A paper laminating machine

A laminating machine and laminating technology, applied in printing machines, general parts of printing machinery, printing and other directions, can solve the problems of difficult collection and cleaning of films, deformation, inconvenience of tensile strength films, etc., to reduce the influence of electrostatic adsorption, improve Collect the effect, avoid leaking the floating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

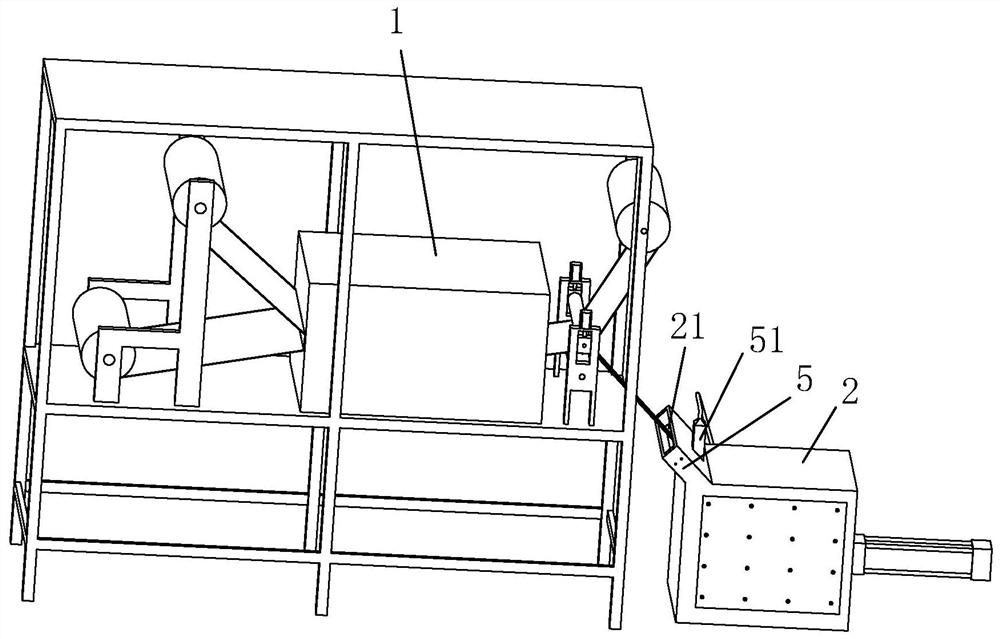

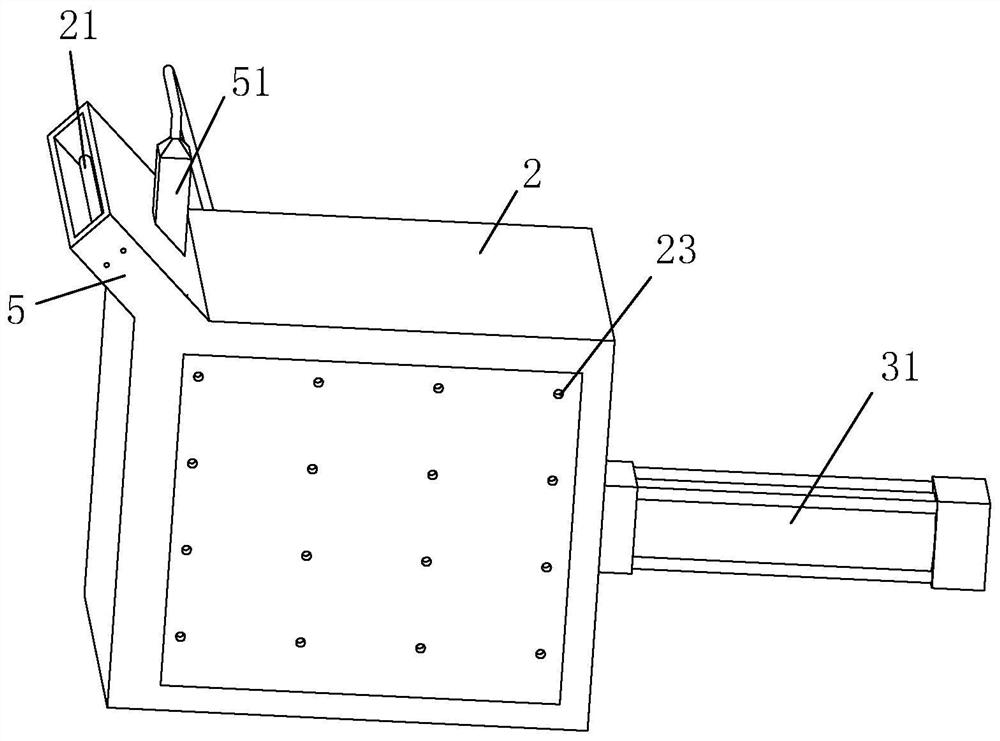

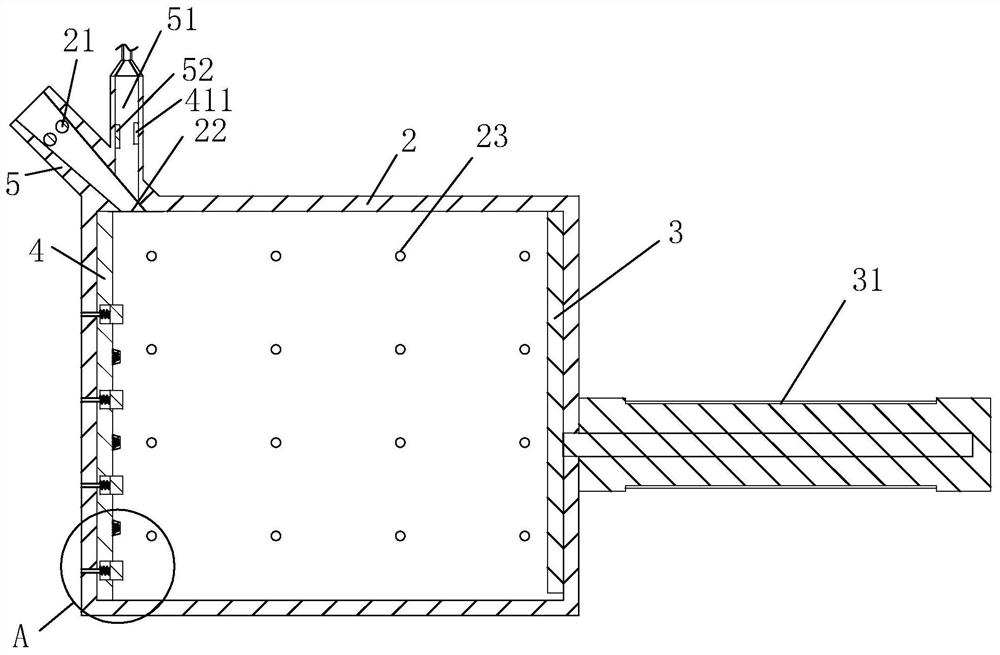

[0035] A paper laminating machine such as figure 1 , 3 As shown, the laminating body 1 is included, the tail of the laminating body 1 is provided with a waste box 2, and the waste port 22 on the top of the waste box 2 is provided with a waste guide roller 21. In the process of paper laminating, people need to roll paper and film The rolls are respectively mounted on the laminating body 1, and then the paper end of the paper roll and the film end of the film roll are overlapped and stretched into the laminating body 1. Two mutually conflicting laminating rollers are arranged in the laminating body 1. The paper and film are laminated by lamination roller, and the paper after lamination passes out of the lamination body 1, and at the same time, the excess waste film on the edge of the paper is cut off by a cutter, and then passed into the paper collection rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com