Hot-static pressure molding apparatus

A technology of static pressure forming and pressure rod, which is applied in the field of hot static pressure forming devices, which can solve the problems of pressure fluctuation, limited compression stroke, uneven heating of the mold, etc., to reduce heat loss, accurately control the pressure value, The effect of improving the demolding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

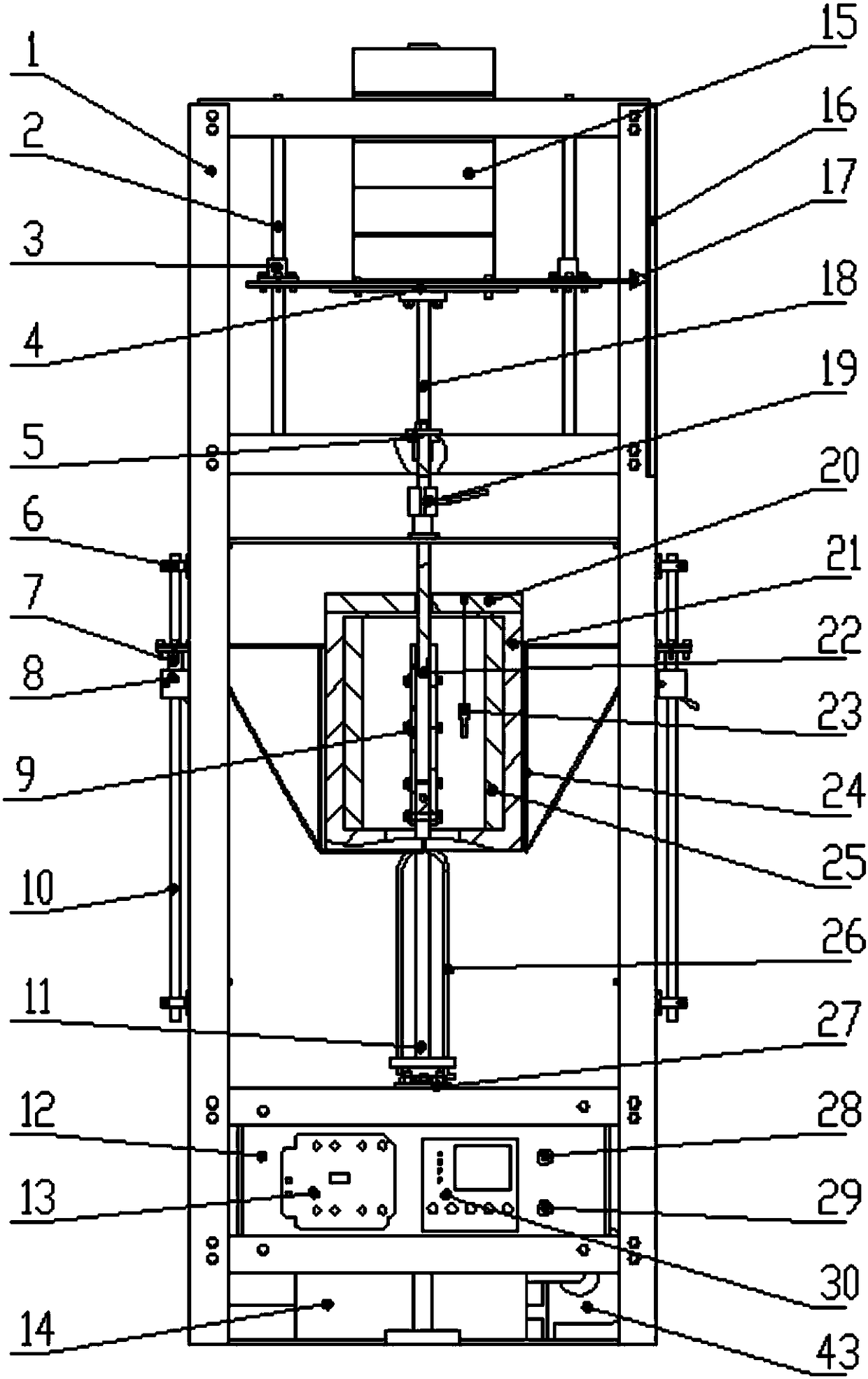

[0043] like Figure 1 to Figure 7 As shown, this embodiment proposes a preferred hot static pressing forming device, which includes a pressing mechanism installed on the frame 1, a mold 9, a heating mechanism, a cooling mechanism, and a power control box 12, etc. component.

