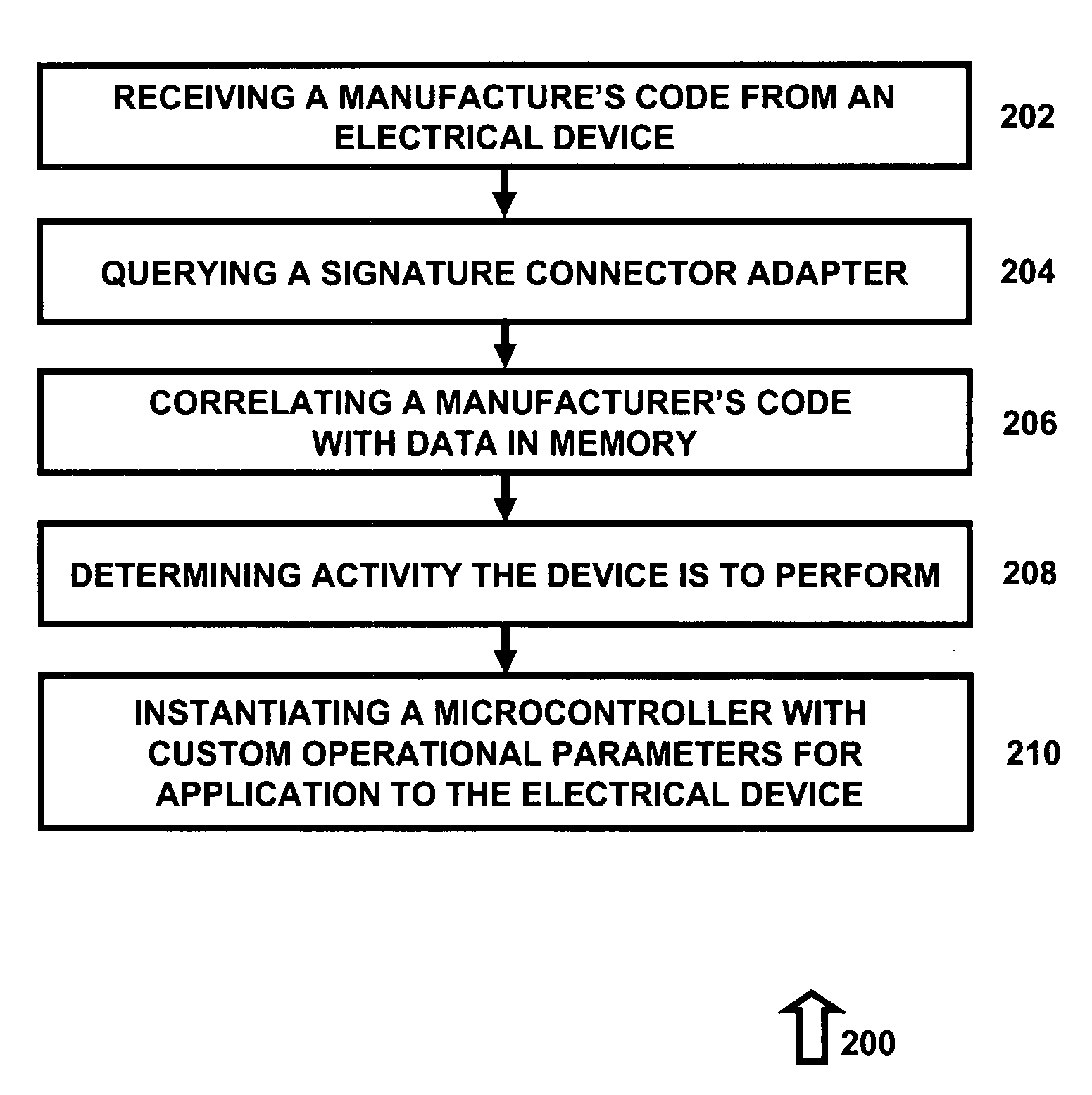

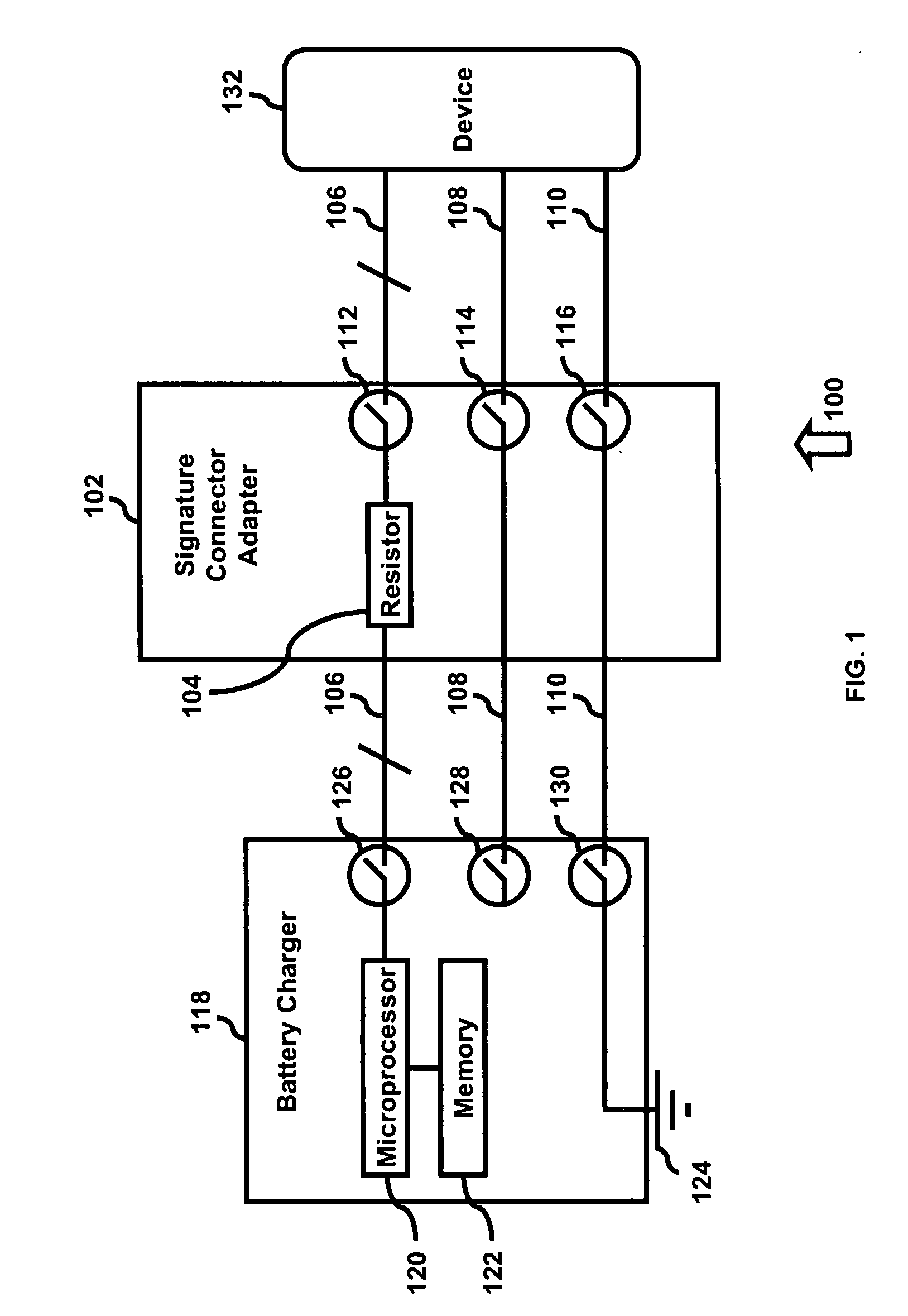

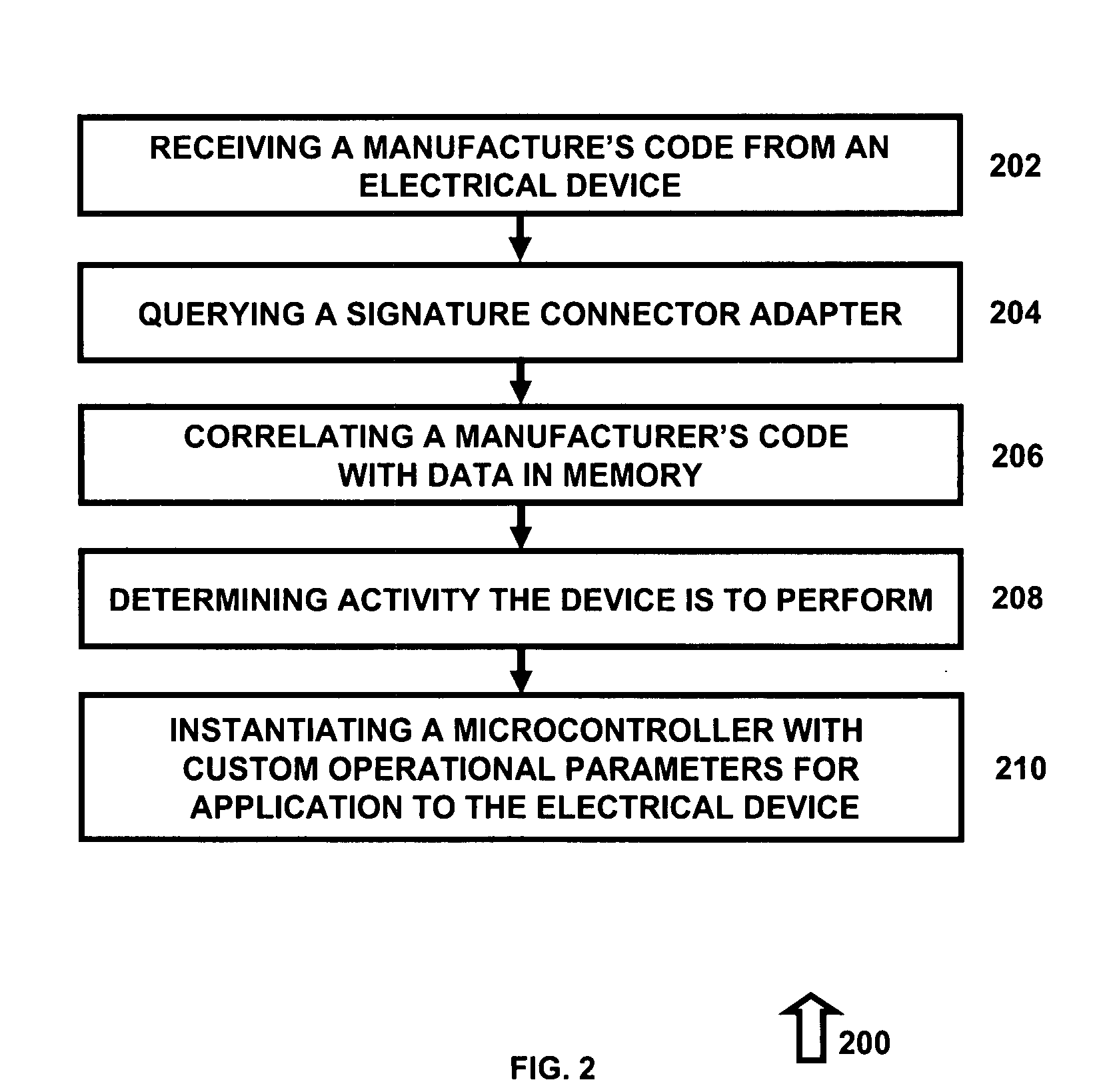

Transformation of battery charger to power source using signature adapters

InactiveUS20090001928A1Easy to optimizeDifferent batteries chargingElectric powerThermal limitUser Friendly

A signature connector adapter adapted to provide additional capabilities for a battery charger beyond not only charge batteries, but performing other user-friendly functions is presented. One embodiment utilizes a resistor disposed within a signature charger adapter to detect battery type and communicate the battery type to the battery charger. The signature connector adapter provides information such as, but not limited to, battery chemistry, battery voltage, charging capabilities, and thermal limits. The battery charger can then optimize charging performance. The signature connector adapter allows a plurality of household, construction, medical and military devices to be charged and / or powered via the battery charger. Devices such as lights, radios, cigarette lighters, and other such devices requiring specific levels or types of power can now be operated and charged with a single charger, since the signature connector adapter facilitates the charging system changing its output to match the device's requirements.

