Low-creep andalusite composite refractory brick and preparation method and application thereof

A technology of andalusite and refractory bricks, which is applied in the field of low-creep andalusite composite refractory bricks and its preparation, can solve the problems of anode carbon block production impact, low load softening point, poor thermal shock stability, etc., and achieve reasonable composition matching , Improve service life, strong slag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

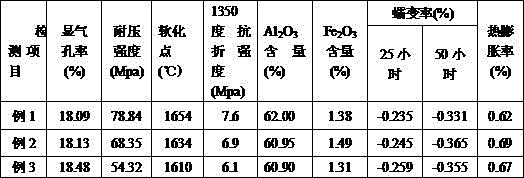

Examples

Embodiment 1

[0027] This embodiment provides a low-creep andalusite composite refractory brick, which includes aggregate, fine material and pulp water, wherein the quality of the pulp water is 4.5% of the total mass of the aggregate and the fine material; The aggregate and the fine material include raw materials in the following mass percentages: bauxite clinker large particles 10%, mullite large particles 21%, andalusite small particles 14%, mullite small particles 14%, Andalusite fine powder 26%, kaolin fine powder 8%, mullite fine powder 5%, silica fine powder 2%.

[0028] Wherein, the particle size of the large bauxite clinker particles is 1 mm to 3 mm, the particle size of the large mullite particles is 1 mm to 3 mm, the particle size of the small mullite particles is less than 1 mm, and the The particle size of the small andalusite particles is less than 1 mm, the particle size of the andalusite fine powder is less than 0.074 mm, the particle size of the kaolin fine powder is less th...

Embodiment 2

[0037]This embodiment provides a low-creep andalusite composite refractory brick, the specific raw material composition is roughly the same as that of Embodiment 1, the difference is that in this embodiment, the quality of the pulp water is the aggregate and the fine 5% of the total mass of the material, the aggregate and the fine material include the following raw materials in mass percentages: bauxite clinker large particles 12%, mullite large particles 19%, andalusite small particles 15%, mullite 14% small granules of stone, 25% fine powder of andalusite, 5% fine powder of kaolin, 7% fine powder of mullite, 3% fine powder of silicon.

[0038] The preparation method of the low-creep andalusite composite refractory brick described in this example is roughly the same as the preparation method in Example 1, the difference is that the mixed and milled mud is pressed into adobe, and then the adobe is placed in Dry in a tunnel-type drying hole for 36 hours, wherein the inlet tempe...

Embodiment 3

[0041] This embodiment provides a low-creep andalusite composite refractory brick, the specific raw material composition is roughly the same as that of Embodiment 1, the difference is that in this embodiment, the quality of the pulp water is the aggregate and the fine 5.5% of the total mass of the material, the aggregate and the fine material include the following raw materials in mass percentages: bauxite clinker large particles 6%, mullite large particles 25%, andalusite small particles 14%, mollite 15% small granules of stone, 20% fine powder of andalusite, 8% fine powder of kaolin, 8% fine powder of mullite, 4% fine powder of silicon.

[0042] The preparation method of the low-creep andalusite composite refractory brick described in this example is roughly the same as the preparation method in Example 1, the difference is that the mixed and milled mud is pressed into adobe, and then the adobe is placed in Dry in a tunnel-type drying hole for 25 hours, wherein the inlet tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com