Coating layer for fracturing bomb propulsive agents and preparation method therefor

A fracturing bomb propellant and coating technology, applied in the direction of adhesive, adhesive type, epoxy resin glue, etc., can solve the problems of pollution, failure to meet the use requirements, poor medium resistance, etc., and achieve simple process, Good water-proof effect and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

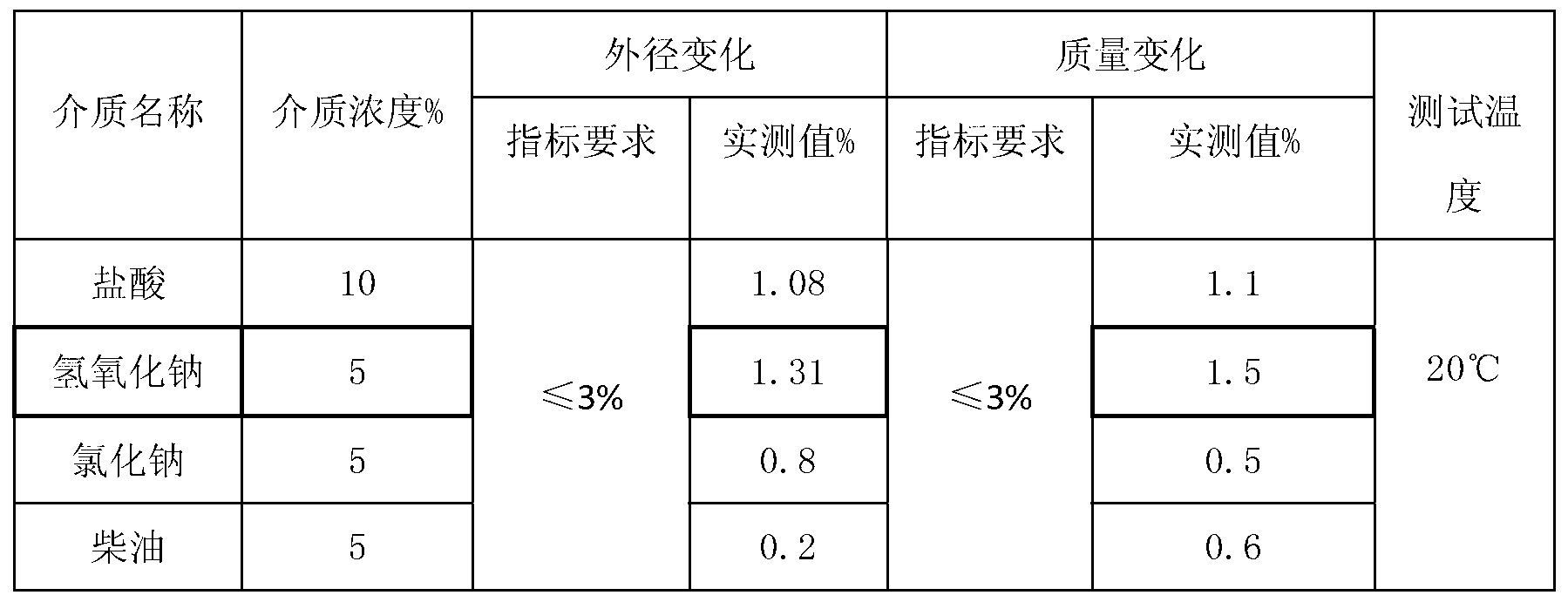

Embodiment 1

[0039] A fracturing bomb propellant cladding layer, the cladding layer is composed of: silicone modified epoxy resin: 78.7%, hydroxyl-terminated polybutadiene: 7.9%, silicone water repellent: 1.6% , polyamide curing agent: 11.8%;

[0040] The propellant coating layer of the fracturing bomb described in this embodiment is prepared according to the following steps:

[0041] Step 1, take a clean container, and weigh the following components according to weight percentage: silicone modified epoxy resin: 78.7%, hydroxyl-terminated polybutadiene: 7.9%, silicone water repellent: 1.6%, poly Amide curing agent: 11.8%;

[0042] Step 2, after mixing and stirring the components weighed in step 1, transfer them to the spray gun storage tank, vacuum defoaming for 15 minutes, and obtain the rubber compound;

[0043] Step 3: Spray the glue obtained in Step 2 on the required coating surface of the propellant to be coated, and place it at room temperature for 8 hours to obtain a fracturing bo...

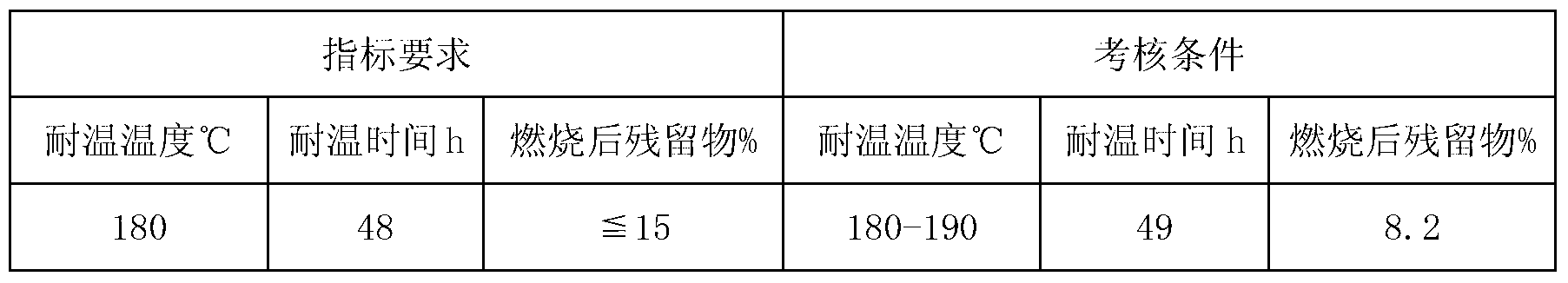

Embodiment 2

[0058] A fracturing bomb propellant coating layer, the weight percentage of the coating layer is composed of:

[0059] Silicone modified epoxy resin: 86.2%, hydroxyl-terminated polybutadiene: 4.3%, silicone water repellent: 0.9%, polyamide curing agent: 8.6%.

