Method and equipment for clearing hot anode scrap electrolytes

A technology of electrolyte and residual electrode, which is applied in the field of electrolyte cleaning, can solve the problems of high labor intensity and low efficiency, and achieve the effects of reducing production processes, convenient use, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

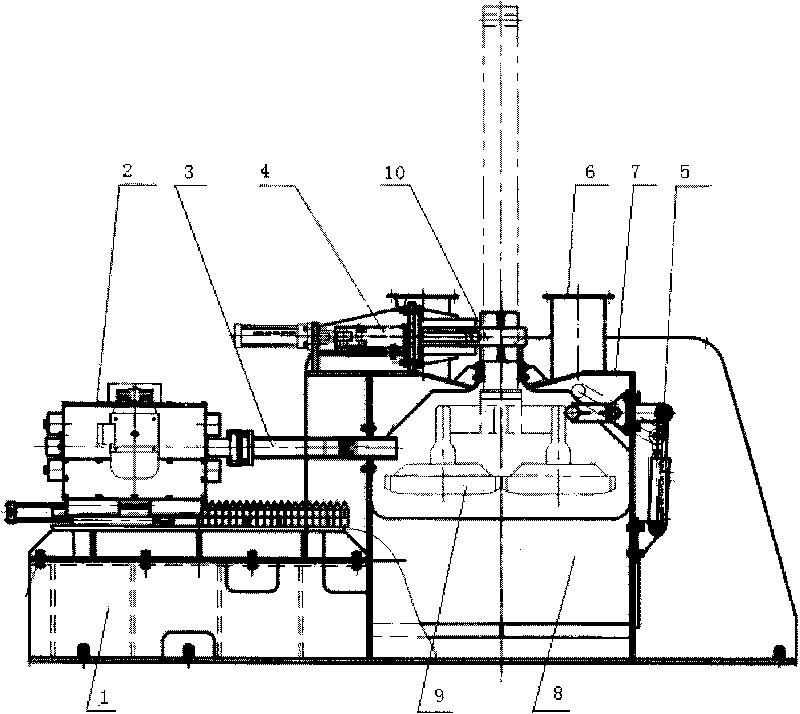

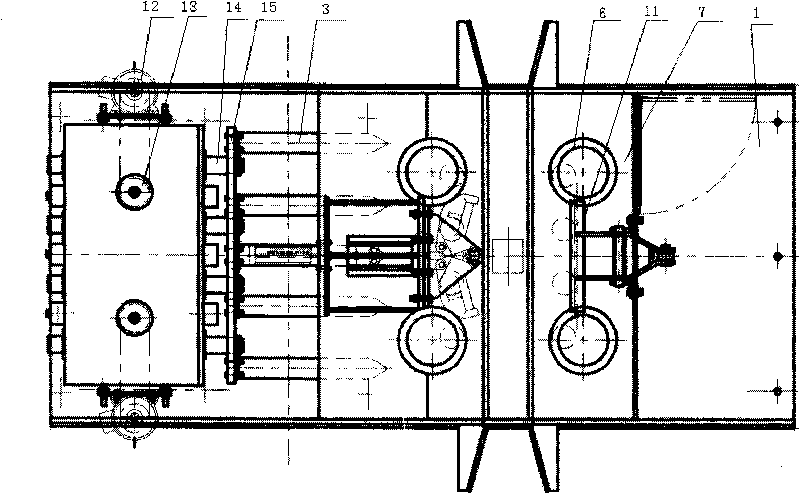

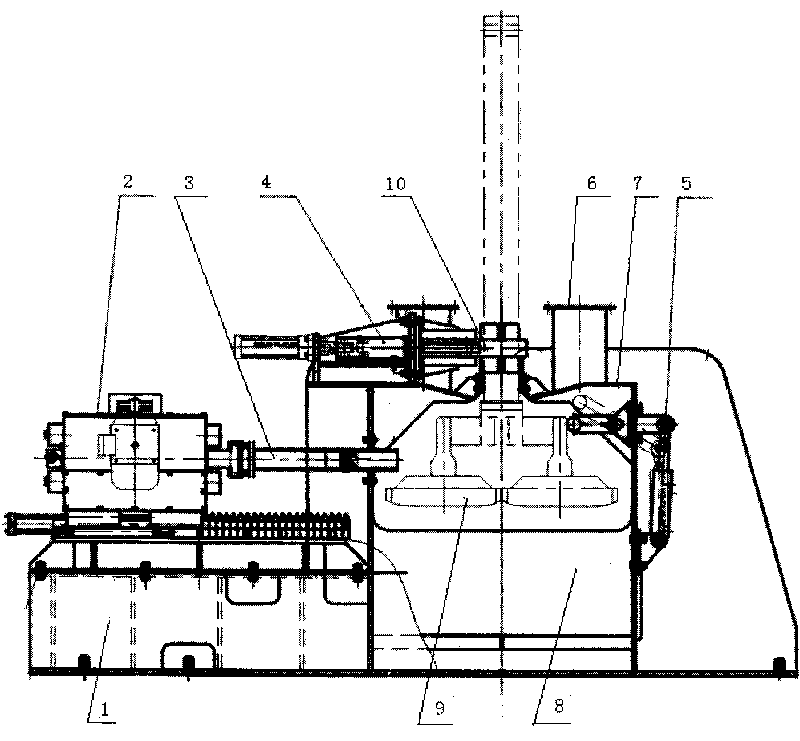

[0030] like figure 1 , 2 Shown: A method of cleaning the hot residual electrode electrolyte is to use the rapping method to clean the hot electrolyte on the surface of the residual electrode, and the dust generated during operation is collected into the dust collector through the dust removal nozzle 6, and the cleaned electrolyte is passed through the lower part. The hopper 8 is discharged, and the steps are as follows:

[0031] a. The hot stump 9 with electrolyte taken out from the electrolytic cell enters the stump positioning device of the equipment for cleaning the hot stump electrolyte through a hanging conveying system; the hanging conveying system has the hot slug with electrolyte taken out from the electrolytic cell Between the cooling poles for cleaning the hot residual electrode electrolyte equipment and the nearby treatment, there is a catenary or ring rail car for transporting the hot residual poles in the cooling pole room. In the closed space set up, the entire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com