Owner:SINO YI HUA INT INVESTMENT CO LTD

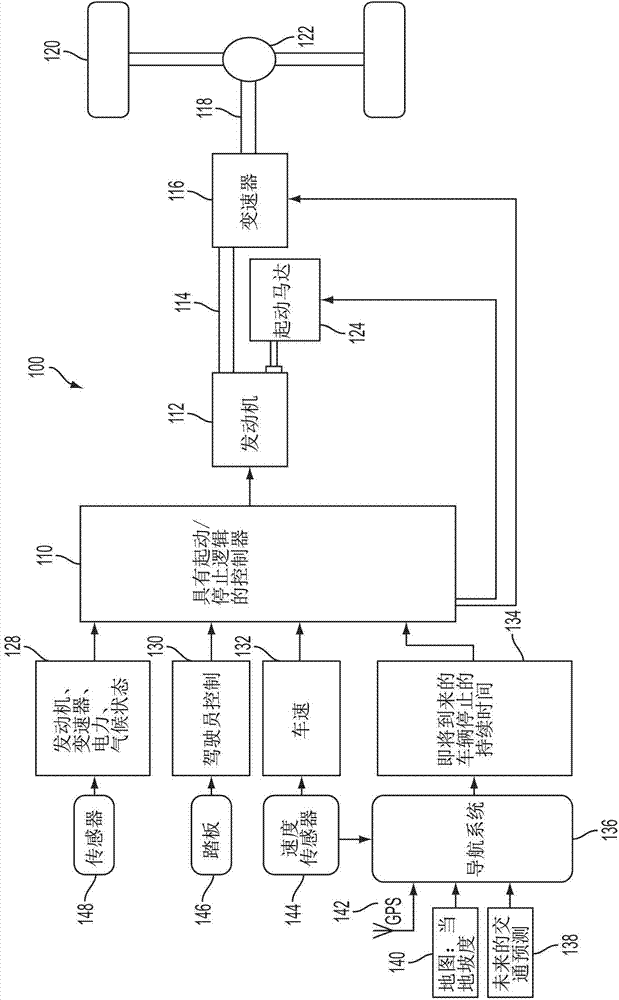

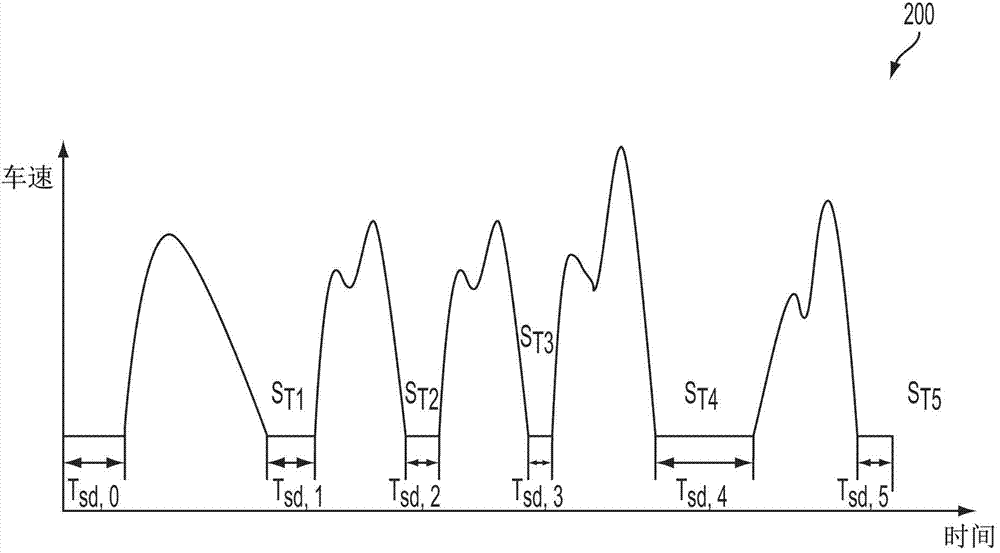

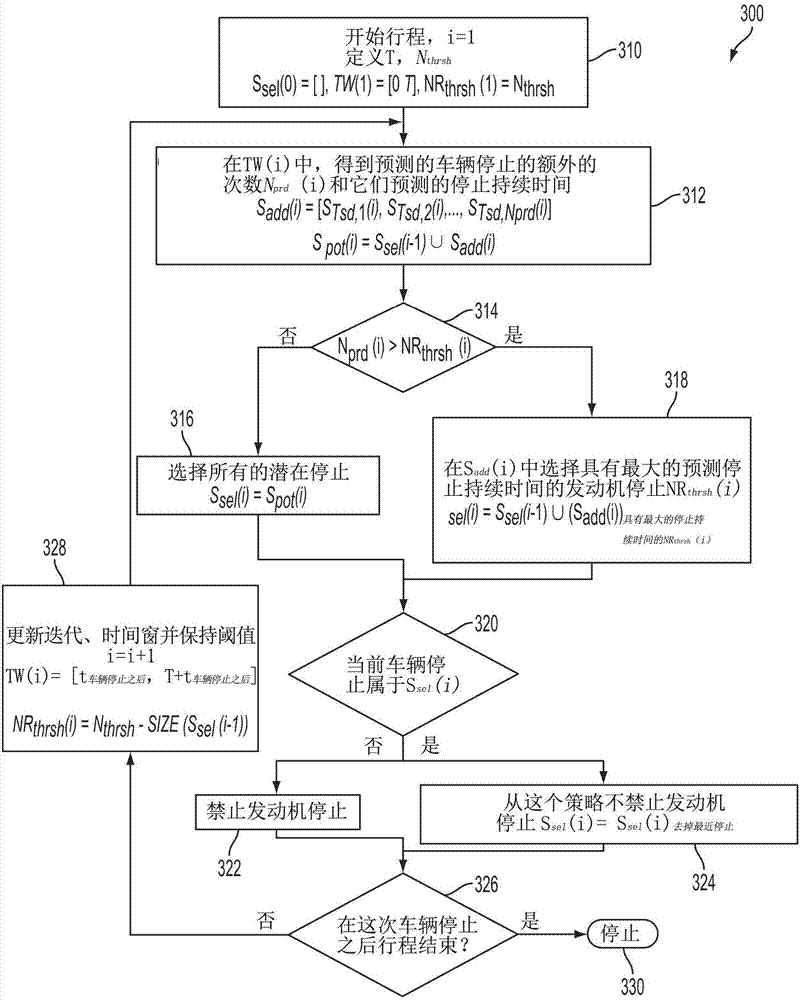

System And Method For Engine Idle Stop Control With Starter Motor Protection

ActiveCN104724111ALess discomfortReduce starter motor overheatingHybrid vehiclesInternal combustion piston enginesThermal limitControl system

A system and method for controlling engine idle stop in a hybrid vehicle that uses predictive information to schedule engine stops with relatively longer stop duration time to gain more fuel savings and extend life of starter motor. More specifically, predictive information may be used to determine potential vehicle stop events, along with corresponding stop duration times, within a time window. An engine stop scheduler and / or controller may be configured to schedule stops of longer duration for optimal total engine stop time. Similarly, taking into account constraints imposed by the thermal limits of the motor, engine stop may be inhibited for predicted short events to allow engine stop at later longer stop events.

