Method for batched formation of square beams for biological soil reinforcement

A molding method and square technology, applied in the direction of soil protection, joists, girders, etc., can solve water pollution, affect human health and other problems, achieve the effect of improving quality, good soil fixing effect, and sharp edges and corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] A method for forming batches of square beams with bio-fixed soil, the method comprising the steps of:

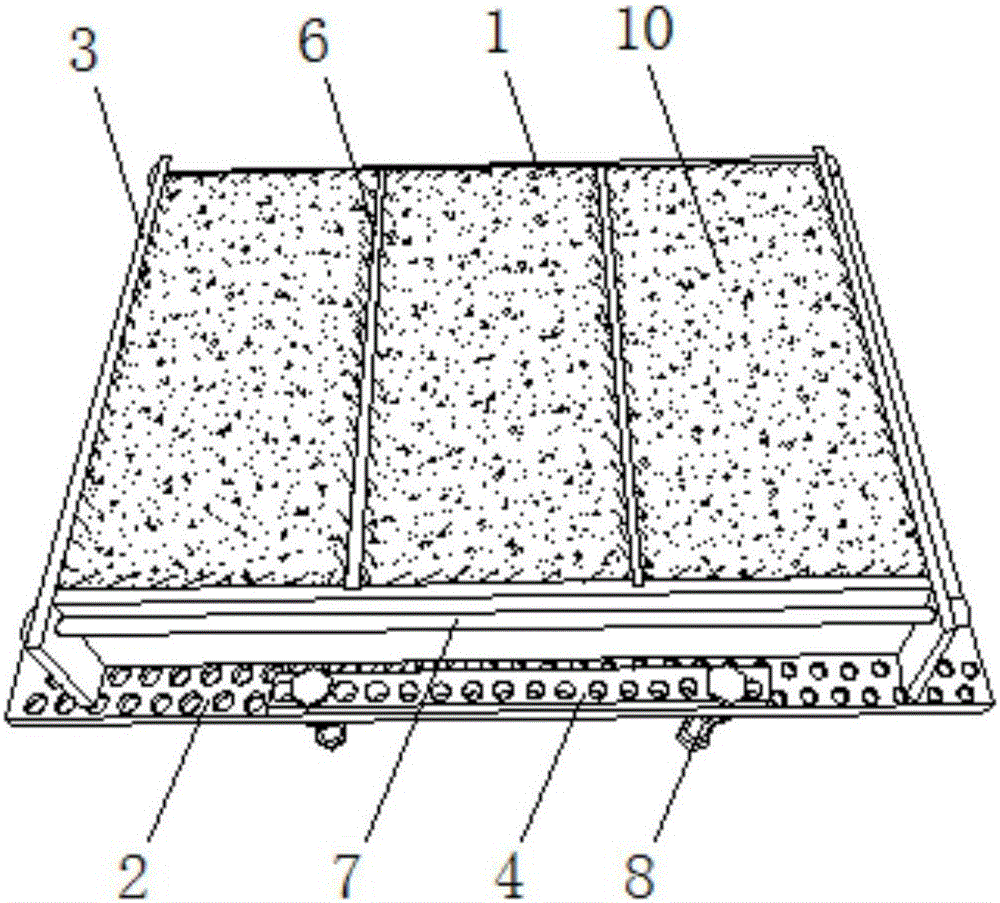

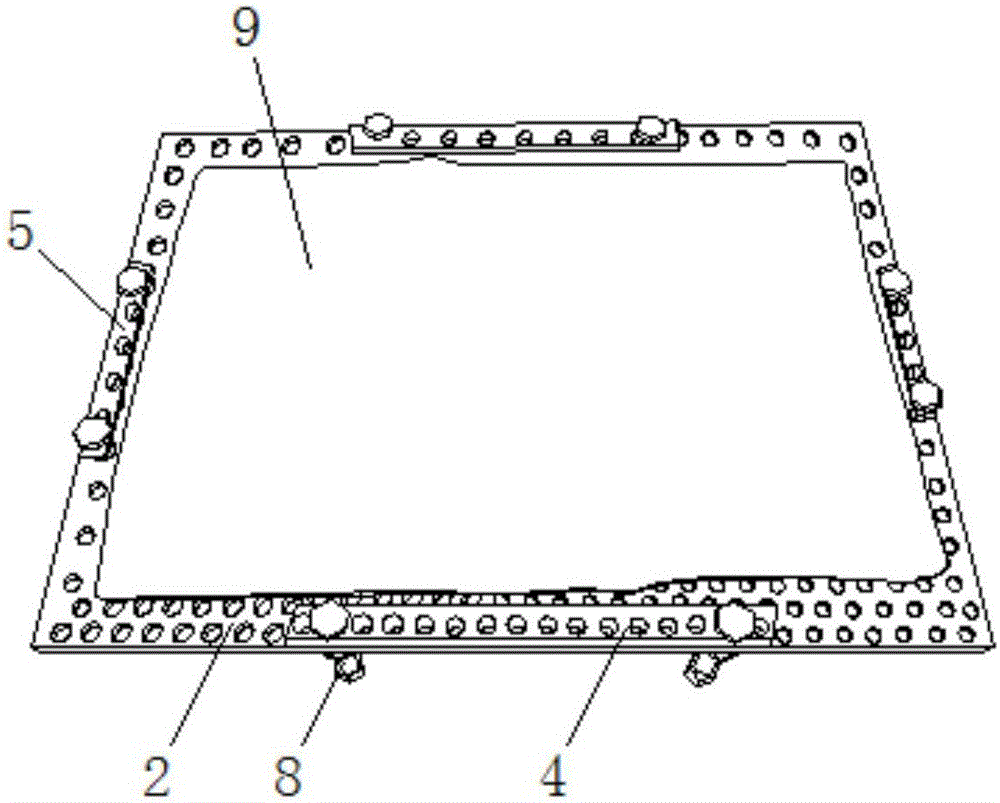

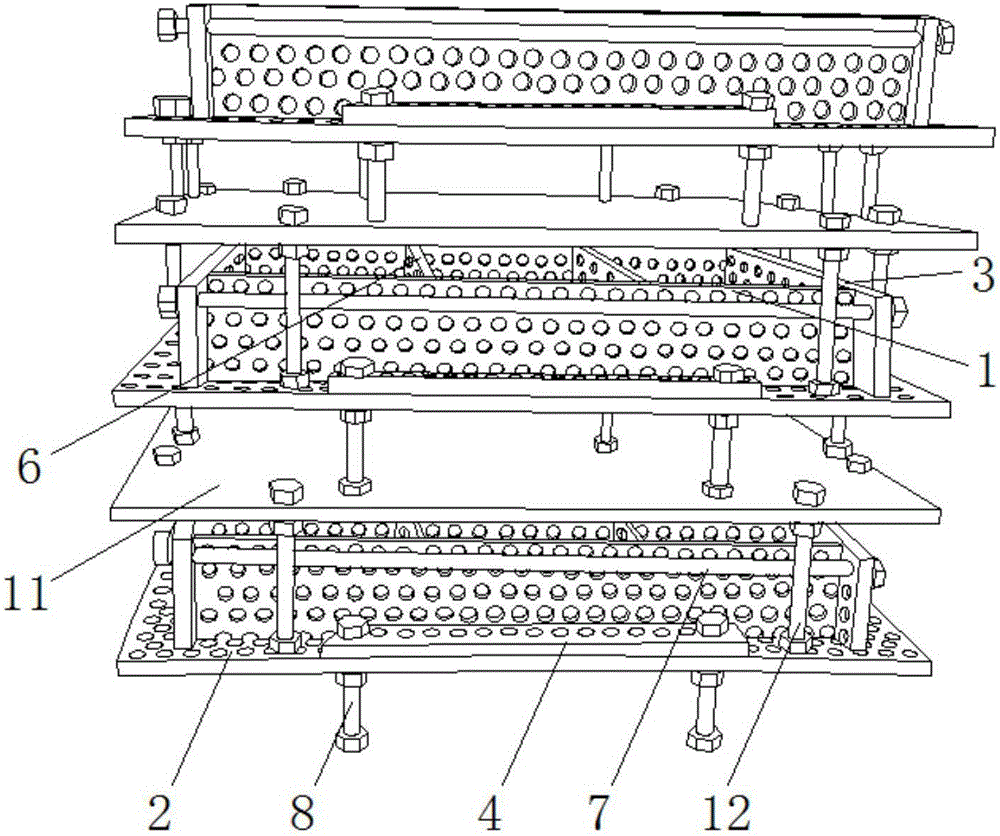

[0042] 1) Prepare the materials needed for the mold (such as figure 1 , 2Shown): Drill holes on the plexiglass flat plate or buy ready-made plexiglass with holes, the holes on the plexiglass are arranged in dislocation (the drilling positioning is, the diameter of the hole is 6mm, the net distance between the holes is 3mm, and the holes in adjacent columns are dislocated In addition, the hole diameter and the net distance between the holes can also be modified and adjusted according to actual needs); then the plexiglass is cut into plates with a woodworking saw blade, and the plates include two longitudinal side panels 1 (241.3mm×38.1mm ), one bottom plate 2 (299.7mm×238.8mm), two end plates 3 (213.4mm×38.1mm), two longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com