[0060] The propellant coating layer of the fracturing bomb described in this embodiment is prepared according to the following steps:

[0061] Step 1, take a clean container, and weigh the following components according to weight percentage: silicone modified epoxy resin: 86.2%, hydroxyl-terminated polybutadiene: 4.3%, silicone water repellent: 0.86%, poly Amide curing agent: 8.6%;

[0062] Step 2, after mixing and stirring the components weighed in step 1, transfer them to the spray gun storage tank, vacuum defoaming for 10 minutes, and obtain the rubber compound;

[0063] Step 3: Spray the sizing material obtained in Step 2 on the required coating surface of the propellant to be coated, and place it at room temperat...

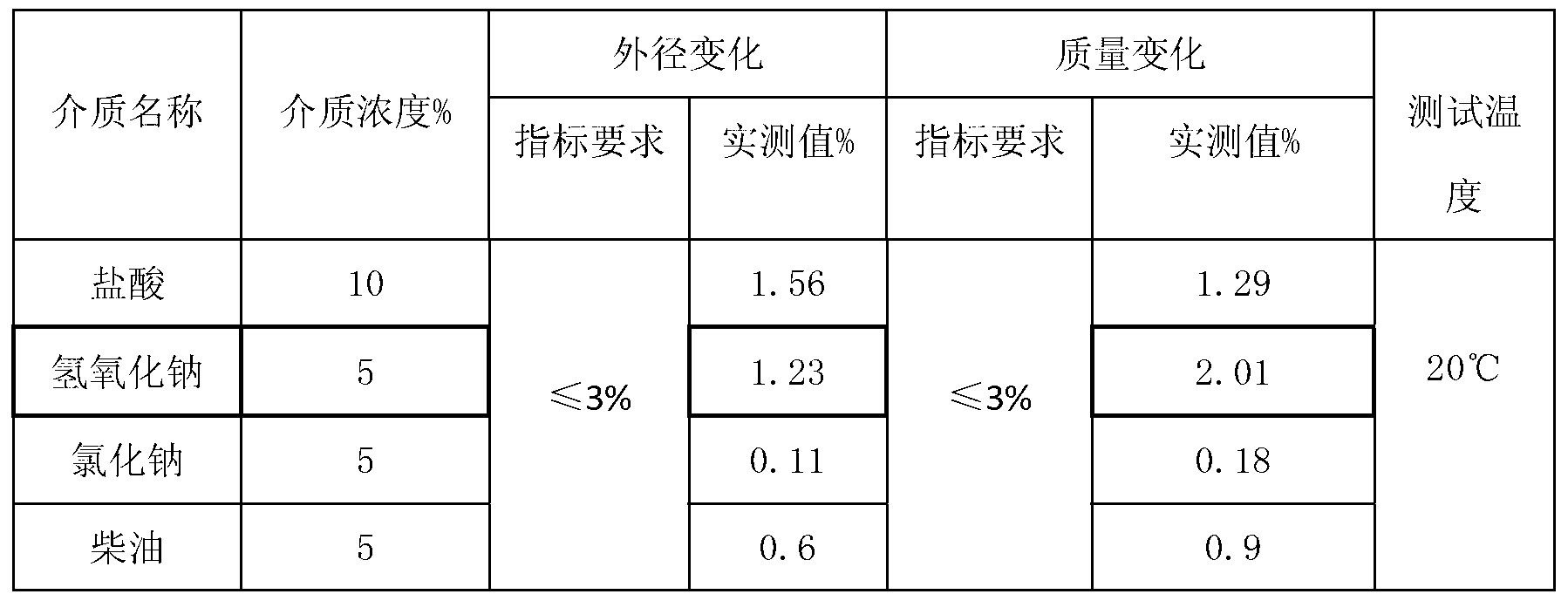

Embodiment 3

[0080] A fracturing bomb propellant coating layer, the weight percentage of the coating layer is composed of:

[0081] Silicone modified epoxy resin: 82.84%, hydroxyl terminated polybutadiene: 5.8%, silicone water repellent: 0.86%, polyamide curing agent: 10.5%.

[0082] The propellant coating layer of the fracturing bomb described in this embodiment is prepared according to the following steps:

[0083] Step 1, take a clean container, and weigh the following components according to weight percentage: silicone modified epoxy resin: 82.84%, hydroxyl-terminated polybutadiene: 5.8%, silicone water repellent: 0.86%, poly Amide curing agent: 10.5%;

[0084] Step 2, after mixing and stirring the components weighed in step 1, transfer them to the spray gun storage tank, vacuum defoaming for 15 minutes, and obtain the rubber compound;

[0085] Step 3: Spray the glue obtained in Step 2 on the required coating surface of the propellant to be coated, and place it at room temperature fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com