Owner:FORD GLOBAL TECH LLC

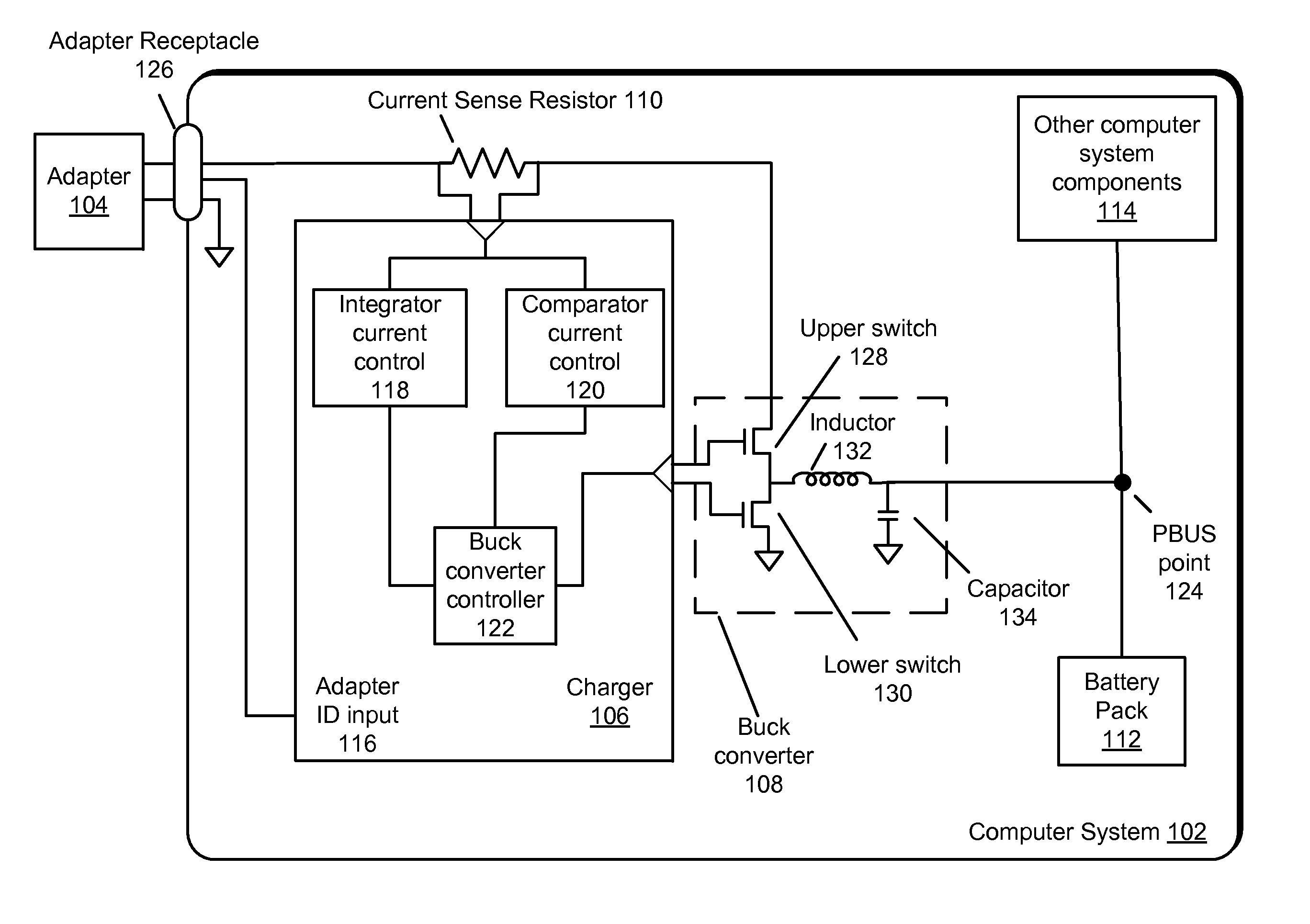

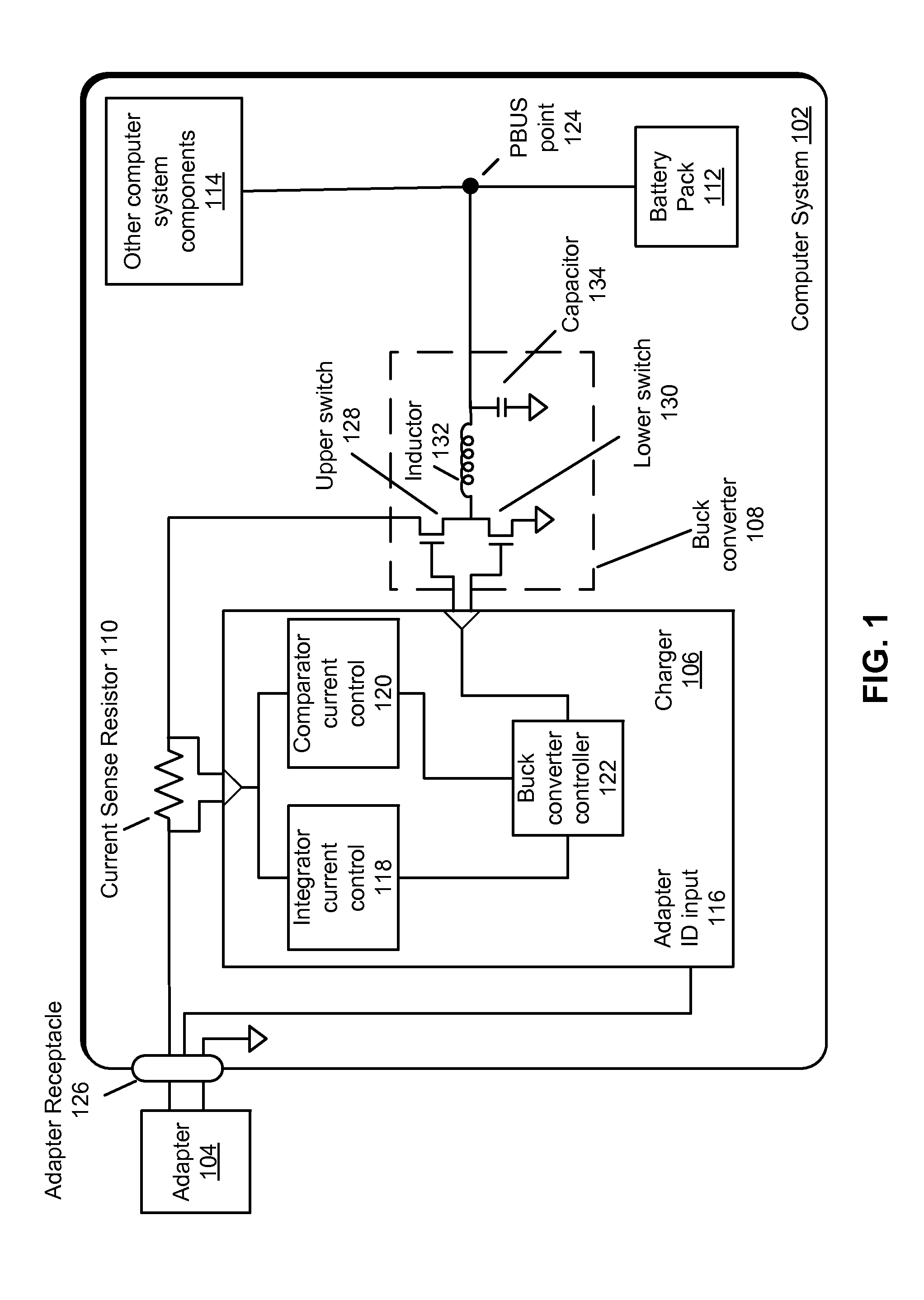

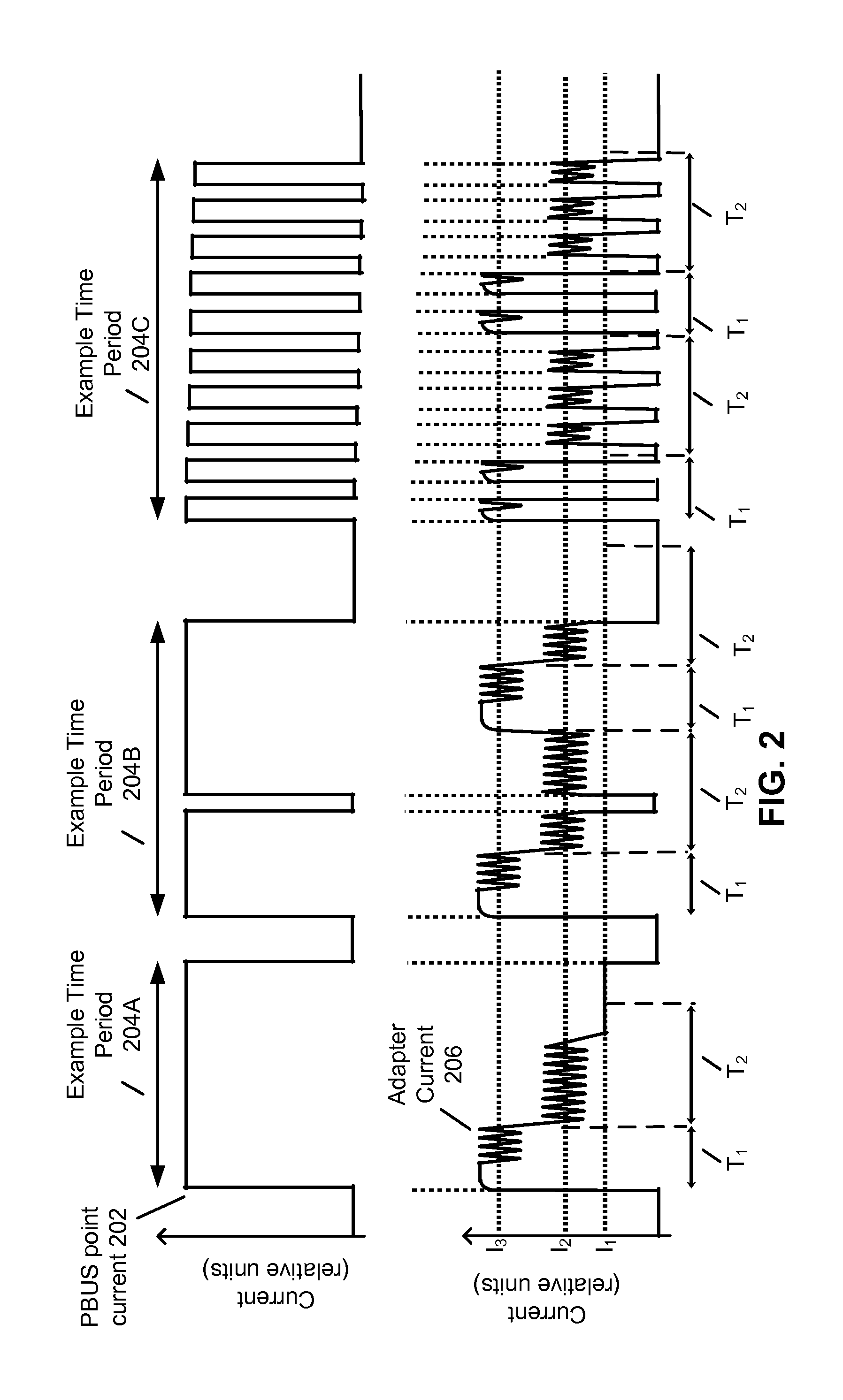

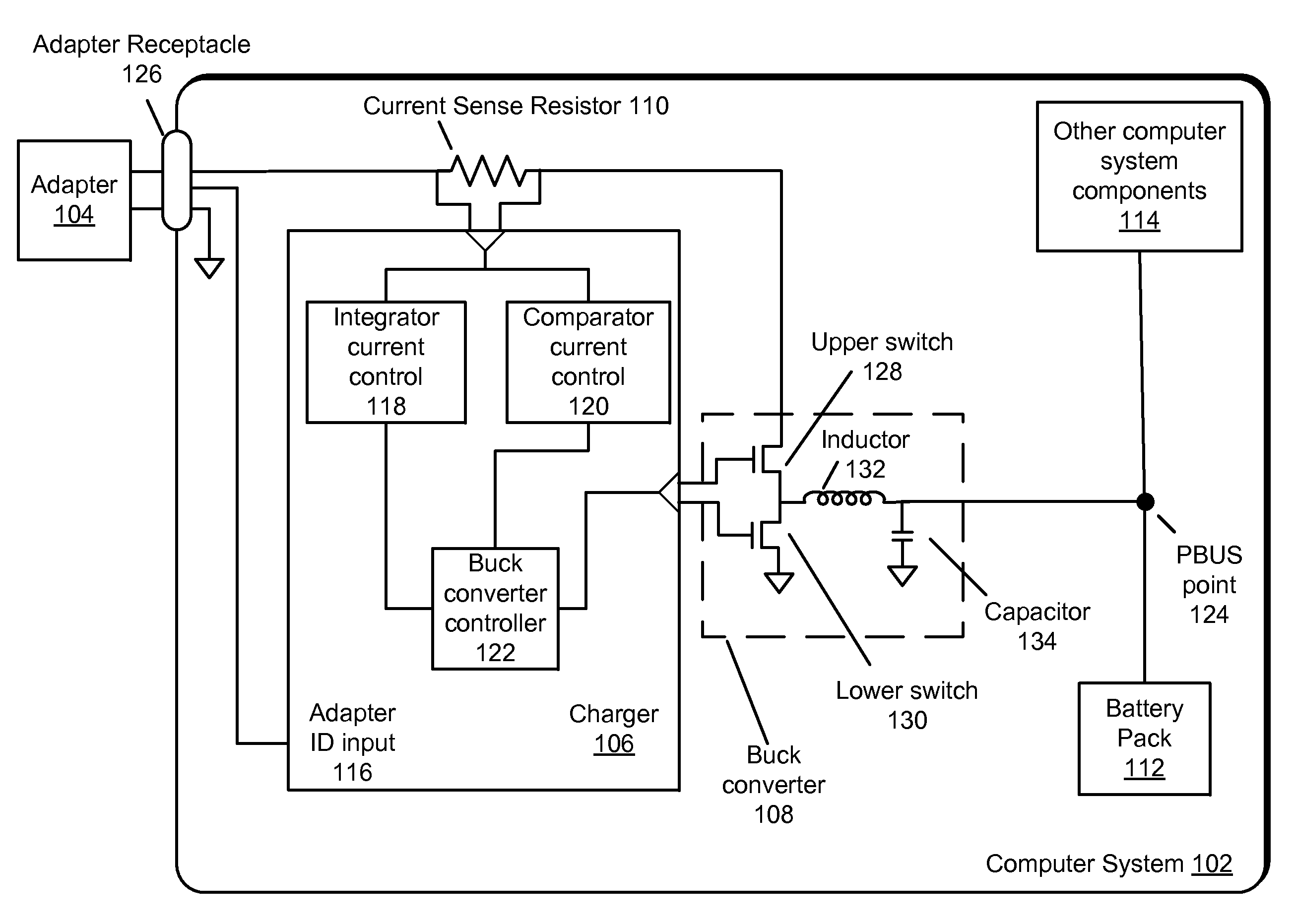

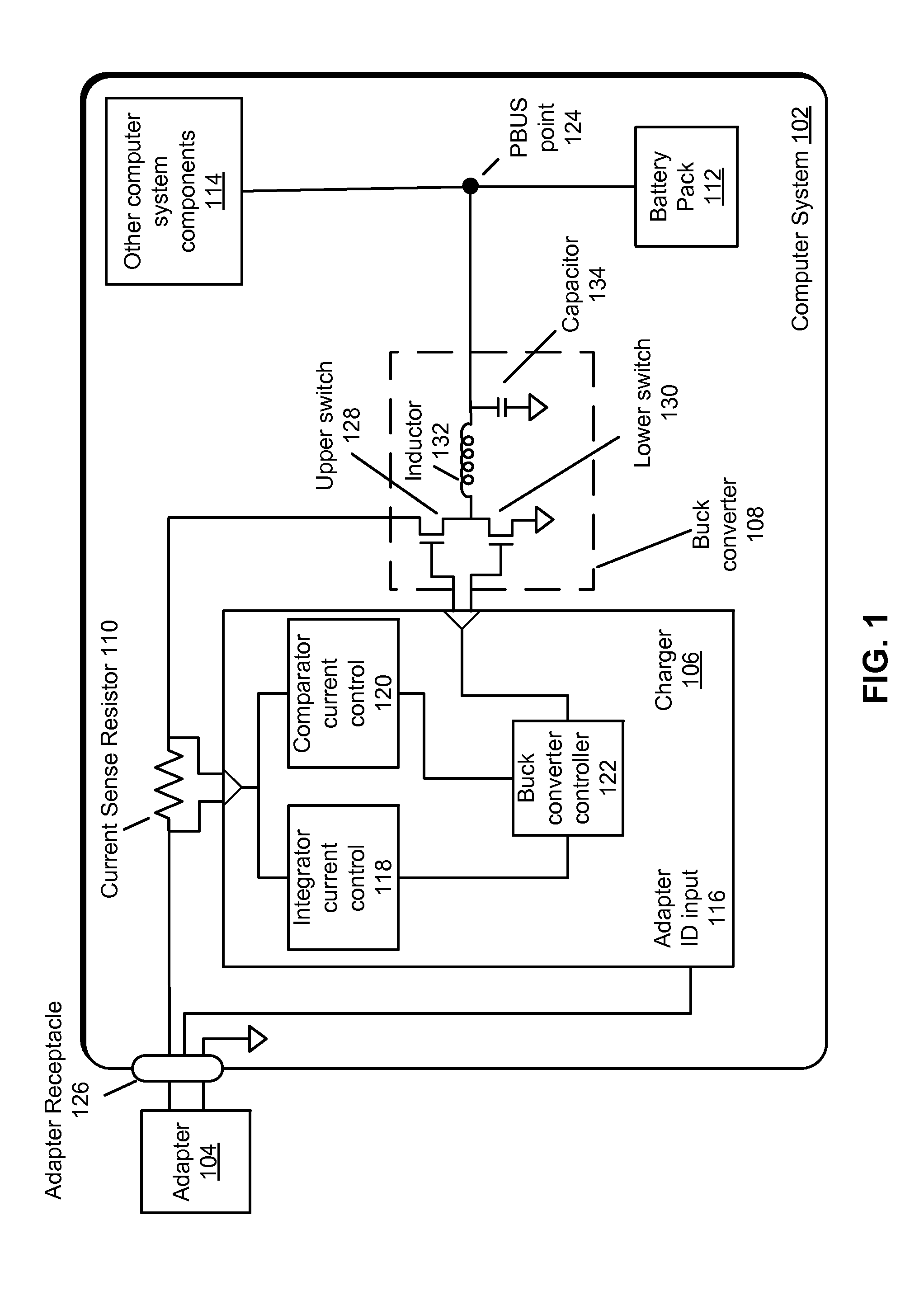

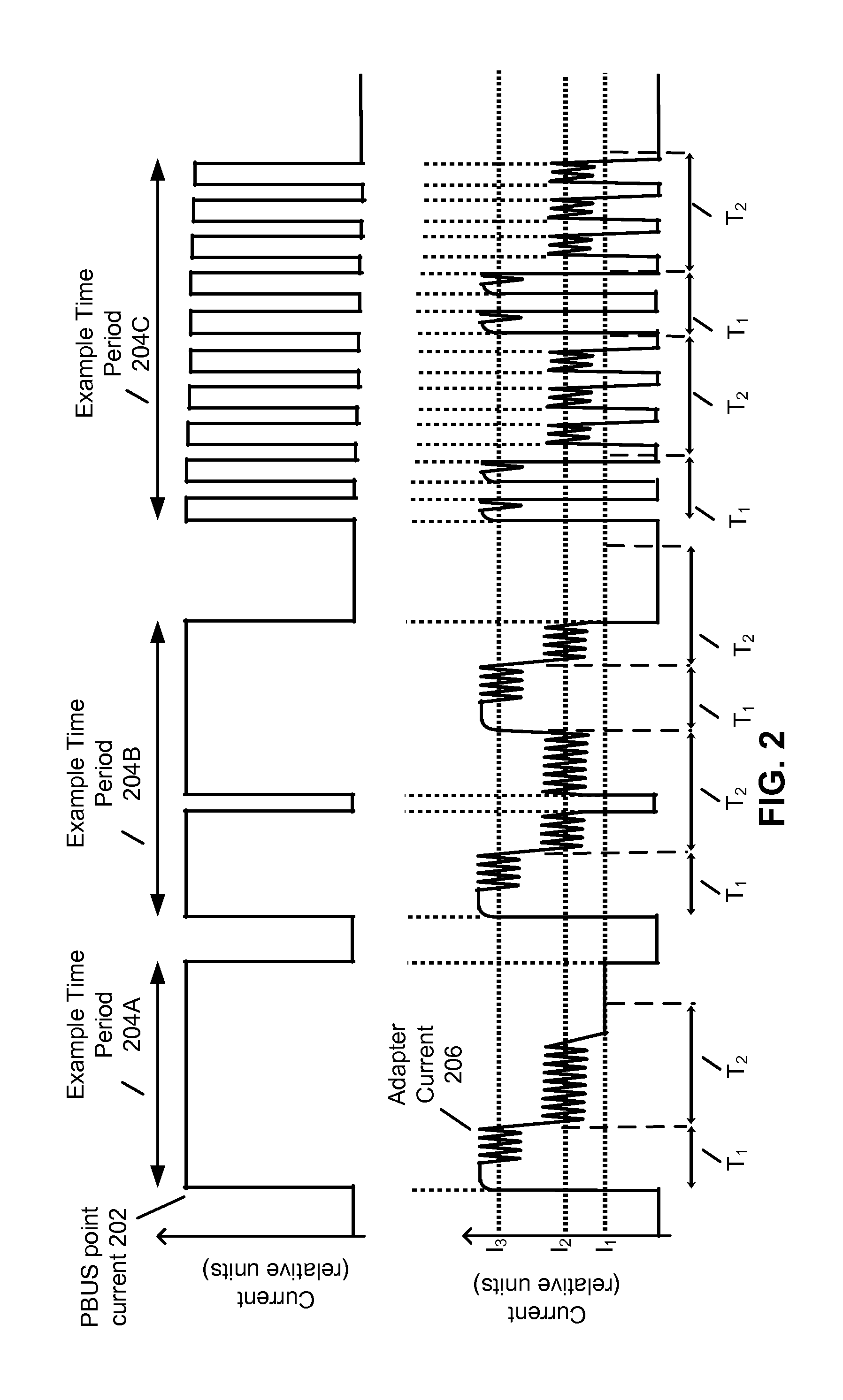

Controlling a current drawn from an adapter by a computer system

InactiveUS20130227319A1Volume/mass flow measurementPower supply for data processingCurrent limitingThermal limit

The disclosed embodiments provide an apparatus that controls a current drawn from an adapter by a computer system. During operation, the apparatus senses the current drawn from the adapter using a first current sensor and a second current sensor, wherein a response time of the first current sensor is faster than a response time of the second current sensor. Then, when the current sensed using the first current sensor exceeds a predetermined high-current threshold, the apparatus limits the current drawn from the adapter to a first predetermined current limit. Additionally, when the current sensed using the second current sensor exceeds a predetermined thermal-limit current, the apparatus limits the current drawn from the adapter to the predetermined thermal-limit current.

