A kind of sound insulation cotton waste recycling method

A technology for recycling waste materials and sound-insulating cotton, which is applied in the fields of recycling technology, plastic recycling, mechanical material recycling, etc., and can solve the problem that there is no device or method for recycling and reusing sound-proof cotton waste, there is no sound-proof cotton waste crushing and separation device, Lack of problems such as sound insulation cotton waste dust removal and recovery devices, to achieve the effects of easy industrial application, lower production costs, and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

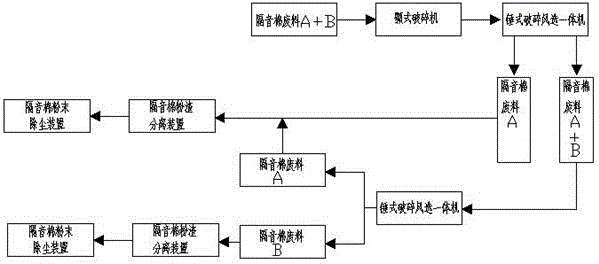

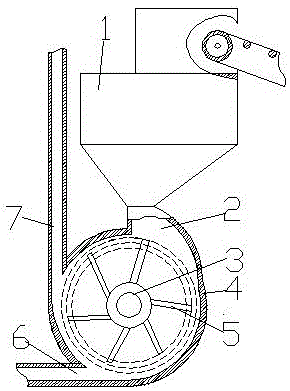

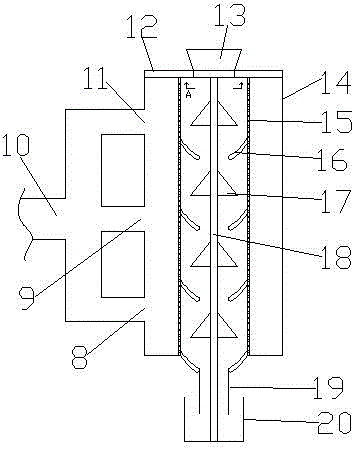

[0032] Such as figure 1 As shown, a sound insulation cotton waste recycling system includes a jaw crusher, a first hammer-type crushing and winnowing integrated machine, a second hammer-type crushing and winnowing integrated machine, a sound-insulating cotton powder slag separation device and a sound-proof cotton powder dust collector device, the outlet end of the jaw crusher is connected to the feed port of the first hammer-type crushing and air-separation integrated machine through the first belt conveyor, and the first hammer-type crushing and air-separated integrated machine is equipped with a first coarse The material outlet and the first A material outlet, the first coarse material outlet is connected to the inlet of the second hammer-type crushing and winnowing integrated machine through the second belt conveyor, and the second hammer The integrated crushing and winnowing machine is equipped with a B material outlet and a second A material outlet. The B material outlet ...

Embodiment 2

[0040] The same as in Example 1, the difference is that the sound-insulating cotton powder and slag separation device separates the first A material and the second A material respectively, so as to improve the separation effect on A material, so that in the recycling process of the sound-insulating cotton waste The purity of the waste in the process is higher, so as to more effectively guarantee the quality of the product after recycling, melting and casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com