Vapor chamber

A technology of vapor chamber and vacuum chamber, which is applied in the direction of cooling/ventilation/heating transformation, etc. It can solve the problems of single circulation flow mode of working fluid, small capillary limit and boiling limit range, and achieve great application value, promote circulation flow, Improve the effect of heat exchange function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

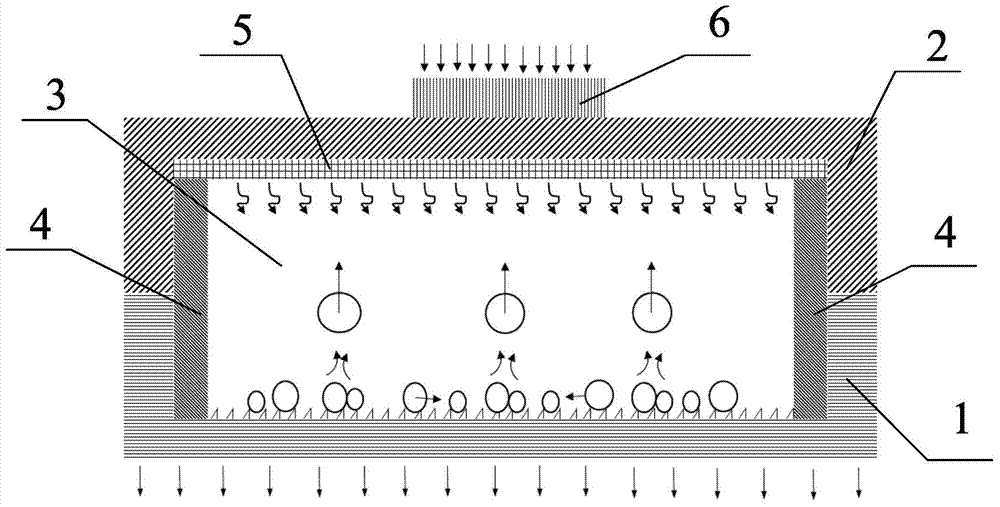

[0026] Such as figure 1 As shown, in this embodiment, a vacuum chamber vapor chamber includes a bottom plate 1 and a cover plate 2 , both sides of the bottom plate 1 and the cover plate 2 are welded and sealed to form a hollow airtight chamber 3 . The airtight chamber 3 is filled with a certain fluid working medium, and the liquid filling rate is 30%-50%. Bottom plate 1 has a superhydrophobic surface and serves as a condensation zone for the vapor chamber of the vacuum chamber. The cover plate 2 has a super-hydrophilic surface and serves as the evaporation zone of the vapor chamber. Copper foam 4 is buried in the airtight cavity 3 with a porosity of 85% to 95%. One end of the copper foam 4 is connected to the cover plate 2 , and the other end of the copper foam 4 is connected to the bottom plate 1 . The microstructure of the porous medium 5 on the copper foam 4 and the cover plate 1 serves as a liquid-absorbing core for promoting the return of the working fluid from the cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com