Owner:APPLE INC

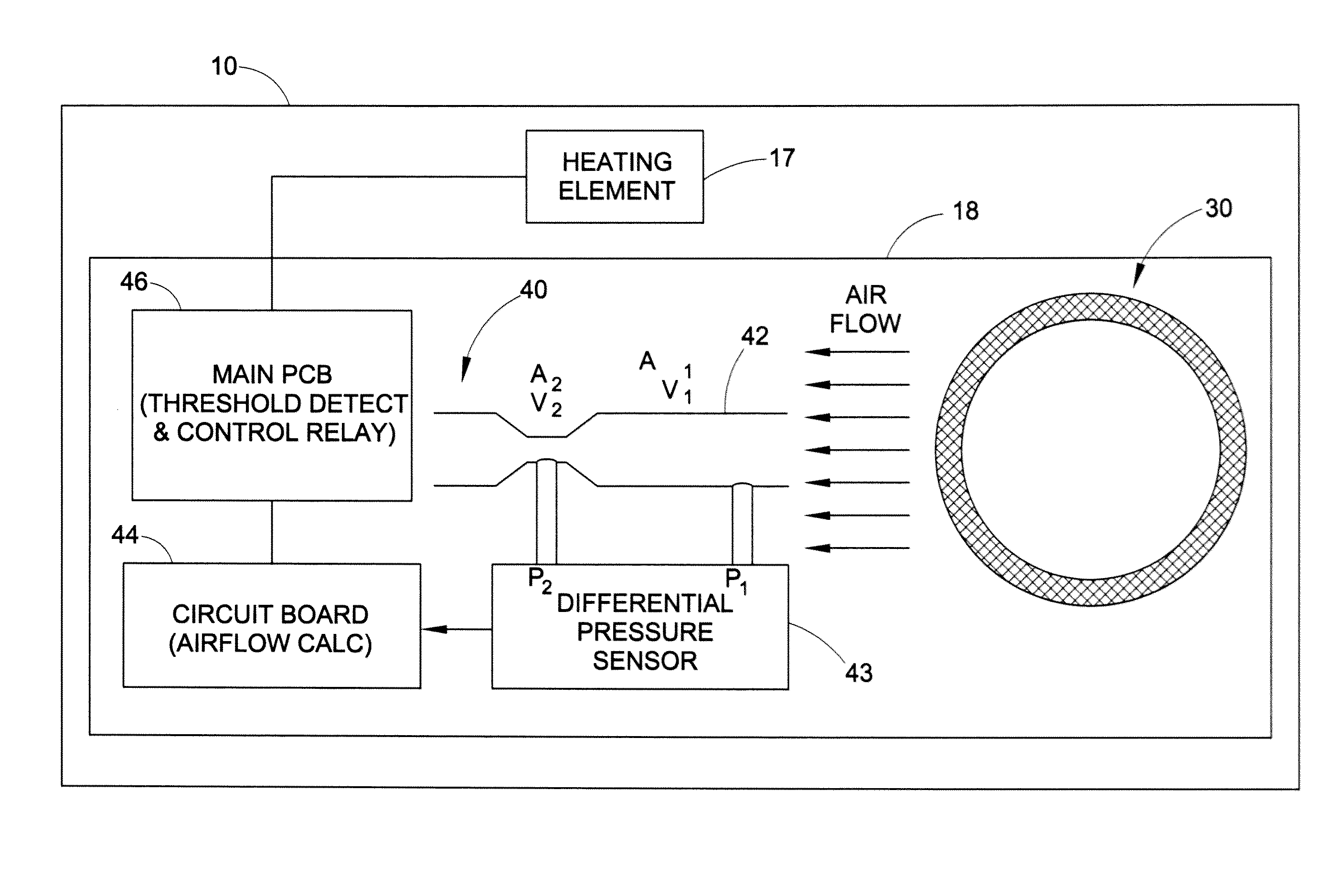

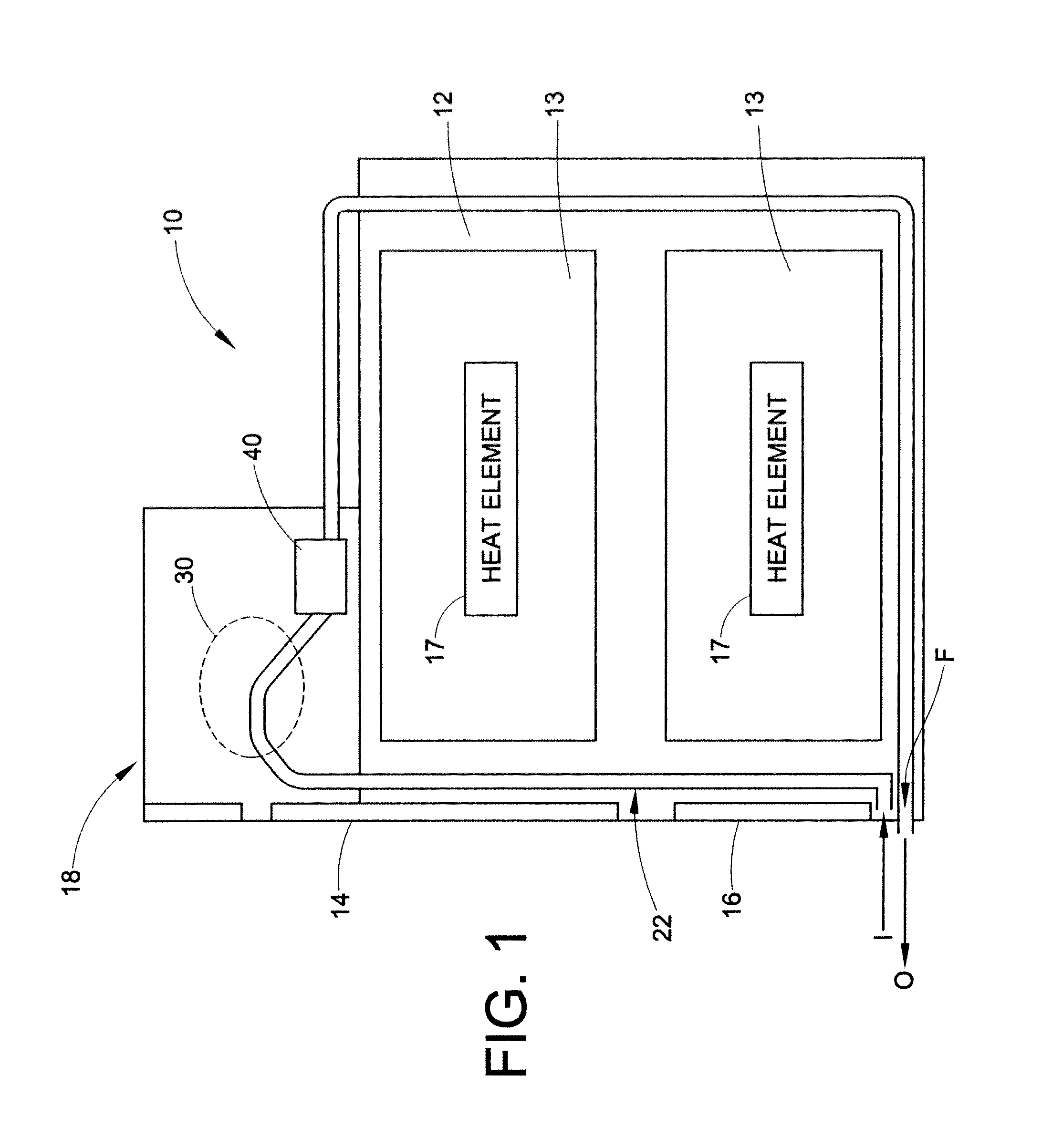

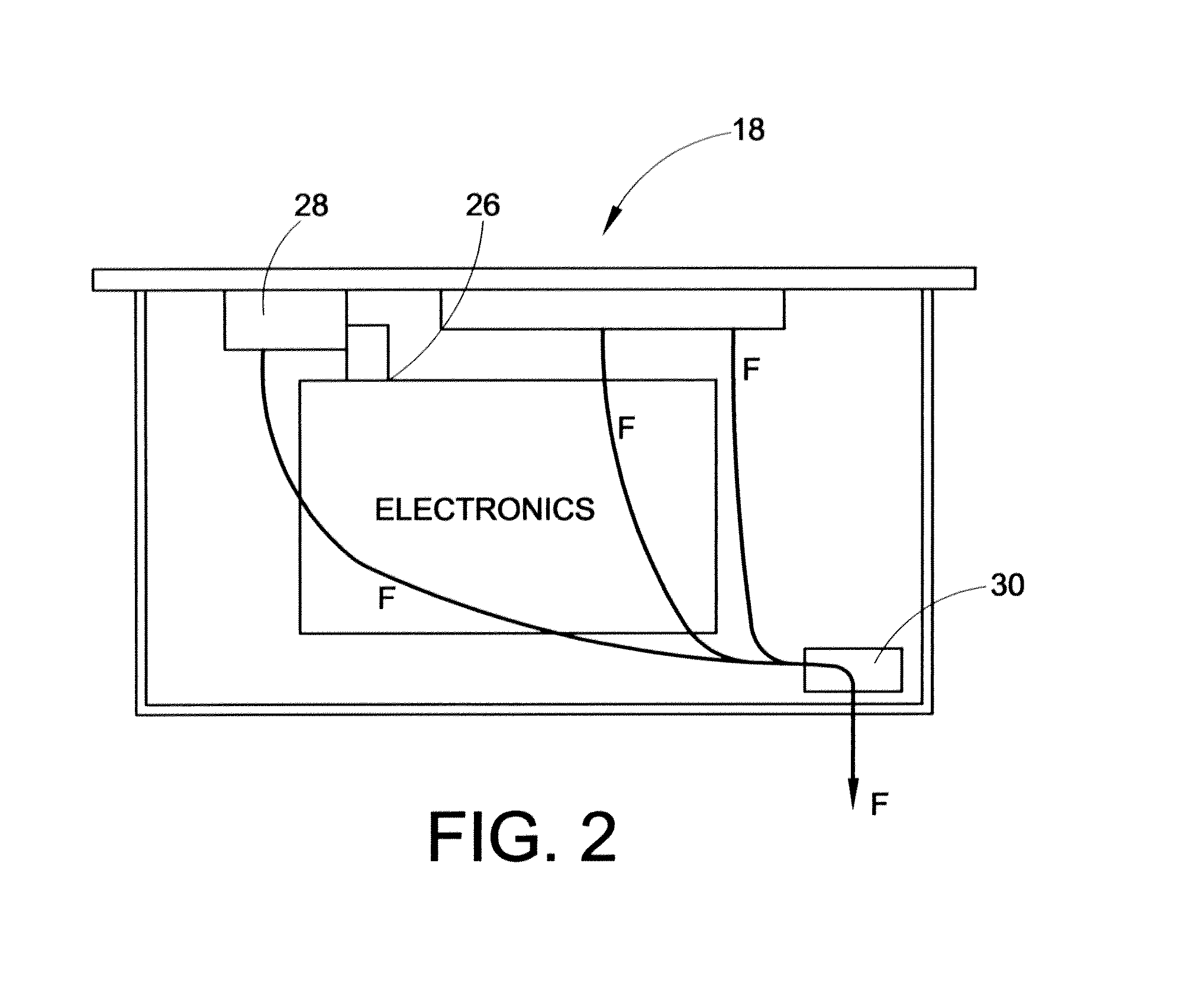

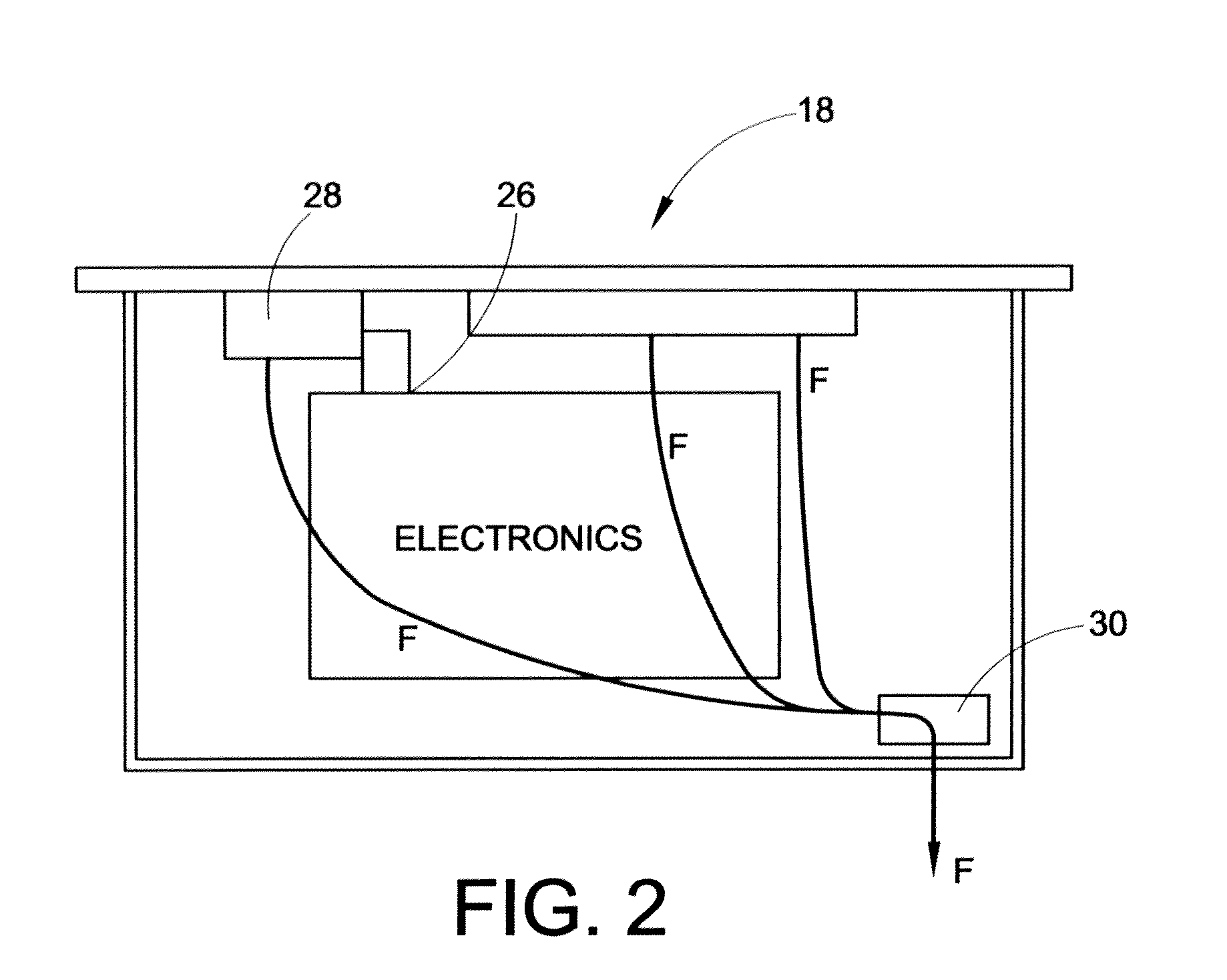

Appliance airflow detection using differential pressure sensing

ActiveUS9267700B2Easy CalibrationCalibration difficultyDucting arrangementsDomestic stoves or rangesTraffic capacityThermal limit

A device for detecting and / or measuring air flow in a cooling air flow passageway of an appliance using solid-state flow detectors. Heat generating components of the appliance are controlled in response to detected air flow. More specifically, the disclosure provides a device for detecting the presence of airflow and / or the approximate rate of airflow in a cooling channel of an appliance chassis. Based on this information, the appliance can perform safety-related tasks, such as de-energizing associated heating elements if there is too-low (or no) airflow detected. The solid-state flow detectors are easily fabricated, installed, and calibrated and avoids the calibration, fabrication and / or installation difficulties associated with sail switches and other such approaches such as thermal limit switches.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Temperature throttling mechanism for DDR3 memory

ActiveUS9122648B2Performance maximizationGuaranteed normal operationDigital storageInput/output processes for data processingThermal limitMemory bus

