Zero-drainage treatment system and zero-drainage treatment method for nickel plating wastewater in steel workshop

A treatment system, zero-discharge technology, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as environmental and human health hazards, waste of resources, etc. The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the specific embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

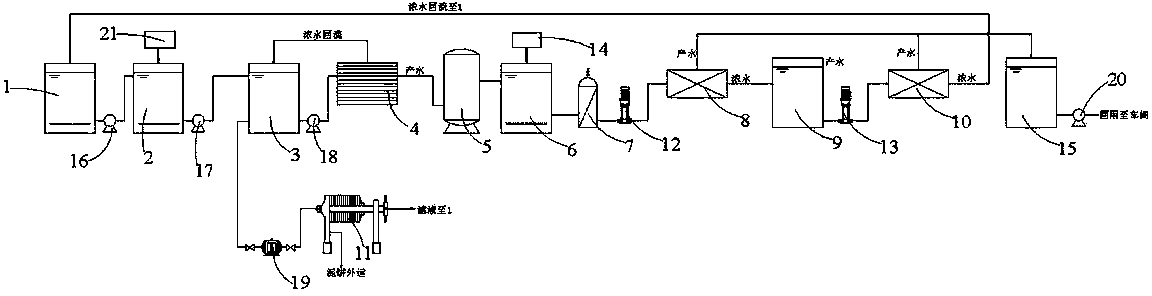

[0030] like figure 1 As shown, a zero-discharge treatment system for nickel-plating waste water in a steel workshop provided by the present invention includes a collection aeration water tank 1, a reaction aeration water tank 2, a concentrated water tank 3, a tubular membrane filtration system 4, an activated carbon filter 5, Call back aeration water tank 6, security filter 7, primary RO system 8, concentrated water tank 9, secondary RO system 10 and plate and frame filter press 11, and connect the outlet of collection aeration water tank 1 to the inlet of reaction aeration water tank 2 , the outlet of the reaction aeration water tank 2 is connected with the waste water inlet of the concentrated water tank 3, the water outlet of the concentrated water tank 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com