Maerz active lime kiln shell crack sealing device

A sealing device and lime kiln technology, applied in the field of Maerz active lime kiln equipment, can solve the problems of no refractory protection of the kiln shell, rising temperature of the discharge platform, air leakage, etc. The effect of cleaner production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

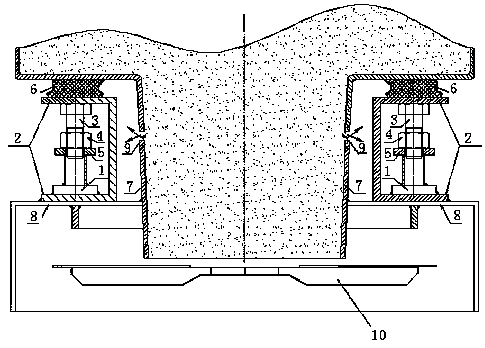

[0017] In this example, refer to the attached figure 1 , The support assembly 1 includes a support fixed on the lower plate of the sealing plate 2 and a galvanized pipe fixed on the support.

[0018] The support assembly 1 is welded on the lower plate of the sealing plate 2, the lower plate of the sealing plate 2 is welded on the steel structure 8 of the kiln body, and the high temperature resistant sealing strip 6 is placed on the upper plate of the sealing plate 2, and the diameter of the kiln shell is The bottom surface of the large end is offset, the head of the bolt 3 is offset against the upper plate of the sealing plate 2, the screw of the bolt 3 passes through the gasket 5 and is placed in the galvanized pipe of the support assembly, and the nut 4 is screwed on the appropriate position of the screw and the gasket The sheet 5 offsets, the gasket 5 offsets the galvanized pipe, and the bolt 3 and the nut 4 form a spiral pair. When the nut 4 is rotated counterclockwise, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com