A method for throttling a bus, e.g. a memory bus, may be used to compensate for potential inaccuracy of feedback information received for monitored characteristics, e.g. temperature, reported by sensors configured in monitored devices, e.g. memory devices, accessed through the bus. For example, in case of a memory bus, a memory controller may be configured to throttle the memory bus in a way that maximizes system performance while ensuring that the memory devices keep operating within their thermal limits. Readings obtained from the memory, or from close proximity to the memory, may indicate whether the temperature of the memory has crossed over one or more designated trip points, and one or more algorithms may be executed to perform throttling according to the readings and based on fixed and dynamic throttling modes. The memory controller may infer temperature changes taking place in the memory devices when successive readings are indicating that the temperature of the memory device has remained over a given trip point. Based on these inferences, the memory controller may then change the manner in which the bus is throttled.

Owner:ADVANCED MICRO DEVICES INC

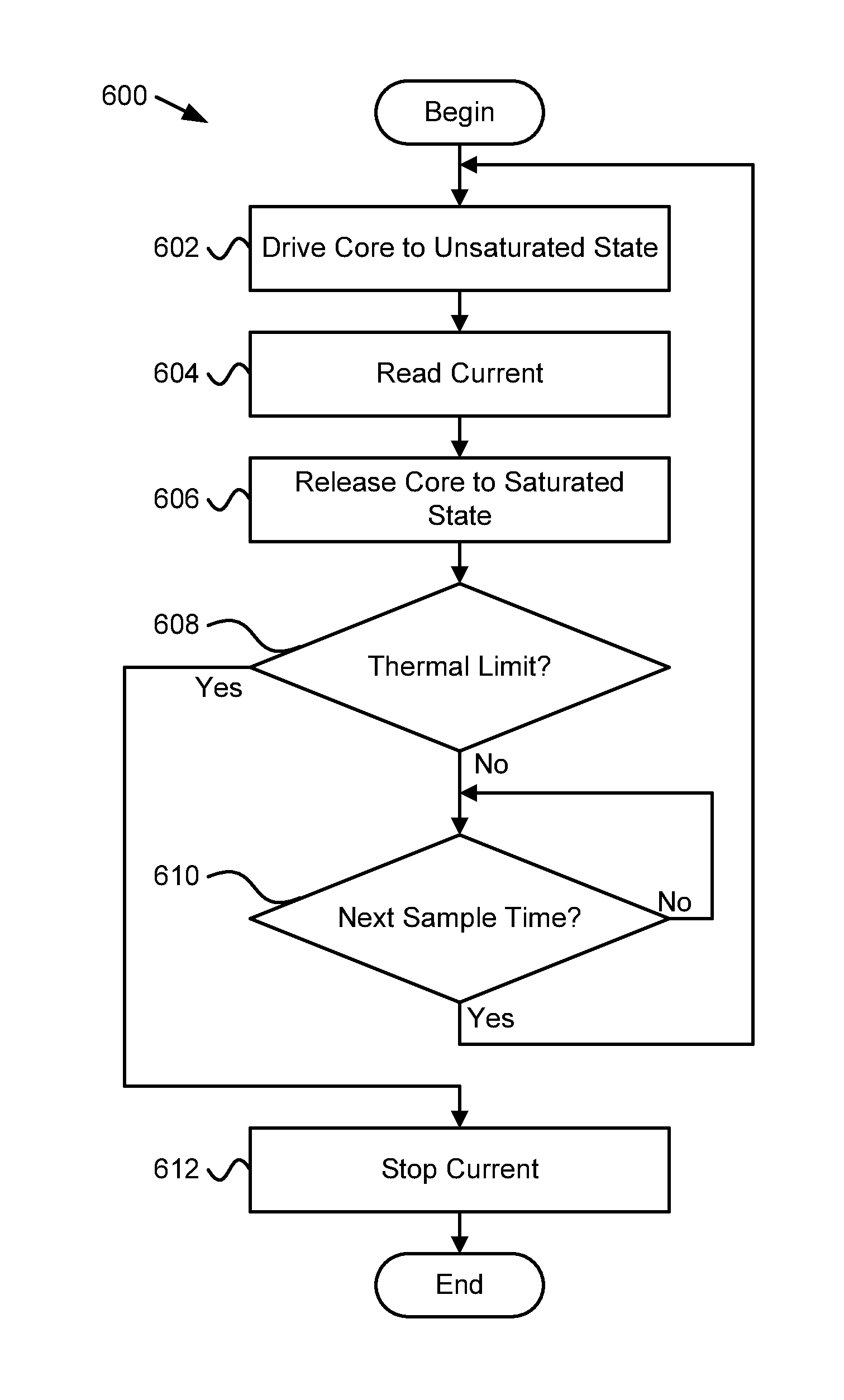

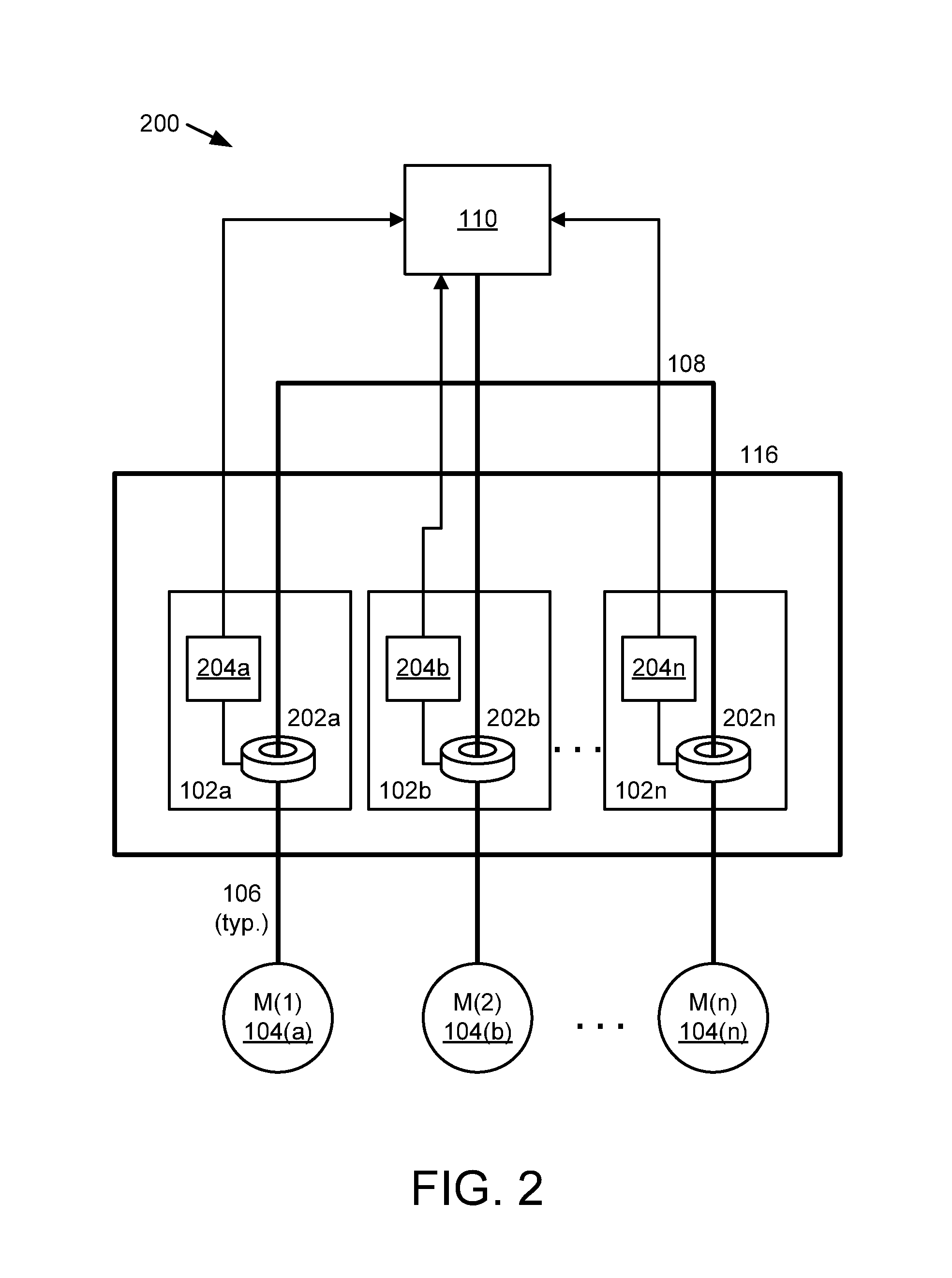

Multimotor variable frequency overload

ActiveUS20140268432A1Reduce cooling effectParameter calibration/settingElectric motor controlThermal limitThermal state

