Intelligently-controllable electromagnetic telescopic injection molding car lamp mold

A car lamp mold, intelligent control technology, applied to household appliances, other household appliances, household components, etc., can solve the problems of affecting the stability of the finished product, high manual operation intensity, manual shaking, etc., to reduce the manual operation intensity and facilitate the movement. , Molding and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

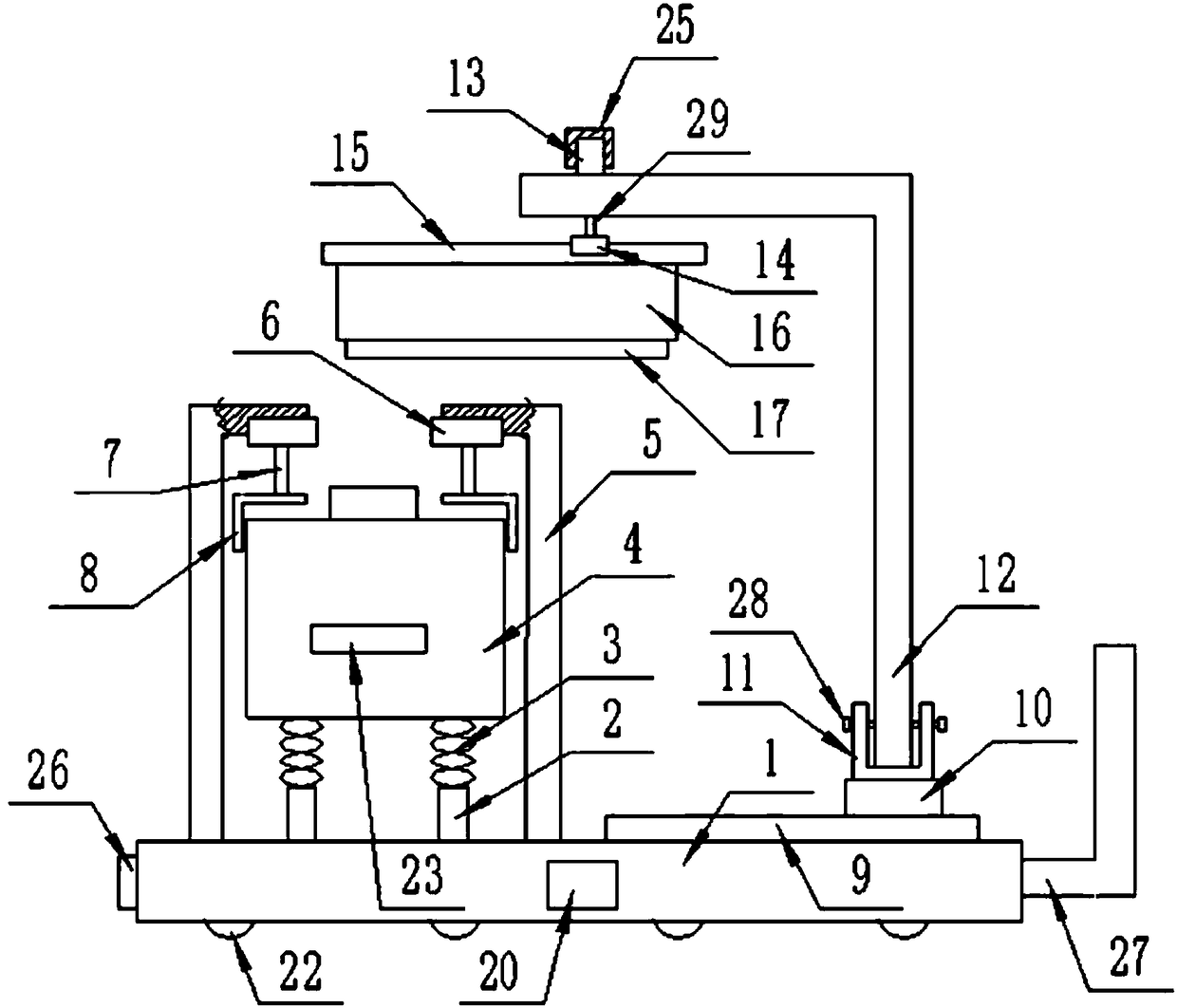

