Infrared temperature measuring pipe for continuously measuring temperature of molten steel and components, and preparation method thereof

A technology of infrared temperature measurement and temperature measurement tube, which is applied in the direction of radiation pyrometry, measurement device, optical radiation measurement, etc., can solve the problems of pollution of the optical channel of the temperature measurement tube, and achieve the solution of smoke and volatile pollution, blackness Large, good slag resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

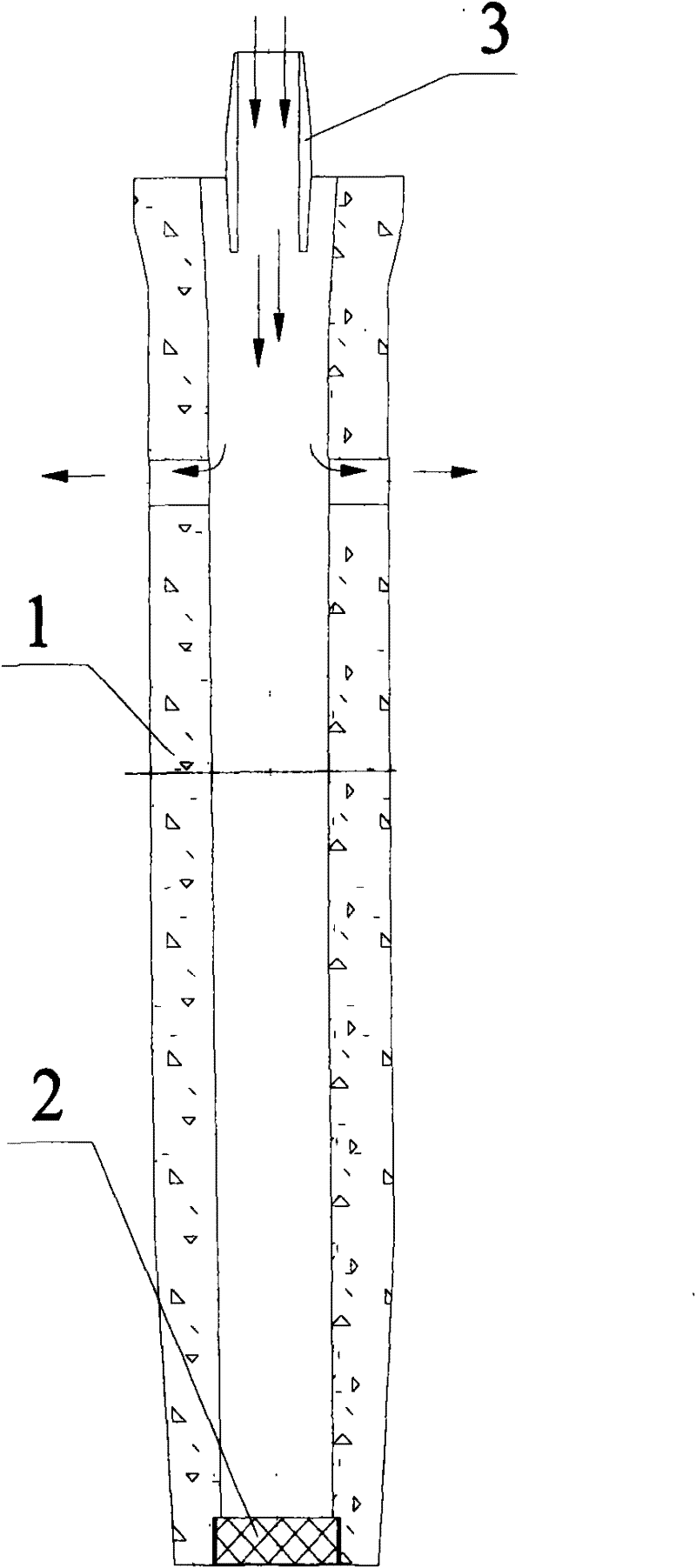

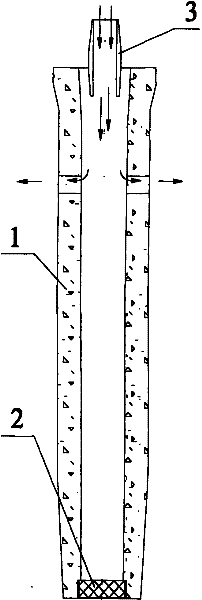

[0020] ①Making pipe body 1: 45% of 3-5mm plate-shaped corundum particles, 20% of 1-0mm plate-shaped corundum particles, 25% of 200 mesh corundum powder, Gr 2 o 3 Micropowder 2%, A80 alumina cement 3%, a-AL 2 o 3 Micropowder 3%, silicon micropowder 2%, plus 0.2% sodium hexametaphosphate additive, add an appropriate amount of water in the mixer, stir and mix evenly, and use the vibration molding method to make the temperature measuring tube body 1. The lower end of the pipe body 1 is provided with a groove for inlaying the heat conduction block 2 ; the upper end of the pipe body 1 is open for installing the connecting pipe 3 . Two exhaust holes with a diameter of 15 mm are radially arranged on the pipe body 1 at a distance of 250 mm from the upper end for exhausting the cooling gas of the infrared temperature measuring head. After the tube body is demolded, it is baked at 110°C for 24 hours.

[0021] ②Make heat conduction block 2: 35% of graphite, 50% of 0.5-0mm plate-shaped...

Embodiment 2

[0026] ①Making pipe body 1: 45% of 3-5mm plate-shaped corundum particles, 25% of 1-0mm plate-shaped corundum particles, 22% of 200 mesh corundum powder, Gr 2 o 3 Micropowder 1%, A80 alumina cement 2.5%, a-AL 2 o 3 Micropowder 3%, silicon micropowder 1.5%, plus sodium hexametaphosphate additive 0.2%, add appropriate amount of water in the mixer and mix evenly, adopt the vibration molding method to make the temperature measuring tube body 1. The lower end of the pipe body 1 is provided with a groove for inlaying the heat conduction block 2 ; the upper end of the pipe body 1 is open for installing the connecting pipe 3 . Two exhaust holes with a diameter of 15 mm are radially arranged on the pipe body 1 at a distance of 250 mm from the upper end for exhausting the cooling gas of the infrared temperature measuring head. After the tube body is demolded, it is baked at 110°C for 24 hours.

[0027] ②Make heat conduction block 2: 37% of graphite, 50% of 0.5-0mm plate-shaped corund...

Embodiment 3

[0032] ①Making pipe body 1: 40% of 3-5mm plate-shaped corundum particles, 20% of 1-0mm plate-shaped corundum particles, 25% of 200 mesh corundum powder, Gr 2 o 3 Micropowder 2%, A80 alumina cement 5%, a-AL 2 o 3 Micropowder 5%, silicon micropowder 3%, plus 0.2% sodium hexametaphosphate additive, add appropriate amount of water in the mixer, stir and mix evenly, adopt vibration molding method to make temperature measuring tube body 1. The lower end of the pipe body 1 is provided with a groove for inlaying the heat conduction block 2 ; the upper end of the pipe body 1 is open for installing the connecting pipe 3 . Two exhaust holes with a diameter of 15 mm are radially arranged on the pipe body 1 at a distance of 250 mm from the upper end for exhausting the cooling gas of the infrared temperature measuring head. After the tube body is demolded, it is baked at 110°C for 24 hours.

[0033] ②Make heat conduction block 2: 39% of graphite, 50% of 0.5-0mm plate-shaped corundum par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com