Apparatus for controlling the pressure in a process chamber and method of operating same

A technology for controlling processing and processing chambers, applied to the components of pumping devices for elastic fluids, pump control, mechanical equipment, etc., can solve problems such as pump damage, pump exceeding heat limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

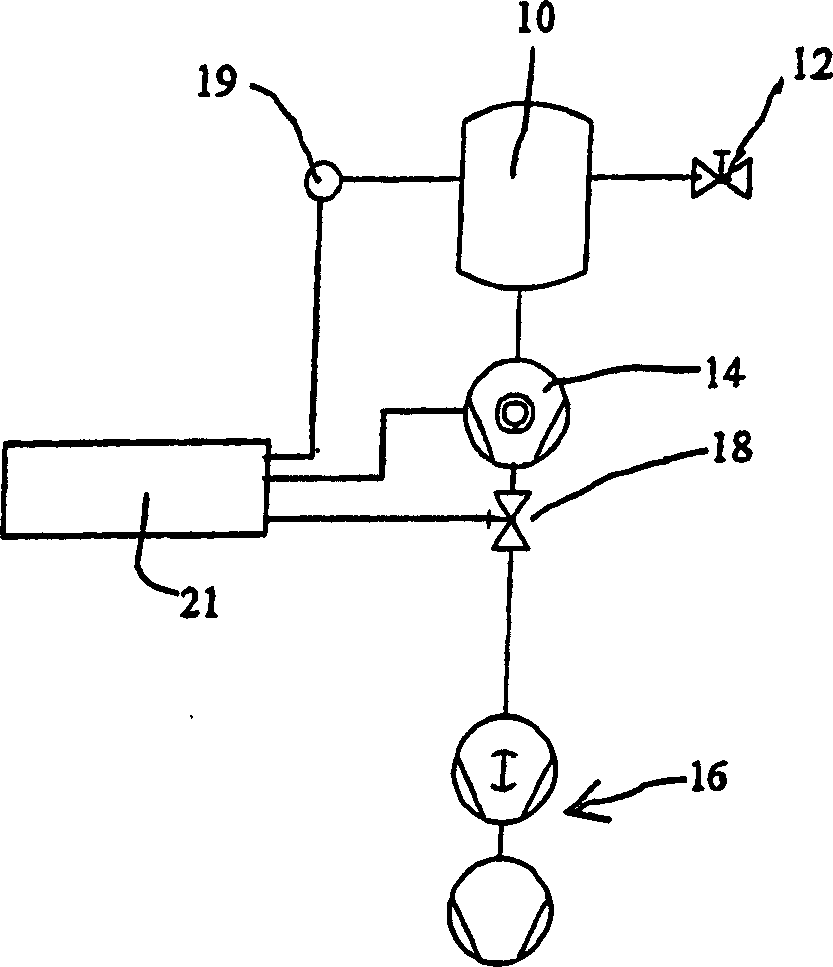

[0027] Such as figure 1 As shown in , the inlet of the semiconductor processing chamber 10 is fluidly connected to an upstream valve 12 to control the introduction of process gas into the processing chamber. Many different process gases are used in the processing of semiconductor products. For example nitrogen, argon or chlorine. It will be appreciated that the molecular or atomic structures of these gases vary considerably, and thus have different requirements for the pumping means downstream of the process chamber 10, and that the process chamber also requires different pressures.

[0028] The pumping device described is not only applicable to semiconductor processing chambers, but also applicable to pressure control in other types of processing chambers.

[0029] The outlet of the processing chamber 10 is fluidly connected to the inlet of the first pump unit 14, which as shown includes a turbomolecular pump (TMP), which may include a turbomolecular pump stage, a molecular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com