Environment-friendly treatment method for 3-chloropropyltrichlorosilane synthetic tail gas

A technology of chloropropyltrichlorosilane and propyltrichlorosilane, which is applied in the field of environmental protection treatment of chemical synthesis tail gas, can solve problems such as difficult treatment, environmental pollution, and treatment technology that cannot meet the needs of the development of the times, and achieve the elimination of corrosion, The effect of high removal rate, extended service life and maintenance interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

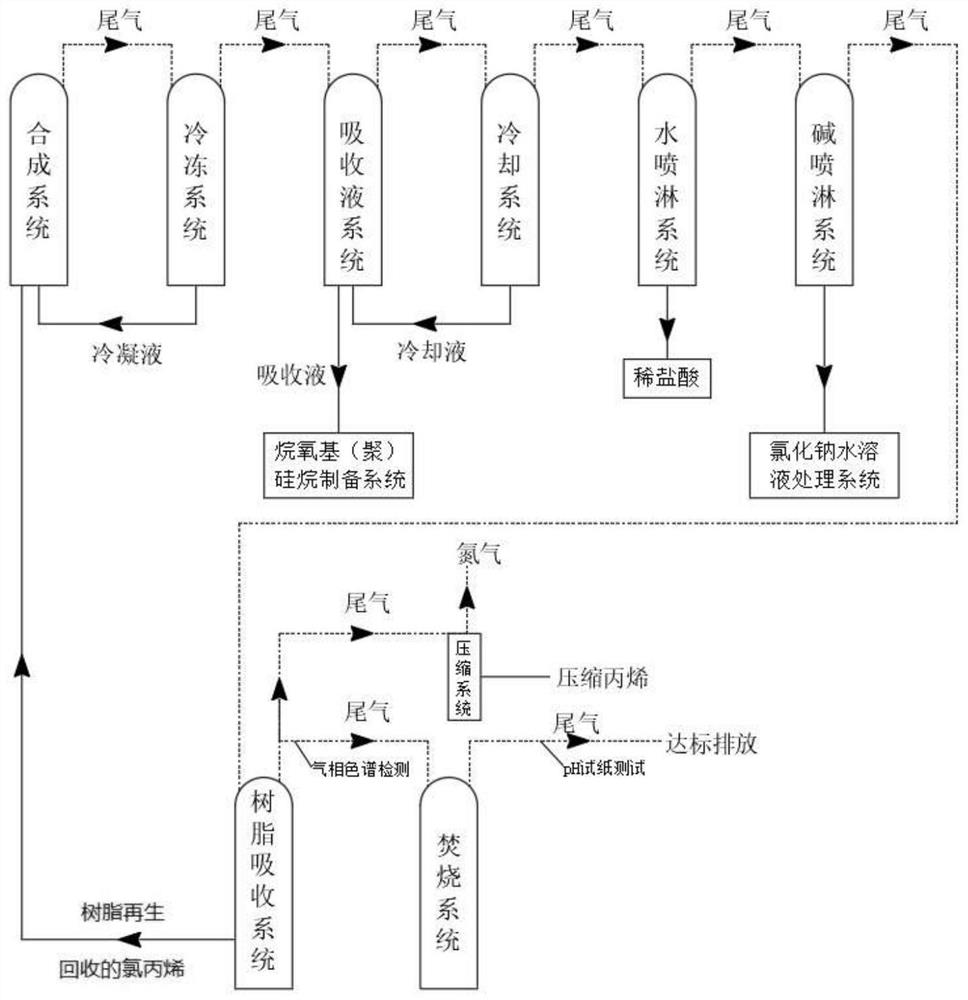

[0048] see figure 1 , an environmentally friendly treatment method for the synthesis tail gas of 3-chloropropyl trichlorosilane, the tail gas produced by synthesizing 3-chloropropyl trichlorosilane as raw materials with trichlorosilane and chloropropene, after flowing out from the synthesis system, passes through the Refrigeration system, absorption liquid system, cooling system, water spray system, alkali spray system, resin absorption system, and finally discharge tail gas after passing the on-line monitoring of the incineration system, or finally obtain compressed propylene products through the compression system.

[0049] Refrigeration system: The initial tail gas first passes through the -35°C refrigeration system to obtain condensate. When the next batch of 3-chloropropyltrichlorosilane is synthesized, the condensate is pressurized to 320kPa with nitrogen and reused in 3-chloropropane In base trichlorosilane synthesis system;

[0050] Absorbing liquid system: The tail g...

Embodiment 2

[0063] Refrigeration system: The initial tail gas first passes through the -35°C refrigeration system to obtain condensate. When the next batch of 3-chloropropyltrichlorosilane is synthesized, the condensate is pressurized to 320kPa with nitrogen and reused in 3-chloropropane In base trichlorosilane synthesis system;

[0064] Absorbing liquid system: The tail gas discharged from the refrigeration system enters into the A set of ethanol absorbing liquid system. The absorbing liquid system uses -15°C frozen water to keep warm. After 48 hours of continuous operation, the ethanol absorbing liquid is detected by gas chromatography. 42%, the tail gas discharge is switched to the B set of ethanol absorption liquid system, and the ethanol absorption liquid in the A set is transferred to the alkoxy (poly) silane preparation system for the preparation of alkoxy (poly) silane;

[0065] Cooling system: The tail gas discharged from the absorption liquid system enters the -15°C cooling syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com