Calculating method for feeding of thin-walled bent copper pipes

A calculation method and pipe bending technology, applied in calculation, instrumentation, electrical digital data processing, etc., can solve the problems of difficulty in determining the position and inability to guarantee the molding size, and achieve high accuracy, small difference in the axial length of the centerline, and bending tube simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

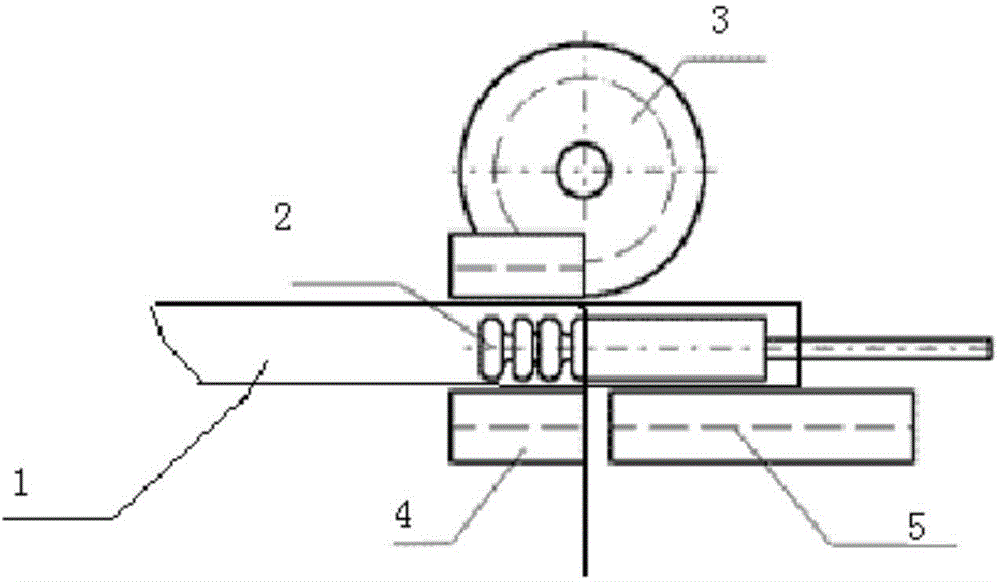

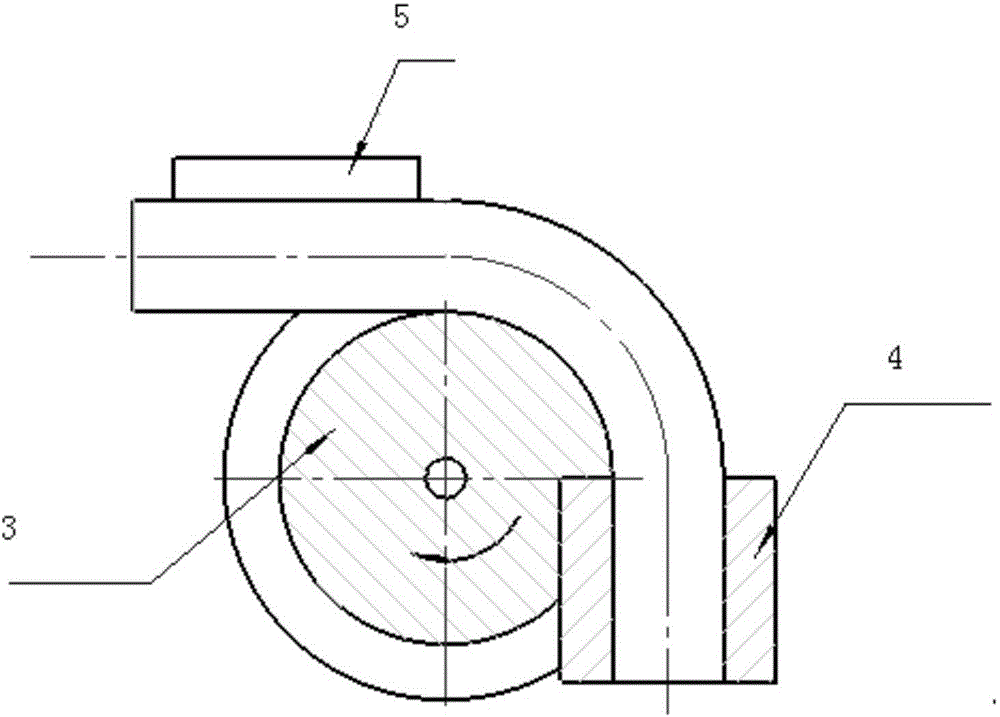

Image

Examples

Embodiment Construction

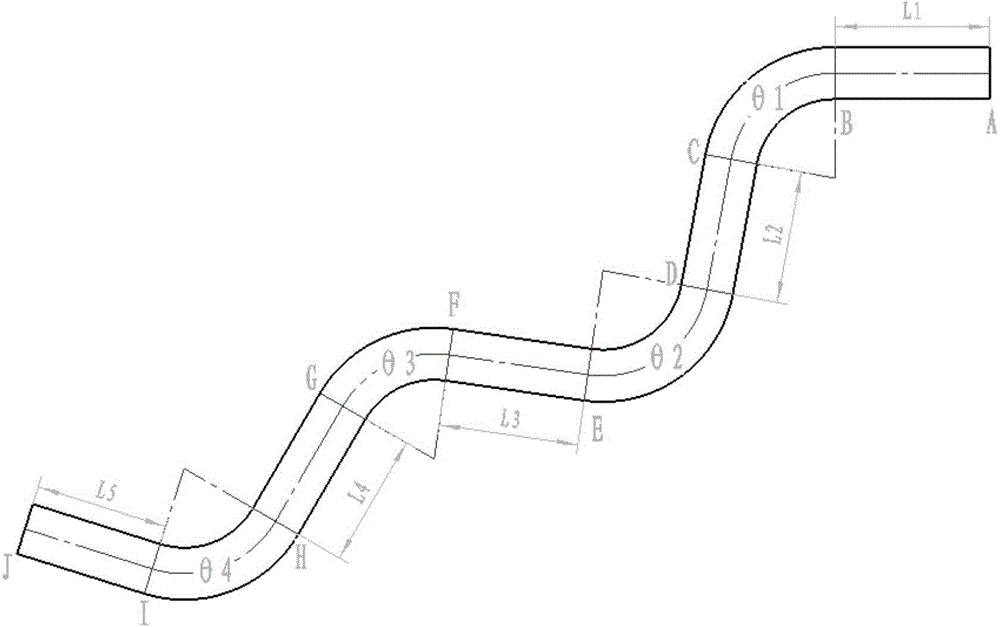

[0022] The elbow radius is determined by the equipment mold, which is a known quantity, that is, the equipment manufacturer designs and manufactures the mold according to this value. The principle of this value is generally proposed by the user according to the design requirements of the system pipeline and combined with the equipment manufacturer's mold It is determined by the cold bending capacity of copper pipes that the production technology can meet. In order to ensure standardization and design standardization, the current industry generally adopts the bend radius to design and manufacture molds according to 2 times, 2.5 times, and 3 times the outer diameter of the copper pipe. , In this embodiment, the radius of the elbow is R=2D, where D is the outer diameter of the copper pipe.

[0023] refer to image 3 As shown, the present invention provides a calculation method for blanking of thin-walled copper pipe bends, which includes the following steps: first, select three c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com