Metal bar inner core type self-propagating welding pen and preparation method thereof

A technology of self-propagating welding and metal rods, which is applied in metal processing equipment, welding equipment, aluminothermic welding equipment, etc., can solve the problems of low liquid metal yield, large metal loss ratio, increased use cost, etc., and achieves low price , less metal loss, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

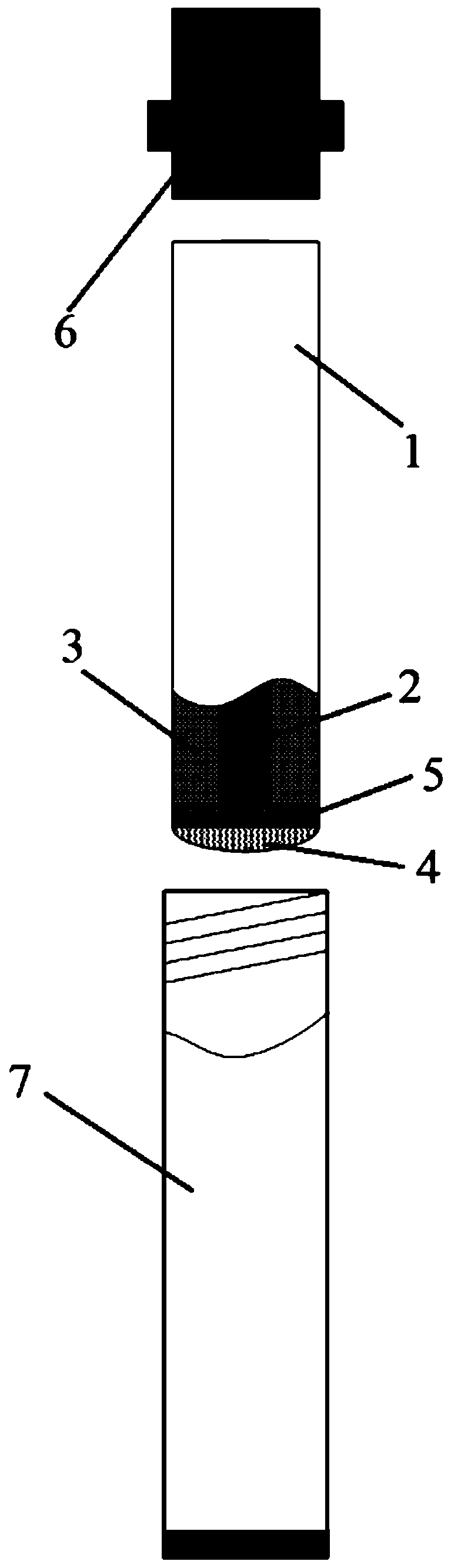

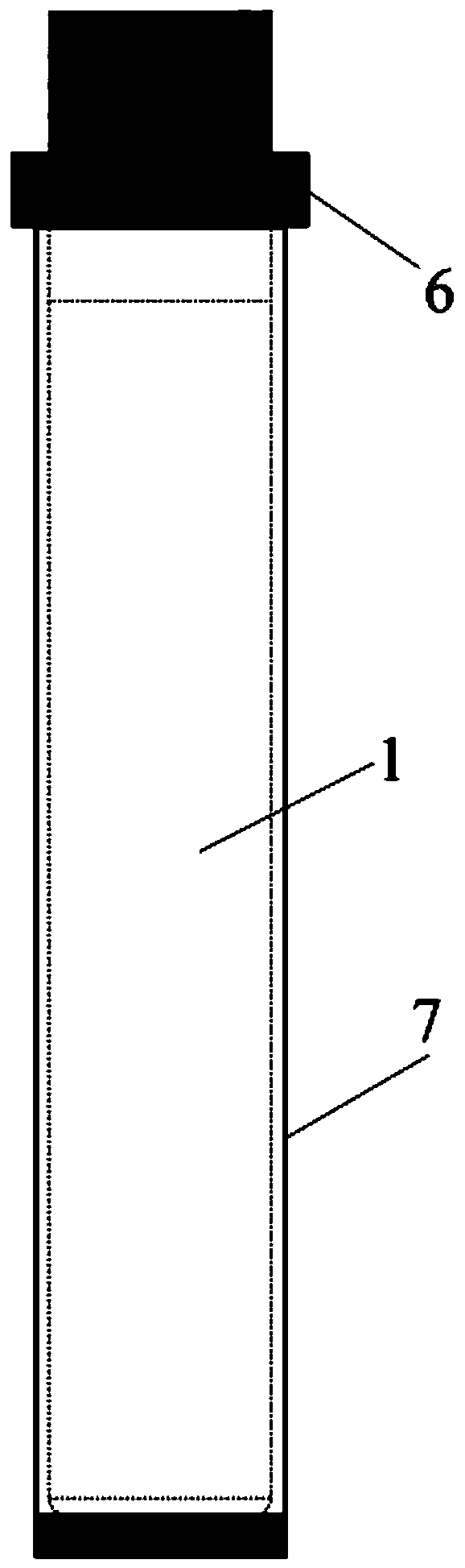

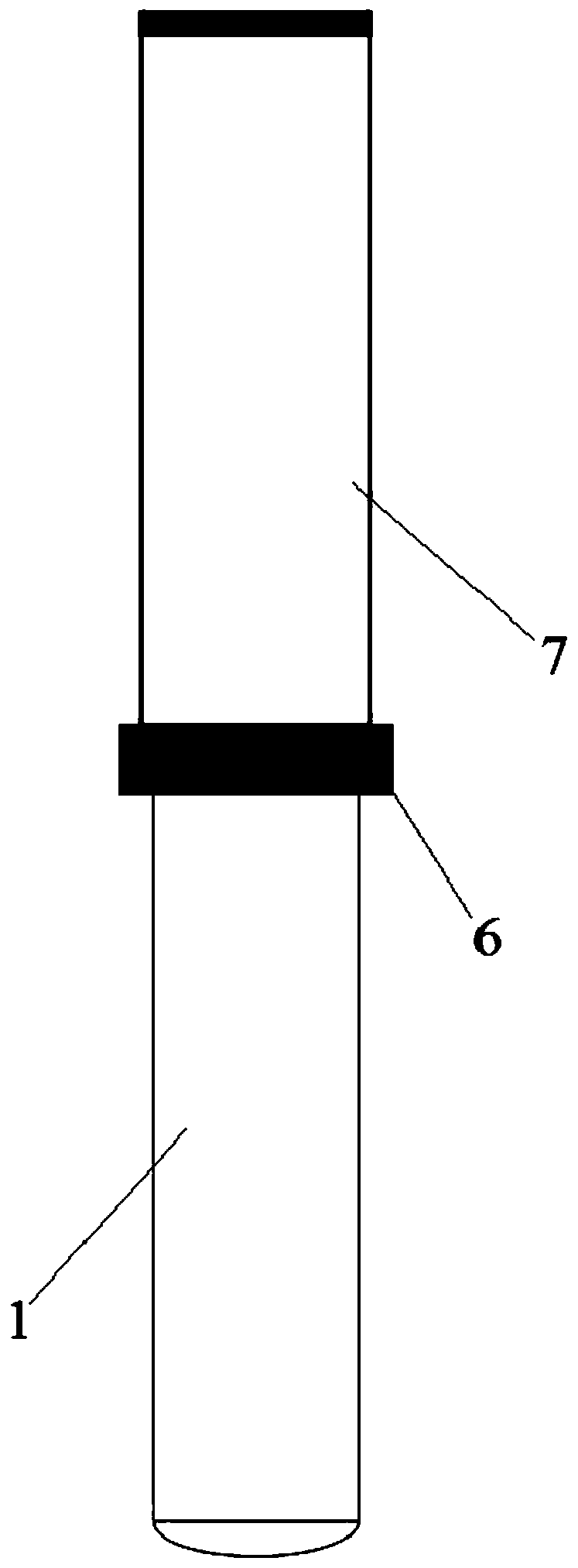

Embodiment 1

[0030] The medicine tube is a paper medicine tube with a diameter of 12mm and a length of 200mm; the inner core of the metal rod is an iron rod with a diameter of 4.0mm and a length of 200mm; the thermite composition is CuO powder 68.0wt.%, Al powder 16.0wt.%, CaF 2 Powder 4.2wt.%, B powder 0.8wt.%, SiO 2 Fe powder 5.6wt.%, Fe powder 2.4wt.%, NiO powder 3.0wt.%. After the welding pen is prepared according to the above preparation process, two Q235 plates of 100mm×40mm×5mm are flat-plate butt welded. 7mm / s. The welding process is stable and controllable, and the surface welding slag is removed after welding, and the weld seam is well formed.

Embodiment 2

[0032] The medicine tube is a paper medicine tube with a diameter of 10mm and a length of 150mm; the inner core of the metal rod is a copper rod with a diameter of 3.8mm and a length of 150mm; the thermite composition is CuO powder 70.0wt.