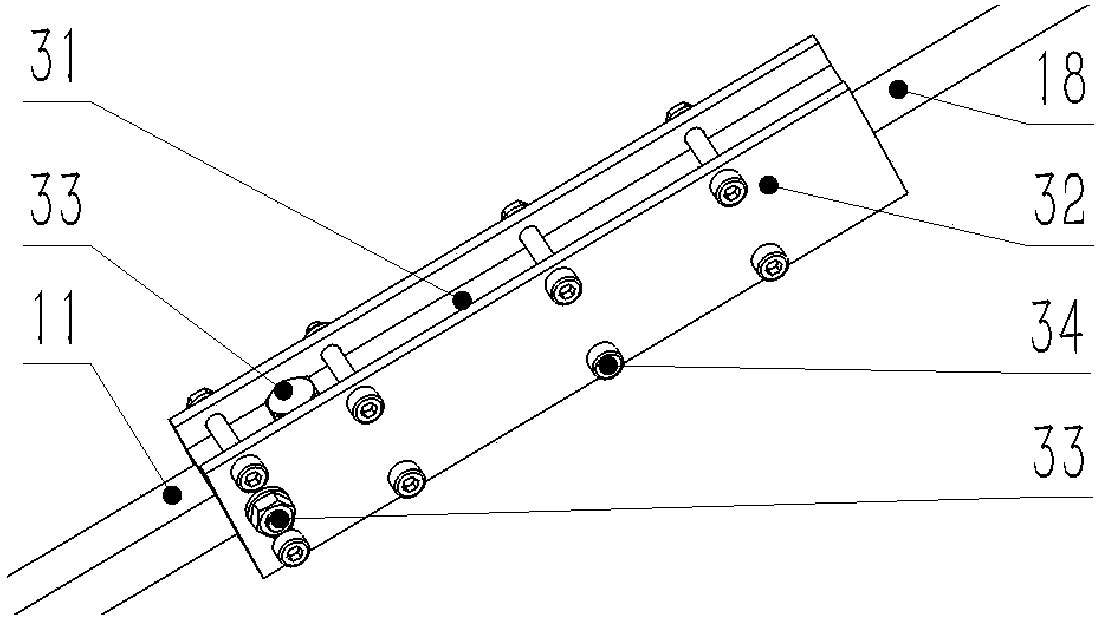

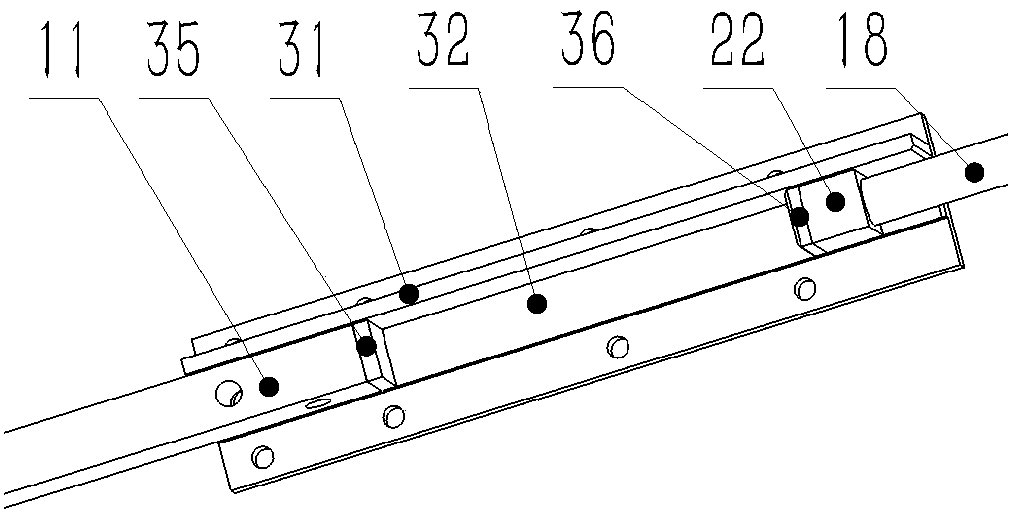

[0044]In this embodiment, the pressurizing mechanism includes several weights 15 , weight bearing plates 4 , four pressure guide rods 2 and four linear bearings 3 and other components. The four pressure guide rods 2 can provide an effective compression stroke of 300mm. The four pressure guide rods 2 are symmetrically installed on both sides of the frame 1, and the top and bottom ends of each pressure guide rod 2 are fixed on the upper part of the frame 1 adjacent to each other. on the beam. Each pressure guide rod 2 is provided with a linear bearing 3 fixedly connected to the weight bearing plate 4. Each linear bearing 3 forms a clearance fit with the corresponding pressure guide rod 2. Under the guidan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com