Self-locking pneumoelectric driving auxiliary supporting device

A technology of auxiliary support and pneumatic support, applied in positioning devices, clamping devices, supports, etc., can solve problems such as affecting the machining accuracy of parts, "elastic deformation and retreat of the surface of parts, hindering the elastic recovery of the surface of parts, etc., to ensure clean production. , reliable performance, non-polluting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

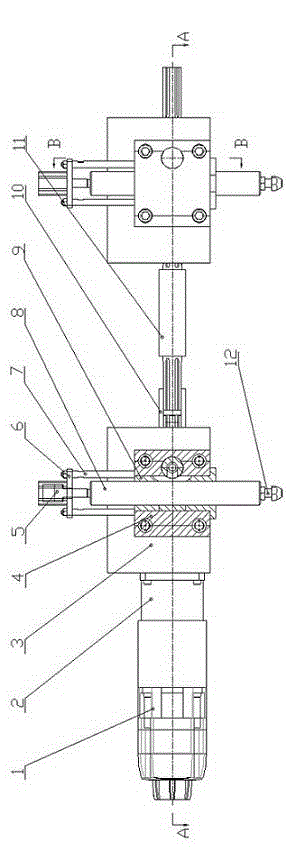

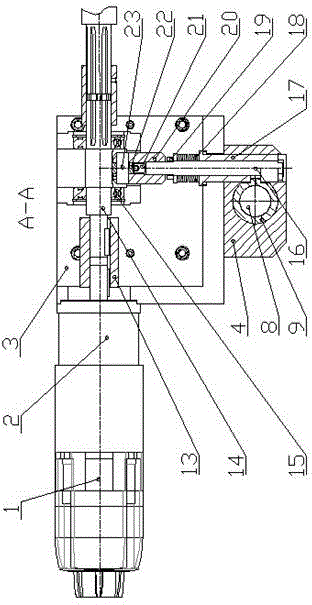

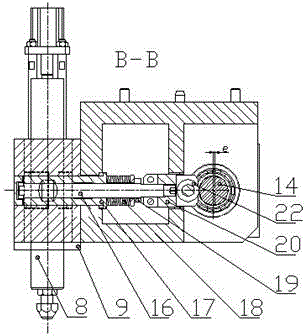

[0022] The invention is composed of a pneumatic support mechanism, a spring locking mechanism and an electric unlocking mechanism.

[0023] The pneumatic support mechanism includes a cylinder (5), a pressure rod (8), an opening guide sleeve (9) and a pressure head (12), the pressure rod (8) is driven by the cylinder (5) to move linearly, and the pressure rod (8) The outer side is provided with the opening guide sleeve (9) that can hug tightly or loosen the depression bar (8). The pressing rod (8) is supported on the fixed seat (3) by the opening guide sleeve (9) and the guide seat (4). The cylinder (5) is supported on the holder (3) by the cylinder block (6) and the support rod (7).

[0024] The spring locking mechanism includes an opening guide sleeve (9), a pull rod (16), a support sleeve (17), a disc spring assembly (18) and a nut (19), a support sleeve (17) and a disc spring assembly (18) It is arranged on the pull rod (16), and the disc spring assembly (18) is axially p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com