%, Al powder 15.0wt.%, CaF 2 Powder 4.5wt.%, B powder 1.0wt.%, SiO 2 Fe powder 4.6wt.%, Fe powder 2.2wt.%, NiO powder 2.7wt.%. After the welding pen is prepared according to the above preparation process, two copper plates of 100mm×40mm×5mm are flat-plate butt-welded, the welding direction is tilted backward, the welding inclination is about 70°, the welding rod flame length is controlled at about 5mm, and the welding speed is 8mm / s. The welding process is stable and controllable, and the surface welding slag is removed after welding, and the weld seam is well formed.

Embodiment 3

[0034] The medicine tube is a paper medicine tube with a diameter of 12.5mm and a length of 180mm; the inner core of the metal rod is an iron rod with a diameter of 4.2mm and a length of 180mm; the thermite composition is CuO powder 67.0wt.%, Al powder 18.0wt.%, CaF 2 Powder 5.0wt.%, B powder 0.6wt.%, SiO 2 Fe powder 4.9wt.%, Fe powder 2.0wt.%, NiO powder 2.5wt.%. After the welding pen is prepared according to the above preparation process, two pieces of 70mm×25mm×5mm stainless steel are plate butt welded, the welding direction is backward tilted, the welding inclination is about 70°, the welding rod flame length is controlled at about 5mm, and the welding speed is 7mm / s. The welding process is stable and controllable, and the surface welding slag is removed after welding, and the weld seam is well formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com