An apparatus for protecting a motor includes two or more motor overloads, within a motor overload enclosure, protecting two or more motors. Each motor overload includes one or more current sensors where each current sensor includes a magnetic core and each current sensor includes a conductor positioned within the magnetic core where the conductor providing power to a motor protected by the two or more motor overloads (“protected motor”). Each motor overload includes a motor trip module that stops current flow to the protected motor in response determining that a thermal state of the protected motor has reached a thermal limit. Determining that the protected motor has reached a thermal limit includes using a current signal from at least one current sensor of the one or more current sensors that senses current of the protected motor to determine a thermal state of the protected motor.

Owner:ROCKWELL AUTOMATION TECH

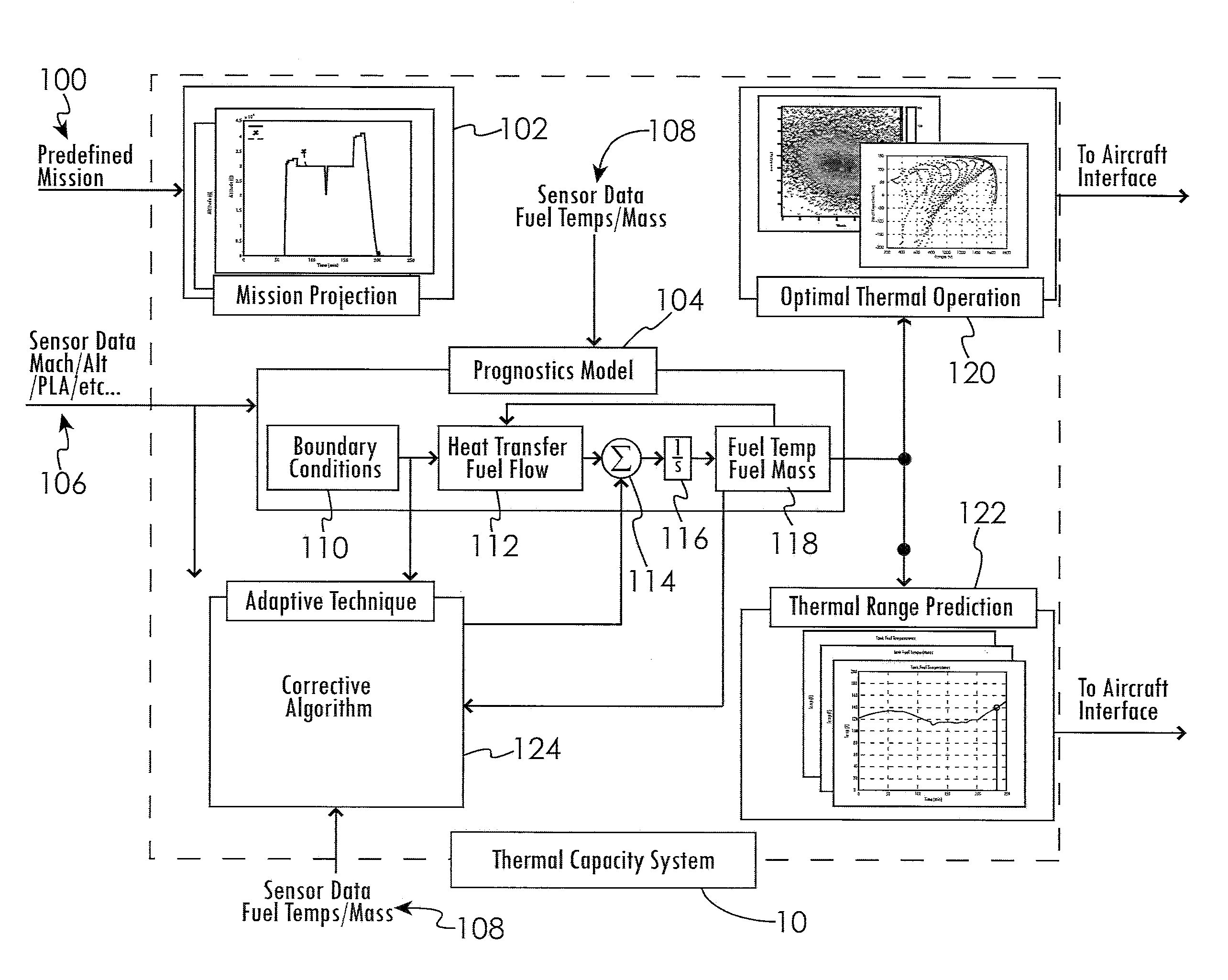

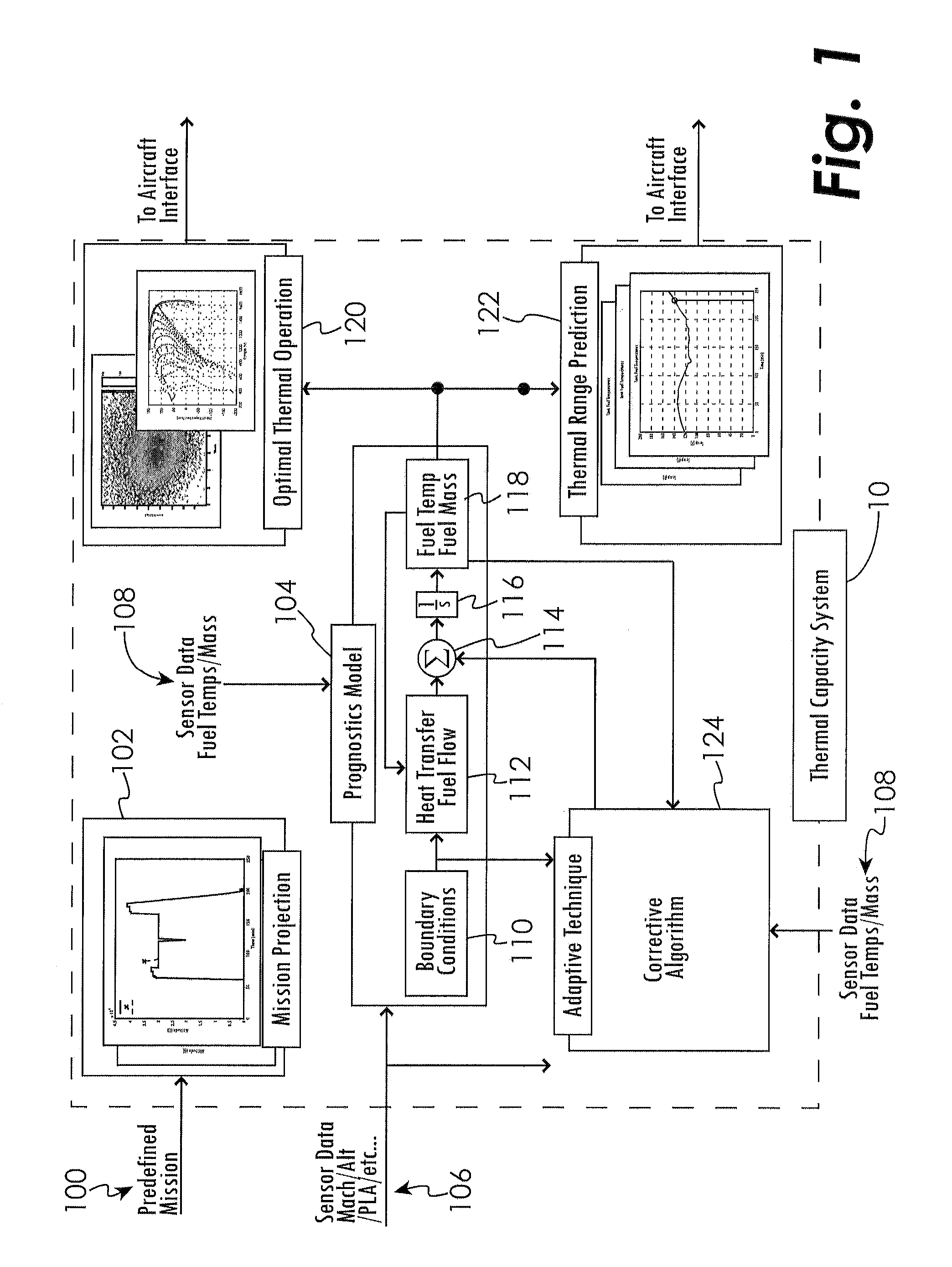

System and method for aircraft thermal capacity prediction

ActiveUS20130046423A1Improve abilitiesAircraft controlAnalogue computers for trafficThermal limitAirplane

A technique for identifying, projecting, displaying, and enhancing the thermal capacity for an aircraft is disclosed wherein the thermal capacity is defined as the amount of time or range the aircraft can continue until a thermal limit is exceeded.

Owner:P C KRAUSE & ASSOC

Appliance airflow detection using differential pressure sensing

ActiveUS20130035030A1Easy to installEasy CalibrationDucting arrangementsDomestic stoves or rangesTraffic capacityThermal limit

A device for detecting and / or measuring air flow in a cooling air flow passageway of an appliance using solid-state flow detectors. Heat generating components of the appliance are controlled in response to detected air flow. More specifically, the disclosure provides a device for detecting the presence of airflow and / or the approximate rate of airflow in a cooling channel of an appliance chassis. Based on this information, the appliance can perform safety-related tasks, such as de-energizing associated heating elements if there is too-low (or no) airflow detected. The solid-state flow detectors are easily fabricated, installed, and calibrated and avoids the calibration, fabrication and / or installation difficulties associated with sail switches and other such approaches such as thermal limit switches.

