Ceramic die shell capable of eliminating casting hot crack defects of section-variable parts and molding method thereof

A technology of ceramic mold shell and variable cross-section, applied in casting molding equipment, mold, mold composition, etc., can solve the problem of not considering the ceramic mold shell structure and molding process, to eliminate hot crack defects, improve structural strength, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

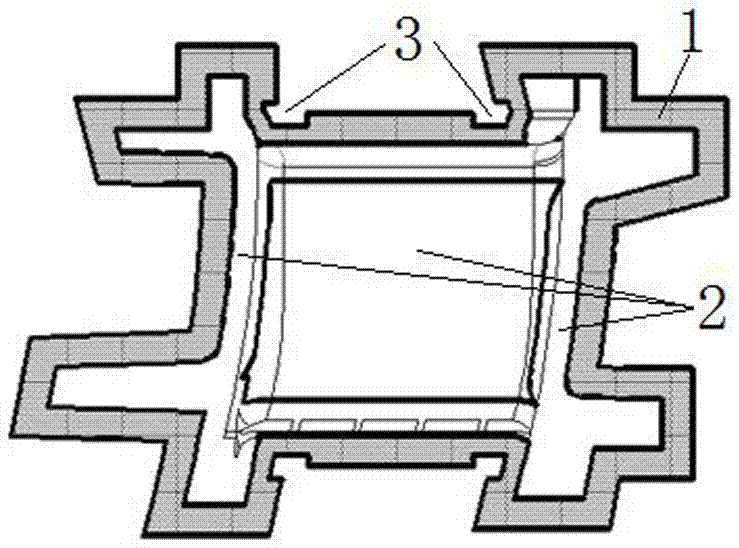

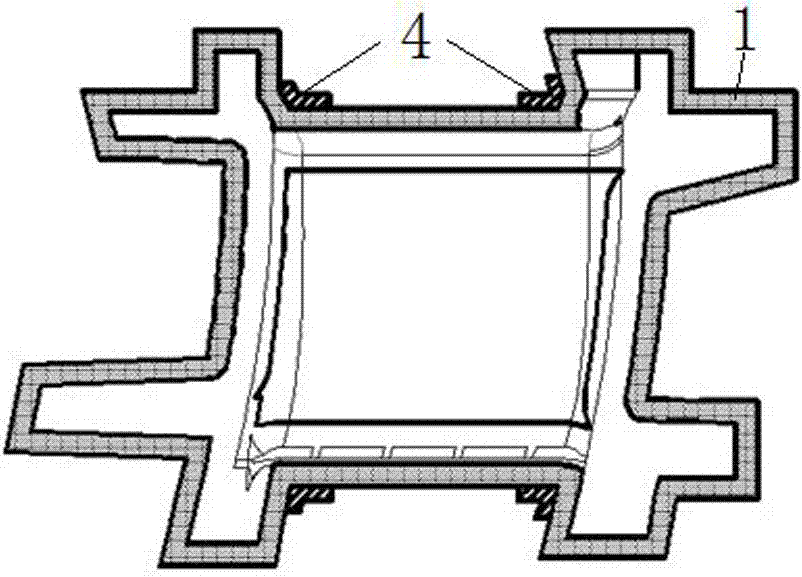

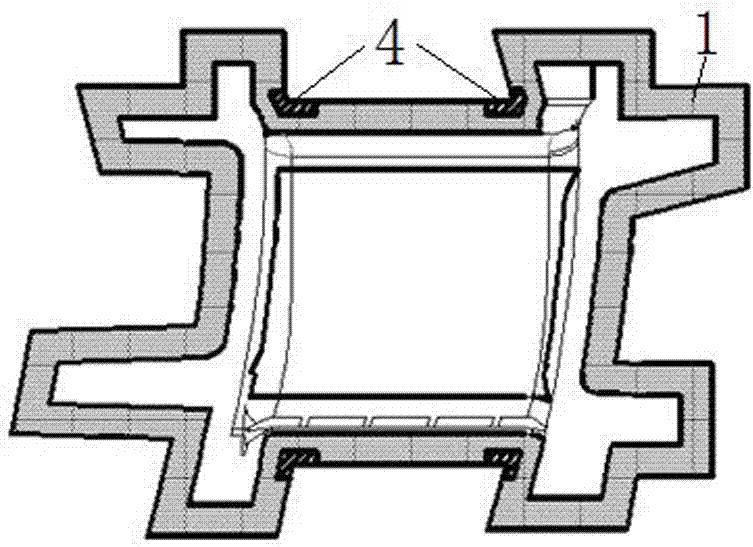

[0029] see figure 1 As shown, the present invention is a variable cross-section part-a ceramic mold shell for precision casting of a heavy-duty gas turbine guide vane. The ceramic mold shell 1 has a casting cavity 2 matching the design structure of the turbine guide vane.

[0030] The above-mentioned casting cavity 2 has an inner edge plate part, an airfoil body part and an outer edge plate part according to the turbine guide vane, and the connection transition between the inner edge plate part and the airfoil body part respectively forms a cross-sectional mutation structure, that is, the inner edge plate part , The cross-sectional area of the outer edge plate portion is larger than the cross-sectional area of the airfoil portion. When casting molten steel in the casting cavity 2 with such a structure for precision casting, hot knot effects will occur at the sudden change in cross section—that is, the solidification process at the sudden cross section is slower than that o...

Embodiment 2

[0041] The invention relates to a ceramic mold shell for precise casting of a variable cross-section part-turbine blade, and the ceramic mold shell has a casting cavity matching the design structure of the turbine blade.

[0042] According to the turbine blade, the above-mentioned casting cavity has a shroud, a blade body and a tenon root, and a cross-sectional mutation structure is formed at the connection transition between the blade crown, tenon root and blade body, that is, the cross-sectional area of the blade crown and tenon root is larger than that of the blade body cross-sectional area. When casting molten steel in such a casting cavity for precision casting, hot knot effects will occur at the sudden change in section—that is, the solidification process at the sudden change in cross section is slower than that of the surrounding area, so there will be hot crack defects including porosity. That is to say, according to the solidification characteristics of the molten s...

Embodiment 3

[0053] The invention relates to a variable cross-section part-a ceramic mold shell for precision casting of a small T-shaped high-temperature alloy part. The ceramic mold shell has a casting cavity matching the design structure of the T-shaped high-temperature alloy part.

[0054] The above-mentioned casting cavity has a crown and a body according to the T-shaped superalloy part, and a cross-sectional abrupt structure is formed at the connection transition between the crown and the body, that is, the cross-sectional area of the crown is larger than that of the body. When casting molten steel in such a casting cavity for precision casting, hot knot effects will occur at the sudden change in section—that is, the solidification process at the sudden change in cross section is slower than that of the surrounding area, so there will be hot crack defects including porosity. That is to say, according to the solidification characteristics of the molten steel in the aforementioned cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com