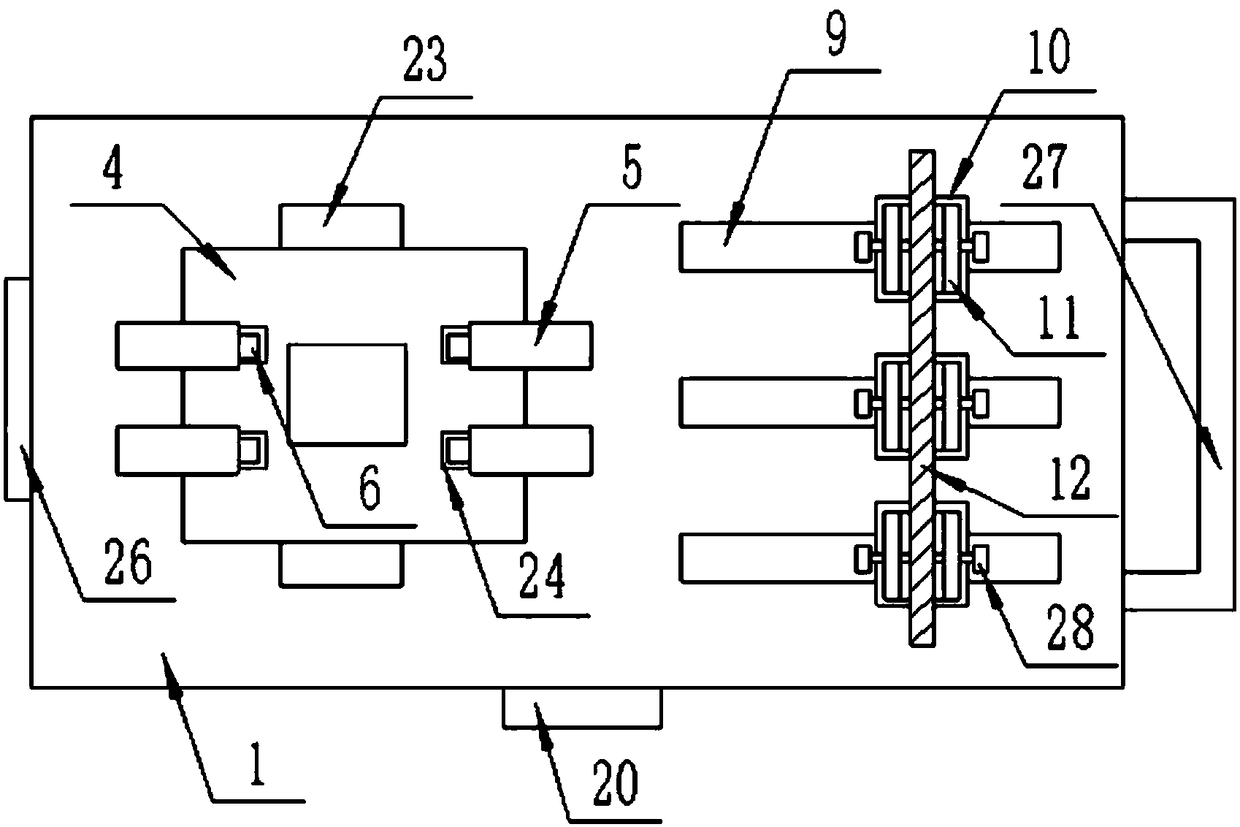

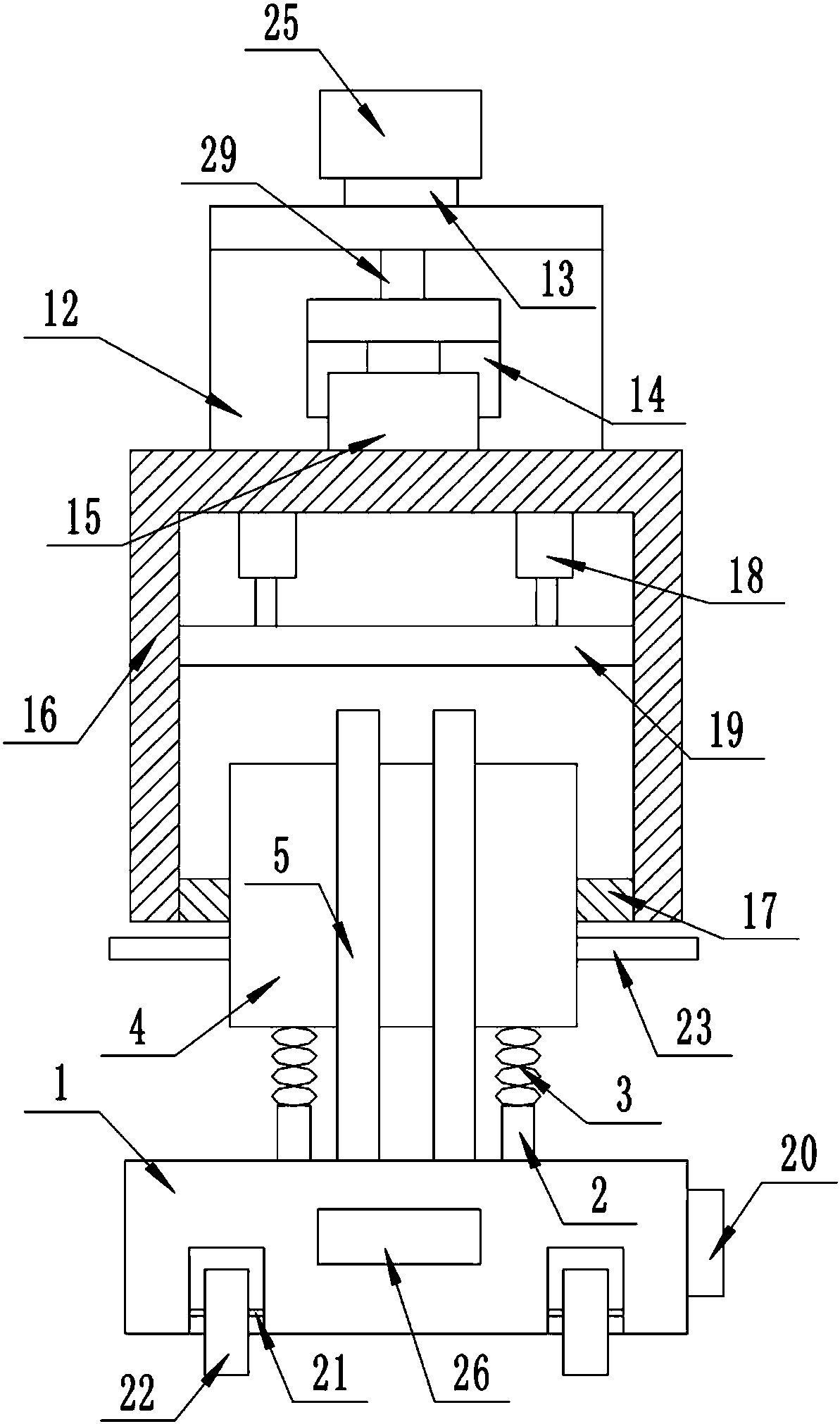

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, an intelligently controllable electromagnetic telescopic injection molding vehicle lamp mold includes a strip-shaped bearing base 1, and the center of the upper surface of the strip-shaped bearing base 1 is fixedly connected to two sets of supporting columns 2, each of which supports The upper surface of the column 2 is equipped with an extrusion spring 3, and the upper surface of the two sets of extrusion springs 3 is provided with an injection lamp mold 4, and the upper surface of the strip-shaped bearing base 1 is in contact with the edge of the upper surface of the injection lamp mold 4. Corresponding two groups of L-shaped support frames 5, each of the L-shaped support frames 5 inner upper surfaces are processed with strip-shaped sliding gaps, and sliding blocks 6, each of the sliding blocks are all arranged in each of the strip-shaped sliding gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com