Owner:HAIER US APPLIANCE SOLUTIONS INC

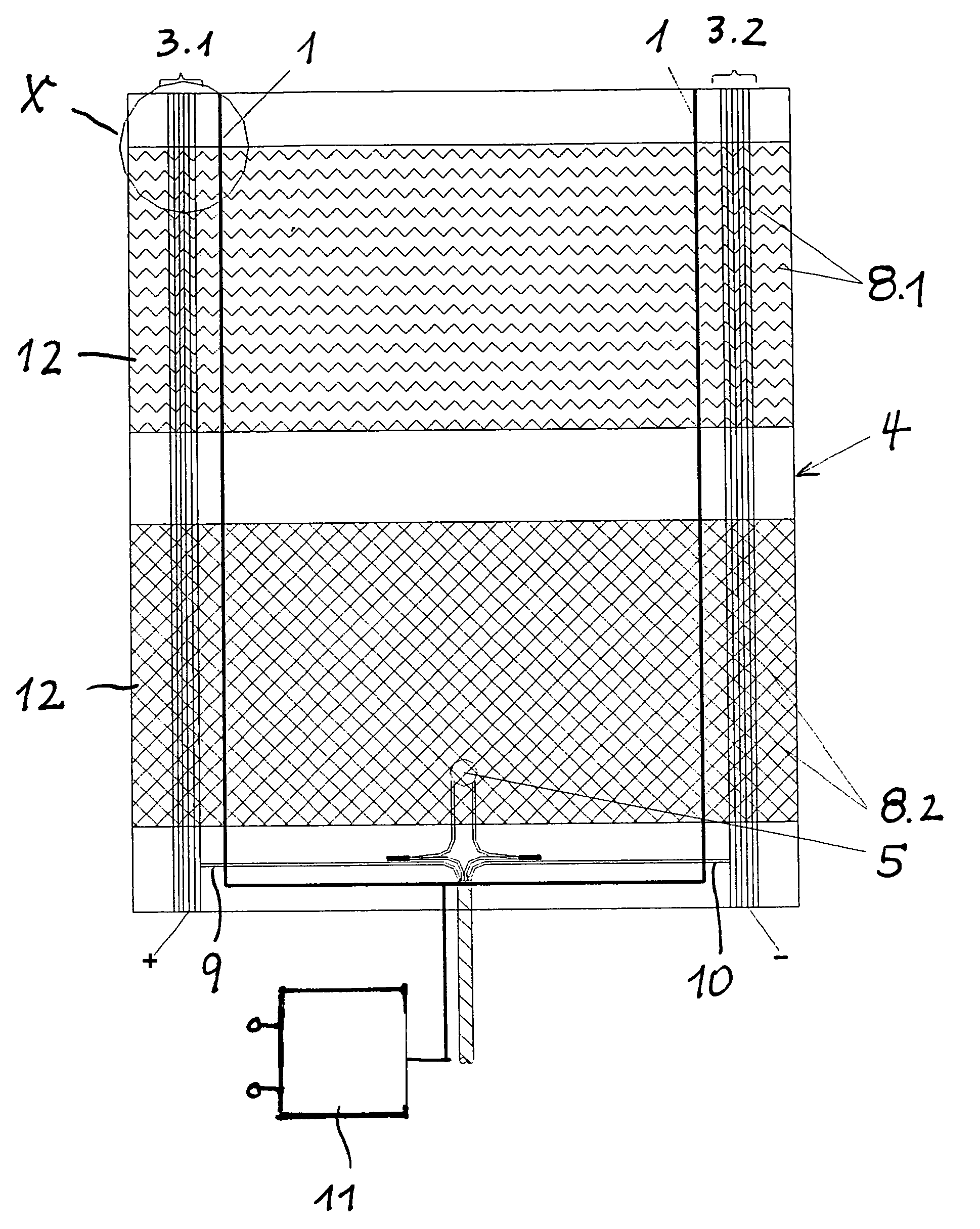

Monitoring device for flexible heating elements

The invention concerns a controlling and monitoring device for avoiding damage through overheating in the case of flexible, textile surface heating elements which include at least two opposed contact conductors (3.1, 3.2) made of electrically conducting, non-insulated fibers or wires between which there extends a plurality of heating conductors (8) which are electrically connected to the contact conductors (3.1, 3.2) and to a current-voltage source. At least one additional conductor (1) is guided along at least one contact conductor over the heating conductors (8), wherein the additional conductor (1) is electrically insulated by a covering material and is connected to an electric or electronic evaluation switch (11). The coating material has a softening range which is above the standard heating temperature of the surface heating element, but below the permissible thermal limit temperature of the surrounding materials and of the base material (12), wherein, in the case of overheating, the coating material melts and wherein the heating conductors (8.1, 8.2), together with the additional conductor, form an electrical contact via which, for the purpose of controlling any overheating, an electric current flows to the electric or electronic evaluation unit which is connected to the current-voltage source.

Owner:I G BAUERHIN GMBH

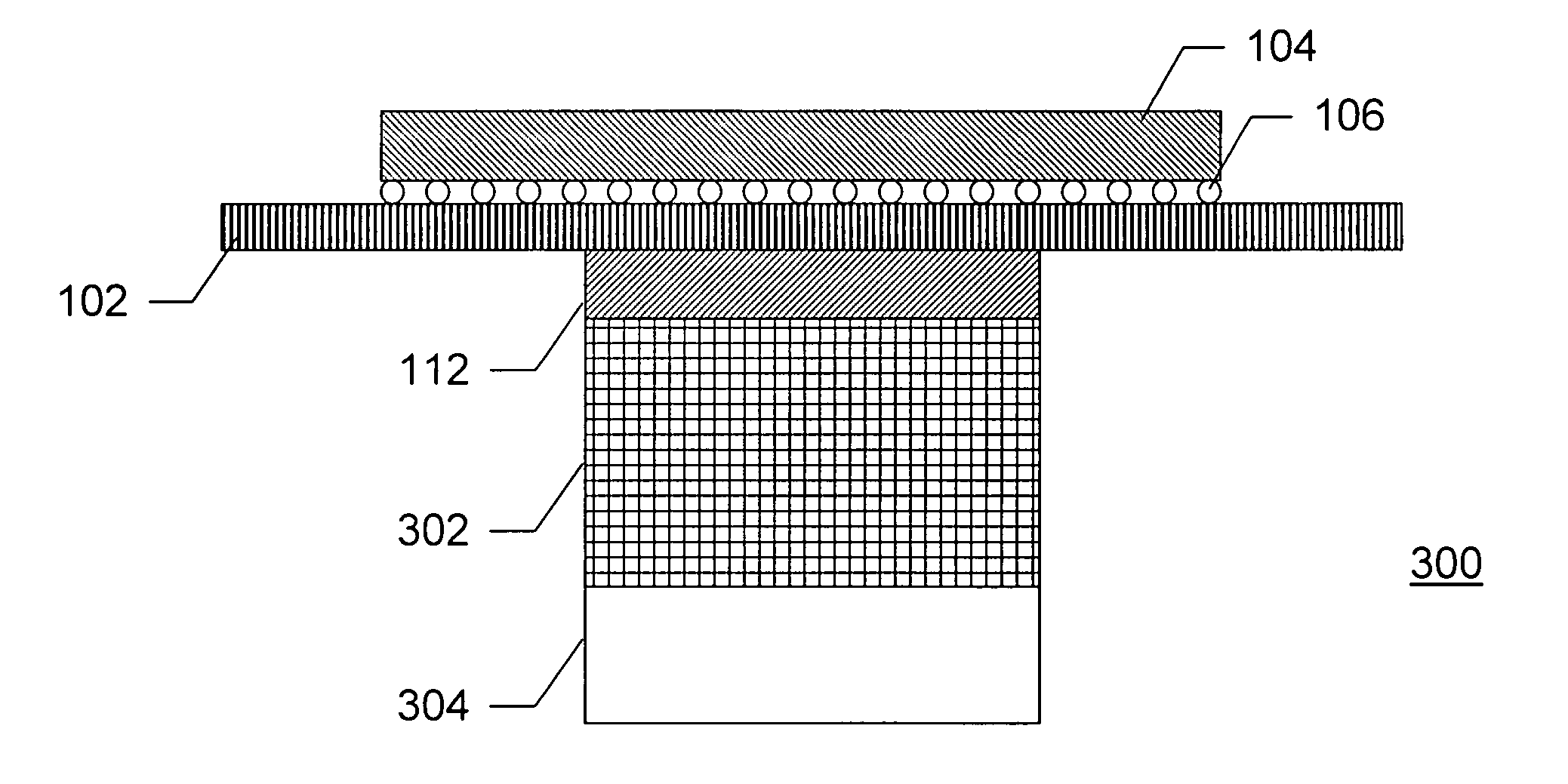

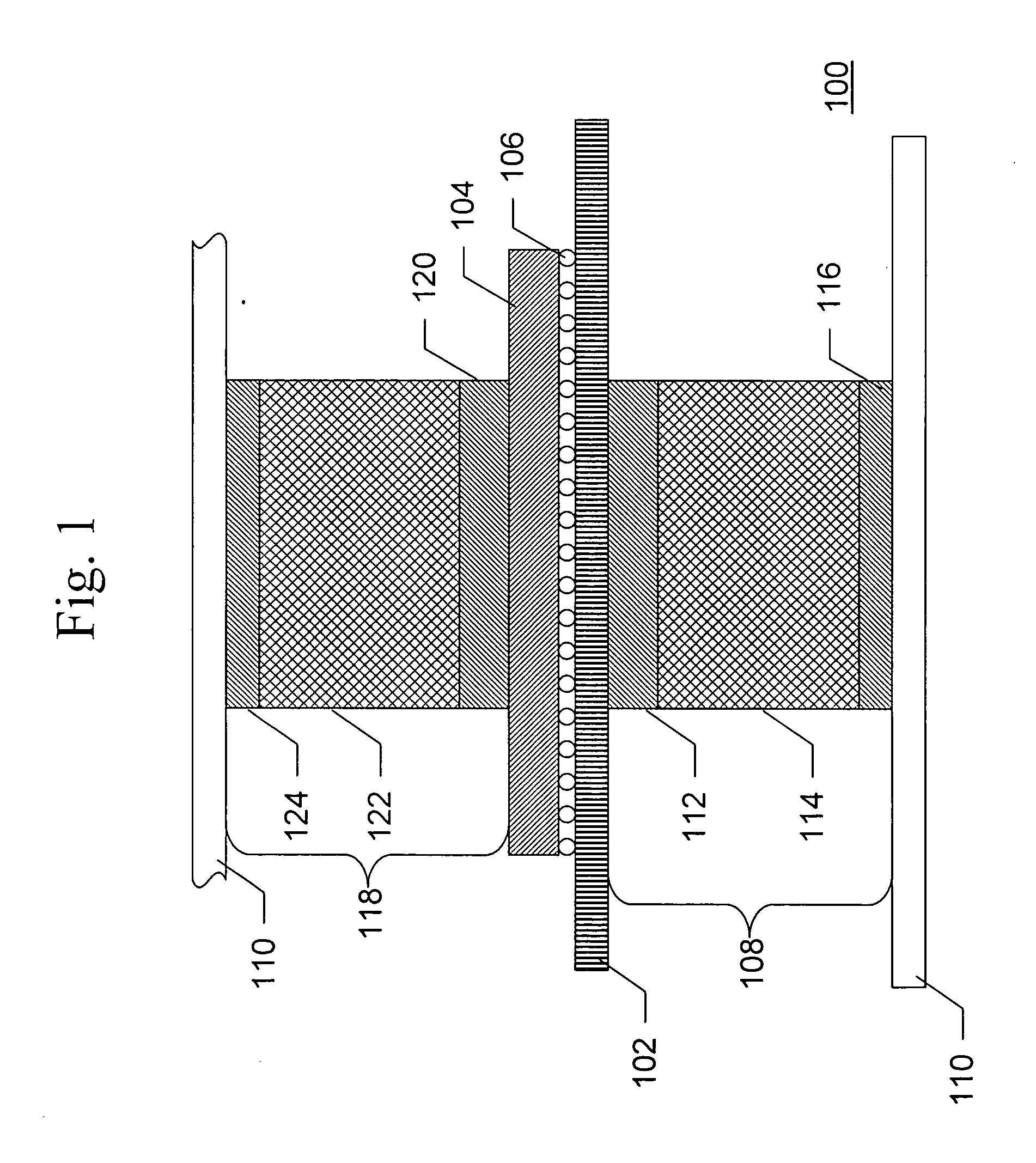

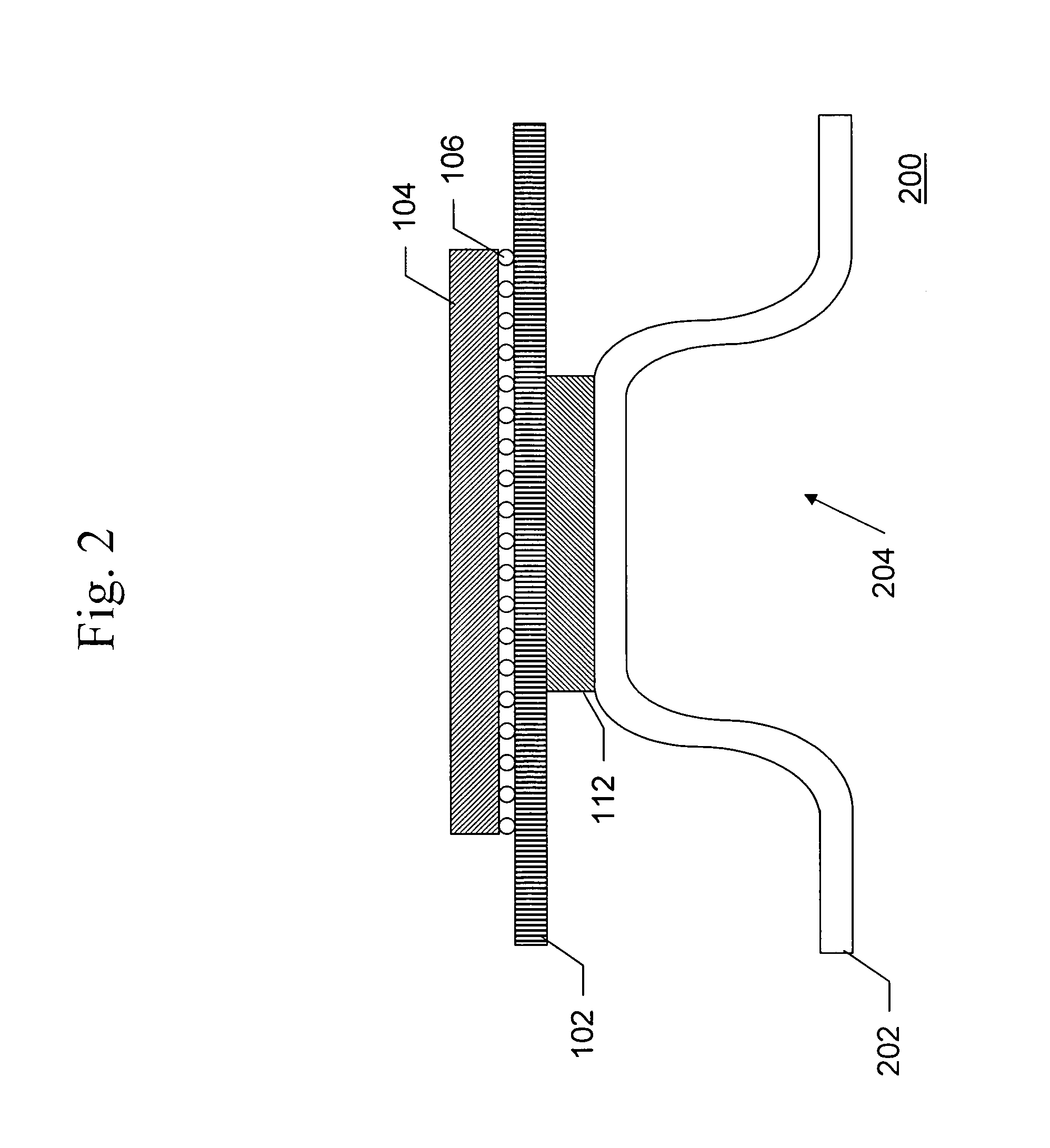

Conductive heat transfer for electrical devices from the solder side and component side of a circuit card assembly

InactiveUS20060171118A1Suppresses component temperature riseBelow its thermal limitSemiconductor/solid-state device detailsPrinted circuit aspectsThermal limitElectrical devices

An apparatus for conductive heat transfer for electrical devices from the solder side of a circuit card assembly can significantly reduce the component temperature, thereby maintaining the electrical device below its thermal limit. The apparatus comprises a thermally conductive member mountable on an opposite face of a circuit board from a face of the circuit board on which an electrical component is mounted, the thermally conductive member operable to conduct heat generated by the electrical component away from the electrical component.

