Ultraviolet light curing monomer as well as preparation method and application thereof

An ultraviolet light, monomer technology, applied in the direction of coating, can solve the problems of poor monomer performance and equipment corrosion, achieve the effect of excellent performance, avoid stress corrosion, and simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The second aspect of the present application provides a method for preparing a UV-curable monomer, comprising the following steps:

[0039] S01. The raw materials of the UV-curable monomer provided are mixed with polyol, acrylic acid, compound additive, hypophosphorous acid and solvent for esterification reaction to obtain the first mixture;

[0040] S02. washing the first mixture with water and alkali to obtain the second mixture;

[0041] S03. mixing the second mixture with p-hydroxyanisole to obtain a third mixture;

[0042] S04. Distilling the third mixture to obtain a UV curable monomer.

[0043] The preparation method adopts the process of "esterification reaction-alkaline solution washing-distillation treatment" to prepare the ultraviolet light curing monomer. In this preparation method, the raw materials are easy to obtain, the preparation process is simple and fast, and no A large amount of washing ensures clean production. At the same time, the prepared UV c...

Embodiment 1

[0057] A kind of ultraviolet curing monomer and preparation method thereof

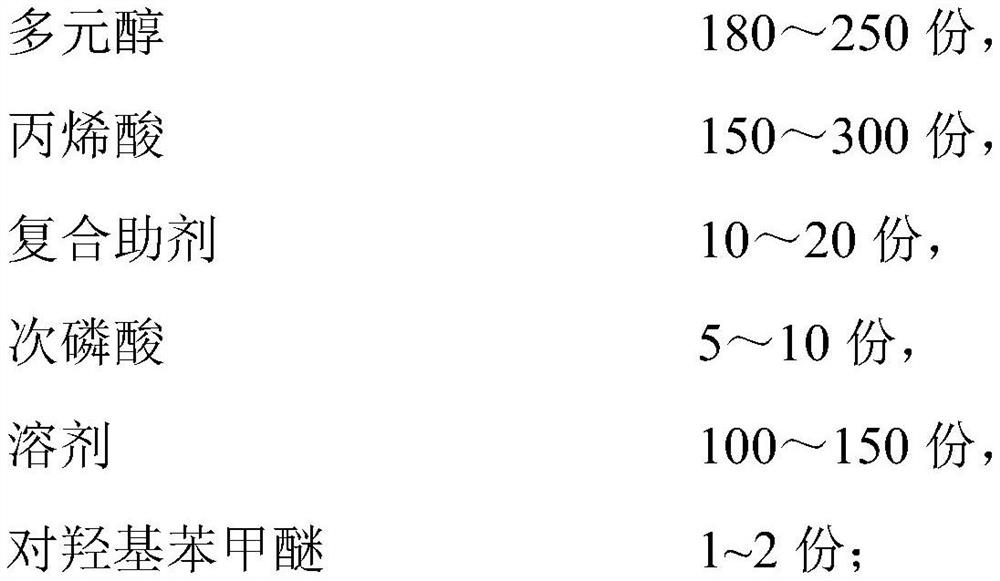

[0058] The raw material of UV-curable monomer comprises the following components in parts by weight:

[0059]

[0060] Among them, the composite auxiliary agent is selected from the mixture of copper methanesulfonate and methanesulfonic acid, and the mass ratio of copper methanesulfonate and methanesulfonic acid is 1:10; the polyol is selected from tripropylene glycol; the solvent is selected from cyclic hexane.

[0061] The preparation method of ultraviolet curing monomer comprises the following steps:

[0062] Provide the raw materials of the UV-curable monomer provided in Example 1, mix polyol, acrylic acid, compounding additives, hypophosphorous acid and solvent at a reaction temperature of 90-95° C. to reflux water to perform esterification treatment to obtain the first mixture, and When the acid value of the first mixture is determined to be lower than 40mg KOH / g, the reaction temperature i...

Embodiment 2

[0067] A kind of ultraviolet curing monomer and preparation method thereof

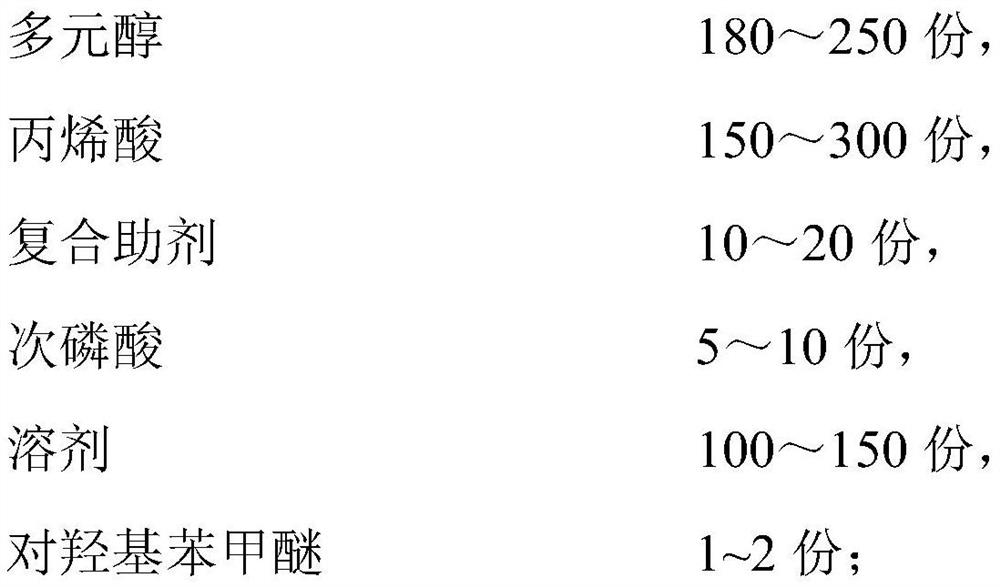

[0068] The raw material of UV-curable monomer comprises the following components in parts by weight:

[0069]

[0070]

[0071] Among them, the composite additive is selected from the mixture of copper methanesulfonate and methanesulfonic acid, and the mass ratio of copper methanesulfonate and methanesulfonic acid is 1:10; the polyol is selected from tripropylene glycol; the solvent is selected from toluene .

[0072] The preparation method of ultraviolet curing monomer comprises the following steps:

[0073] Provide the raw materials of the UV-curable monomer provided in Example 2, mix polyol, acrylic acid, compounding additives, hypophosphorous acid and solvent at a reaction temperature of 105-120° C. to reflux water for esterification to obtain the first mixture, and When the acid value of the first mixture is determined to be lower than 40mg KOH / g, the reaction temperature is lowered to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com