Owner:FUJITSU LTD

System, device, and method for over-current relays protecting motors

InactiveUS7538992B2Prevent the motor from overheatingDC motor speed/torque controlAsynchronous induction motorsThermal limitInduction motor

A system, method, and device for protecting an induction motor are disclosed. The exemplary system may have a module for determining the current drawn by the motor and a module for determining the state of the motor. The system may calculate a used thermal capacity based on a first formula when the motor is in an active state. The system also calculates the used thermal capacity based on a second formula when the motor is in an inactive state. When the used thermal capacity attains a threshold, the relay is tripped thus removing current to the motor and preventing motor from overheating. A method to derive thermal time constants from desired trip time limits (such as those defined by IEC standards or the thermal limit curves provided by motor manufacturers) is also presented. For example, the thermal time constants can then be used in tacking motor used thermal capacity throughout various motor states.

Owner:SIEMENS ENERGY & AUTOMATION INC

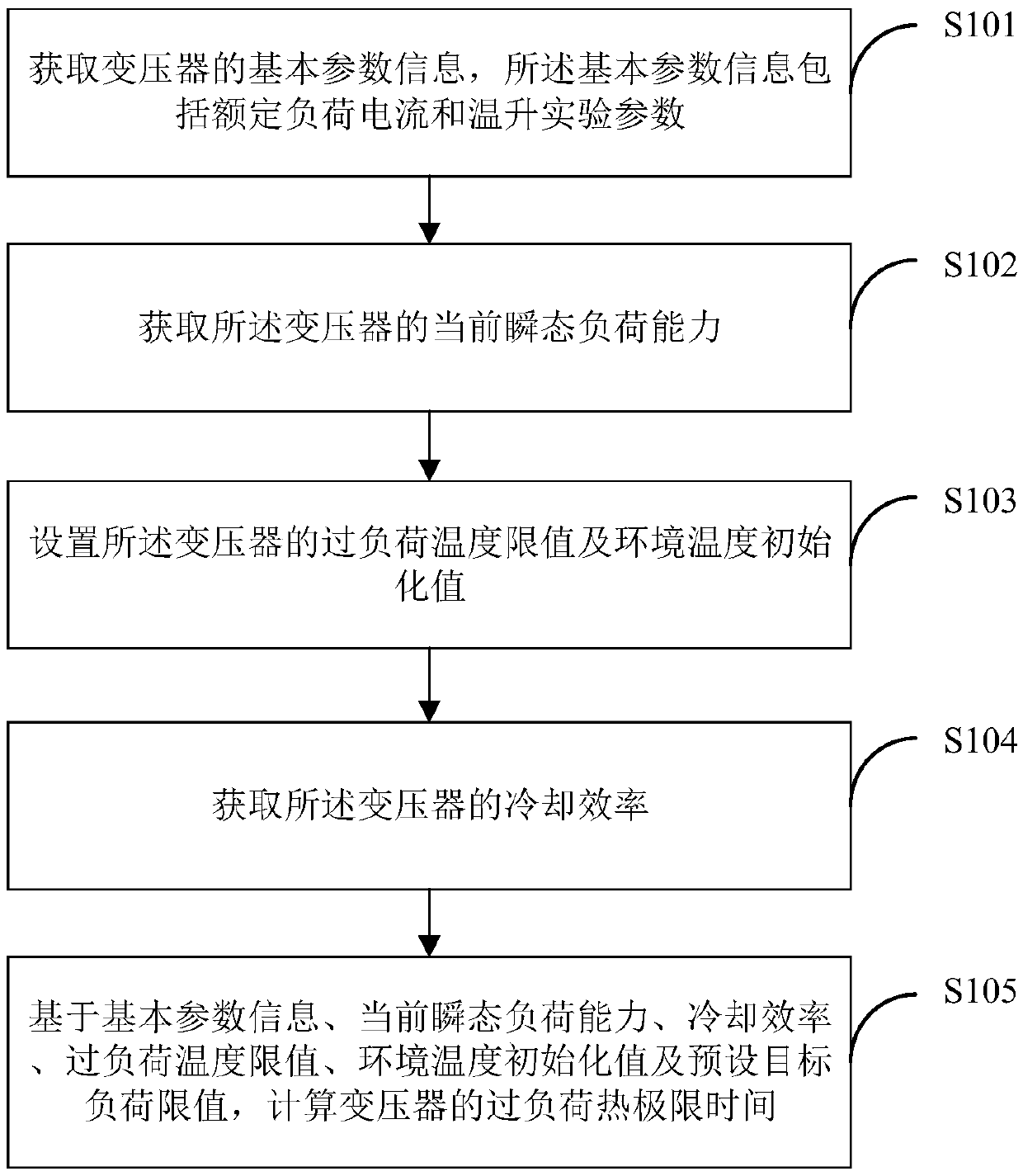

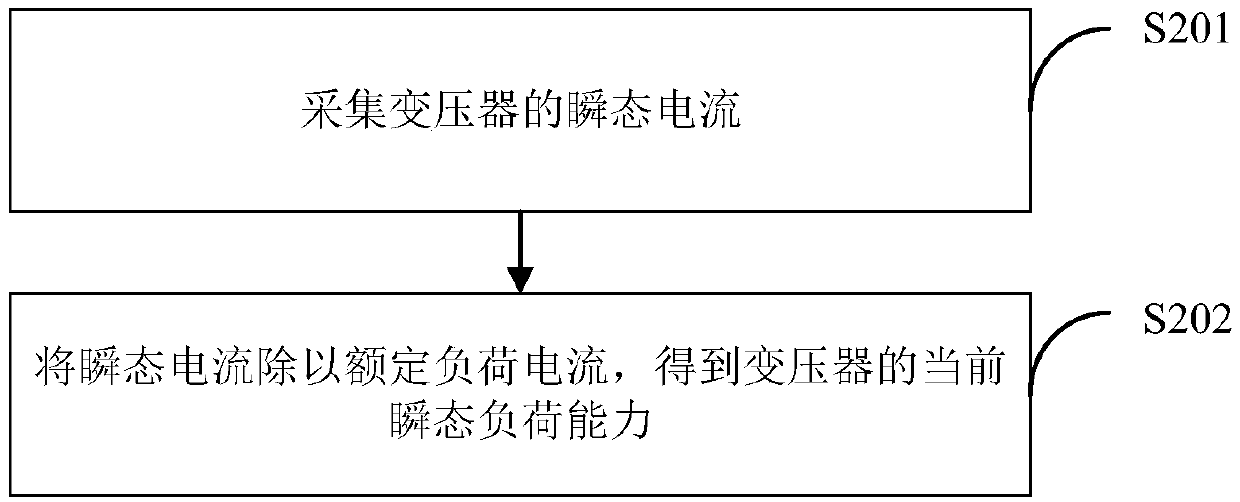

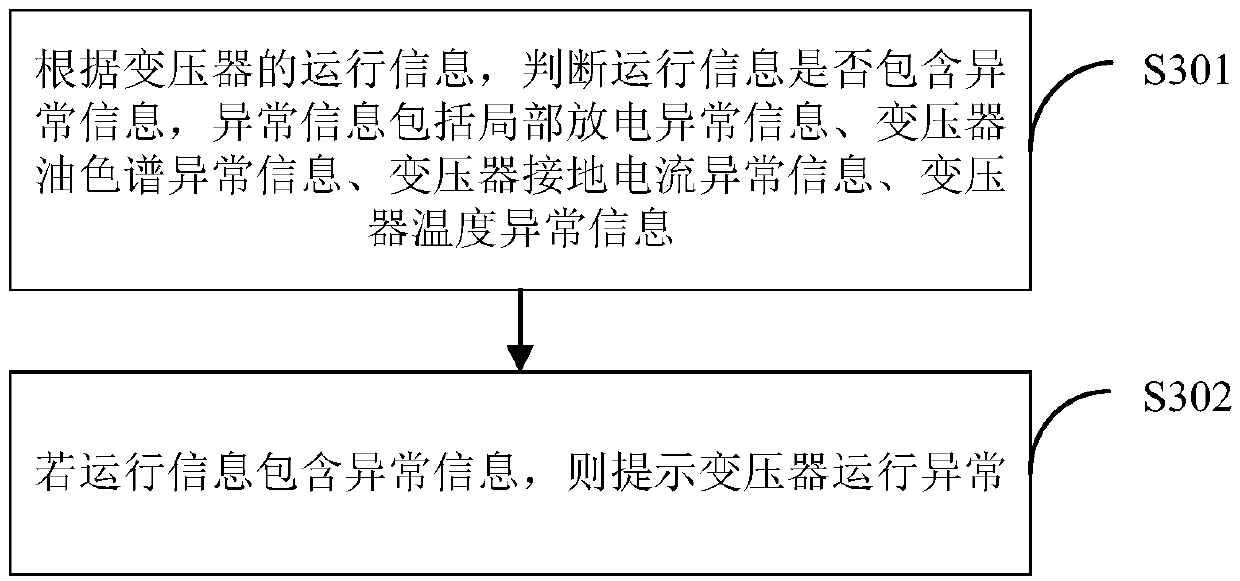

Transformer overload calculation method and system and terminal equipment

ActiveCN108680801ASolve the calculation problem of overload thermal limit timeReduce participationElectrical testingThermal limitTransformer

The invention is suitable for the technical field of transformers, and provides a transformer overload calculation method and system and terminal equipment. The method includes the following steps: obtaining basic parameter information of a transformer; obtaining current transient load capacity of the transformer; setting an overload temperature limit value and an environment temperature initialization value of the transformer; obtaining cooling efficiency of the transformer; and calculating overload thermal limit time of the transformer based on the basic parameter information, the current transient load capacity, the cooling efficiency, the overload temperature limit value, the environment temperature initialization value and preset target load capacity. According to the embodiments of the invention, the dynamic overload capacity of the transformer is calculated in real time by obtaining the current transient load capacity, and so the calculation problem of the overload thermal limittime of the transformer in transient changes is solved. Therefore, the participation of power grid dispatchers is reduced, personnel input cost is reduced, and the work efficiency of the transformeris improved.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

Controller of driver for vehicle

ActiveUS8036798B2Guaranteed normal transmissionSmall sizeDigital data processing detailsGearing controlElectricityThermal limit

A control apparatus for a vehicular drive system arranged to electrically transmit a portion of an output force of an engine through an electric path. The control apparatus is configured to reduce loads of components associated with the electric path and to restrict a temperature rise of the components associated with the electric path, making it possible to reduce the required size of a cooling system. This is accomplished by placing a differential portion in a non-differential state or placing a switching clutch or switching brake in a partially engaged state when electrical energy through the electric path has increased to a thermal limit. As a result, the amount of generated electric energy is reduced, making it possible to restrict the temperature rise of the components associated with the electric path. Accordingly, the cooling system size can be reduced for these components.

Owner:TOYOTA JIDOSHA KK

Temperature-aware task scheduling and proactive power management

Systems, apparatuses, and methods for performing temperature-aware task scheduling and proactive power management. A SoC includes a plurality of processing units and a task queue storing pending tasks. The SoC calculates a thermal metric for each pending task to predict an amount of heat the pending task will generate. The SoC also determines a thermal gradient for each processing unit to predict a rate at which the processing unit's temperature will change when executing a task. The SoC also monitors a thermal margin of how far each processing unit is from reaching its thermal limit. The SoC minimizes non-uniform heat generation on the SoC by scheduling pending tasks from the task queue to the processing units based on the thermal metrics for the pending tasks, the thermal gradients of each processing unit, and the thermal margin available on each processing unit.

Owner:ADVANCED MICRO DEVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com